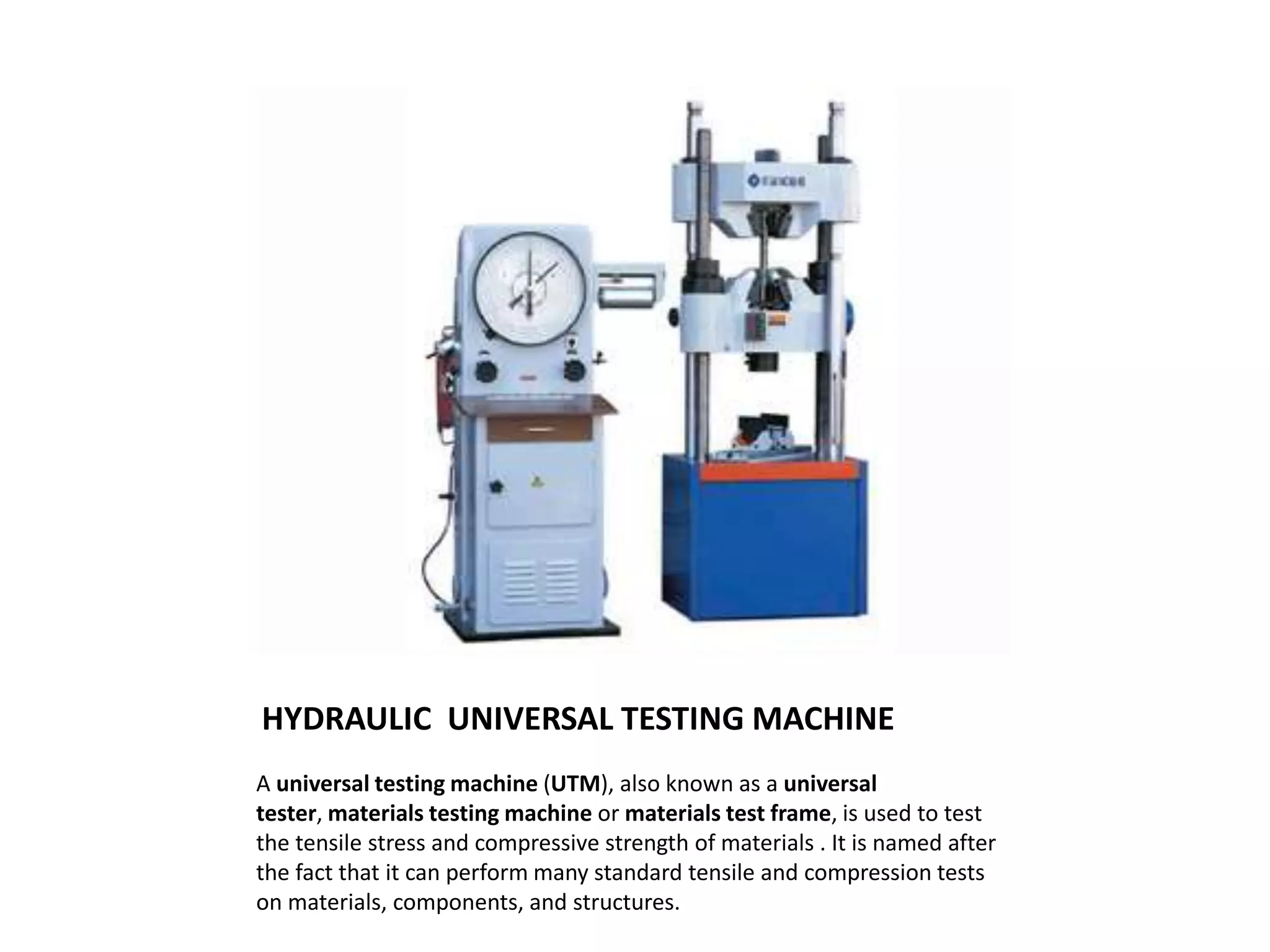

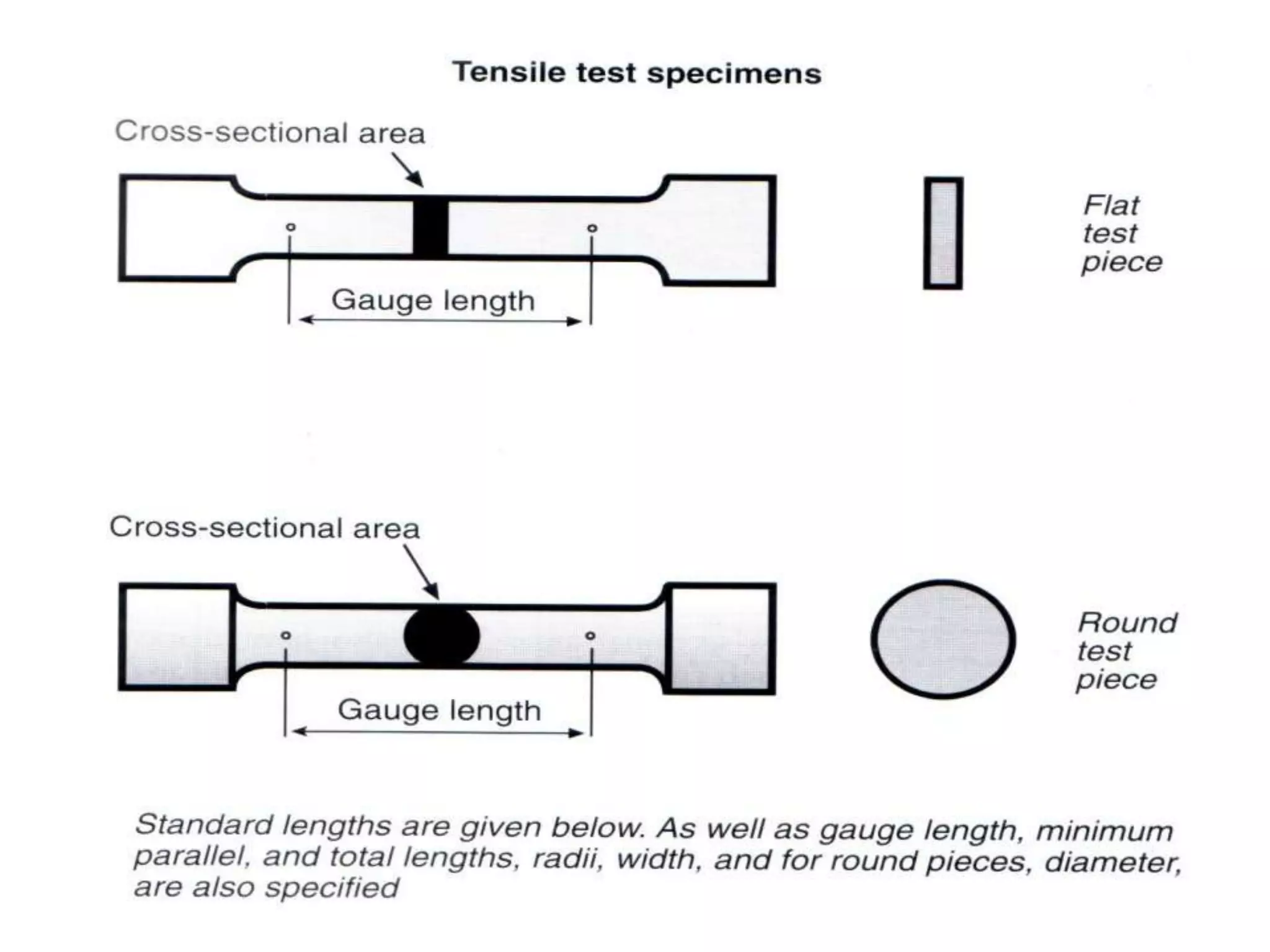

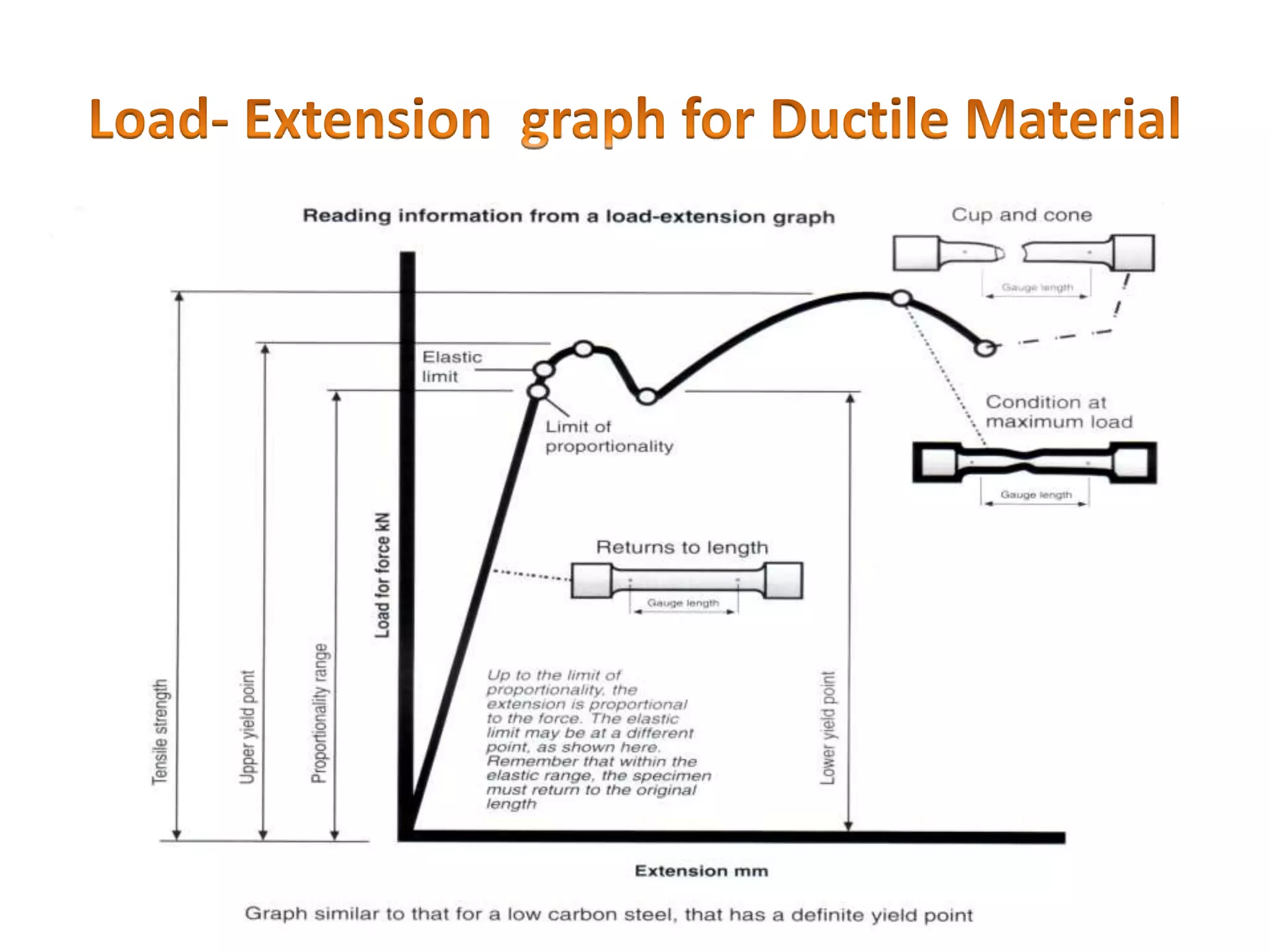

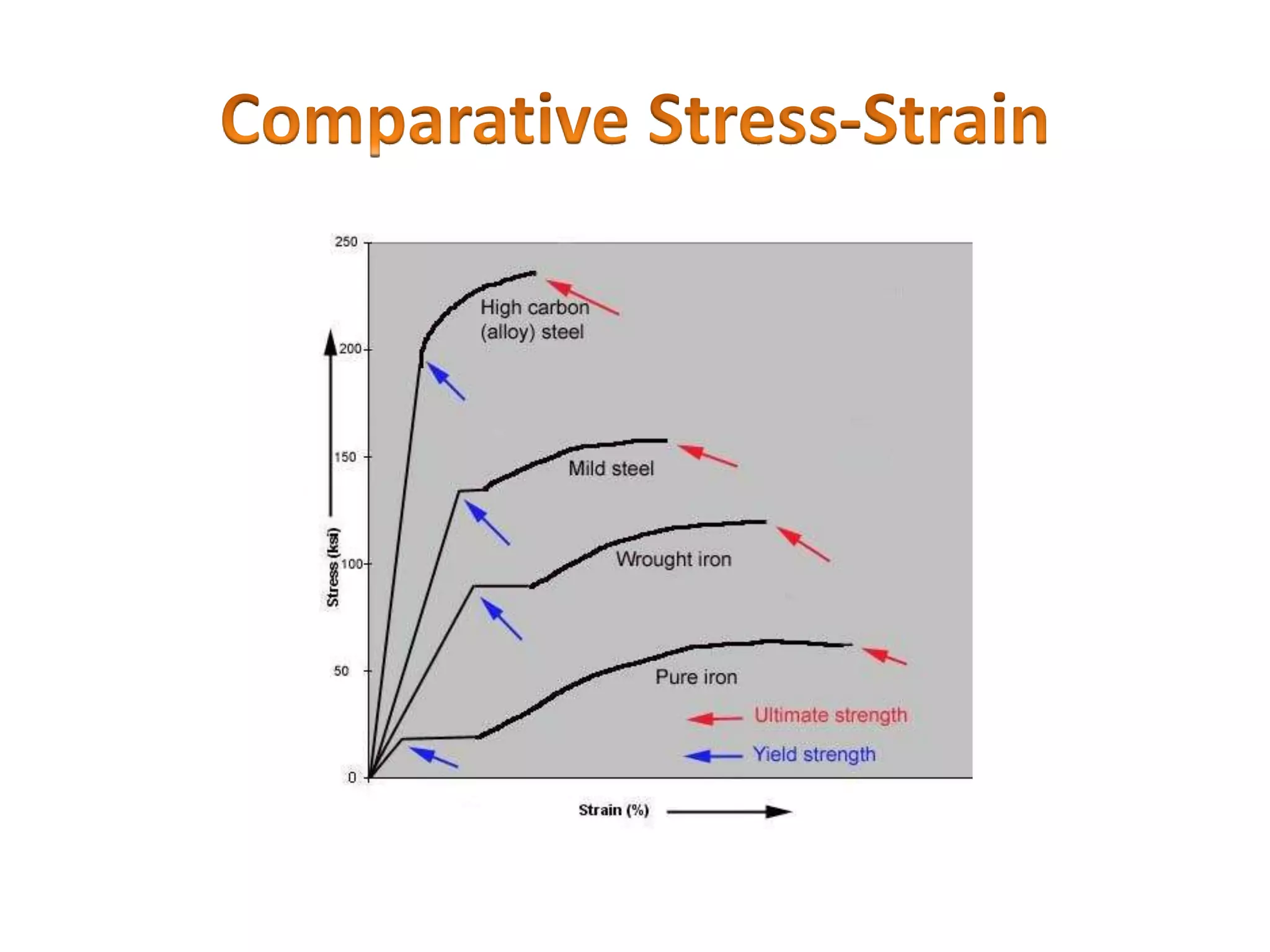

