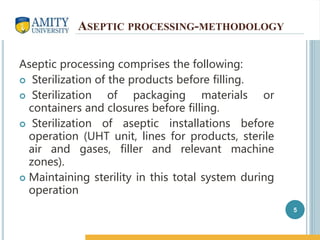

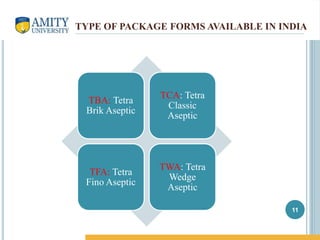

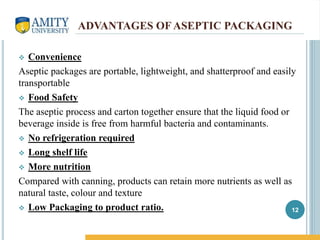

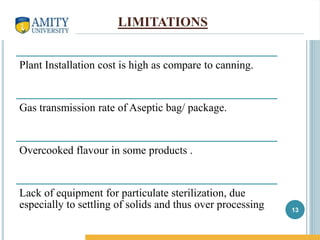

The document outlines aseptic packaging and its advantages in food technology, emphasizing its role in increasing shelf life, convenience, and food safety. Aseptic packaging involves sterilizing both the product and the container to prevent contamination, leading to products being shelf-stable without refrigeration. Additionally, it discusses active packaging, which incorporates additives to further preserve food quality and safety.