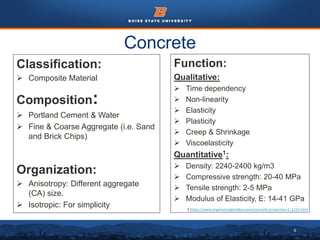

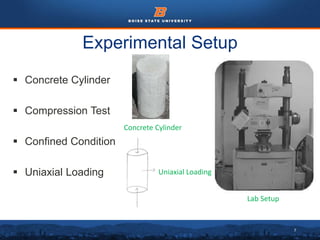

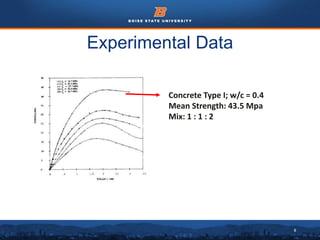

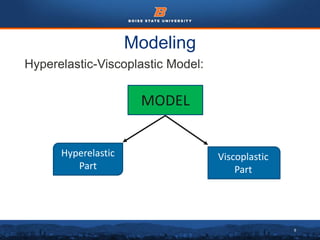

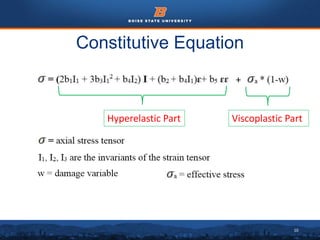

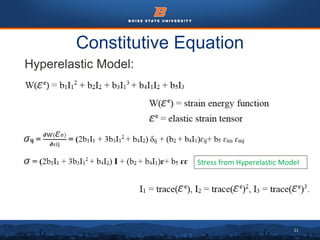

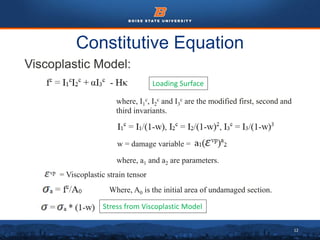

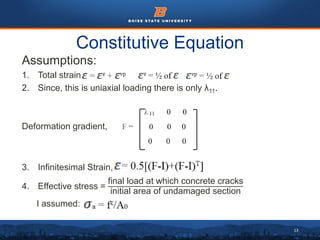

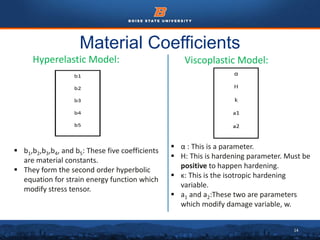

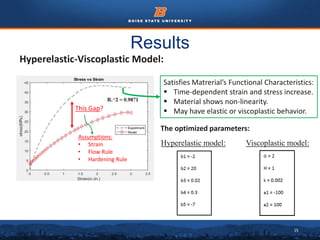

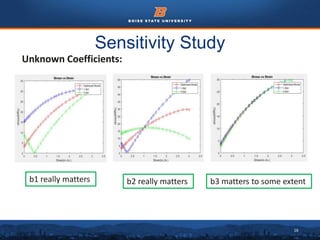

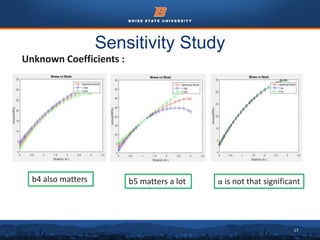

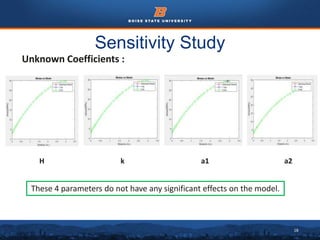

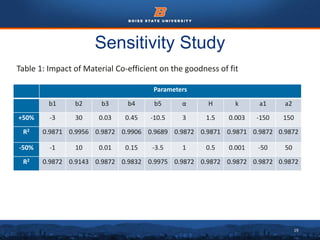

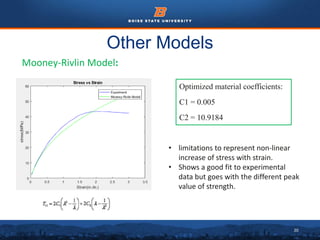

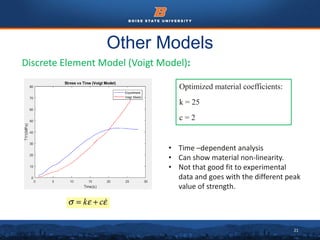

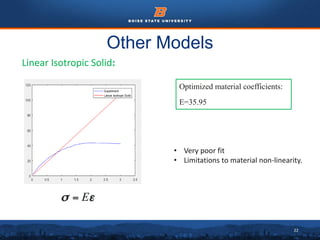

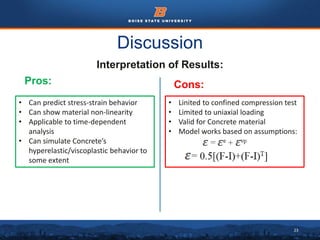

This document summarizes the development of a hyperelastic-viscoplastic model to model the behavior of concrete under uniaxial loading. It describes conducting a uniaxial compression test on a concrete cylinder specimen. A hyperelastic model and viscoplastic model were combined in a constitutive equation to model the material. Material coefficients for the models were optimized by fitting the model predictions to the experimental stress-strain data. A sensitivity study identified which coefficients most significantly affected the model fit. Other material models like Mooney-Rivlin and linear isotropic solid models were also tested but did not fit the experimental data as well. The model reasonably captured the nonlinear stress-strain behavior of concrete but had limitations and assumptions that could be

![25

References

• [1]. Dinesh Panneerselvam and Vassilis P. Panoskaltsis, Numerical

Implementation of A Hyperelastic-Viscoplastic Damage Model for

Asphalt Concrete Materials and Pavements, ASCE journal, 2006.

DOI: 10.1061/40825(185)7

• [2]. Jianlian Cheng, Xudong Qian, Tieshuan Zhao, Rheological

Viscoplastic Models of Asphalt Concrete and Rate-Dependent

Numerical Implement, International Journal of Plasticity, 81 (2016)

209-230, http://dx.doi.org/10.1016/j.ijplas.2016.01.004

• [3]. T. Yu, J.G. Teng, Y.L. Wong, S.L. Dong, Finite Element Modeling

of Confined Concrete-II: Plastic-Damage Model, Engineering

Structures, 32 (2010) 680-691, doi:10.1016/j.engstruct.2009.11.013](https://image.slidesharecdn.com/presentationrahmanmd-190320095535/85/ME-510-Continuum-Mechanics-25-320.jpg)