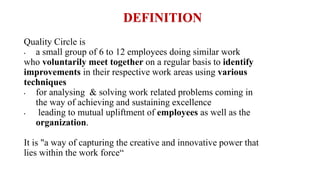

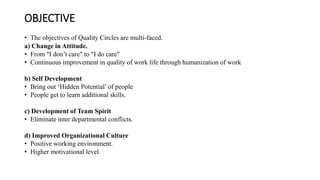

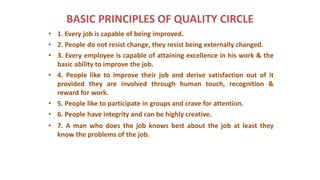

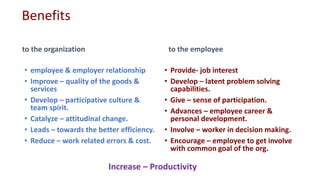

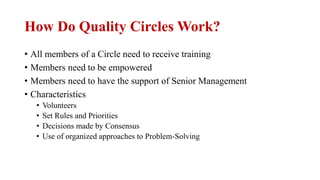

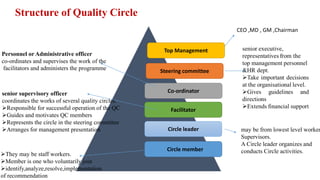

Quality circles are small groups of employees who voluntarily meet regularly to identify improvements in their work areas. The objectives are to change attitudes from not caring to caring about quality, promote self-development, build team spirit, and improve organizational culture. Benefits include improved employee-employer relationships, quality, efficiency, problem solving capabilities, and participation. Quality circles use techniques like brainstorming, data analysis, and cause-and-effect analysis. They can be applied in various organizations to solve work-related problems through group efforts.