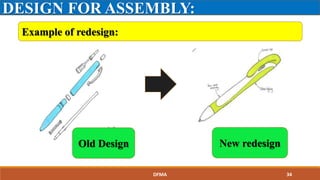

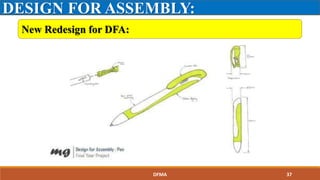

The document discusses various design for manufacturing and assembly (DFMA) principles including: design for machining (standardization, material choice, part size/shape), design for economy (reducing lifecycle costs), design for clampability (ease of clamping parts), design for accessibility (ease of accessing parts), and design for assembly (minimizing parts, using self-locating/fastening features, modular design). It provides guidelines and examples for each principle to facilitate part and product design for efficient manufacturing and assembly.

![DESIGN FOR MACHINABILITY[2]:

STANDAR-

DIZATION ASSEMBLY

CHOIS OF

WORK

MATERIAL

ACCURACY

AND

SURFACE

FINISH

Design for

Machinability

SIZE AND

SHAPE OF

WORK

MATERIAL

DFMA 4](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-4-320.jpg)

![DESIGN FOR MACHINABILITY[2]:

DESIGN GUIDLINES:

1) STANDARDIZATION:

Utilize standard component.

Utilize standard pre-shaped

workpiece .

Employ standard machined

features.

DFMA 5](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-5-320.jpg)

![DESIGN FOR MACHINABILITY[2]:

DESIGN GUIDLINES:

2) CHOICE OF MATERIAL:

Choose material with

minimum cost.

Utilize raw material in the

standard form supplier.

DFMA 6](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-6-320.jpg)

![DESIGN FOR MACHINABILITY[2]:

DESIGN GUIDLINES:

3) SHAPE AND SIZE OF MATERIAL(General):

It can be machined on one machine tool.

workpiece should be gripped so that it can be rigid to

withstand machining force.

The tool, toolholder, work and workholding device would not

interfere with one another.

Auxiliary holes or bores should cylindrical and with standard

L/D ratio.

DFMA 7](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-7-320.jpg)

![DESIGN FOR MACHINABILITY[2]:

DESIGN GUIDLINES:

3) SHAPE AND SIZE OF MATERIAL(Rotational):

Cylindrical surface should be concentric and plane surface

are normal to the component axis.

Avoid internal features for long component.

Avoid very large or very small L/D ratio.

DFMA 9](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-9-320.jpg)

![DESIGN FOR MACHINABILITY[2]:

DESIGN GUIDLINES:

4) ASSEMBLY:

Ensure that each operating machined surface on a component

has a corresponding machined surface on mating component.

Ensure that internal corners do not interfere with a

corresponding external corner on the mating component.

DFMA 10](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-10-320.jpg)

![DESIGN FOR MACHINABILITY[2]:

DESIGN GUIDLINES:

5) ACCURACY AND SURFACE FINISH:

Specify the widest tolerance and roughness surface that

would give the required performance for operating surface.

DFMA 12](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-12-320.jpg)

![DESIGN FOR ECONOMY[6]:

DESIGN FOR

ECONOMY

DESIGN FOR COST DESIGN TO COST

Design for cost is the continues

use of engineering process and

technology to reduce life cycle

cost.

Engineering driven process.

Design to cost is the iterative

redesign of project until the

content of project meets a given

budget.

Iterative by nature.

Management driven process.

DFMA 14](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-14-320.jpg)

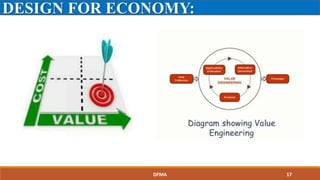

![DESIGN FOR ECONOMY[6]:

METHOD FOR DESIGNING FOR COST

1)VALUE ENGINEERING:

Uses function cost analysis to reduce cost.

2)COST TABLE

Uses function cost analysis to reduce cost.

3)RESPONCE SURFACE METHODOLOGY:

Collection of mathematical and statical techniques that are

useful for the modeling and analysis of problem to reduce

cost.

DFMA 16](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-16-320.jpg)

![DESIGN FOR ECONOMY[6]:

4)TAGUCHI METHOD:

Improve the implementation of Total Quality Control to

reduce cost.

5)MULTIDISCIPLINARY OPTIMIXATION:

it is optimization technique to reduce cost.

