Cutting tool tech

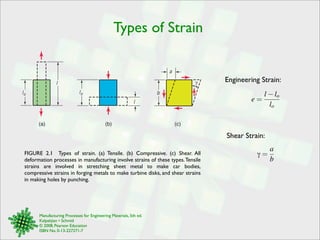

- 1. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Types of Strain Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 FIGURE 2.1 Types of strain. (a) Tensile. (b) Compressive. (c) Shear. All deformation processes in manufacturing involve strains of these types.Tensile strains are involved in stretching sheet metal to make car bodies, compressive strains in forging metals to make turbine disks, and shear strains in making holes by punching. (c)(b)(a) lo l lo l a b g e = l −lo lo γ = a b Engineering Strain: Shear Strain:

- 2. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tensile-Test FIGURE 2.2 (a) Original and final shape of a standard tensile-test specimen. (b) Outline of a tensile-test sequence showing different stages in the elongation of the specimen. (a) (b) Original gage length, lo Fracture lf tan-1 E PlasticElastic Stress UTS Y Fracture Strain (for lo = 1) l eueo ef 0 Offset Af Ao Uniform elongation Neck Total elongation Y Post-uniform elongation lo le lu lf

- 3. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Mechanical Properties TABLE 2.1 Typical mechanical properties of various materials at room temperature. See also Tables 10.1, 10.4, 10.8, 11.3 and 11.7. Elongation Poisson’s E (GPa) Y (MPa) UTS (MPa) in 50 mm (%) Ratio (ν) METALS (WROUGHT) Aluminum and its alloys 69-79 35-550 90-600 45-5 0.31-0.34 Copper and its alloys 105-150 76-1100 140-1310 65-3 0.33-0.35 Lead and its alloys 14 14 20-55 50-9 0.43 Magnesium and its alloys 41-45 130-305 240-380 21-5 0.29-0.35 Molybdenum and its alloys 330-360 80-2070 90-2340 40-30 0.32 Nickel and its alloys 180-214 105-1200 345-1450 60-5 0.31 Steels 190-200 205-1725 415-1750 65-2 0.28-0.33 Stainless steels 190-200 240-480 480-760 60-20 0.28-0.30 Titanium and its alloys 80-130 344-1380 415-1450 25-7 0.31-0.34 Tungsten and its alloys 350-400 550-690 620-760 0 0.27 NONMETALLIC MATERIALS Ceramics 70-1000 — 140-2600 0 0.2 Diamond 820-1050 — — — — Glass and porcelain 70-80 — 140 0 0.24 Rubbers 0.01-0.1 — — — 0.5 Thermoplastics 1.4-3.4 — 7-80 1000-5 0.32-0.40 Thermoplastics, reinforced 2-50 — 20-120 10-1 — Thermosets 3.5-17 — 35-170 0 0.34 Boron fibers 380 — 3500 0 — Carbon fibers 275-415 — 2000-5300 1-2 — Glass fibers (S, E) 73-85 — 3500-4600 5 — Kevlar fibers (29, 49, 129) 70-113 — 3000-3400 3-4 — Spectra fibers (900, 1000) 73-100 — 2400-2800 3 — Note: In the upper table, the lowest values for E, Y , and UTS and the highest values for elongation are for the pure metals. Multiply GPa by 145,000 to obtain psi, and MPa by 145 to obtain psi. For example 100 GPa = 14,500 ksi, and 100 MPa = 14,500 psi.

- 4. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Loading & Unloading; Elongation FIGURE 2.3 Schematic illustration of loading and unloading of a tensile-test specimen. Note that during unloading the curve follows a path parallel to the original elastic slope. Elastic recovery Permanent deformation Strain Unload Load Stress FIGURE 2.4 Total elongation in a tensile test as a function of original gage length for various metals. Because necking is a local phenomenon, elongation decreases with gage length. Standard gage length is usually 2 in. (50 mm), although shorter ones can be used if larger specimens are not available. 0 1 2 3 4 5 6 87 9 10 80 70 60 50 40 30 20 10 0 0 50 100 150 200 250 Elongation(%) Gage length (in.) mm 1100-O Aluminum Mild steelStructural silicon steel Magnesium Copper High-purityalum i num -annealed Brass Monel

