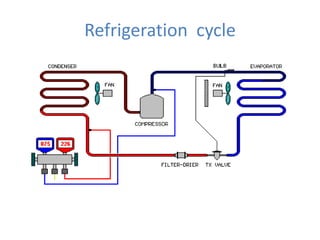

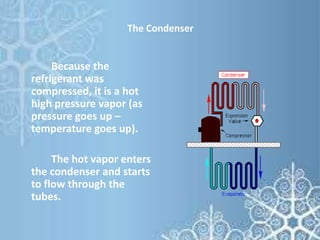

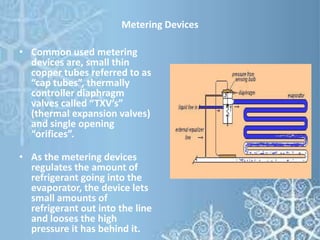

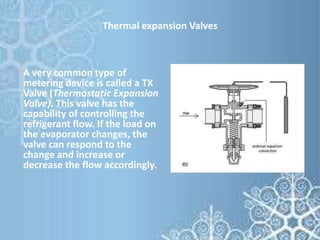

This document summarizes the basic components and process of a refrigeration cycle. It outlines the four main components: compressor, condenser, metering device, and evaporator. It describes that the compressor increases the pressure and temperature of the refrigerant vapor from the evaporator. In the condenser, heat is removed from the refrigerant as it cools and changes state into a liquid. The metering device then regulates the flow of refrigerant into the evaporator, where it absorbs heat from the surrounding air and changes back into a vapor before returning to the compressor to repeat the cycle.