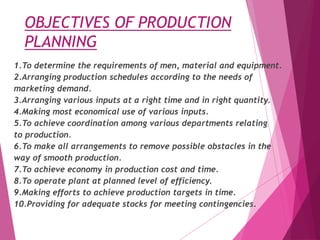

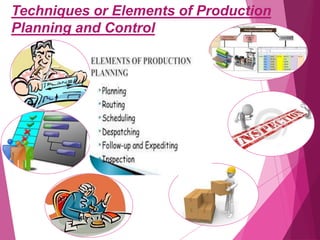

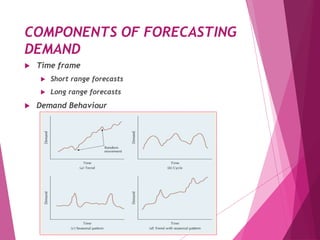

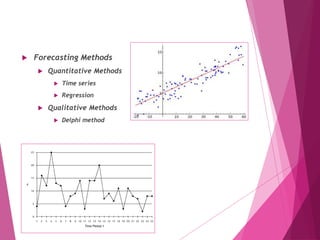

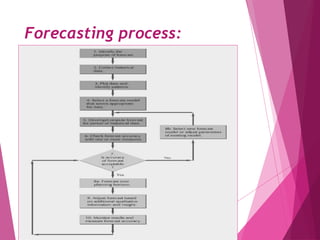

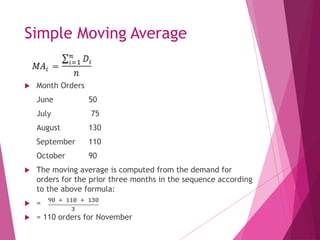

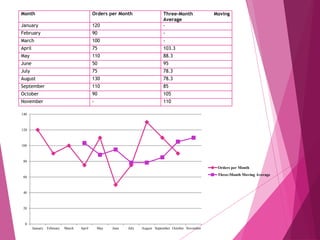

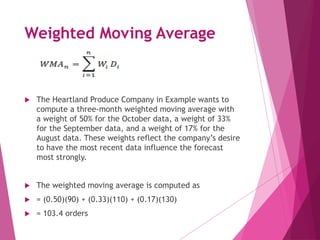

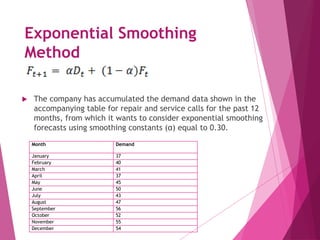

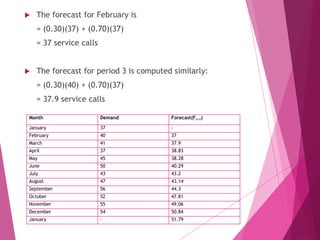

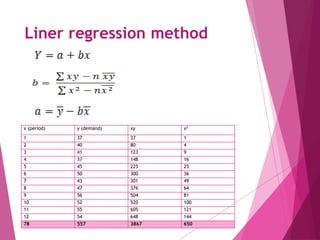

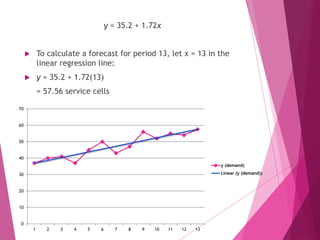

Production planning and control involves determining resource requirements, production schedules, and quality control to efficiently produce goods at the lowest cost. It aims to coordinate departments, remove obstacles, achieve targets on time, and provide contingency stocks. Production control implements plans through work orders and ensures availability of inputs and adherence to schedules. Techniques include planning, routing, scheduling, dispatching, follow-up, expediting, and inspection. Forecasting estimates future demand through time series methods and is essential for supply chain, quality, and strategic planning.