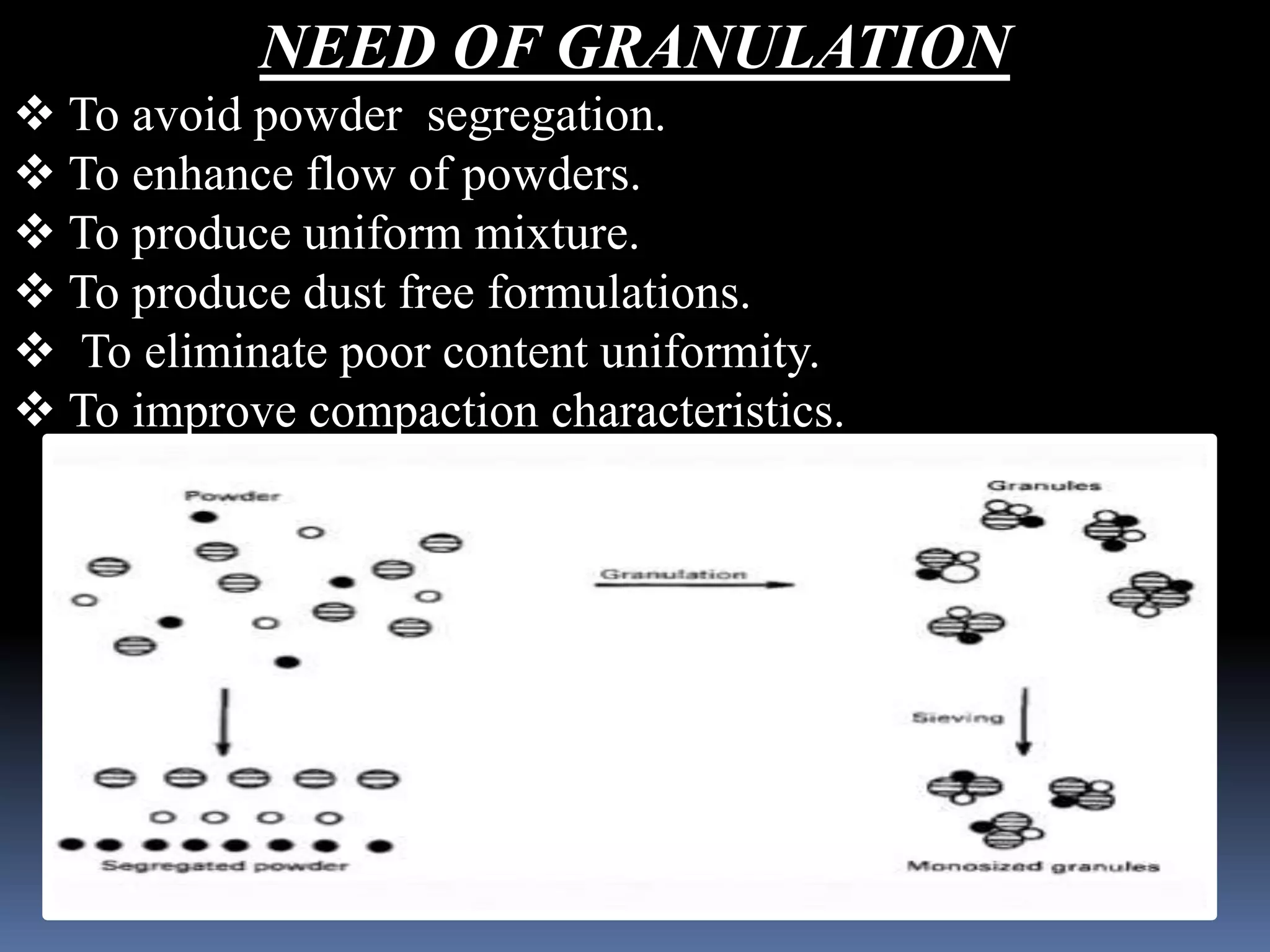

