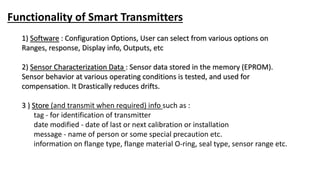

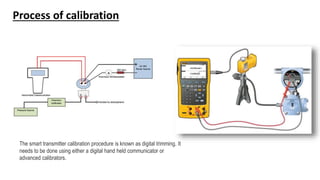

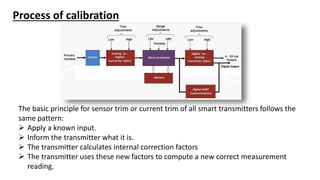

Smart transmitters have microprocessors that allow for self-diagnostics, non-linear compensation, remote recalibration without physical visits, and digital communication over networks. They offer advantages like performing calculations, producing diagnostics, better accuracy and stability, remote calibration, and reduced inventory needs compared to conventional analog transmitters. Smart transmitters can be calibrated digitally by applying a known input and informing the transmitter, which then calculates internal correction factors to compute a new correct measurement reading.