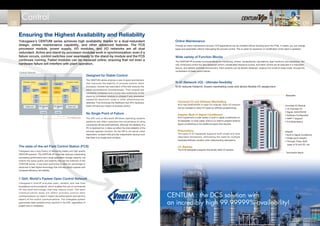

Yokogawa's Centum VP is an advanced integrated production control system designed for optimized process automation, featuring high availability (99.99999%) and a commitment to evolving alongside customer needs. The system integrates automation design, flexible I/O solutions, and advanced engineering tools to enhance operational efficiency, maintain data integrity, and support lifecycle management for plants. Yokogawa also prioritizes cybersecurity with robust measures to protect control systems against threats, ensuring dependable and secure manufacturing environments.

![CENTUM, Lifecycle Effectiveness Services, Opportunity Identification Services, ProSafe, Solution Implementation Services, STARDOM, FieldMate, VigilantPlant,

VigilantPlant Services and Vnet/IP are either trademarks or registered trademarks of Yokogawa Electric Corporation.

All other company brand or product names in this bulletin are trademarks or registered trademarks of their respective holders.

[Ed:02/b] Printed in Japan, 412(KP)

2014

http://www.yokogawa.com/dcs/

With the release of the world’s first DCS nearly four decades ago,

Yokogawa helped empower an entire generation of plant operators.

With our focus on creating a sustainable future, we are committed in

our efforts to support a new generation of plant operators.](https://image.slidesharecdn.com/centumvp-control-platform-yokogawa-170927163006/85/Yokogawa-CENTUM-VP-Process-Control-and-Automation-Platform-9-320.jpg)