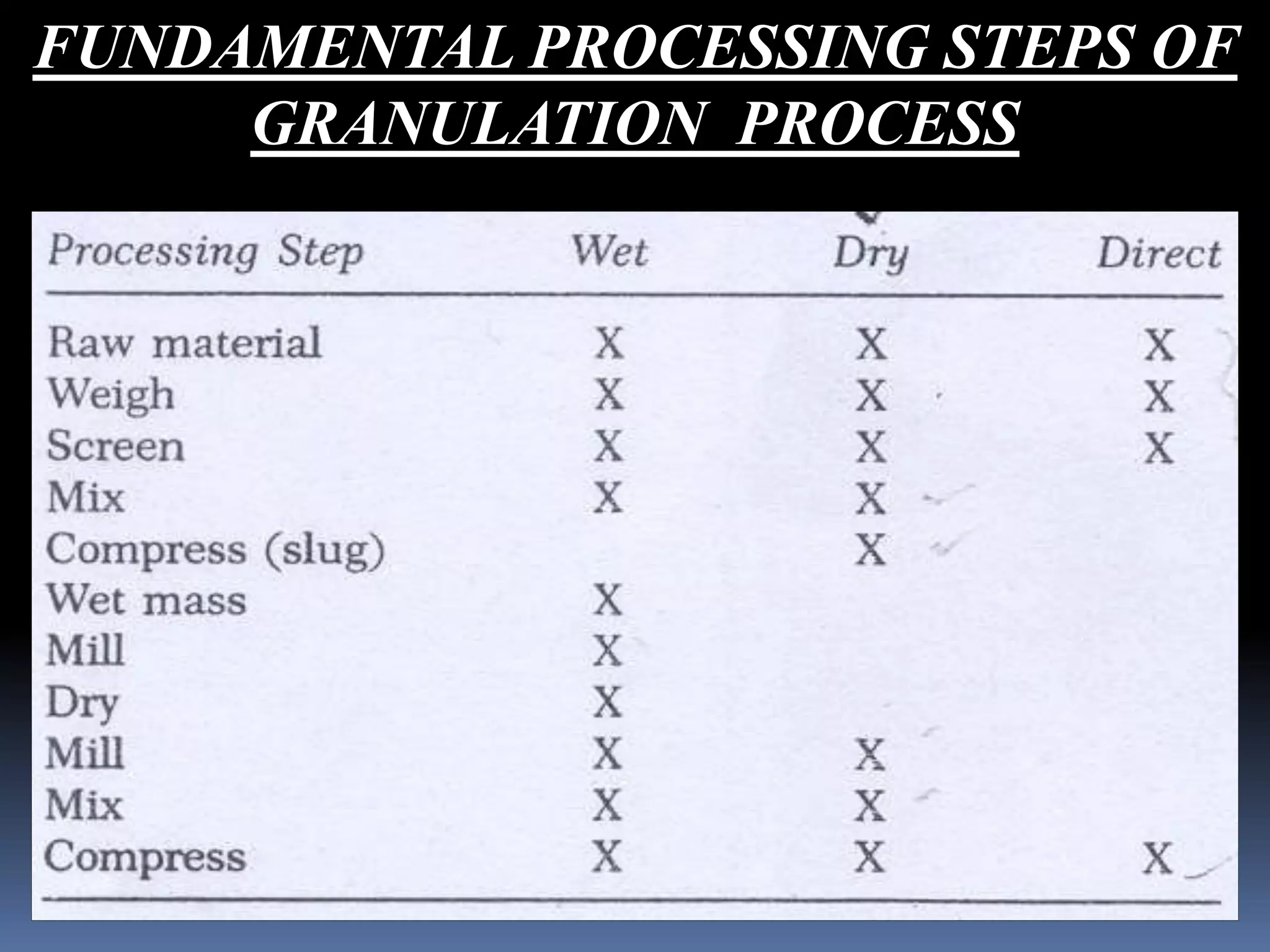

