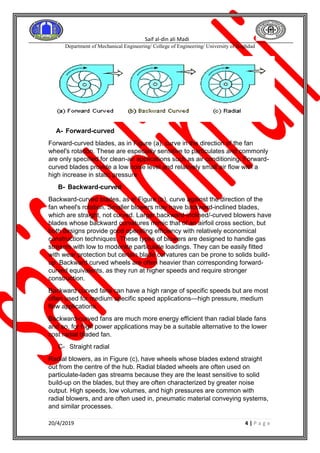

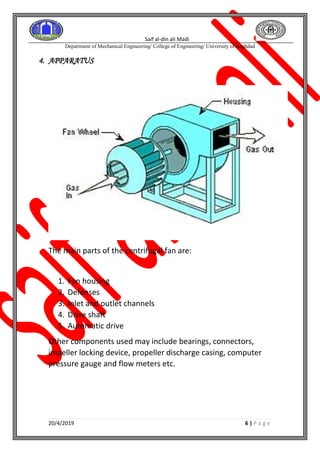

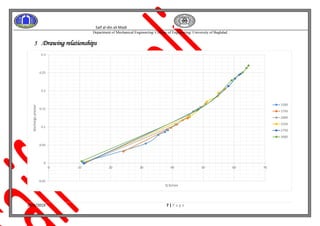

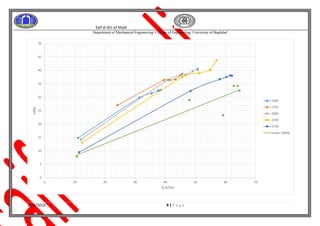

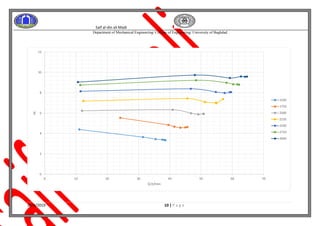

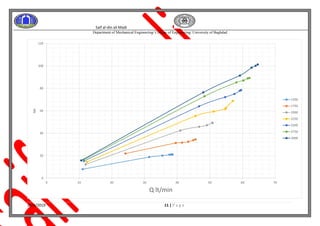

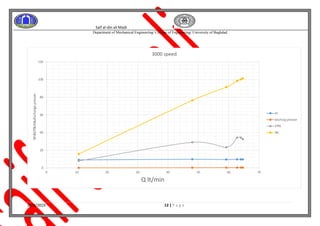

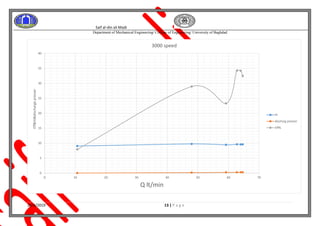

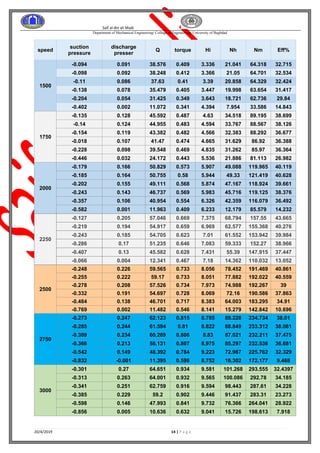

The document details an experiment on centrifugal fans conducted by Saif Al-Din Ali Madi at the University of Baghdad. It discusses the operation, design features, performance characteristics, and efficiency losses associated with centrifugal fans, along with relevant apparatus and component specifications. The experimentation focuses on practical applications of centrifugal fans and their operational parameters, with data and graphical representations analyzing the fan's performance.

![Saif al-din ali Madi

Department of Mechanical Engineering/ College of Engineering/ University of Baghdad

20/4/2019 1 | P a g e

[Fluid Laboratory II]

University of Baghdad

Name: - Saif Al-din Ali -B-](https://image.slidesharecdn.com/new-190507071413/85/Fluid-Laboratory-Centrifugal-fan-1-320.jpg)