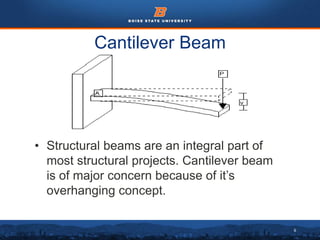

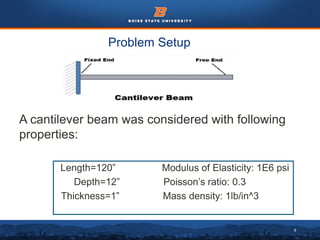

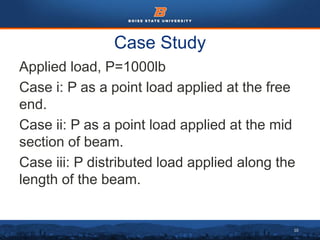

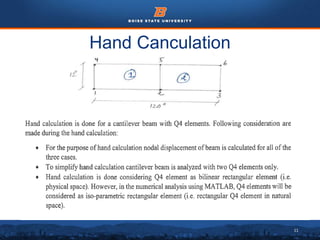

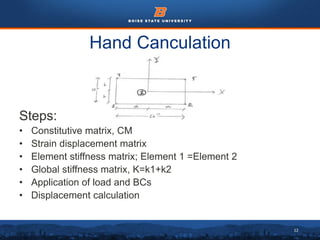

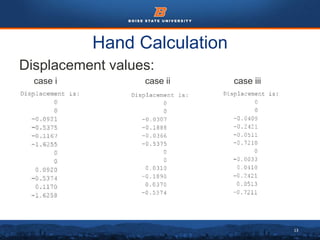

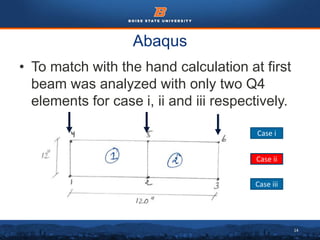

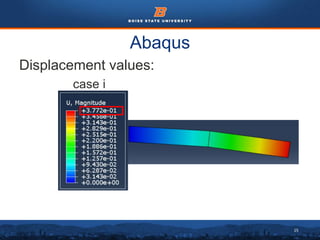

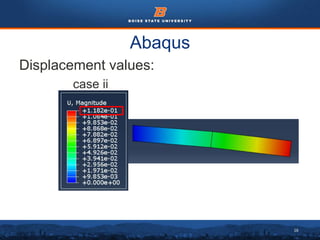

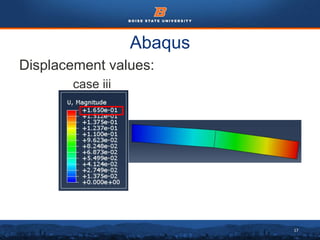

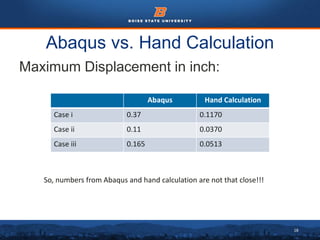

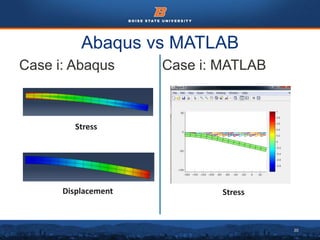

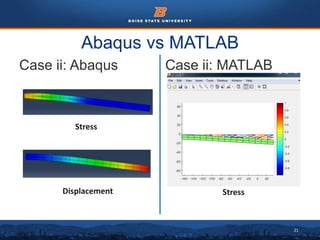

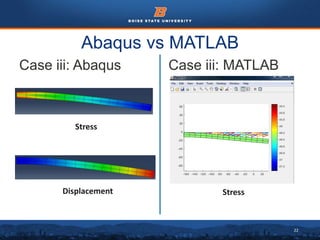

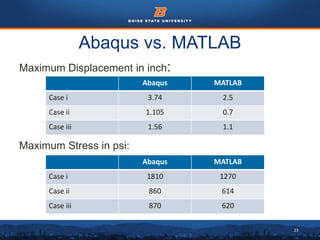

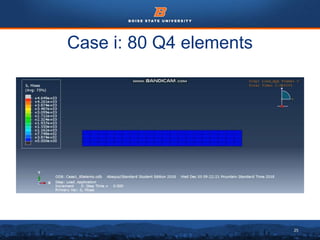

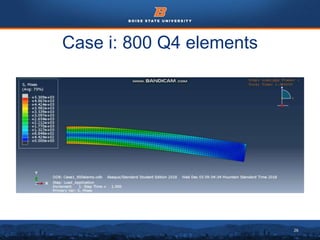

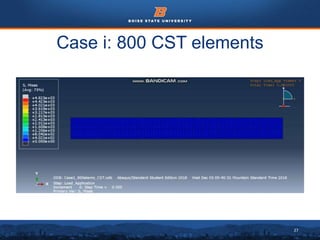

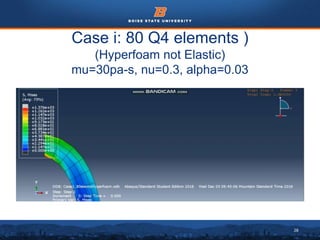

This document summarizes a finite element analysis of a cantilever beam using quadrilateral meshing elements. The beam is modeled and analyzed in Abaqus for three loading cases: a point load at the free end, a point load at the mid-section, and a distributed load along the length. Hand calculations are also performed and compared to Abaqus and MATLAB results. Increasing the number of elements improves accuracy of the models. Quadrilateral elements are preferred over triangular elements for beam bending problems. Maximum displacement occurs under a point load at the free end. The study concludes with recommendations for accurate beam modeling and design using finite element analysis.

![31

References

[1]. E. Monterrubio, Luis. Analytical solution, finite element

analysis, and experimental validation of a cantilever beam.

Robert Morris university.

[2]. Belendez, Tarsicio et. Al. Large and small deflections of a

cantilever beam.

[3]. Kumar, Sanjay. Comparison of deflection and slope of

cantilever beam with analytical and finite element method for

different loading conditions.

[4]. Ghuku, Sushanta et. Al. A theoretical and experimental

study on geometric nonlinearity of initially curved cantilever

beams.

[5]. Jadhao, V.B. et. Al. Investigation of stresses in cantilever

beam by FEM and its experimental verification.

[6]. Samal, Ashis Kumar, et. Al. Analysis of stress and

deflection of cantilever beam and its validation using ANSYS](https://image.slidesharecdn.com/presentationrahmanmd-190320095757/85/ME-570-Finite-Element-Methods-31-320.jpg)