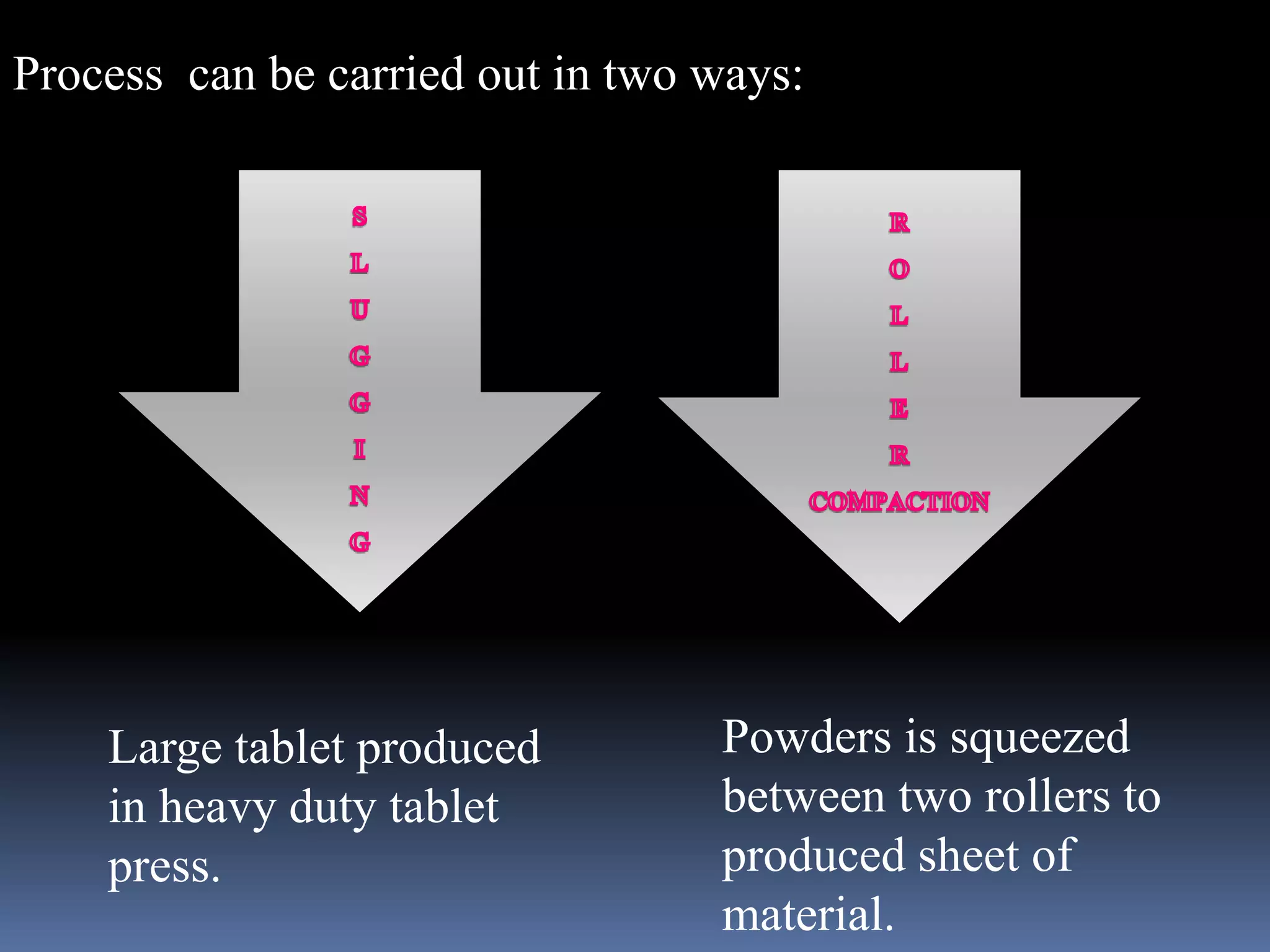

