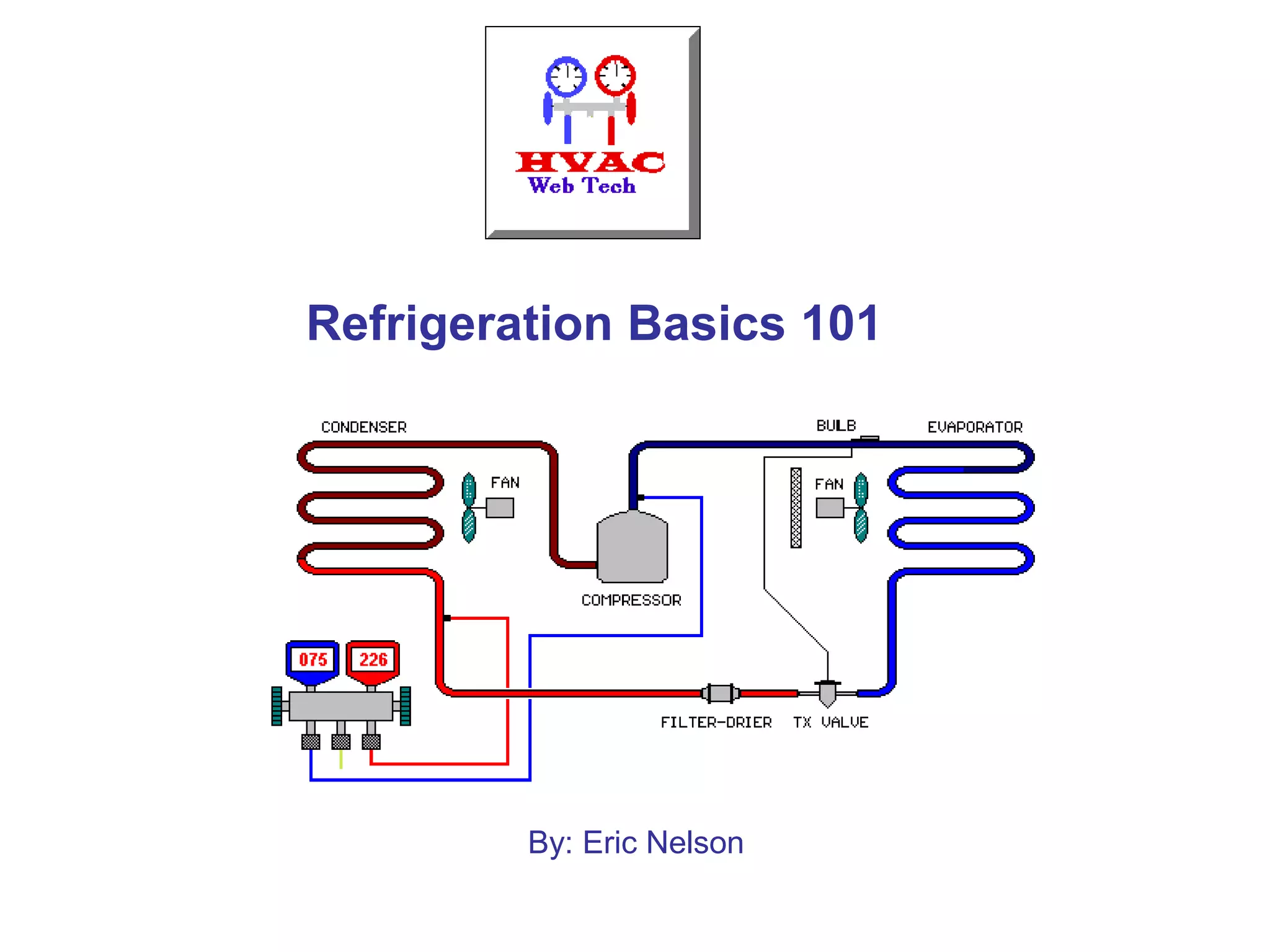

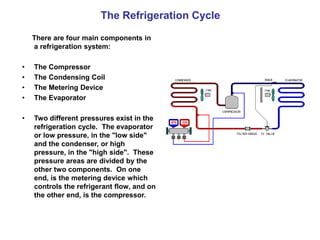

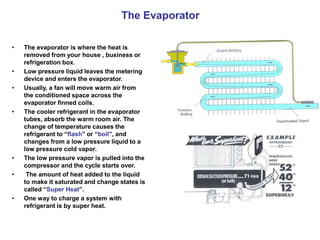

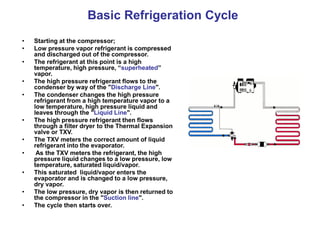

Refrigeration systems use a refrigerant that changes between gas and liquid states to remove heat from one area and release it to another area. The refrigerant absorbs heat in the evaporator, changing from liquid to gas. It is compressed to a high pressure gas and releases heat in the condenser, changing back to a liquid. The refrigerant then passes through a metering device and expansion valve back to the low pressure evaporator, completing the refrigeration cycle. Key components include the compressor, condenser, expansion valve, and evaporator. Refrigerant properties like saturation temperature and latent heat allow this heat transfer process to occur.