- 5. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 True Stress and True Strain TABLE 2.2 Comparison of engineering and true strains in tension e 0.01 0.05 0.1 0.2 0.5 1 2 5 10 0.01 0.049 0.095 0.18 0.4 0.69 1.1 1.8 2.4 True stress True strain σ = P A ε = ln l lo = ln Ao A = ln Do D 2 = 2ln Do D

- 6. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 True Stress - True Strain Curve FIGURE 2.5 (a) True stress--true strain curve in tension. Note that, unlike in an engineering stress-strain curve, the slope is always positive and that the slope decreases with increasing strain. Although in the elastic range stress and strain are proportional, the total curve can be approximated by the power expression shown. On this curve, Y is the yield stress and Yf is the flow stress. (b) True stress- true strain curve plotted on a log-log scale. (c) True stress-true strain curve in tension for 1100-O aluminum plotted on a log-log scale. Note the large difference in the slopes in the elastic and plastic ranges. Source: After R. M. Caddell and R. Sowerby. True strain ( ) Truestress K Yf Y 0 0 1 1 f = K n Fracture (a) n Log Log (b) (c) n = 0.25 K = 25,000 0.0001 0.001 0.01 0.1 1 1 10 100 Y Truestress(psix103) n 1 True strain ( )

- 7. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Power Law Flow Rule TABLE 2.3 Typical values for K and n in Eq. 2.11 at room temperature. Material K (MPa) n Aluminum, 1100-O 180 0.20 2024-T4 690 0.16 5052-O 210 0.13 6061-O 205 0.20 6061-T6 410 0.05 7075-O 400 0.17 Brass, 7030, annealed 895 0.49 85-15, cold rolled 580 0.34 Bronze (phosphor), annealed 720 0.46 Cobalt-base alloy, heat treated 2070 0.50 Copper, annealed 315 0.54 Molybdenum, annealed 725 0.13 Steel, low carbon, annealed 530 0.26 1045 hot rolled 965 0.14 1112 annealed 760 0.19 1112 cold rolled 760 0.08 4135 annealed 1015 0.17 4135 cold rolled 1100 0.14 4340 annealed 640 0.15 17-4 P-H, annealed 1200 0.05 52100, annealed 1450 0.07 304 stainless, annealed 1275 0.45 410 stainless, annealed 960 0.10 Note: 100 MPa = 14,500 psi. Flow rule: σ = Kεn K = Strength coefficient n = Strain hardening exponent

- 8. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 True Stress-True Strain forVarious Materials FIGURE 2.6 True stress-true strain curves in tension at room temperature for various metals. The point of intersection of each curve at the ordinate is the yield stress Y; thus, the elastic portions of the curves are not indicated. When the K and n values are determined from these curves, they may not agree with those given in Table 2.3 because of the different sources from which they were collected. Source: S. Kalpakjian. Copper, annealed 2024-T36 Al 0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 0 40 60 80 100 120 140 160 180 1200 1000 800 600 400 0 True strain ( ) Truestress(psix103 ) MPa 304 Stainless steel 70–30 Brass, as received 70–30 Brass, annealed 1020 Steel 1100-O Al 1100-H14 Al 6061-O Al 2024-O Al 8650 Steel 1112 CR Steel 4130 Steel 200 20

- 9. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Idealized Stress-Strain Curves FIGURE 2.7 Schematic illustration of various types of idealized stress- strain curves. (a) Perfectly elastic. (b) Rigid, perfectly plastic. (c) Elastic, perfectly plastic. (d) Rigid, linearly strain hardening. (e) Elastic, linearly strain hardening. The broken lines and arrows indicate unloading and reloading during the test. (b) (c) =Y + Ep! (e) Y Y + Ep( -Y/E ) Y (d) (a) Y = Y tan-1 E tan-1 Ep Strain Stress = EP Y = Y Y/E =E Y/E E FIGURE 2.8 The effect of strain-hardening exponent n on the shape of true stress- true strain curves. When n = 1, the material is elastic, and when n = 0, it is rigid and perfectly plastic. = K n n = 1 0<n<1 n = 0K 0 1 True strain (P) Truestress

