Ch08

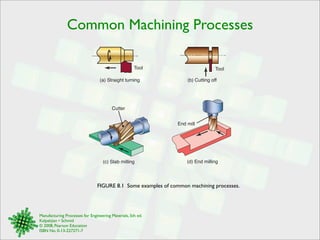

- 1. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Common Machining Processes FIGURE 8.1 Some examples of common machining processes. (c) Slab milling (d) End milling End mill Cutter (b) Cutting off(a) Straight turning ToolTool

- 2. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Orthogonal Cutting FIGURE 8.2 Schematic illustration of a two-dimensional cutting process, or orthogonal cutting. (a) Orthogonal cutting with a well-defined shear plane, also known as the Merchant model; (b) Orthogonal cutting without a well-defined shear plane. Rake angle Chip Tool face V Flank Relief or clearance angle Shear angle Shear plane ! Tool Shiny surfaceRough surface Workpiece to tc - + " (a) Chip Rough surface Primary shear zone Flank Relief or clearance angle Tool face Tool tc to V - + " Rake angle (b) Rough surface

- 3. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Chip Formation FIGURE 8.3 (a) Schematic illustration of the basic mechanism of chip formation in cutting. (b) Velocity diagram in the cutting zone. Shear plane Workpiece d Chip Tool A C B A C BO Rake angle, (b) Vc Vs V (a) (90°- ) (90°- + ) ( - ) ( - )

- 4. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Types of Chips FIGURE 8.4 Basic types of chips produced in metal cutting and their micrographs: (a) continuous chip with narrow, straight primary shear zone; (b) secondary shear zone at the tool-chip interface; (c) continuous chip with built-up edge; (d) segmented or nonhomogeneous chip; and (e) discontinuous chip. Source: After M.C. Shaw, P.K.Wright, and S. Kalpakjian. (e)(d) (a) (b) (c) Tool Workpiece Primary shear zone Chip Primary shear zone Chip Tool Secondary shear zones BUE Low shear strain High shear strain FIGURE 8.5 Shiny (burnished) surface on the tool side of a continuous chip produced in turning.

- 5. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Hardness in Cutting Zone FIGURE 8.6 (a) Hardness distribution in the cutting zone for 3115 steel. Note that some regions in the built-up edge are as much as three times harder than the bulk workpiece. (b) Surface finish in turning 5130 steel with a built-up edge. (c) Surface finish on 1018 steel in face milling. Source: Courtesy of Metcut Research Associates, Inc. (a) (b) (c) 474 661 588 492 588 656 604 684 565 432 589 656 567 578 512 704 704 639 655770734 466 587 704 372 306 329 289 325 331 286 289 371 418 383 306 386 261 565 327 361 281 289 410 341 281 308 231 201 251 266 317229 377503544409297 316 230 Workpiece Built-up edge Hardness (HK) Chip

- 6. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Chip Breakers FIGURE 8.7 (a) Schematic illustration of the action of a chip breaker. Note that the chip breaker decreases the radius of curvature of the chip. (b) Chip breaker clamped on the rake face of a cutting tool. (c) Grooves on the rake face of cutting tools, acting as chip breakers. Most cutting tools now are inserts with built-in chip-breaker features. (a) (b) Workpiece Tool After Chip Before Chip breaker Rake face of tool Tool Clamp Chip breaker (c) Positive rake Rake face 0° rakeRadius FIGURE 8.8 Various chips produced in turning: (a) tightly curled chip; (b) chip hits workpiece and breaks; (c) continuous chip moving radially outward from workpiece; and (d) chip hits tool shank and breaks off. Source: After G. Boothroyd. (a) (b) (c) (d)

- 7. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Oblique Cutting FIGURE 8.9 (a) Schematic illustration of cutting with an oblique tool. (b) Top view, showing the inclination angle, i. (c) Types of chips produced with different inclination angles. Workpiece i = 30° i = 15° i = 0° Chip (a) (b) (c) i a o Tool Top view Workpiece i a o Tool Chip y z x c t

- 8. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Right-Hand Cutting Tool FIGURE 8.10 (a) Schematic illustration of a right-hand cutting tool for turning. Although these tools have traditionally been produced from solid tool-steel bars, they are now replaced by inserts of carbide or other tool materials of various shapes and sizes, as shown in (b). (a) (b) End-cutting edge angle (ECEA) Side-rake angle, + (SR) Axis Axis Cutting edge Face Back-rake angle, + (BR) Nose radius Flank Side-relief angle Side-cutting edge angle (SCEA) Clearance or end-relief angle Axis Shank Insert Clamp Clamp screw Toolholder Seat or shim

- 9. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Cutting Forces FIGURE 8.11 (a) Forces acting on a cutting tool in two-dimensional cutting. Note that the resultant forces, R, must be collinear to balance the forces. (b) Force circle to determine various forces acting in the cutting zone. Source: After M.E. Merchant. Chip Tool Workpiece (a) (b) Fn Fc Fs Ft R F N R Chip V V Tool Workpiece Fc Fs Ft F N R Cutting force Friction coefficient Fc = Rcos(β−α) = wtoτcos(β−α) sinφcos(φ+β−α) µ= tanβ = Ft +Fc tanα Fc −Ft tanα