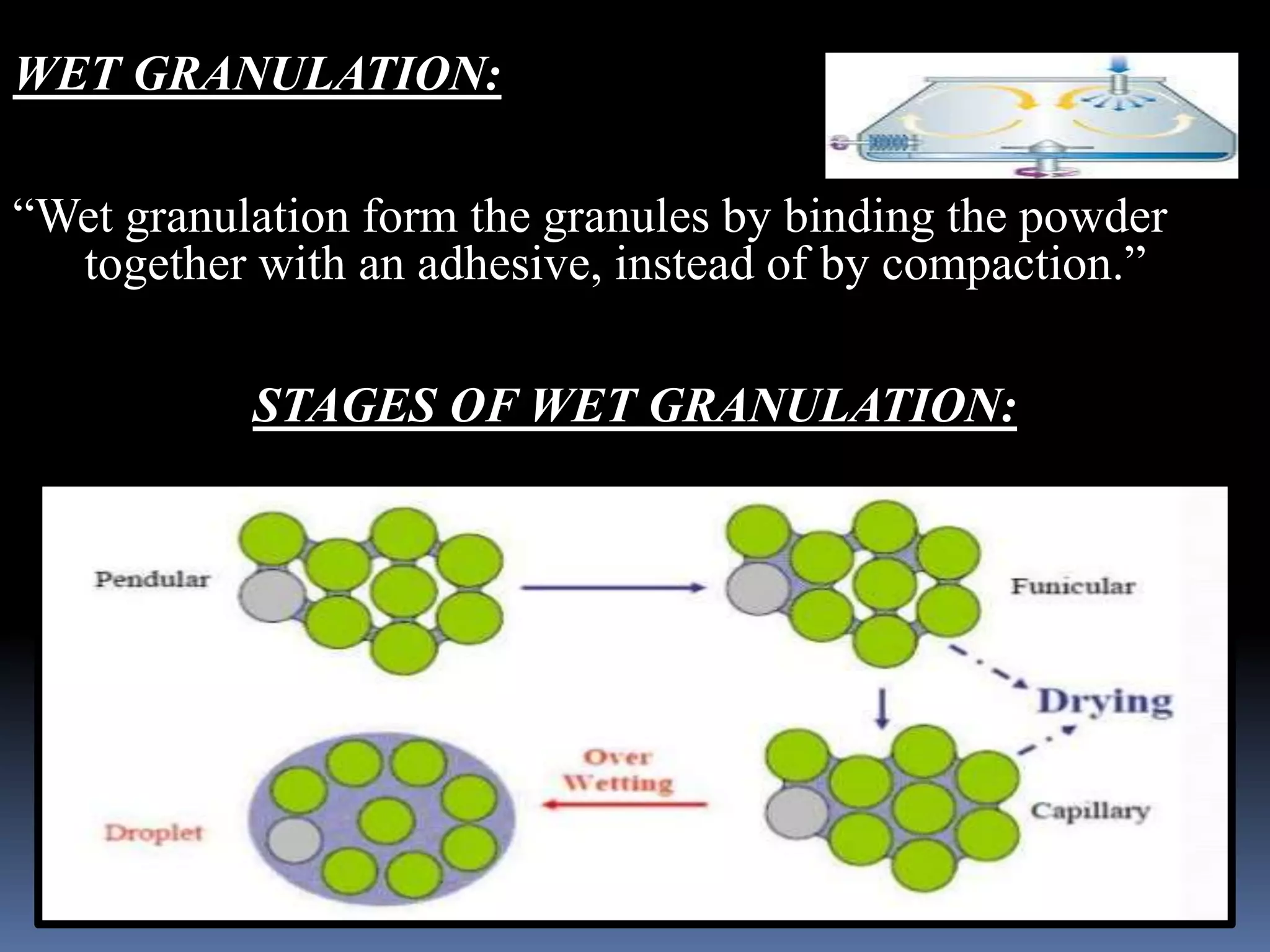

