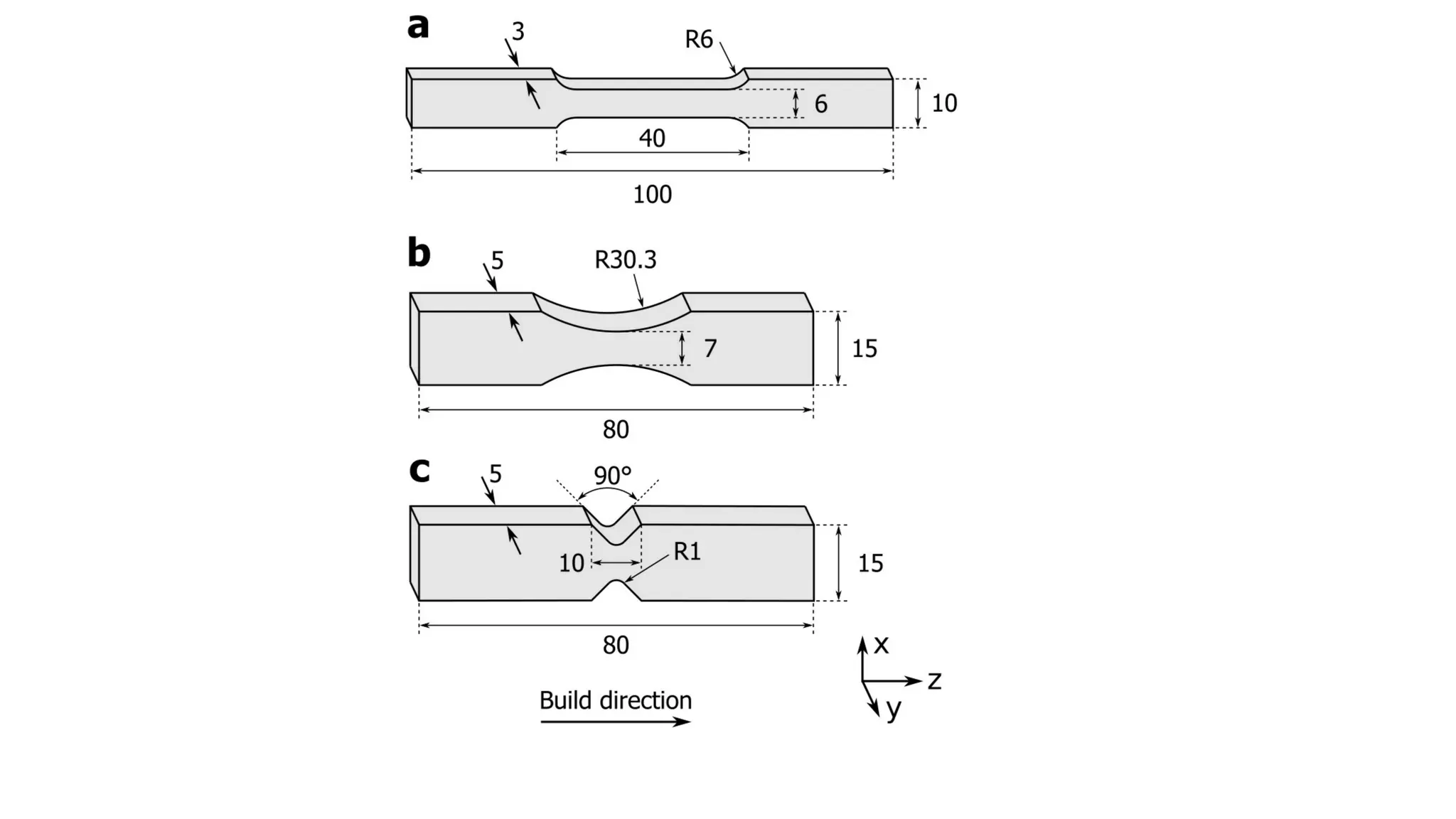

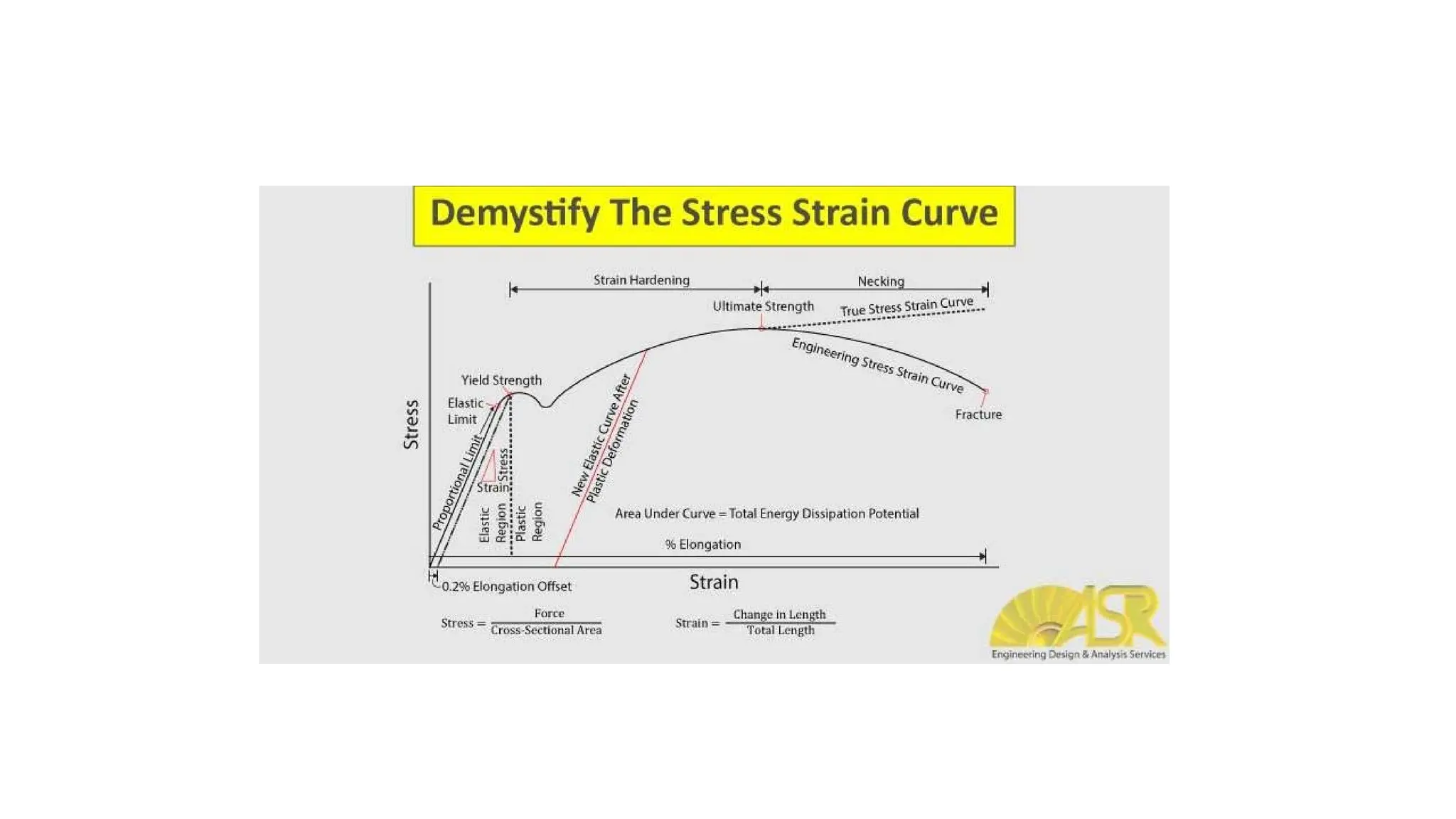

Tensile testing is a mechanical test used to assess a material's strength and ductility by measuring its resistance to tensile loads. The process involves preparing specimens, applying loads incrementally, and analyzing the resulting stress-strain curve to determine characteristics like ultimate tensile strength and ductility. This testing is essential for material selection, quality control, and research in engineering applications.