- 10. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Temperature and Strain Rate Effects FIGURE 2.9 Effect of temperature on mechanical properties of a carbon steel. Most materials display similar temperature sensitivity for elastic modulus, yield strength, ultimate strength, and ductility. 0 200 400 600 (°C) 0 200 400 600 800 1000 1200 1400 Temperature (°F) Stress(psi3103) 120 80 40 0 Stress(MPa) 600 400 200 0 Elongation Elastic modulus 200 150 100 50 0 Elasticmodulus(GPa) Elongation(%) 0 20 40 60 Tensile strength Yield strength 200 100 50 10 1 2 4 6 8 10 20 30 40 10-6 10-4 10-2 100 102 104 106 Strain rate (s-1) Tensilestrength(psix103) 800° 600° 400° 200° 30°C MPa 1000° FIGURE 2.10 The effect of strain rate on the ultimate tensile strength of aluminum. Note that as temperature increases, the slope increases. Thus, tensile strength becomes more and more sensitive to strain rate as temperature increases. Source: After J. H. Hollomon.

- 11. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Typical Strain Rates in Metalworking Process True Strain Deformation Speed (m/s) Strain Rate (s−1) Cold Working Forging, rolling 0.1-0.5 0.1-100 1 − 103 Wire and tube drawing 0.05-0.5 0.1-100 1 − 104 Explosive forming 0.05-0.2 10-100 10 − 105 Hot working and warm working Forging, rolling 0.1-0.5 0.1-30 1 − 103 Extrusion 2-5 0.1-1 10−1 − 102 Machining 1-10 0.1-100 103 − 106 Sheet-metal forming 0.1-0.5 0.05-2 1 − 102 Superplastic forming 0.2-3 10−4 − 10−2 10−4 − 10−2 TABLE 2.4 Typical ranges of strain, deformation speed, and strain rates in metalworking processes.

- 12. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Effect on Homologous Temperature FIGURE 2.11 Dependence of the strain- rate sensitivity exponent m on the homologous temperature T/Tm for various materials. T is the testing temperature and Tm is the melting point of the metal, both on the absolute scale.The transition in the slopes of the curve occurs at about the recrystallization temperature of the metals. Source: After F.W. Boulger. 0 0.2 0.4 0.6 0.8 1.00 0.05 0.10 0.15 0.25 0.20 Copper Steel Aluminum 304 Stainless Titanium Rene 41 Mo-T2C Strainratesensitivityexponent(m) T Tm Homologous temperature,

- 13. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Strain Rate Effects C Material Temperature, ◦C psi × 103 MPa m Aluminum 200-500 12-2 82-14 0.07-0.23 Aluminum alloys 200-500 45-5 310-35 0-0.20 Copper 300-900 35-3 240-20 0.06-0.17 Copper alloys (brasses) 200-800 60-2 415-14 0.02-0.3 Lead 100-300 1.6-0.3 11-2 0.1-0.2 Magnesium 200-400 20-2 140-14 0.07-0.43 Steel Low carbon 900-1200 24-7 165-48 0.08-0.22 Medium carbon 900-1200 23-7 160-48 0.07-0.24 Stainless 600-1200 60-5 415-35 0.02-0.4 Titanium 200-1000 135-2 930-14 0.04-0.3 Titanium alloys 200-1000 130-5 900-35 0.02-0.3 Ti-6Al-4V∗ 815-930 9.5-1.6 65-11 0.50-0.80 Zirconium 200-1000 120-4 830-27 0.04-0.4 ∗ at a strain rate of 2 × 10−4 s−1. Note: As temperature increases, C decreases and m increases. As strain increases, C increases and m may increase or decrease, or it may become negative within certain ranges of temperature and strain. Source: After T. Altan and F.W. Boulger. TABLE 2.5 Approximate range of values for C and m in Eq. (2.16) for various annealed metals at true strains ranging from 0.2 to 1.0. m = Strain-rate sensitivity exponent C = Strength coefficient σ = C˙εm