- 10. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Cutting Data FIGURE 8.12 Thrust force as a function of rake angle and feed in orthogonal cutting of AISI 1112 cold-rolled steel. Note that at high rake angles, the thrust force is negative. A negative thrust force has important implications in the design of machine tools and in controlling the stability of the cutting process. Source: After S. Kobayashi and E.G. Thomsen. ! = 5° 10° 15° 20° 25° 30° 35° 40° 0 0.1 0.2 0.3 mm/revmm/rev 800 400 0 2200 (N) Ft(lb) 200 150 100 50 0 250 0 0.002 0.004 0.006 0.008 0.010 0.012 Feed (in./rev) ut (in.-lb/in3 uf /ut α φ γ µ β Fc (lb) Ft (lb) ×103) us uf (%) 25◦ 20.9◦ 2.55 1.46 56 380 224 320 209 111 35 35 31.6 1.56 1.53 57 254 102 214 112 102 48 40 35.7 1.32 1.54 57 232 71 195 94 101 52 45 41.9 1.06 1.83 62 232 68 195 75 120 62 to = 0.0025 in.; w = 0.475 in.; V = 90 ft/min; tool: high-speed steel. uf /ut α V φ γ µ β Fc Ft ut us uf (%) +10 197 17 3.4 1.05 46 370 273 400 292 108 27 400 19 3.1 1.11 48 360 283 390 266 124 32 642 21.5 2.7 0.95 44 329 217 356 249 107 30 1186 25 2.4 0.81 39 303 168 328 225 103 31 -10 400 16.5 3.9 0.64 33 416 385 450 342 108 24 637 19 3.5 0.58 30 384 326 415 312 103 25 1160 22 3.1 0.51 27 356 263 385 289 96 25 to = 0.037 in.; w = 0.25 in.; tool: cemented carbide. TABLE 8.1 Data on orthogonal cutting of 4130 steel. TABLE 8.2 Data on orthogonal cutting of 9445 steel.

- 11. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Shear Force & Normal Force FIGURE 8.13 (a) Shear force and (b) normal force as a function of the area of the shear plane and the rake angle for 85-15 brass. Note that the shear stress in the shear plane is constant, regardless of the magnitude of the normal stress, indicating that the normal stress has no effect on the shear flow stress of the material. Source: After S. Kobayashi and E.G.Thomsen. = 20° to 40° 800 400 0 = 50,000 psi 0 1 32 4 5 6 0 1 32 1200 320 280 240 200 160 120 80 40 0 mm2 (N) As (in2 x 10-3) Fs(lb) (a) 0 1 32 4 5 6 0 1 32 1200 320 280 240 200 160 120 80 40 0 800 400 As (in2 x 10-3) mm2 (N) Ft(lb) (b) 25 30 35 40 20°

- 12. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Shear Stress on Tool Face FIGURE 8.14 Schematic illustration of the distribution of normal and shear stresses at the tool-chip interface (rake face). Note that, whereas the normal stress increases continuously toward the tip of the tool, the shear stress reaches a maximum and remains at that value (a phenomenon known as sticking; see Section 4.4.1). ! " Tool face Sliding Sticking Stresses on tool face Tool tip Tool Flank face

- 13. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Shear-Angle Relationships FIGURE 8.15 (a) Comparison of experimental and theoretical shear-angle relationships. More recent analytical studies have resulted in better agreement with experimental data. (b) Relation between the shear angle and the friction angle for various alloys and cutting speeds. Source: After S. Kobayashi. 50 40 30 20 10 0 230 220 210 0 10 20 30 40 50 60 Lead Copper Tin Eq. (8.21) Eq. (8.20) Mild steel Aluminum (! - ") Shearangle,#(deg.) " = 0 ! = 10 30 50 70 (deg.) µ=0 0.5 1 2 60 40 20 0 #(deg.) (a) (b) Merchant [Eq. (8.20)] Shaffer [Eq. (8.21)] Mizuno [Eqs. (8.22)-(8.23] φ = 45◦ + α 2 − β 2 φ = 45◦ +α−β φ = α for α > 15◦ φ = 15◦ for α < 15◦

- 14. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Specific Energy Specific Energy∗ Material W-s/mm3 hp-min/in3 Aluminum alloys 0.4-1.1 0.15-0.4 Cast irons 1.6-5.5 0.6-2.0 Copper alloys 1.4-3.3 0.5-1.2 High-temperature alloys 3.3-8.5 1.2-3.1 Magnesium alloys 0.4-0.6 0.15-0.2 Nickel alloys 4.9-6.8 1.8-2.5 Refractory alloys 3.8-9.6 1.1-3.5 Stainless steels 3.0-5.2 1.1-1.9 Steels 2.7-9.3 1.0-3.4 Titanium alloys 3.0-4.1 1.1-1.5 ∗ At drive motor, corrected for 80% efficiency; multiply the energy by 1.25 for dull tools. TABLE 8.3 Approximate Specific-Energy Requirements in Machining Operations

- 15. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Temperatures in Cutting 400 500 450 Workpiece Tool Chip 30 80 130 380 600 360 500 600 650 700 Temperature (°C) 650 600 FIGURE 8.1 Typical temperature distribution in the cutting zone. Note the severe temperature gradients within the tool and the chip, and that the workpiece is relatively cool. Source: After G.Vieregge. 200 300 V = 550 ft/min Work material: AISI 52100 Annealed: 188 HB Tool material: K3H carbide Feed: 0.0055 in./rev (0.14 mm/rev) 0 0.5 1.0 1.5 mm 700 600 500 400 °C 0 .008 .016 .024 .032 .040 .048 .056 Distance from tool tip (in.) 1400 1300 1200 1100 1000 900 800 700 Flanksurfacetemperature(°F) (a) 550ft/min 3 00 200 2000 1800 1600 1400 1200 1000 800 600 400 Localtemperatureattool-chipinterface(°F) 0 0.2 0.4 0.6 0.8 1.0 Fraction of tool-chip contact length measured in the direction of chip flow 1100 900 700 500 300 °C (b) FIGURE 8.2 Temperature distribution in turning as a function of cutting speed: (a) flank temperature; (b) temperature along the tool-chip interface. Note that the rake-face temperature is higher than that at the flank surface. Source: After B.T. Chao and K.J.Trigger. T = 1.2Yf ρc 3 Vto K FIGURE 8.18 Proportion of the heat generated in cutting transferred to the tool, workpiece, and chip as a function of the cutting speed. Note that most of the cutting energy is carried away by the chip (in the form of heat), particularly as speed increases. W orkpiece Cutting speed Energy(%) Tool Chip

