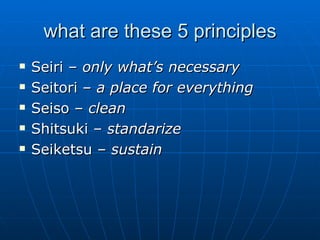

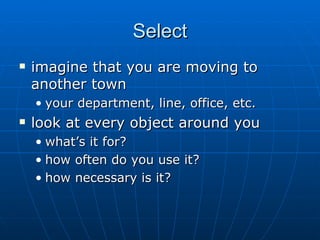

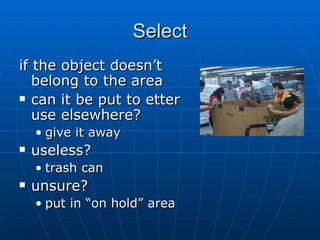

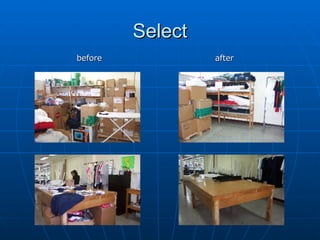

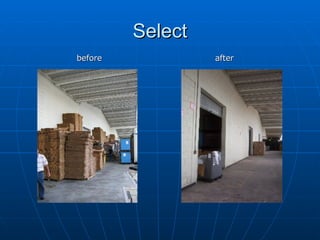

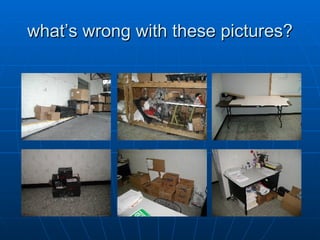

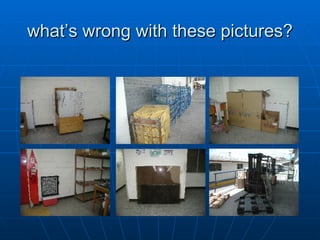

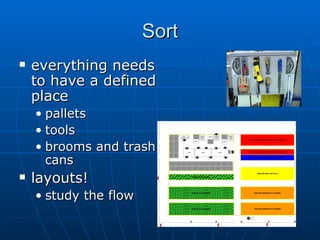

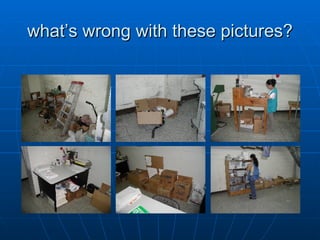

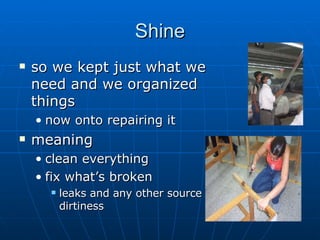

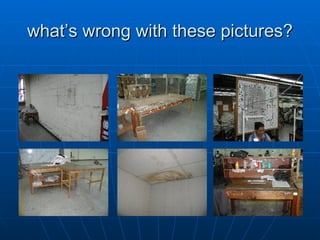

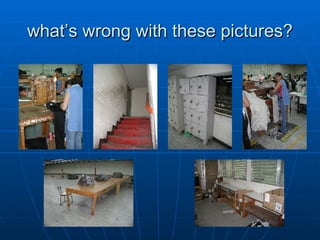

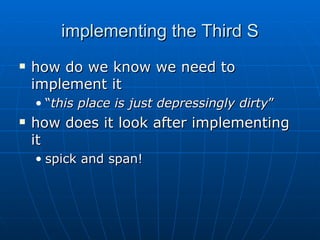

The document discusses the 5S principles of Japanese philosophy for eliminating waste in the workplace. The 5S principles are: Select (only keep necessary items), Sort (have a place for everything), Shine (keep everything clean), Standardize (establish processes), and Sustain (maintain standards over time). It provides examples of applying each principle, such as removing unnecessary items during Select, organizing a workspace during Sort, and establishing rules during Standardize. Implementing the 5S principles helps create a more productive, safe, and efficient work environment.