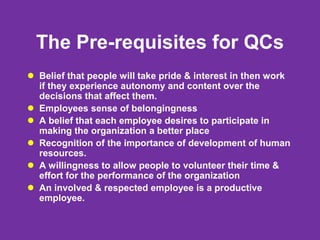

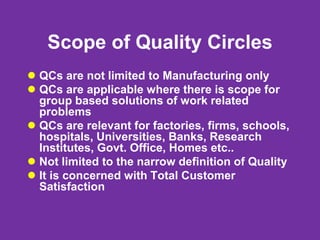

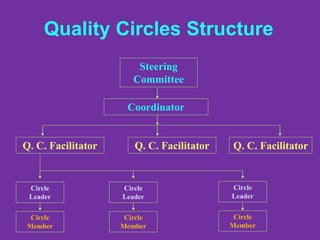

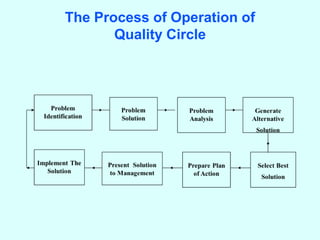

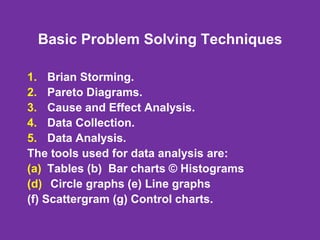

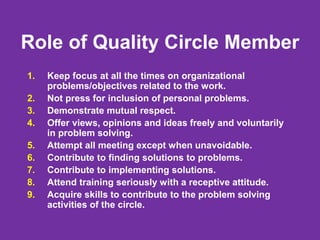

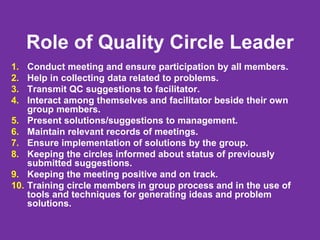

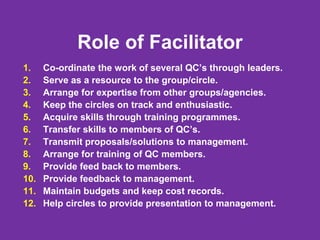

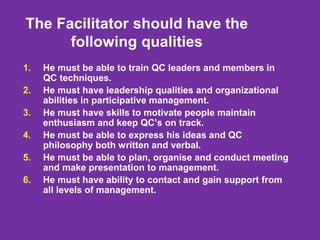

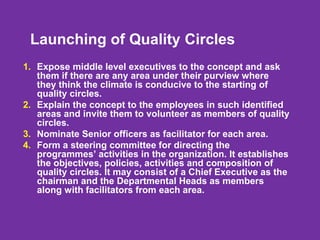

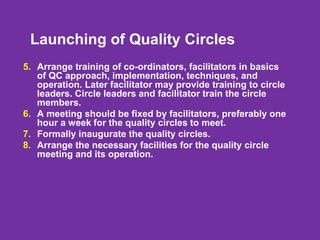

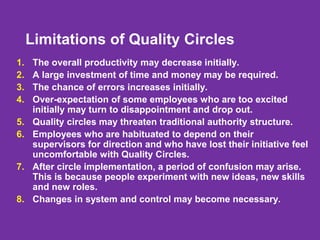

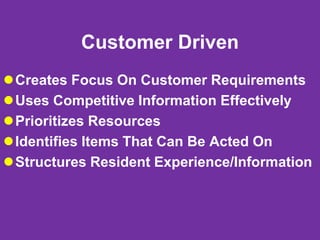

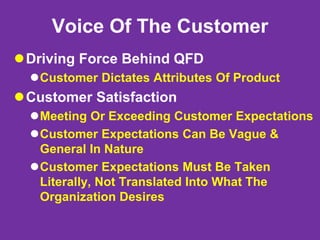

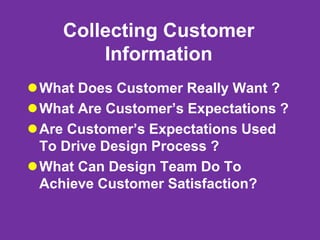

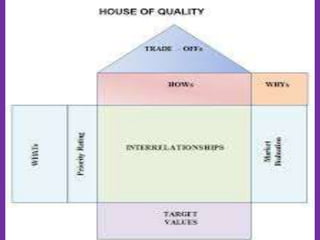

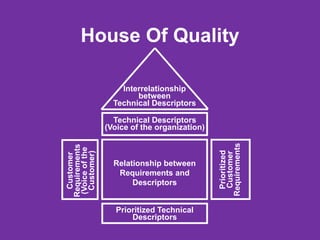

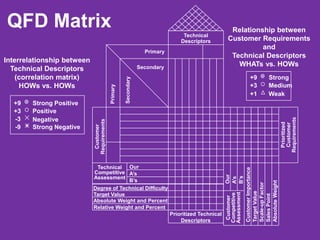

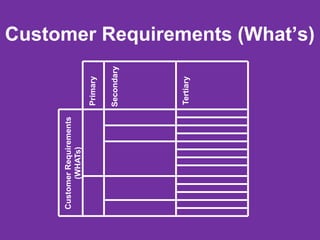

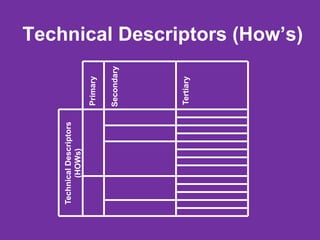

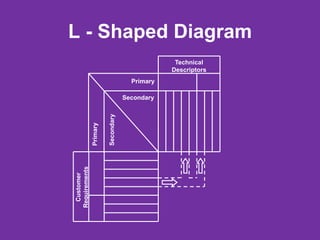

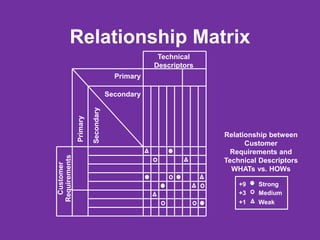

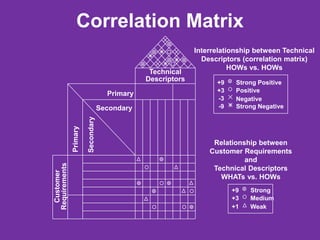

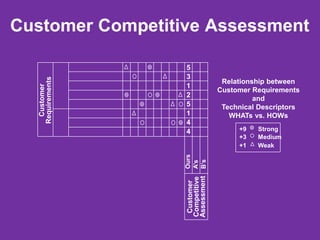

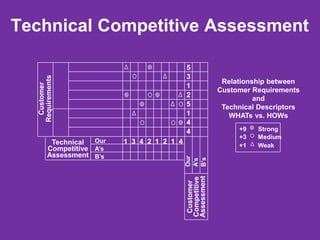