- 16. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Terminology in Turning FIGURE 8.19 Terminology used in a turning operation on a lathe, where f is the feed (in mm/rev or in./rev) and d is the depth of cut. Note that feed in turning is equivalent to the depth of cut in orthogonal cutting (see Fig. 8.2), and the depth of cut in turning is equivalent to the width of cut in orthogonal cutting. See also Fig. 8.42. Depth of cut (mm or in.) Feed (mm/rev or in./rev) Tool Chip

- 17. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tool Wear FIGURE 8.20 Examples of wear in cutting tools. (a) Flank wear; (b) crater wear; (c) chipped cutting edge; (d) thermal cracking on rake face; (e) flank wear and built-up edge; (f) catastrophic failure (fracture). Source: Courtesy of Kennametal, Inc. Flank face Rake face Flank wear Flank face BUE Rake face Crater wear Flank face Rake face Thermal cracking (b) (d) (c) (e) (a) Rake face Crater wear depth (KT) Flank wear Flank face Tool Rake face Crater wear Depth-of-cut line Nose radius R Flank wear Depth-of-cut line VBmax VB Flank face Taylor tool life equation: VTn = C High-speed steels 0.08-0.2 Cast alloys 0.1-0.15 Carbides 0.2-0.5 Ceramics 0.5-0.7 TABLE 8.4 Range of n values for various cutting tools.

- 18. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Effect of Workpiece on Tool Life FIGURE 8.21 Effect of workpiece microstructure on tool life in turning.Tool life is given in terms of the time (in minutes) required to reach a flank wear land of a specified dimension. (a) Ductile cast iron; (b) steels, with identical hardness. Note in both figures the rapid decrease in tool life as the cutting speed increases. Hardness (HB) Ferrite Pearlite a. As cast b. As cast c. As cast d. Annealed e. Annealed 265 215 207 183 170 20% 40 60 97 100 80% 60 40 3 _ 50 100 300 500 700 900 100 150 200 250 0 40 80 120 m/min Cutting speed (ft/min) Toollife(min) a b c d e (a) Pearlite-ferrite Martensitic Sp heroidized 0.1 0.2 0.3 0.4 m/s (b) 100 80 60 40 20 0 Toollife(min) 20 30 40 50 60 70 80 90 Cutting speed (ft/min)

- 19. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tool-Life Curves FIGURE 8.22 (a) Tool-life curves for a variety of cutting-tool materials. The negative inverse of the slope of these curves is the exponent n in tool-life equations. (b) Relationship between measured temperature during cutting and tool life (flank wear). Note that high cutting temperatures severely reduce tool life. See also Eq. (8.30). Source: After H.Takeyama andY. Murata. 300 50 300 m/min 3000 100 300 100 10 20 Toollife(min) 5 1 10,00050001000 Cutting speed (ft/min) n High-speedsteel Castalloy CarbideCeramic Feed constant, speed variable Speed constant, feed variable 800 1000 1200 1400 °C 400 200 100 60 40 20 10 6 4 2 1 0.6 0.2 Toollife(min) 1500 1800 2100 2400 Temperature (°F) Work material: Heat-resistant alloy Tool material: Tungsten carbide Tool life criterion: 0.024 in. (0.6 mm) flank wear (a) (b)

- 20. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tool Wear FIGURE 8.23 Relationship between crater- wear rate and average tool-chip interface temperature in turning: (a) high-speed-steel tool; (b) C1 carbide; (c) C5 carbide. Note that crater wear increases rapidly within a narrow range of temperature. Source: After K.J.Trigger and B.T. Chao. Average tool-chip interface temperature (°F) 800 1200 1600 2000 0.15 0.3020 500 700 900 1100 10 0 0 °C mm3/min Craterwearrate (in3/minx10-6) a b c Allowable Wear Land (mm) Operation High-Speed Steels Carbides Turning 1.5 0.4 Face milling 1.5 0.4 End milling 0.3 0.3 Drilling 0.4 0.4 Reaming 0.15 0.15 TABLE 8.5 Allowable average wear lands for cutting tools in various operations. Rake face Crater wear Chip Flank face FIGURE 8.23 Interface of chip (left) and rake face of cutting tool (right) and crater wear in cutting AISI 1004 steel at 3 m/s (585 ft/min). Discoloration of the tool indicates the presence of high temperature (loss of temper). Note how the crater-wear pattern coincides with the discoloration pattern. Compare this pattern with the temperature distribution shown in Fig. 8.16. Source: Courtesy of P.K.Wright.

