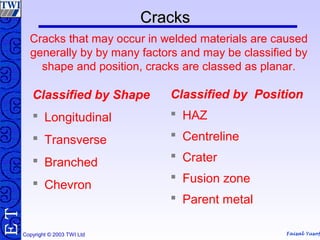

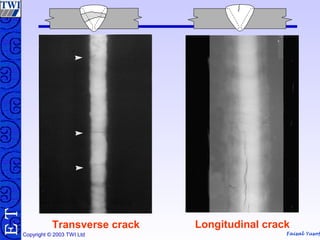

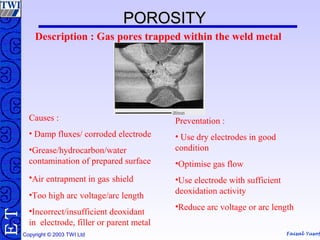

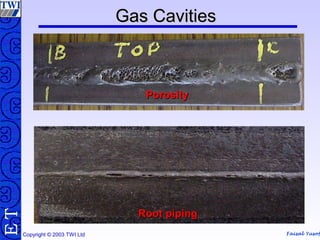

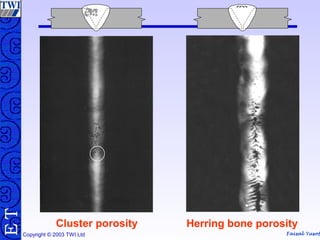

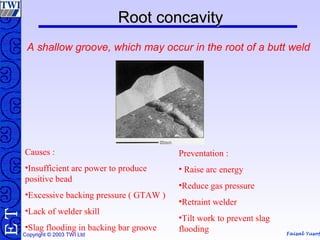

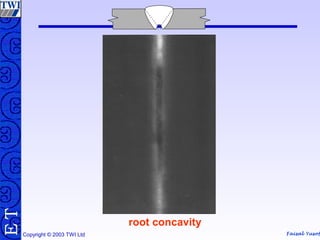

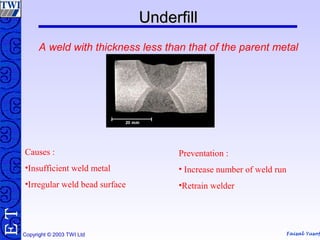

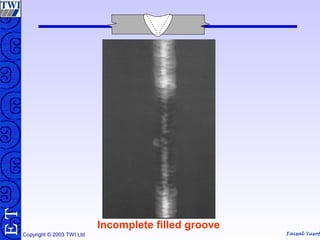

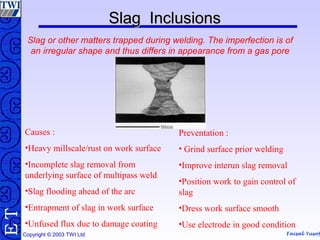

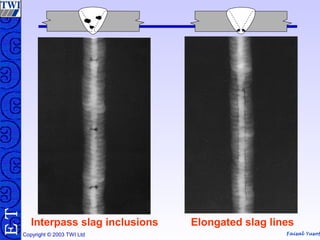

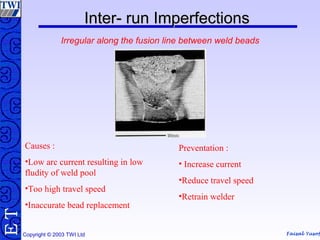

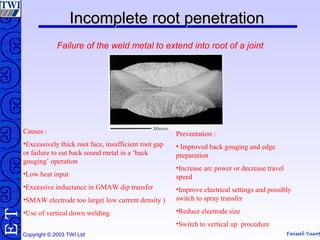

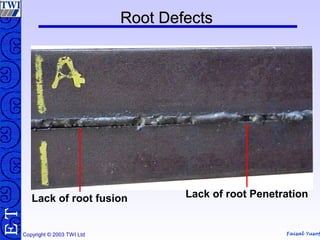

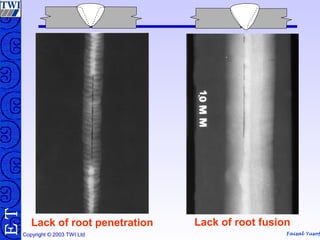

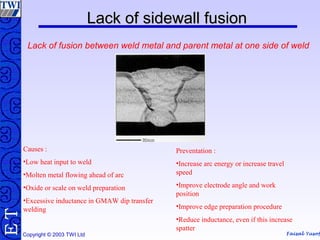

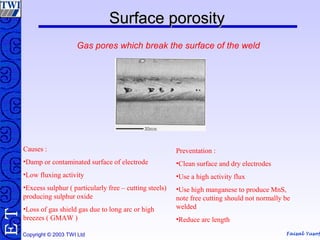

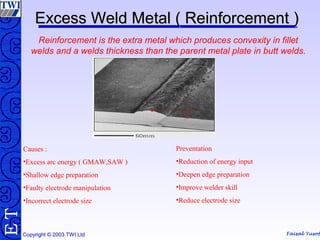

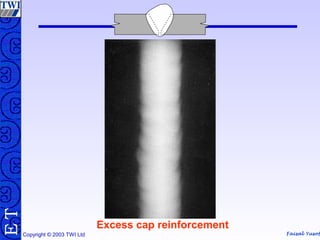

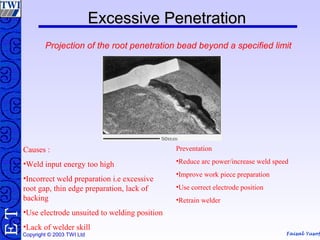

