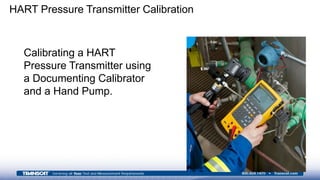

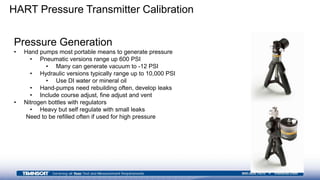

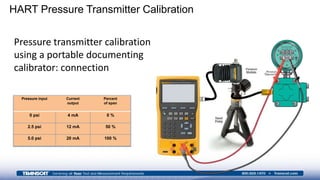

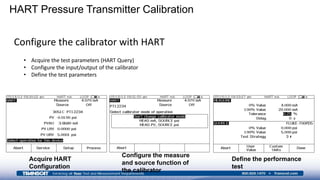

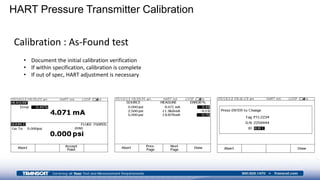

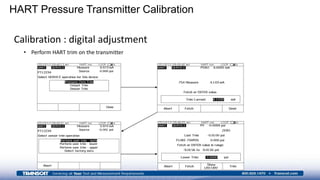

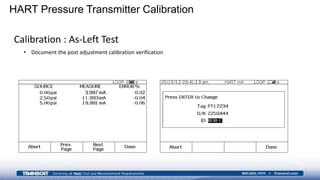

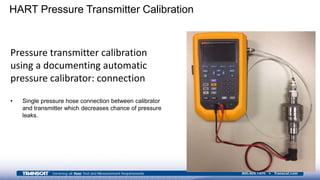

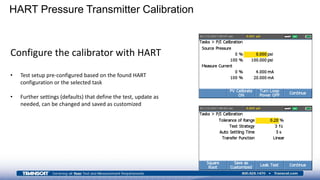

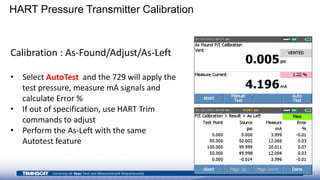

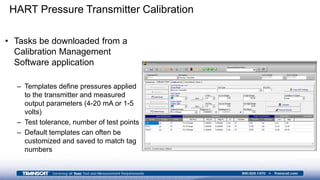

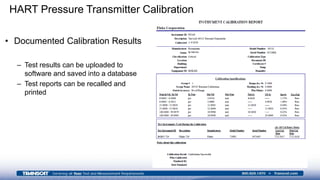

This document discusses calibrating HART pressure transmitters using documenting calibrators. It begins by explaining what HART is and its benefits. It then describes how to calibrate a HART pressure transmitter using a documenting calibrator and hand pump, including configuring the calibrator, performing as-found and as-left tests, and making digital adjustments. It also covers calibrating with an automatic documenting pressure calibrator, which provides automatic pressure generation. The document concludes by discussing benefits of documenting calibrators such as eliminating errors and enabling data analysis to optimize calibration schedules.