- 21. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Acoustic Emission and Wear FIGURE 8.25 Relationship between mean flank wear, maximum crater wear, and acoustic emission (noise generated during cutting) as a function of machining time.This technique has been developed as a means for continuously and indirectly monitoring wear rate in various cutting processes without interrupting the operation. Source: After M.S. Lan and D.A. Dornfeld. Crater wear Flank wear 0.005 0.004 0.003 0.002 0.001 0 in. mm 0.15 0.1 0.05 0 Maximumcraterdepth Meanflankwear 1.5 1.0 0.5 0 mm in. MeanRMS(mV) 0.050 0.040 0.030 0.020 0.010 1500 1000 500 0 0 10 20 30 40 50 60 Elapsed machining time (min)

- 22. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Surface Finish FIGURE 8.26 Range of surface roughnesses obtained in various machining processes. Note the wide range within each group, especially in turning and boring. (See also Fig. 9.27). Flame cutting Snagging (coarse grinding) Sawing Planing, shaping Drilling Chemical machining Electrical-discharge machining Milling Broaching Reaming Electron-beam machining Laser machining Electrochemical machining Turning, boring Barrel finishing Electrochemical grinding Roller burnishing Grinding Honing Electropolishing Polishing Lapping Superfinishing Process 2000 1000 500 250 125 63 32 16 8 4 2 1 0.5 50 25 12.5 6.3 3.2 1.6 0.8 0.40 0.20 0.10 0.05 0.025 0.012 Roughness (Ra) µin. µm Average application Less frequent application Sand casting Die casting Hot rolling Forging Permanent mold casting Investment casting Extruding Cold rolling, drawing Rough cutting Casting Forming Machining Advanced machining Finishing processes

- 23. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Surfaces in Machining FIGURE 8.27 Surfaces produced on steel in machining, as observed with a scanning electron microscope: (a) turned surface, and (b) surface produced by shaping. Source: J.T. Black and S. Ramalingam. (a) (b) FIGURE 8.28 Schematic illustration of a dull tool in orthogonal cutting (exaggerated). Note that at small depths of cut, the rake angle can effectively become negative. In such cases, the tool may simply ride over the workpiece surface, burnishing it, instead of cutting. Increasingdepth ofcut Workpiece Machined surface Tool

- 24. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Inclusions in Free-Machining Steels FIGURE 8.29 Photomicrographs showing various types of inclusions in low-carbon, resulfurized free- machining steels. (a) Manganese-sulfide inclusions in AISI 1215 steel. (b) Manganese-sulfide inclusions and glassy manganese-silicate-type oxide (dark) in AISI 1215 steel. (c) Manganese sulfide with lead particles as tails in AISI 12L14 steel. Source: Courtesy of Ispat Inland Inc. (a) (b) (c)

- 25. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Hardness of Cutting Tools FIGURE 8.30 Hardness of various cutting-tool materials as a function of temperature (hot hardness). The wide range in each group of tool materials results from the variety of compositions and treatments available for that group. 0 55 60 65 70 75 80 85 90 95 100 300 500 700 200 400 600 800 1000 1200 1400 20 25 30 35 40 45 50 55 60 65 70 Hardness(HRA) HRC Temperature (°F) °C Ceramics Carbides High-speedsteels Cast alloys Car bon toolsteels

- 26. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tool Materials Carbides Cubic Single High-Speed Cast Boron Crystal Property Steel Alloys WC TiC Ceramics Nitride Diamond∗ Hardness 83-86 HRA 82-84 HRA 90-95 HRA 91-93 HRA 91-95 HRA 4000-5000 HK 7000-8000 HK Compressive strength MPa 4100-4500 1500-2300 4100-5850 3100-3850 2750-4500 6900 6900 psi ×103 600-650 220-335 600-850 450-560 400-650 1000 1000 Transverse rupture strength MPa 2400-4800 1380-2050 1050-2600 1380-1900 345-950 700 1350 psi ×103 350-700 200-300 150-375 200-275 50-135 105-200 Impact strength J 1.35-8 0.34-1.25 0.34-1.35 0.79-1.24 < 0.1 < 0.5 < 0.2 in.-lb 12-70 3-11 3-12 7-11 < 1 < 5 < 2 Modulus of elasticity GPa 200 — 520-690 310-450 310-410 850 820-1050 psi ×106 30 — 75-100 45-65 45-60 125 120-150 Density kg/m3 8600 8000-8700 10,000-15,000 5500-5800 4000-4500 3500 3500 lb/in3 0.31 0.29-0.31 0.36-0.54 0.2-0.22 0.14-0.16 0.13 0.13 Volume of hard phase (%) 7-15 10-20 70-90 — 100 95 95 Melting or decom- position temperature ◦ C 1300 — 1400 1400 2000 1300 700 ◦ F 2370 — 2550 2550 3600 2400 1300 Thermal conductivity, W/mK 30-50 — 42-125 17 29 13 500-2000 Coefficient of thermal expansion, ×10−6 /◦ C 12 — 4-6.5 7.5-9 6-8.5 4.8 1.5-4.8 ∗ The values for polycrystalline diamond are generally lower, except impact strength, which is higher. TABLE 8.6 Typical range of properties of various tool materials.

- 27. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Properties of Tungsten-Carbide Tools FIGURE 8.31 Effect of cobalt content in tungsten-carbide tools on mechanical properties. Note that hardness is directly related to compressive strength (see Section 2.6.8) and hence, inversely to wear [see Eq. (4.6)]. Wear(mg),compressiveandtransverse- rupturestrength(kg/mm2) Cobalt content (% by weight) Vickershardness(HV) 600 500 400 300 200 100 0 0 5 10 15 20 25 30 1750 1500 1250 1000 750 500 HRA 92.4 90.5 88.5 85.7 Compressive strength Hardness Wear Transverse-rupture strength

- 28. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Inserts FIGURE 8.32 Methods of mounting inserts on toolholders: (a) clamping, and (b) wing lockpins. (c) Examples of inserts mounted using threadless lockpins, which are secured with side screws. Source: Courtesy ofValenite. (c)(b) Shank Seat Lockpin Insert (a) Insert Clamp Clamp screw Seat or shim Toolholder