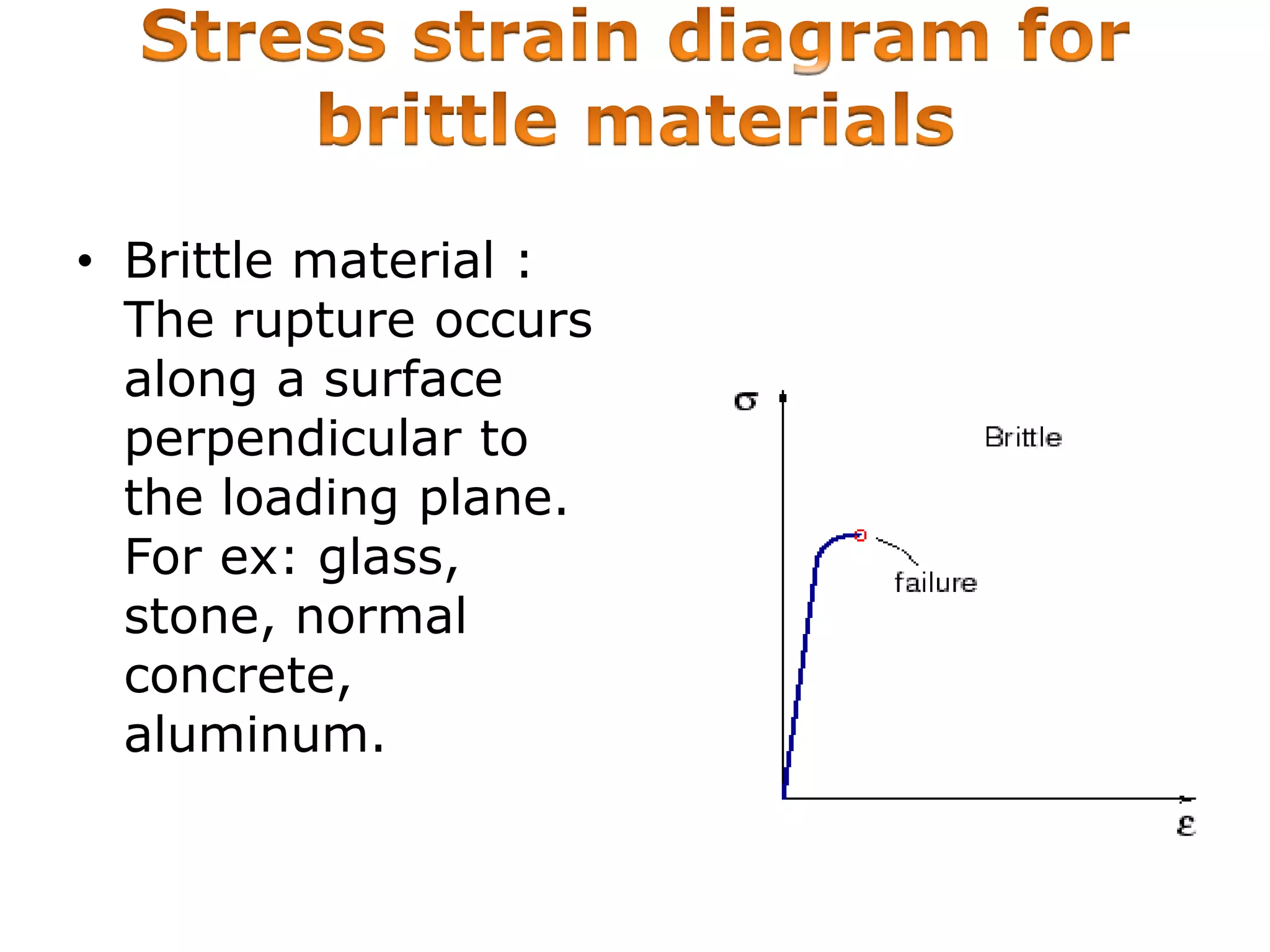

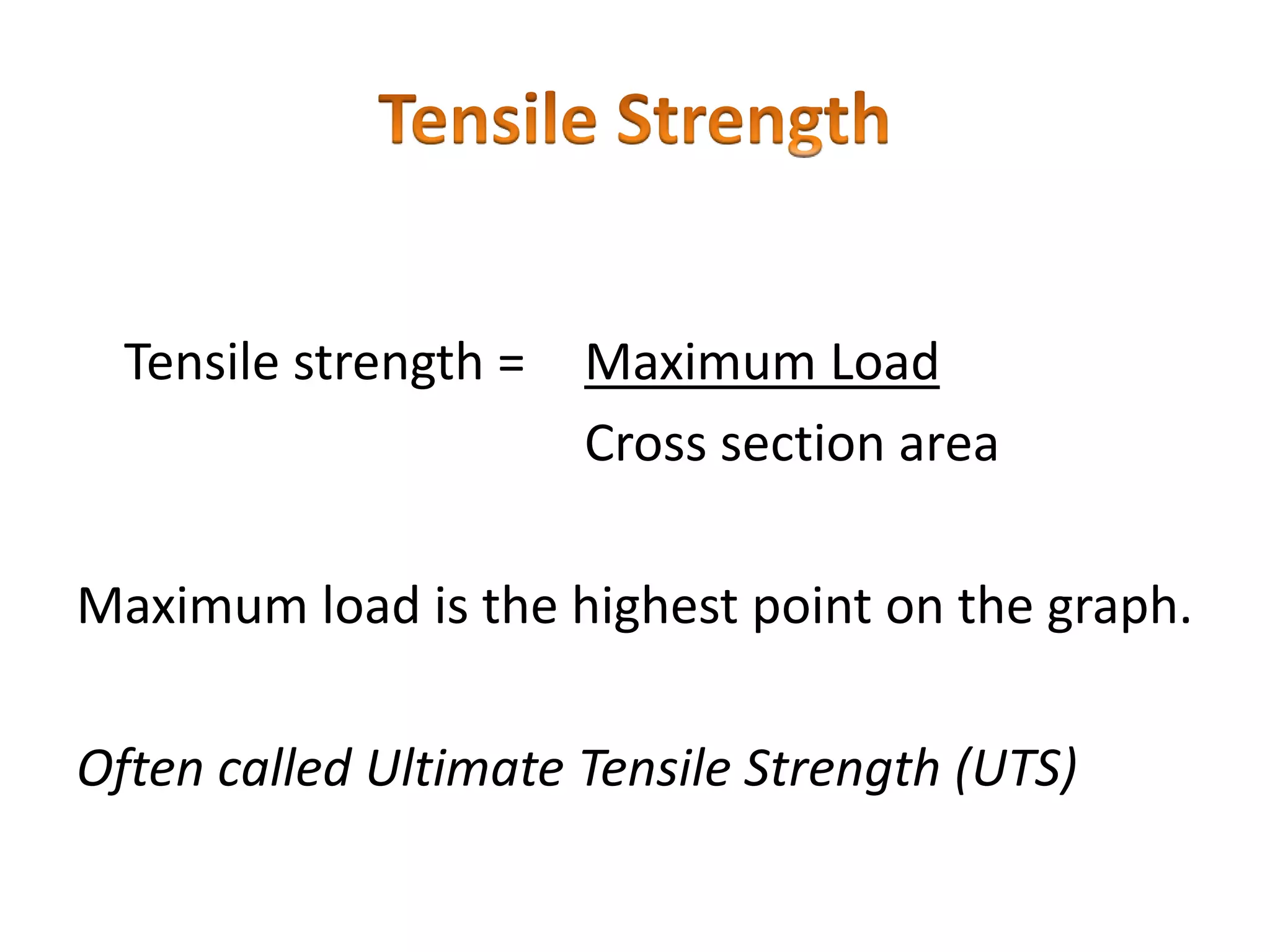

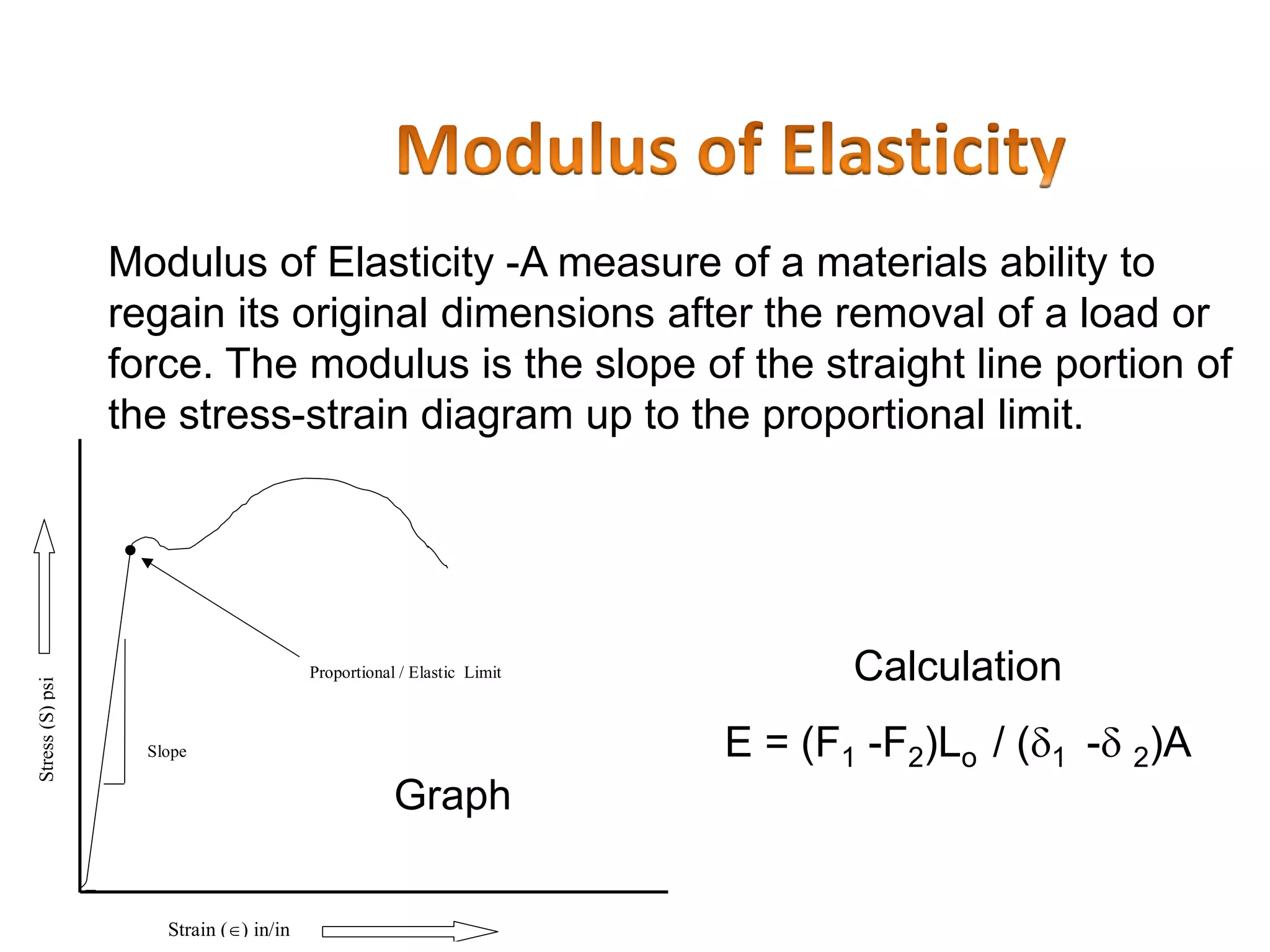