- 14. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Effect of Strain Rate Sensitivity on Elongation FIGURE 2.12 (a) The effect of strain-rate sensitivity exponent m on the total elongation for various metals. Note that elongation at high values of m approaches 1000%. Source: After D. Lee and W.A. Backofen. (b) The effect of strain-rate sensitivity exponent m on the post uniform (after necking) elongation for various metals. Source: After A.K. Ghosh. 0.20.1 0.3 0.4 0.5 0.6 0.70 10 102 103 Totalelongation(%) m Ti–5A1–2.5Sn Ti–6A1–4V Zircaloy–4 High- and ultra-high- carbon steels 0 0.060.040.020 10 30 20 50 40 m Post-uniformelongation(%) A-K Steel HSLA Steel C.R. Aluminum (1100) 2036-T4 Aluminum 3003-O Aluminum 5182-O Aluminum 5182-O Al (150C) 70-30 Brass Zn-Ti Alloy (a) (b)

- 15. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Hydrostatic Pressure & Barreling FIGURE 2.13 The effect of hydrostatic pressure on true strain at fracture in tension for various metals. Even cast iron becomes ductile under high pressure. Source: After H.L.D. Pugh and D. Green. 5 4 3 2 1 0 300 600 900 MPa 0 0 20 40 60 80 100 120 Truestrainatfracture(f) Zinc Copper Aluminum Magnesium Cast iron Hydrostatic pressure (ksi) FIGURE 2.14 Barreling in compressing a round solid cylindrical specimen (7075-O aluminum) between flat dies. Barreling is caused by friction at the die-specimen interfaces, which retards the free flow of the material. See also Figs.6.1 and 6.2. Source: K.M. Kulkarni and S. Kalpakjian.

- 16. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Plane-Strain Compression Test FIGURE 2.15 Schematic illustration of the plane-strain compression test. The dimensional relationships shown should be satisfied for this test to be useful and reproducible. This test gives the yield stress of the material in plane strain, Y’. Source: After A. Nadai and H. Ford. b w h w > 5h w > 5b b > 2h to 4h Yield stress in plane strain: Y = 2 √ 3 Y = 1.15Y

- 17. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Tension & Compression; Baushinger Effect FIGURE 2.16 True stress-true strain curve in tension and compression for aluminum. For ductile metals, the curves for tension and compression are identical. Source: After A.H. Cottrell. Tension Compression 0 4 8 12 16 Truestress(ksi) 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 True strain ( ) MPa 100 50 0 FIGURE 2.17 Schematic illustration of the Bauschinger effect.Arrows show loading and unloading paths. Note the decrease in the yield stress in compression after the specimen has been subjected to tension.The same result is obtained if compression is applied first, followed by tension, whereby the yield stress in tension decreases. Y 2Y P Tension Compression

- 18. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Disk & Torsion Tests FIGURE 2.18 Disk test on a brittle material, showing the direction of loading and the fracture path.This test is useful for brittle materials, such as ceramics and carbides. Fracture P P σ = 2P πdt FIGURE 2.19 A typical torsion-test specimen. It is mounted between the two heads of a machine and is twisted. Note the shear deformation of an element in the reduced section. l l r r r r t τ = T 2πr2t γ = rφ l

- 19. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Simple vs. Pure Shear FIGURE 2.20 Comparison of (a) simple shear and (b) pure shear. Note that simple shear is equivalent to pure shear plus a rotation. 3 1 3 3 1 = - 3 2 3 1 1 (a) (b)

- 20. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Three- and Four-Point Bend-Tests FIGURE 2.21 Two bend-test methods for brittle materials: (a) three- point bending; (b) four-point bending.The shaded areas on the beams represent the bending-moment diagrams, described in texts on the mechanics of solids. Note the region of constant maximum bending moment in (b), whereas the maximum bending moment occurs only at the center of the specimen in (a). (a) (b) Maximum bending moment σ = Mc I