- 29. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Insert Strength FIGURE 8.33 Relative edge strength and tendency for chipping and breaking of inserts with various shapes. Strength refers to that of the cutting edge shown by the included angles. Source: Courtesy of Kennametal, Inc. 90°100° 80° 60° 55° 35° Increasing strength Increased chipping and breaking FIGURE 8.34 Edge preparations for inserts to improve edge strength. Source: Courtesy of Kennametal, Inc. Negative withland andhone Negative withland Negative honed Negative sharp Positive withhone Positive sharp Increasing edge strength

- 30. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Historical Tool Improvement FIGURE 8.35 Relative time required to machine with various cutting-tool materials, with indication of the year the tool materials were introduced. Note that, within one century, machining time has been reduced by two orders of magnitude. Source:After Sandvik Coromant. Carbon steel High-speed steel Cast cobalt-based alloys Cemented carbides Improved carbide grades First coated grades First double-coated grades First triple-coated grades 1900 !10 !20 !30 !40 !50 !60 !70 !80 !90 100 26 15 6 3 1.5 1 0.7 Machiningtime(min) Year !00 0.5 Functionally graded triple-coated

- 31. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Coated Tools FIGURE 8.36 Wear patterns on high-speed-steel uncoated and titanium-nitride-coated cutting tools. Note that flank wear is lower for the coated tool. TiN coated Uncoated Flank wear Rake face Tool FIGURE 8.37 Multiphase coatings on a tungsten-carbide substrate. Three alternating layers of aluminum oxide are separated by very thin layers of titanium nitride. Inserts with as many as 13 layers of coatings have been made. Coating thicknesses are typically in the range of 2 to 10 µm. Source: Courtesy of Kennametal, Inc. TiN TiN TiN TiC + TiN TiC + TiN Carbide substrate Al2O3 Al2O3 Al2O3

- 32. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Properties of Cutting Tool Materials FIGURE 8.38 Ranges of properties for various groups of cutting-tool materials. (See also Tables 8.1 through 8.5.) Hothardnessandwearresistance Strength and toughness Diamond, cubic boron nitride Aluminum oxide (HIP) Aluminum oxide + 30% titanium carbide Silicon nitride Cermets Coated carbides Carbides HSS FIGURE 8.39 Construction of polycrystalline cubic- boron-nitride or diamond layer on a tungsten-carbide insert. Braze Polycrystalline cubic boron nitride or diamond layer Carbide substrate Tungsten-carbide insert

- 33. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Characteristics of Machining Commercial tolerances Process Characteristics (±mm) Turning Turning and facing operations are performed on all types of materials; requires skilled labor; low production rate, but medium to high rates can be achieved with turret lathes and automatic machines, requiring less skilled labor. Fine: 0.05-0.13 Rough: 0.13 Skiving: 0.025-0.05 Boring Internal surfaces or profiles, with characteristics similar to those produced by turning; stiffness of boring bar is impor- tant to avoid chatter. 0.025 Drilling Round holes of various sizes and depths; requires boring and reaming for improved accuracy; high production rate, labor skill required depends on hole location and accuracy specified. 0.075 Milling Variety of shapes involving contours, flat surfaces, and slots; wide variety of tooling; versatile; low to medium production rate; requires skilled labor. 0.13-0.25 Planing Flat surfaces and straight contour profiles on large surfaces; suitable for low-quantity production; labor skill required de- pends on part shape. 0.08-0.13 Shaping Flat surfaces and straight contour profiles on relatively small workpieces; suitable for low-quantity production; labor skill required depends on part shape. 0.05-0.13 Broaching External and internal flat surfaces, slots, and contours with good surface finish; costly tooling; high production rate; labor skill required depends on part shape. 0.025-0.15 Sawing Straight and contour cuts on flats or structural shapes; not suitable for hard materials unless the saw has carbide teeth or is coated with diamond; low production rate; requires only low skilled labor. 0.8 TABLE 8.7 General characteristics of machining processes.

- 34. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Lathe Operations FIGURE 8.40 Variety of machining operations that can be performed on a lathe. Depth of cut ToolFeed, f (a) Straight turning (g) Cutting with a form tool (e) Facing (b) Taper turning (c) Profiling (k) Threading (d) Turning and external grooving (f) Face grooving (h) Boring and internal grooving (i) Drilling (j) Cutting off (l) Knurling Workpiece

- 35. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tool Angles FIGURE 8.41 Designations and symbols for a right-hand cutting tool. The designation “right hand” means that the tool travels from right to left, as shown in Fig. 8.19. High-speed steel Carbide inserts Material Back Side End Side Side and end Back Side End Side Side and end rake rake relief relief cutting edge rake rake relief relief cutting edge Aluminum and magnesium alloys 20 15 12 10 5 0 5 5 5 15 Copper alloys 5 10 8 8 5 0 5 5 5 15 Steels 10 12 5 5 15 -5 -5 5 5 15 Stainless steels 5 8-10 5 5 15 -5-0 -5-5 5 5 15 High-temperature 0 10 5 5 15 5 0 5 5 45 alloys Refractory alloys 0 20 5 5 5 0 0 5 5 15 Titanium alloys 0 5 5 5 15 -5 -5 5 5 5 Cast irons 5 10 5 5 15 -5 -5 5 5 15 Thermoplastics 0 0 20-30 15-20 10 0 0 20-30 15-20 10 Thermosets 0 0 20-30 15-20 10 0 15 5 5 15 (a) End view (b) Side view Shank Flank face Back rake angle (BRA) End relief angle (ERA) Wedge angle Side rake angle (RA) Side relief angle (SRA) (c) Top view Rake face End cutting-edge angle (ECEA) Side cutting-edge angle (SCEA) Nose angle Nose radius TA B L E 8 . 8 G e n e r a l recommendations for tool angles in turning.

