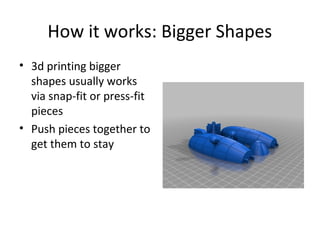

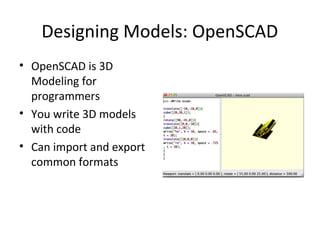

This document provides an overview of 3D printing. It discusses the different types of 3D printing technologies, such as fused deposition modeling (FDM) which is used in most home/hobby 3D printers. It also reviews specific 3D printer models like the Makerbot and Printrbot and the materials they can use, such as PLA and ABS plastics. The document outlines the 3D printing process including designing models, slicing files, generating G-code instructions, and layer-by-layer printing. It highlights some complex prints and larger assembled objects that can be made as well as sharing models through sites like Thingiverse.