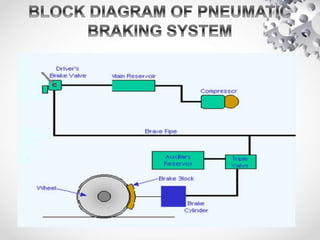

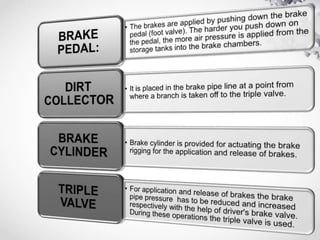

The document summarizes the key components and operation of a pneumatic braking system. It discusses how pneumatic brakes work by using compressed air to apply pressure to brake pads to stop a vehicle. The system works through three stages - charging, applying, and releasing brakes. It is commonly used in large vehicles like trucks and buses. While powerful, pneumatic brakes require special training to operate due to their complexity compared to hydraulic systems. Overall, the document provides a high-level overview of how pneumatic braking systems function in vehicles.

![ Bennett, Sean (2010). Heavy Duty Truck Systems, 5th Ed. USA: Cengage

Learning. p. 907. ISBN 1435483820. State of California, Copyright 2003,

California Commercial Driver Handbook, Sec.

Mechanics Corner: Understanding air brake systems.

Types of Automotive Braking Systems

S .Selvamani, Brake System Engineering, Sundaram Clayton limited,

Chennai, (1996)

S.F. Williams and R.R. Knipling, "Automatic slack adjusters for heavy

Vehicle air brake systems," Research Report DOT HS, vol. 807, pp. 724,

1991.

New Brunswick Department of Public Safety, "Air brake manual," [On¬ Line].

Available: http://www.gnb.ca/0276/vehicle/pdf/anual-e.pdf, accessed May

2008

S.C. Subramanian, S. Darbha, and K.R. Rajagopal, "Modeling the

Pneumatic subsystem of a scam air brake system," Journal of Dynamic

Systems, Measurement, and Control, vol. 126, pp. 36, 2004.](https://image.slidesharecdn.com/pneumaticbrakingsystem-150508101629-lva1-app6892/85/Pneumatic-braking-system-23-320.jpg)