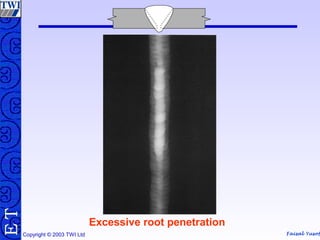

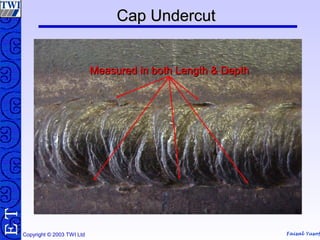

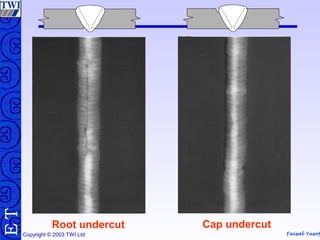

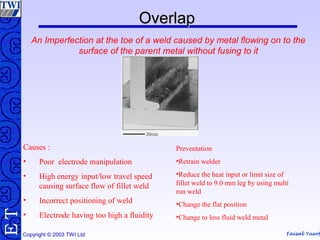

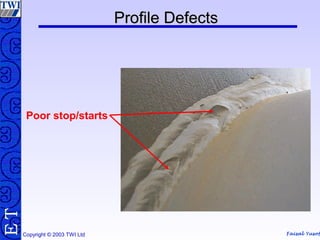

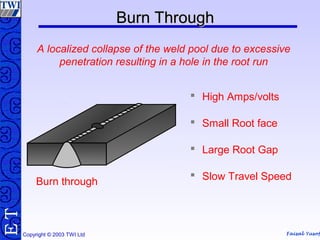

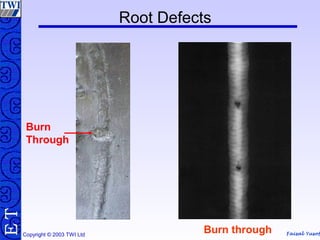

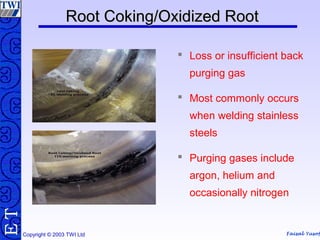

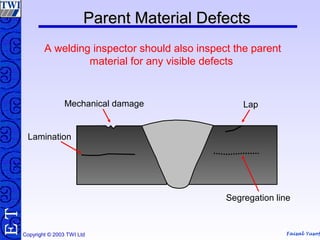

The document discusses various welding defects that can be visually detected, including cracks, lack of solid metal, lack of fusion, lack of smoothly blended surfaces, and miscellaneous defects. It provides details on different types of each defect, their causes, and methods for prevention. It also discusses welding repairs, noting that repairs require authorization and testing to ensure defects have been fully removed before performing the repair weld.