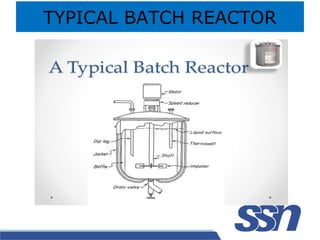

This document discusses biological waste water treatment using a batch reactor. It defines a batch reactor as a vessel used for processes like chemical reactions that does not have inflow or outflow during the reaction. Batch reactors are commonly used for small-scale production and biological reactions. They consist of a tank with agitation and heating/cooling systems to control temperature. Batch reactors are versatile but have disadvantages like variability between batches and lower intensity than continuous processes. They are often used in industries like brewing and for processes like waste water treatment.