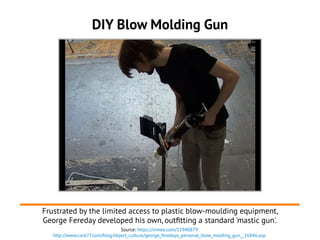

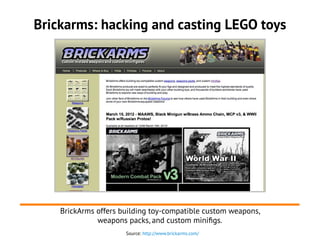

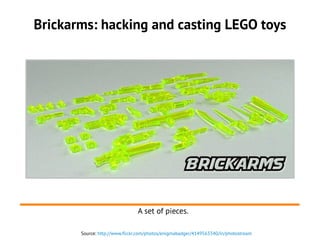

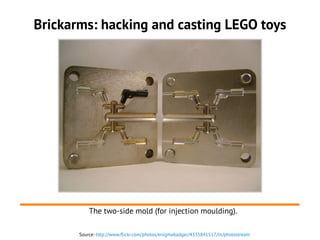

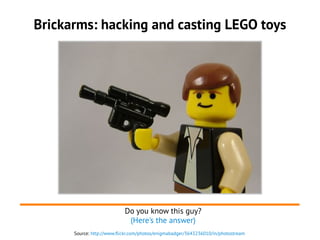

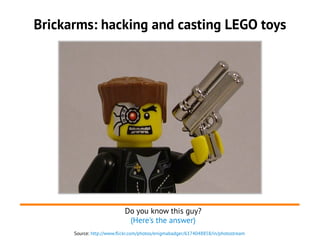

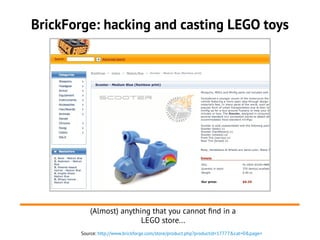

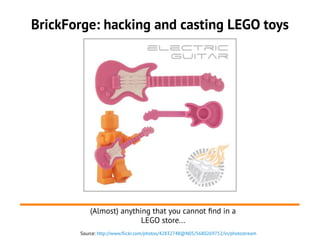

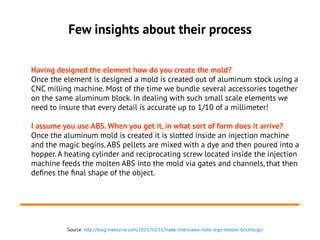

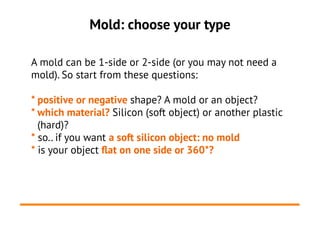

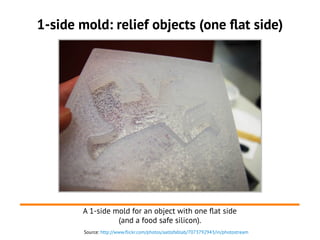

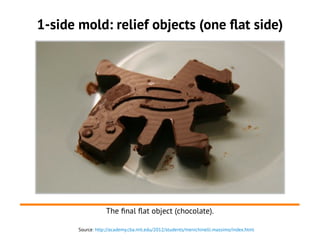

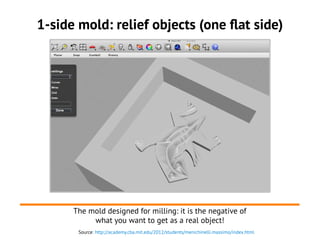

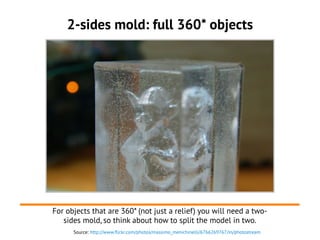

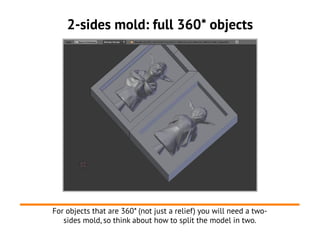

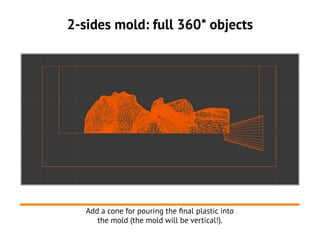

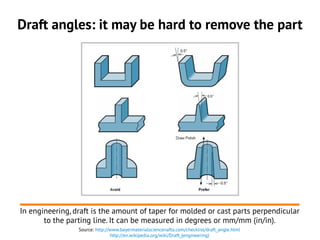

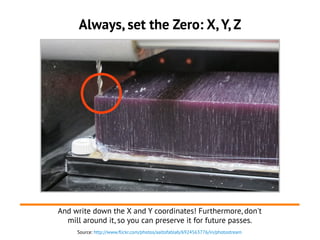

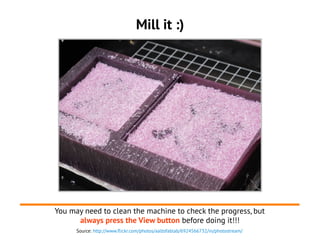

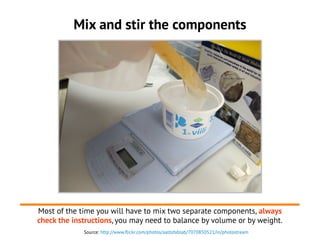

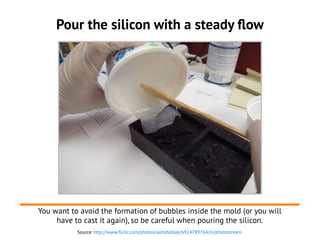

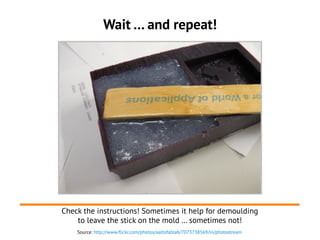

George Fereday developed his own DIY blow molding gun to gain access to plastic blow molding equipment after becoming frustrated by limited access. BrickArms offers custom LEGO compatible weapons, weapon packs, and minifigs that are created through molding and casting techniques. BrickForge considers themselves intermediaries between the LEGO community and the company, producing custom pieces through CNC milling aluminum molds and injection molding ABS plastic. Proper mold design and material selection is important for different object shapes, as is carefully following instructions for milling, mixing, pouring, and setting materials.