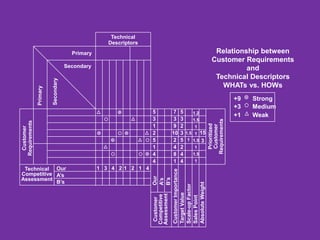

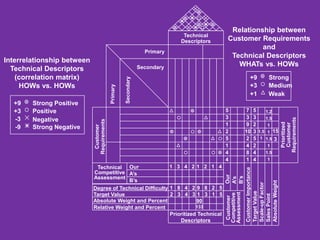

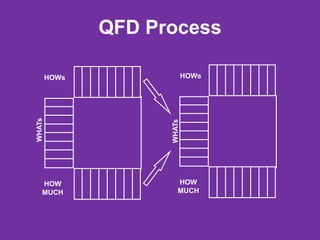

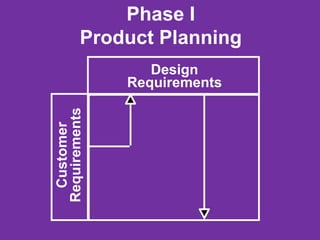

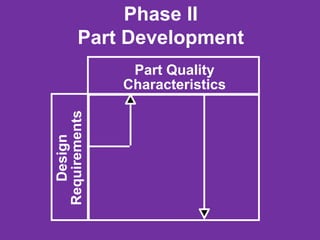

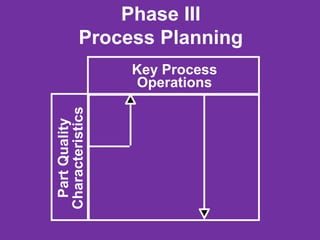

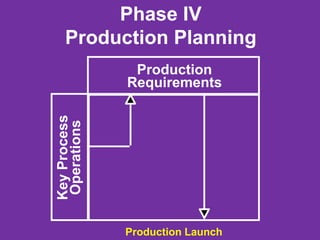

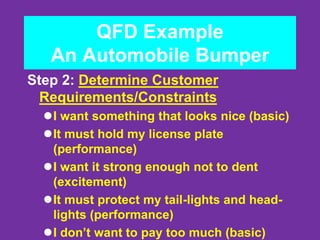

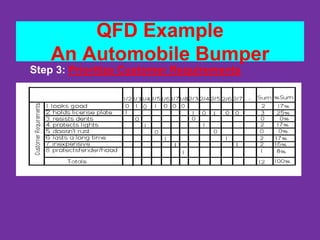

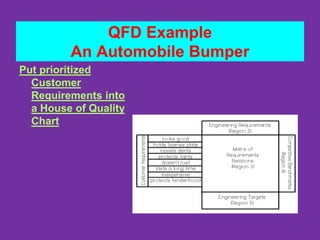

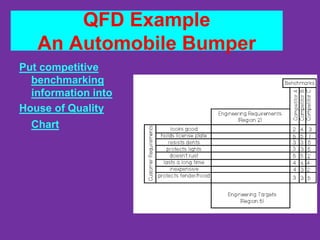

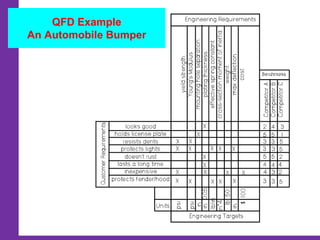

The document outlines various Total Quality Management (TQM) tools and techniques, focusing on Quality Circles, Quality Function Deployment, and the Taguchi Loss Function. Quality Circles are voluntary employee groups aimed at improving work quality through problem-solving teamwork, while Quality Function Deployment (QFD) translates customer needs into actionable design steps, enhancing product development efficiency. The document also discusses the roles, structures, benefits, and limitations of these quality improvement methods within organizations.