6)KAIZEN:

Improvement in quality of product to reduce cost.

7)JUST IN TIME:

Cost is reduced by reducing inventory.

METHOD FOR DESIGNING FOR COST

DFMA 18](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-18-320.jpg)

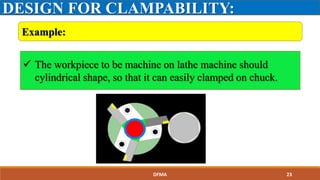

![What is Clampability ?

DESIGN FOR CLAMPABILITY[4]:

"Capability of

being clamped"

DFMA 19](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-19-320.jpg)

![DESIGN FOR CLAMPABILITY[4]:

What is Design for Clampability ?

“It is defined as the ease

with which part or product

can be clamped with other

part easily“.

DFMA 20](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-20-320.jpg)

![DESIGN FOR CLAMPABILITY[5]:

DESIGN GUIDLINES:

1) Self fastening

2) Self locking

DFMA 21](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-21-320.jpg)

![DESIGN FOR CLAMPABILITY[5]:

DESIGN GUIDLINES:

3) Modular design

4) Using standard part

5) Symmetric parts

6) Extra features for clamping

DFMA 22](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-22-320.jpg)

![What is Design for Accessibility ?

DESIGN FOR ACCESSIBILITY[5]:

“Design for accessibility is

a process by which

products are design with

ease of accessibility in

mind“.

DFMA 24](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-24-320.jpg)

![DESIGN GUIDLINES:

DESIGN FOR ACCESSIBILITY[5]:

1) Indicate orientation

2) Part do not tangle or stick to each other.

3) Prevent nesting

4) Insertion from top is preferred.

5) Use standard part

DFMA 26](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-26-320.jpg)

![DESIGN GUIDLINES:

DESIGN FOR ACCESSIBILITY[5]:

5) Deep channels should be sufficiently wide to provide access.

6) Proper spacing

7) Prevent obstracted access.

8) Provide adequate access and visibility.

DFMA 27](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-27-320.jpg)

![DESIGN GUIDLINES:

DESIGN FOR ACCESSIBILITY[2]:

DFMA 28](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-28-320.jpg)

![DESIGN FOR ASSEMBLY[2]:

What is Design for Assembly ?

“Design for Assembly is

the method of design of the

product for ease of

assembly“.

DFMA 29](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-29-320.jpg)

![DESIGN FOR ASSEMBLY[2]:

1) Use minimum part.

2) Design part with self-locating features.

3) Design part with self-fastning features.

4) Use modular design.

5) Use base part to locate other parts.

DESIGN GUIDLINES:

DFMA 32](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-32-320.jpg)

![DESIGN FOR ASSEMBLY[2]:

DESIGN GUIDLINES:

6) Design part for retrieval, handling and insertion.

7) Use symmetric component.

8) Use top-down assembly.

DFMA 33](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-33-320.jpg)

![DESIGN FOR ASSEMBLY[2],[5]:

DFA Process:

STEP-1

Product information:

1)Functional requirement

2)Function analysis

3)Identify parts that can be standardized

4)Determine part count efficiencies.

STEP-2

Determine your practical part count.

STEP-3

Identify quality(mistake proofing) opportunities.

DFMA 35](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-35-320.jpg)

![DESIGN FOR ASSEMBLY[2],[5]:

STEP-6

Identify opportunities to reduce secondary operations.

STEP-7

Analyze data for new design.

STEP-5

Identify insertion (locate and secure) opportunities.

STEP-4

Identify handling (grasp and orientation) opportunities.

DFA Process:

DFMA 36](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-36-320.jpg)

![REFRENCE:

[1] Assembly automation & Product Design.G.Boothroyd, Marcell dekker, Inc.1992.

[2] Product Design for Manufacturing & Assembly.G.Boothroyd and

P.Dewhurst.Inc.1989. Marcell Dekker.Inc.1994.

[3] Engineering Design. George E.Dieter, Linda C. Schmidt.

[4] https://en.m.wikipedia.org/wiki/Design_for_assembly.

[5] National Programme On Technology Enhanced Learning. nptl.ac.in

[6] Design for cost (Article).Edwin B.Dean, R.Unal (1991).

DFMA 38](https://image.slidesharecdn.com/dfmappt-170513113622/85/Dfma-ppt-38-320.jpg)