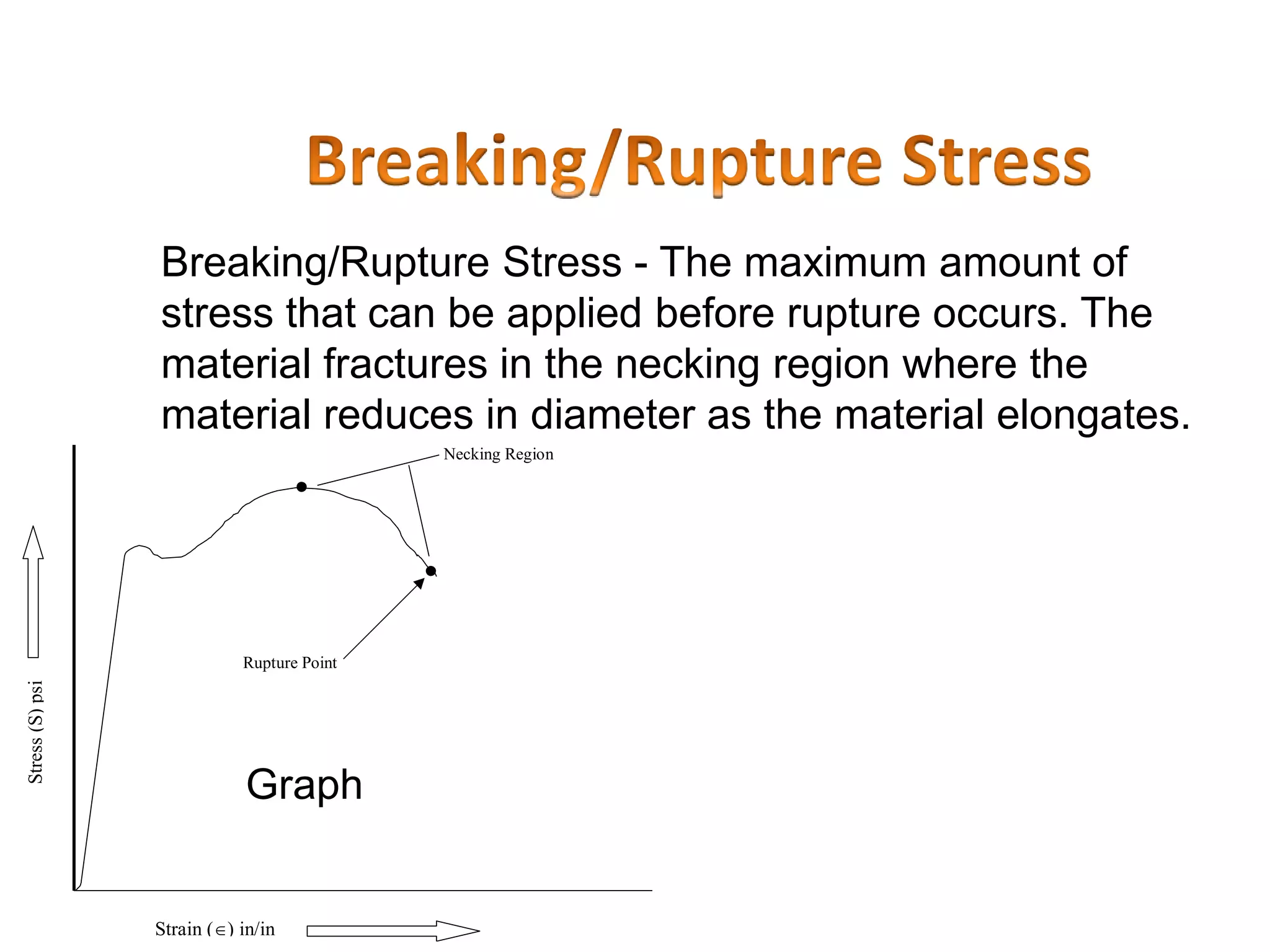

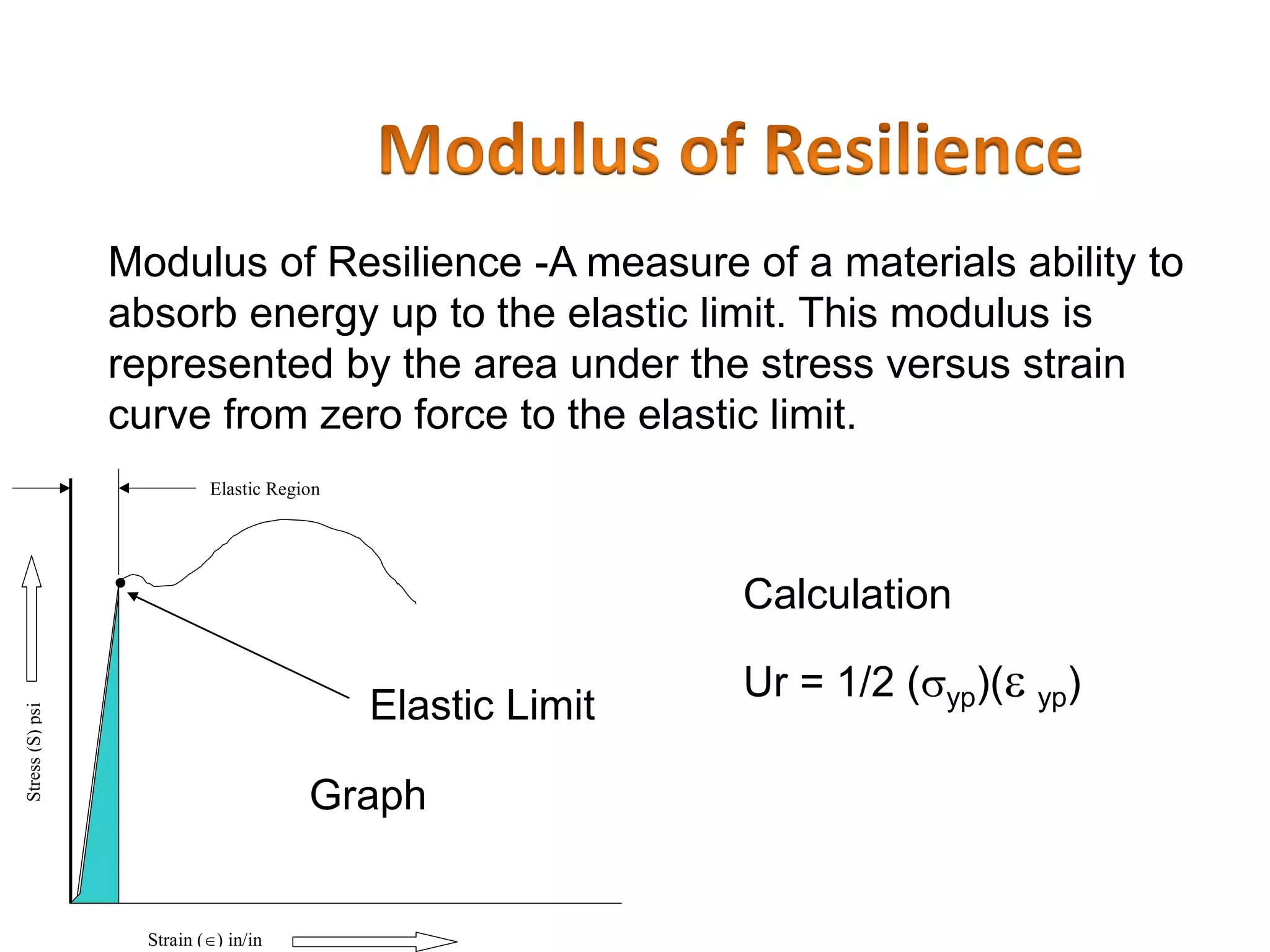

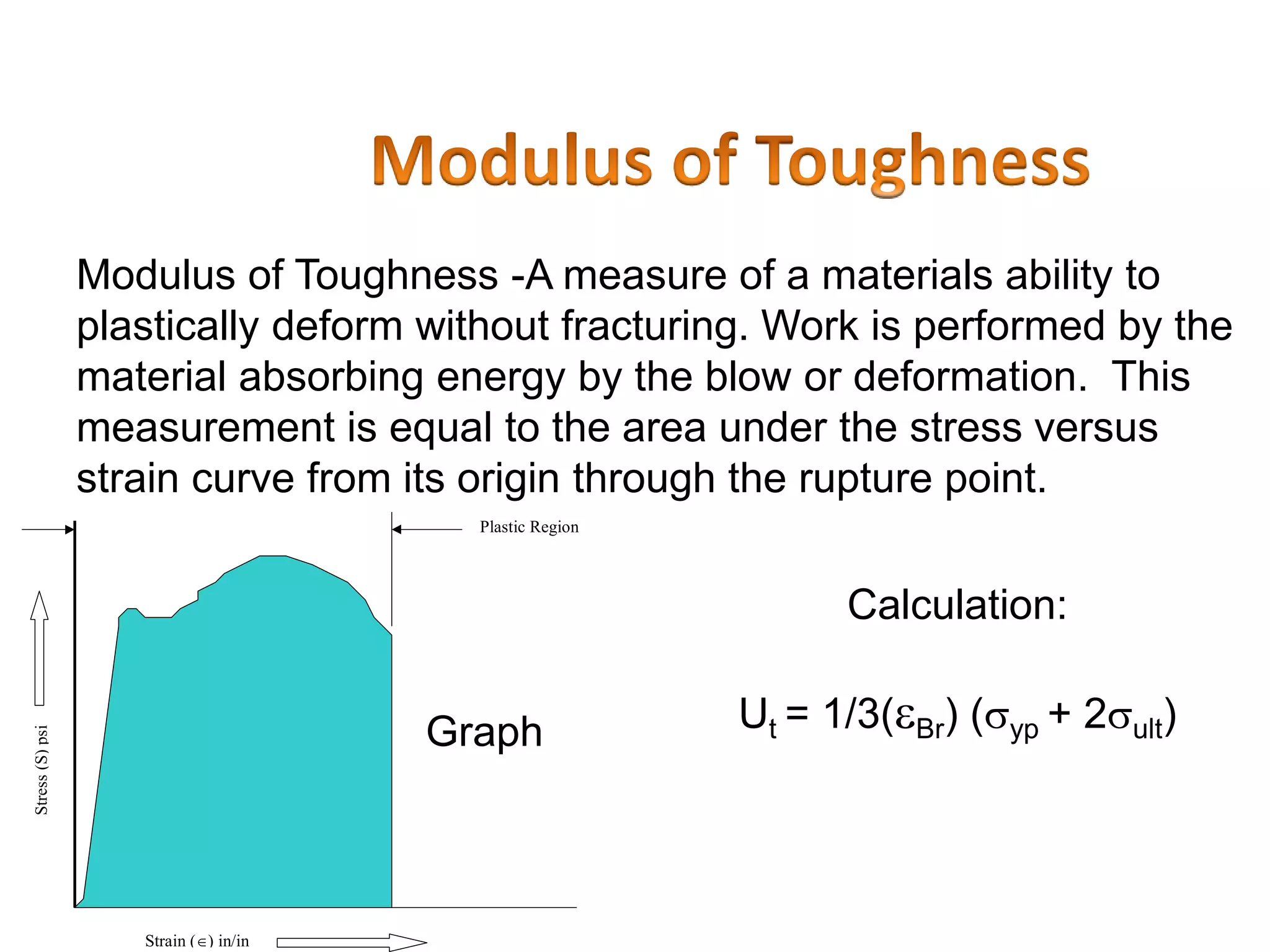

This document discusses tensile testing and universal testing machines. It defines tensile testing as applying opposing tensile forces to a test specimen to measure the specimen's properties. A universal testing machine typically uses a hydraulic cylinder to apply the force. The document lists several material properties that can be determined from tensile tests, including strength, ductility, elasticity, and stiffness. It provides diagrams illustrating how properties like tensile strength, modulus of elasticity, and breaking stress are calculated from the stress-strain graph generated during tensile testing. Finally, it gives some examples of industries that use tensile testing, like aerospace and textiles, and notes benefits like determining batch quality and aiding design.