- 36. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Turning Operations FIGURE 8.42 (a) Schematic illustration of a turning operation, showing depth of cut, d, and feed, f. Cutting speed is the surface speed of the workpiece at the tool tip. (b) Forces acting on a cutting tool in turning. Fc is the cutting force; Ft is the thrust or feed force (in the direction of feed); and Fr is the radial force that tends to push the tool away from the workpiece being machined. Compare this figure with Fig. 8.11 for a two-dimensional cutting operation. (a) (b) d DoDf Workpiece N Chuck Tool Feed, f Tool Feed, f N Fc Ft Fr

- 37. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Cutting Speeds for Turning FIGURE 8.43 The range of applicable cutting speeds and feeds for a variety of cutting-tool materials. Cubic boron nitride, diamond, and ceramics Cermets Coated carbides Uncoated carbides 3000 2000 1000 500 300 200 Cuttingspeed(ft/min) 0.004 0.008 0.012 0.020 0.030 Feed (in./rev) 0.10 0.20 0.30 0.50 0.75 mm/rev 900 600 300 150 100 50 m/min Cutting Speed Workpiece Material m/min ft/min Aluminum alloys 200-1000 650-3300 Cast iron, gray 60-900 200-3000 Copper alloys 50-700 160-2300 High-temperature alloys 20-400 65-1300 Steels 50-500 160-1600 Stainless steels 50-300 160-1000 Thermoplastics and thermosets 90-240 300-800 Titanium alloys 10-100 30-330 Tungsten alloys 60-150 200-500 Note: (a) The speeds given in this table are for carbides and ce- ramic cutting tools. Speeds for high-speed-steel tools are lower than indicated. The higher ranges are for coated carbides and cer- mets. Speeds for diamond tools are significantly higher than any of the values indicated in the table. (b) Depths of cut, d, are generally in the range of 0.5-12 mm (0.02- 0.5 in.). (c) Feeds, f, are generally in the range of 0.15-1 mm/rev (0.006- 0.040 in./rev). TABLE 8.9 Approximate Ranges of Recommended Cutting Speeds for Turning Operations

- 38. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Lathe FIGURE 8.44 General view of a typical lathe, showing various major components. Source: Courtesy of Heidenreich & Harbeck. Spindle speed selector Headstock assembly Spindle (with chuck) Tool post Compound rest Cross slide Carriage Ways Dead center Tailstock quill Tailstock assembly Handwheel Bed Feed selector Clutch Chip pan Apron Split nut Clutch Longitudinal & transverse feed control Feed rod Lead screw

- 39. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 CNC Lathe FIGURE 8.45 (a) A computer-numerical-control lathe, with two turrets; these machines have higher power and spindle speed than other lathes in order to take advantage of advanced cutting tools with enhanced properties; (b) a typical turret equipped with ten cutting tools, some of which are powered. Drill Multitooth cutter Tool for turning or boring Reamer Individual motors Drill Round turret for OD operationsCNC unit Chuck End turret for ID operations Tailstock (a) (b)

- 40. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Typical CNC Parts FIGURE 8.46 Typical parts made on computer-numerical-control machine tools. (a) Housing base Material: Titanium alloy Number of tools: 7 Total machining time (two operations): 5.25 minutes Material: 52100 alloy steel Number of tools: 4 Total machining time (two operations): 6.32 minutes (c) Tube reducer Material: 1020 Carbon Steel Number of tools: 8 Total machining time (two operations): 5.41 minutes (b) Inner bearing race 67.4 mm (2.654") 87.9 mm (3.462") 98.4 mm (3.876") 85.7 mm (3.375") 32 threads per in. 235.6 mm (9.275") 78.5 mm (3.092") 50.8 mm (2") 23.8 mm (0.938") 53.2 mm (2.094")

- 41. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Typical Production Rates Operation Rate Turning Engine lathe Very low to low Tracer lathe Low to medium Turret lathe Low to medium Computer-control lathe Low to medium Single-spindle chuckers Medium to high Multiple-spindle chuckers High to very high Boring Very low Drilling Low to medium Milling Low to medium Planing Very low Gear cutting Low to medium Broaching Medium to high Sawing Very low to low Note: Production rates indicated are relative: Very low is about one or more parts per hour; medium is approximately 100 parts per hour; very high is 1000 or more parts per hour. TABLE 8.10 Typical production rates for various cutting operations.

- 42. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Boring Mill FIGURE 8.47 Schematic illustration of the components of a vertical boring mill. Cross-rail Tool head Workpiece Work table Bed Column

- 43. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Drills FIGURE 8.48 Two common types of drills: (a) Chisel-point drill.The function of the pair of margins is to provide a bearing surface for the drill against walls of the hole as it penetrates into the workpiece. Drills with four margins (double-margin) are available for improved drill guidance and accuracy. Drills with chip-breaker features are also available. (b) Crankshaft drills. These drills have good centering ability, and because chips tend to break up easily, they are suitable for producing deep holes. (a) Chisel-point drill Tang drive Shank diameter Straight shank Neck Overall length Flute length Body Point angle Lip-relief angle Chisel-edge angle Chisel edge Drill diameter Body diameter clearance Clearance diameter (b) Crankshaft-point drill Lip Margin Land Flutes Helix angle Shank length Web Tang Taper shank Drilling Coredrilling Stepdrilling Counterboring Countersinking Reaming Centerdrilling Gundrilling High-pressure coolant FIGURE 8.49 Various types of drills and drilling operations.

