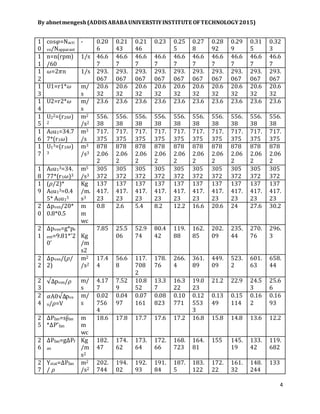

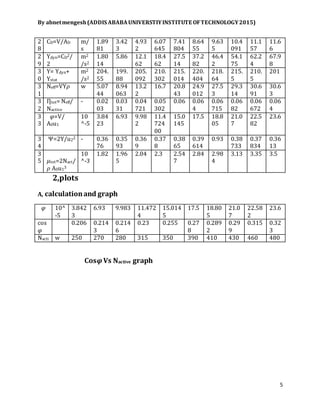

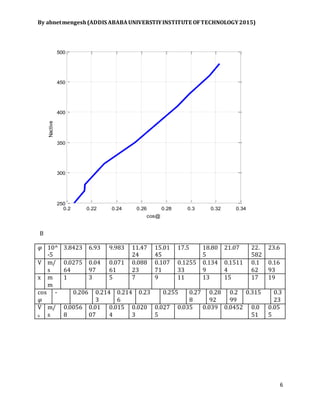

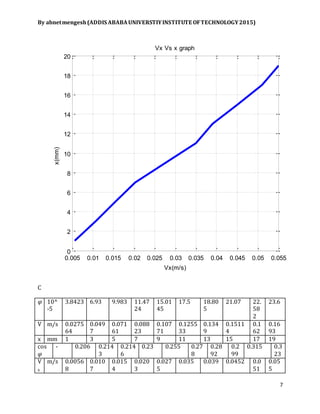

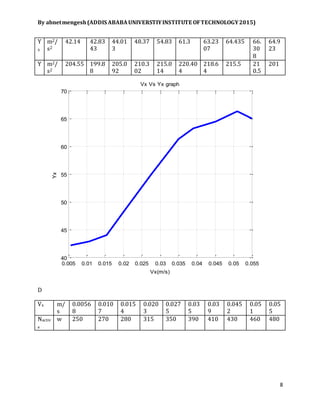

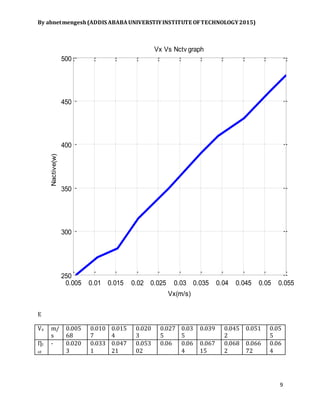

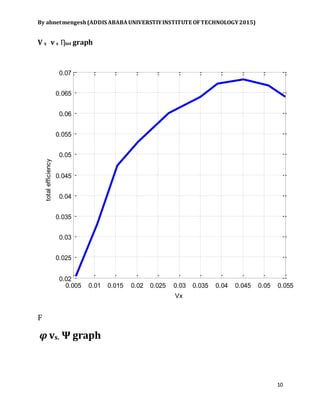

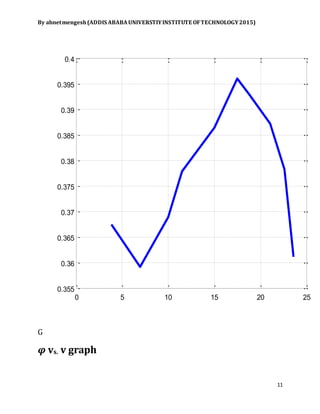

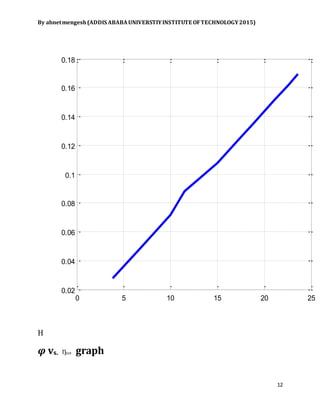

This document summarizes an experiment conducted to measure the performance of a radial flow fan. The objectives were to measure total and static pressure drop with varying flow rates and determine key parameters that affect fan operation and efficiency. Equations related to centrifugal fan operation are provided. Test data was collected for fan speed, voltage, current, venturi pressure drop, and fan pressure drop. Calculations were performed to analyze fan efficiency, power, and other parameters. Graphs were made to show relationships between the calculated values.