1. The document provides guidelines for configuring and applying variant configuration in production planning. It demonstrates an MTO configuration scenario with characteristic parameter entry in the sales order, transfer of requirements from the sales order to MRP, conversion of planned orders to production orders, and selection of appropriate materials and operations from super BOMs and super routings to create deliveries of the finished product.

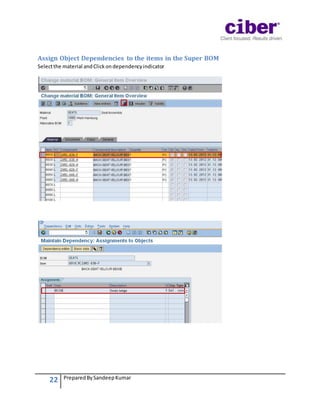

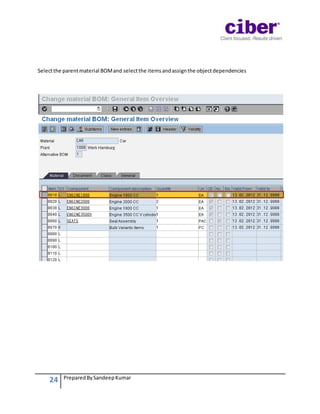

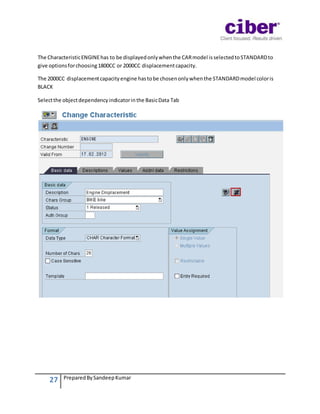

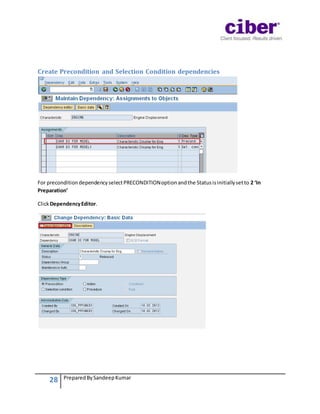

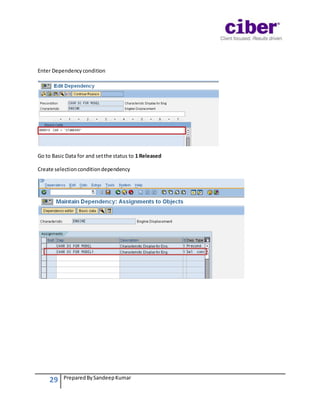

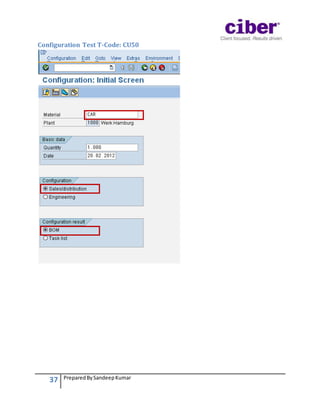

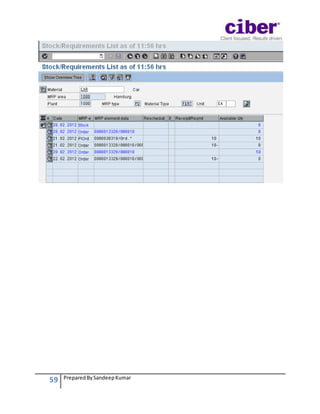

2. Key steps include creating characteristics, classes, a configurable material, super BOM, configuration profile, object dependencies, precondition/selection condition dependencies, super routing, testing the configuration, running MRP, creating production and purchase orders, confirming orders, and delivering the finished product.

3. The configuration allows parameters like car