- 44. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Speeds and Feeds in Drilling Surface Feed, mm/rev (in./rev) Spindle speed (rpm) Speed Drill Diameter Drill Diameter Workpiece 1.5 mm 12.5 mm 1.5 mm 12.5 mm Material m/min ft/min (0.060 in.) (0.5 in.) (0.060 in.) (0.5 in.) Aluminum alloys 30-120 100-400 0.025 (0.001) 0.30 (0.012) 6400-25,000 800-3000 Magnesium alloys 45-120 150-400 0.025 (0.001) 0.30 (0.012) 9600-25,000 1100-3000 Copper alloys 15-60 50-200 0.025 (0.001) 0.25 (0.010) 3200-12,000 400-1500 Steels 20-30 60-100 0.025 (0.001) 0.30 (0.012) 4300-6400 500-800 Stainless steels 10-20 40-60 0.025 (0.001) 0.18 (0.007) 2100-4300 250-500 Titanium alloys 6-20 20-60 0.010 (0.0004) 0.15 (0.006) 1300-4300 150-500 Cast irons 20-60 60-200 0.025 (0.001) 0.30 (0.012) 4300-12,000 500-1500 Thermoplastics 30-60 100-200 0.025 (0.001) 0.13 (0.005) 6400-12,000 800-1500 Thermosets 20-60 60-200 0.025 (0.001) 0.10 (0.004) 4300-12,000 500-1500 Note: As hole depth increases, speeds and feeds should be reduced. Selection of speeds and feeds also depends on the specific surface finish required. TABLE 8.11 General recommendations for speeds and feeds in drilling.

- 45. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Reamers and Taps FIGURE 8.50 Terminology for a helical reamer. Chamfer angle Chamfer length Chamfer relief Helix angle, - Primary relief angle Margin width Land width Radial rake FIGURE 8.51 (a) Terminology for a tap; (b) illustration of tapping of steel nuts in high production. (b) Rake angle Hook angle (a) Tap Nut Land Chamfer relief Flute Cutting edge Heel Chamfer angle

- 46. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Typical Machined Parts FIGURE 8.52 Typical parts and shapes produced by the machining processes described in Section 8.10. (a) (b) (c) (d) (e) (f) Drilled and tapped holes Stepped cavity

- 47. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Conventional and Climb Milling (a) (b) (c) Workpiece Conventional milling Climb milling d N D f tc d v Cutter D v llc Workpiece Cutter FIGURE 8.53 (a) Illustration showing the difference between conventional milling and climb milling. (b) Slab-milling operation, showing depth of cut, d; feed per tooth, f; chip depth of cut, tc and workpiece speed, v. (c) Schematic illustration of cutter travel distance, lc, to reach full depth of cut.

- 48. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Face Milling f w v lc lc l Workpiece D Cutter (b) f v (c)(a) Insert (d) l d w v Machined surface Workpiece Cutter FIGURE 8.54 Face-milling operation showing (a) action of an insert in face milling; (b) climb milling; (c) conventional milling; (d) dimensions in face milling. Peripheral relief (radial relief) Radial rake, 2 Axial rake, 1 End cutting-edge angle Corner angle End relief (axial relief) FIGURE 8.55 Terminology for a face- milling cutter.

- 49. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Cutting Mechanics Insert Undeformed chip thickness Depth of cut, d Lead angle f Feed per tooth, f (a) (b) FIGURE 8.56 The effect of lead angle on the undeformed chip thickness in face milling. Note that as the lead angle increases, the undeformed chip thickness (and hence the thickness of the chip) decreases, but the length of contact (and hence the width of the chip) increases. Note that the insert must be sufficiently large to accommodate the increase in contact length. (b) Exit Entry Re-entry Exit (a) Cutter Workpiece (c) Cutter Desirable Milled surface + - Undesirable FIGURE 8.57 (a) Relative position of the cutter and the insert as it first engages the workpiece in face milling, (b) insert positions at entry and exit near the end of cut, and (c) examples of exit angles of the insert, showing desirable (positive or negative angle) and undesirable (zero angle) positions. In all figures, the cutter spindle is perpendicular to the page.

- 50. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Milling Operations (a) Straddle milling (b) Form milling Arbor (c) Slotting (d) Slitting FIGURE 8.58 Cutters for (a) straddle milling; (b) form milling; (c) slotting; and (d) slitting operations. Cutting Speed Workpiece Material m/min ft/min Aluminum alloys 300-3000 1000-10,000 Cast iron, gray 90-1300 300-4200 Copper alloys 90-1000 300-3300 High-temperature alloys 30-550 100-1800 Steels 60-450 200-1500 Stainless steels 90-500 300-1600 Thermoplastics and thermosets 90-1400 300-4500 Titanium alloys 40-150 130-500 Note: (a) These speeds are for carbides, ceramic, cermets, and diamond cutting tools. Speeds for high-speed-steel tools are lower than those indicated in this table. (b) Depths of cut, d, are generally in the range of 1-8 mm (0.04-0.3 in.). (c) Feeds per tooth, f, are generally in the range of 0.08-0.46 mm/rev (0.003-0.018 in./rev). TABLE 8.12 Approximate range of recommended cutting speeds for milling operations.

- 51. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Milling Machines (a) (b) Work tableHead Column Base Workpiece Saddle Knee Overarm Arbor Column Workpiece Work table Saddle Knee Base T-slots T-slots FIGURE 8.59 (a) Schematic illustration of a horizontal-spindle column-and-knee-type milling machine. (b) Schematic illustration of a vertical-spindle column-and-knee-type milling machine. Source: After G. Boothroyd.

- 52. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Broaching (a) (b) (c) FIGURE 8.60 (a) Typical parts finished by internal broaching. (b) Parts finished by surface broaching. The heavy lines indicate broached surfaces; (c) a vertical broaching machine. Source: (a) and (b) Courtesy of General Broach and Engineering Company, (c) Courtesy of Ty Miles, Inc.