- 21. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Hardness Tests FIGURE 2.22 General characteristics of hardness testing methods.The Knoop test is known as a microhardness test because of the light load and small impressions. Source: After H.W. Hayden, W.G. Moffatt, and V.Wulff. Load, P Hardness number Shape of indentation Side view Top viewTest Indenter 60 kg 150 kg 100 kg 100 kg 60 kg 150 kg 100 kg 500 kg 1500 kg 3000 kg 25 g–5 kg 1–120 kg L136° HK = 14.2P L2 HV = 1.854P L2 HB = ( D)(D - D2 - d2 ) 2P t = mm t = mm 120° L b t L/b = 7.11 b/t = 4.00 dd D = 100 - 500t HRA HRC HRD E Rockwell Knoop Brinell Vickers A C D B F G HRE = 130 - 500t HRB HRF HRG Diamond cone 10-mm steel or tungsten carbide ball Diamond pyramid Diamond pyramid - in. diameter16 1 steel ball - in. diameter8 1 steel ball

- 22. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Hardness Test Considerations FIGURE 2.23 Indentation geometry for Brinell hardness testing: (a) annealed metal; (b) work- hardened metal. Note the difference in metal flow at the periphery of the impressions. (a) (b) d d FIGURE 2.25 Bulk deformation in mild steel under a spherical indenter. Note that the depth of the deformed zone is about one order of magnitude larger than the depth of indentation. For a hardness test to be valid, the material should be allowed to fully develop this zone.This is why thinner specimens require smaller indentations. Source: Courtesy of M.C. Shaw and C.T.Yang. FIGURE 2.24 Relation between Brinell hardness and yield stress for aluminum and steels. For comparison, the Brinell hardness (which is always measured in kg/mm2) is converted to psi units on the left scale. Carbon steels, annealed 5.3 1 3.2 3.4 1 1 Aluminum, cold worked Carbon steels, cold worked MPa 100 200 300 400 500 250 200 150 100 50 0 Hardness(psix103) 10 20 30 40 50 60 70 80 Yield stress (psi x 103) Brinellhardness(kg/mm2) 150 100 50 0

- 23. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Fatigue FIGURE 2.26 Typical S-N curves for two metals. Note that, unlike steel, aluminum does not have an endurance limit. 0 500 400 300 200 100 0 80 60 40 20 1045 Steel Endurance limit Number of cycles, N (a) (b) psix103 Number of cycles, N Stressamplitude,S(MPa) 0 0 2 4 6 psix103 8 10 20 30 40 50 60 Diallyl-phthalate Nylon (dry) P olycarbonate PolysulfonePTFE 103 104 105 107106 108 109 1010 103 104 105 106 107 20 14-T6 Aluminum alloy Phenolic Epoxy Stressamplitude,S(MPa) FIGURE 2.27 Ratio of fatigue strength to tensile strength for various metals, as a function of tensile strength. 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0 50 200 0 200 400 600 800 1000 1200 MPa Endurancelimit/tensilestrength Titanium Steels Cast irons Copper alloys Aluminum alloys Wrought magnesium alloys Cast magnesium alloys Tensile strength (psi x 103) 100 150 0.1 0

- 24. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Creep & Impact FIGURE 2.28 Schematic illustration of a typical creep curve. The linear segment of the curve (constant slope) is useful in designing components for a specific creep life. Primary Time Tertiary Strain Instantaneous deformation Rupture Secondary Specimen (10 x 10 x 75 mm) Pendulum Pendulum Notch Specimen (10 x 10 x 55 mm) (a) (b) FIGURE 2.29 Impact test specimens: (a) Charpy; (b) lzod.

