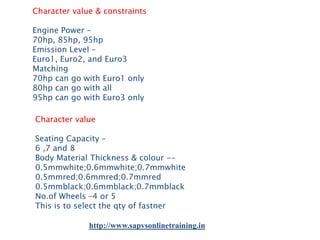

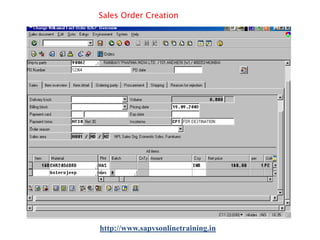

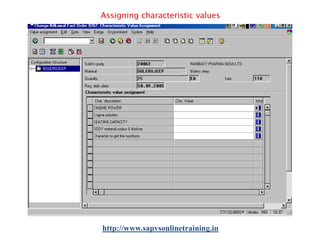

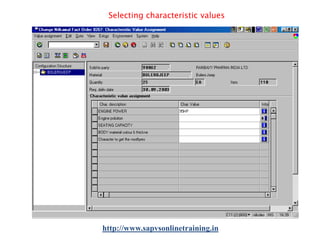

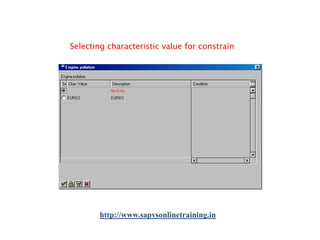

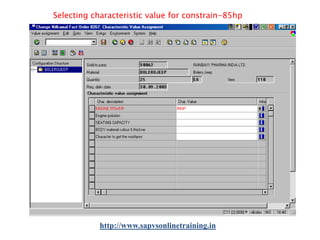

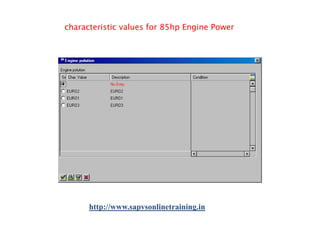

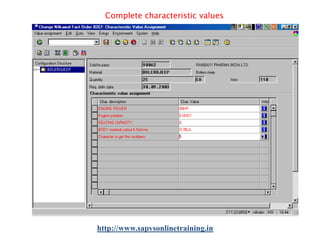

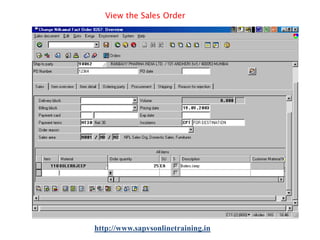

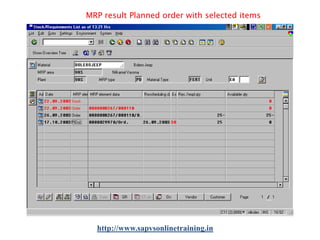

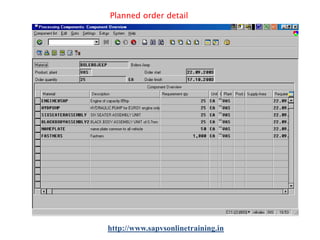

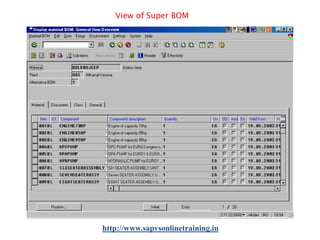

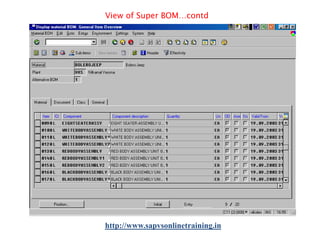

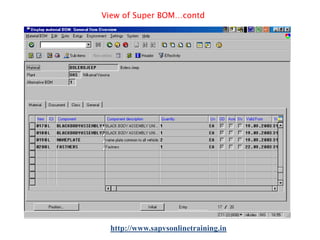

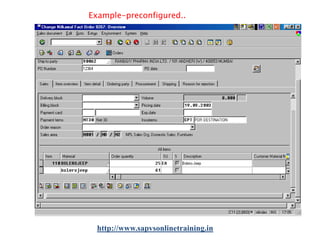

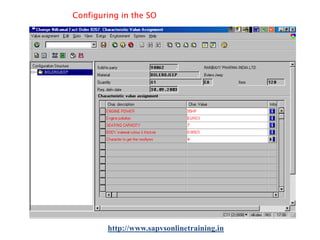

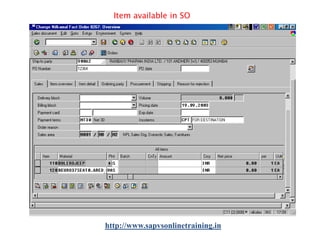

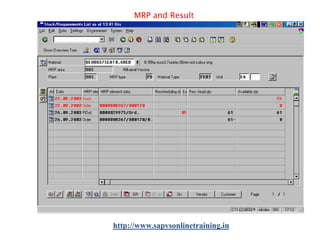

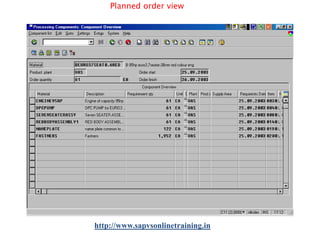

Variant configuration is a tool in SAP that helps simplify the production of products with variations. It uses characteristics and characteristic values to configure products in sales orders. This selects the appropriate components from a super bill of materials. Configurable materials can have pricing dependent on characteristic values. Standard variants can also be predefined and planned for high demand configurations.