- 53. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Broaches (b) Root radius Pitch LandRake or hook angle Tooth depth Backoff or clearance angle (a) Cut per tooth Chip gullet Workpiece FIGURE 8.61 (a) Cutting action of a broach, showing various features. (b) Terminology for a broach. Pull end Root diameter Follower diameter Overall length Shank length Front pilot Roughening teeth Cutting teeth Semifinishing teeth Rear pilot Finishing teeth FIGURE 8.62 Terminology for a pull-type internal broach, typically used for enlarging long holes.

- 54. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Saws and Saw Teeth (a) (b) Straight tooth Raker tooth Wave tooth Tooth set Width Back edge Tooth spacing Tooth face Tooth back (flank) Tooth back clearance angle Tooth rake angle (positive) Gullet depth FIGURE 8.63 (a) Terminology for saw teeth. (b) Types of saw teeth, staggered to provide clearance for the saw blade to prevent binding during sawing. M2 HSS 64-66 HRC Electron-beam weld (a) (b) Carbide insert Flexible alloy-steel backing FIGURE 8.64 (a) High-speed-steel teeth welded on a steel blade. (b) Carbide inserts brazed to blade teeth.

- 55. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Gear Manufacture (b)(a) (c) (d) Top view Gear blank Hob Gear blank Hob Rack-shaped cutter Gear blank Gear cutter Base circle Gear blank Pitch circle Pitch circle Base circle Gear teeth Pinion-shaped cutter Gear blank Spacer Cutter spindle FIGURE 8.65 (a) Schematic illustration of gear generating with a pinion-shaped gear cutter. (b) Schematic illustration of gear generating in a gear shaper, using a pinion-shaped cutter; note that the cutter reciprocates vertically. (c) Gear generating with a rack-shaped cutter. (d) Three views of gear cutting with a hob. Source: After E.P. DeGarmo.

- 56. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Machining Centers Tools (cutters) Index table Tool storage Tool-interchange arm Traveling column Spindle Pallets Bed Spindle carrier Computer numerical-control panel FIGURE 8.67 Schematic illustration of a computer numerical-controlled turning center. Note that the machine has two spindle heads and three turret heads, making the machine tool very flexible in its capabilities. Source: Courtesy of Hitachi Seiki Co., Ltd. 1st Spindle head 2nd Turret head 1st Turret head 2nd Spindle head 3rd Turret head FIGURE 8.66 A horizontal-spindle machining center, equipped with an automatic tool changer.Tool magazines in such machines can store as many as 200 cutting tools, each with its own holder. Source: Courtesy of Cincinnati Machine.

- 57. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Reconfigurable Machines Magazine unit Arm unit Rotational motion Arm unitBase unitBed unit Linear motion Linear motion Functional unit Rotational motion FIGURE 8.68 Schematic illustration of a reconfigurable modular machining center, capable of accommodating workpieces of different shapes and sizes, and requiring different machining operations on their various surfaces. Source: AfterY. Koren.

- 58. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Reconfigurable Machining Center (a) (b) (c) FIGURE 8.69 Schematic illustration of assembly of different components of a reconfigurable machining center. Source: AfterY. Koren.

- 59. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Machining of Bearing Races 1. Finish turning of outside diameter 2. Boring and grooving on outside diameter 3. Internal grooving with a radius-form tool 4. Finish boring of internal groove and rough boring of internal diameter 5. Internal grooving with form tool and chamfering 6. Cutting off finished part; inclined bar picks up bearing race Tube Bearing race Form tool Form tool FIGURE 8.70 Sequences involved in machining outer bearing races on a turning center.

- 60. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Hexapod (a) (b) Spindle Hexapod legs Cutting tool Workpiece FIGURE 8.71 (a) A hexapod machine tool, showing its major components. (b) Closeup view of the cutting tool and its head in a hexapod machining center. Source: National Institute of Standards and Technology.

- 61. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Chatter &Vibration FIGURE 8.72 Chatter marks (right of center of photograph) on the surface of a turned part. Source: Courtesy of General Electric Company. 1.2 0.8 0.4 0.0 -0.4 -0.8 -1.2 -1.6 -2.0 0 1000 2000 3000 4000 10-5 s 10-1V Cast iron (a) 1.2 0.8 0.4 0.0 20.4 20.8 21.2 21.6 22.0 0 1000 2000 3000 4000 10-5 s 10-1V Epoxy/graphite (b) FIGURE 8.73 Relative damping capacity of (a) gray cast iron and (b) epoxy-granite composite material. The vertical scale is the amplitude of vibration and the horizontal scale is time. Increasingdamping Bed only Bed + carriage Bed + headstock Bed + carriage + headstock Complete machine FIGURE 8.74 Damping of vibrations as a function of the number of components on a lathe. Joints dissipate energy; thus, the greater the number of joints, the higher the damping. Source: After J. Peters.

- 62. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Machining EconomicsTotal cost Machining cost Nonproductive cost Tool-change cost Tool cost (a) Costperpiece Cutting speed Machining time Total time Nonproductive time Tool-changing time (b) High-efficiency machining range Cutting speed Timeperpiece FIGURE 8.75 Qualitative plots showing (a) cost per piece, and (b) time per piece in machining. Note that there is an optimum cutting speed for both cost and time, respectively. The range between the two optimum speeds is known as the high-efficiency machining range.

- 63. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Case Study: Ping Golf Putters FIGURE 8.76 (a) The Ping Anser® golf putter; (b) CAD model of rough machining of the putter outer surface; (c) rough machining on a vertical machining center; (d) machining of the lettering in a vertical machining center; the operation was paused to take the photo, as normally the cutting zone is flooded with a coolant; Source: Courtesy of Ping Golf, Inc.