- 25. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Residual Stresses FIGURE 2.30 Residual stresses developed in bending a beam made of an elastic, strain-hardening material. Note that unloading is equivalent to applying an equal and opposite moment to the part, as shown in (b). Because of nonuniform deformation, most parts made by plastic deformation processes contain residual stresses. Note that the forces and moments due to residual stresses must be internally balanced. Tensile Compressive (a) (b) (c) (d) a b c o a d o e f

- 26. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Distortion due to Residual Stress FIGURE 2.31 Distortion of parts with residual stresses after cutting or slitting: (a) rolled sheet or plate; (b) drawn rod; (c) thin-walled tubing. Because of the presence of residual stresses on the surfaces of parts, a round drill may produce an oval-shaped hole because of relaxation of stresses when a portion is removed. (c) (a) Before After Before After Before After (b)

- 27. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Elimination of Residual Stresses FIGURE 2.32 Elimination of residual stresses by stretching. Residual stresses can be also reduced or eliminated by thermal treatments, such as stress relieving or annealing. Stress (a) (b) CompressiveTensile t c (c) Y t c !t !c Tension Y (d) Compression 2Y

- 28. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 State of Stress in Metalworking FIGURE 2.33 The state of stress in various metalworking operations. (a) Expansion of a thin-walled spherical shell under internal pressure. (b) Drawing of round rod or wire through a conical die to reduce its diameter; see Section 6.5 (c) Deep drawing of sheet metal with a punch and die to make a cup; see Section 7.6. (a) (b) (c) !1 !1 !1 !1 !1 !1 !3 !3 !3 !3 !3 !3 !2 !2 !2 !2

- 29. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Strain State in Necking FIGURE 2.34 Stress distribution in the necked region of a tension-test specimen. a Distribution of axial stress Distribution of radial or tangential stress Maximum axial stress Average axial true stress = True stress in uniaxial tension R 1 2 3 Correction factor due to Bridgman: σ σav = 1 1+ 2R a 1+ a 2R

- 30. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 States of Stress FIGURE 2.35 Examples of states of stress: (a) plane stress in sheet stretching; there are no stresses acting on the surfaces of the sheet. (b) plane stress in compression; there are no stresses acting on the sides of the specimen being compressed. (c) plane strain in tension; the width of the sheet remains constant while being stretched. (d) plane strain in compression (see also Fig. 2.15); the width of the specimen remains constant due to the restraint by the groove. (e) Triaxial tensile stresses acting on an element. (f) Hydrostatic compression of an element. Note also that an element on the cylindrical portion of a thin-walled tube in torsion is in the condition of both plane stress and plane strain (see also Section 2.11.7). (a) (c) (e) (b) (f) (d) p p p p p p !1 !1 !3 !1 !1 !3 !2 !2 !1 !3 !3 !3 !3 !1 !1 !3 !1 !3

- 31. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Yield Criteria Tension Y Compression Maximum-shear stress criterion Distortion-energy criterion Tension Compression Y !1 !1 !1 !3 !3 !3 !1 !3 !3 !1 !1 !1 !1 !1 !3 !3 !3 !3 FIGURE 2.36 Plane-stress diagrams for maximum -shear-stress and distortion-energy criteria. Note that 2 = 0. Maximum-shear-stress criterion: Distortion-energy criterion: σmax −σmin = Y (σ1 −σ2)2 +(σ2 −σ3)2 +(σ3 −σ1)2 = 2Y2

- 32. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Flow Stress and Work of Deformation FIGURE 2.37 Schematic illustration of true stress-true strain curve showing yield stress Y, average flow stress, specific energy u1 and flow stress Yf. Yf Y Y Truestress u1 True strain (!) !10 0 Flow stress: Specific energy ¯Y = Kεn 1 n+1 u = Z ε 0 ¯σd¯ε

- 33. Manufacturing Processes for Engineering Materials, 5th ed. Kalpakjian • Schmid © 2008, Pearson Education ISBN No. 0-13-227271-7 Ideal & Redundant Work FIGURE 2.38 Deformation of grid patterns in a workpiece: (a) original pattern; (b) after ideal deformation; (c) after inhomogeneous deformation, requiring redundant work of deformation. Note that (c) is basically (b) with additional shearing, especially at the outer layers.Thus (c) requires greater work of deformation than (b). See also Figs. 6.3 and 6.49. (a) (b) (c) Total specific energy: Efficiency: utotal = uideal +ufriction +uredundant η = uideal utotal