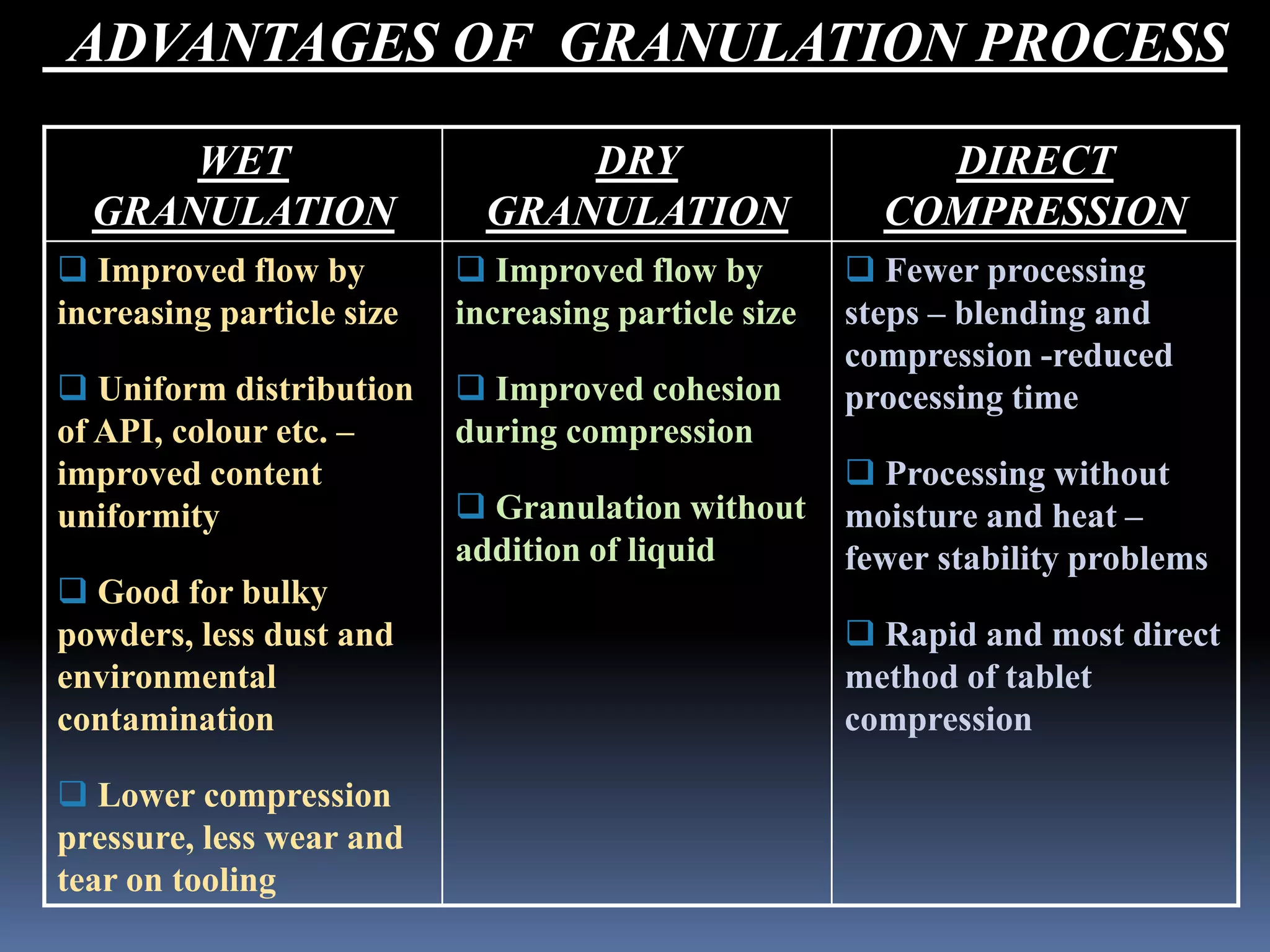

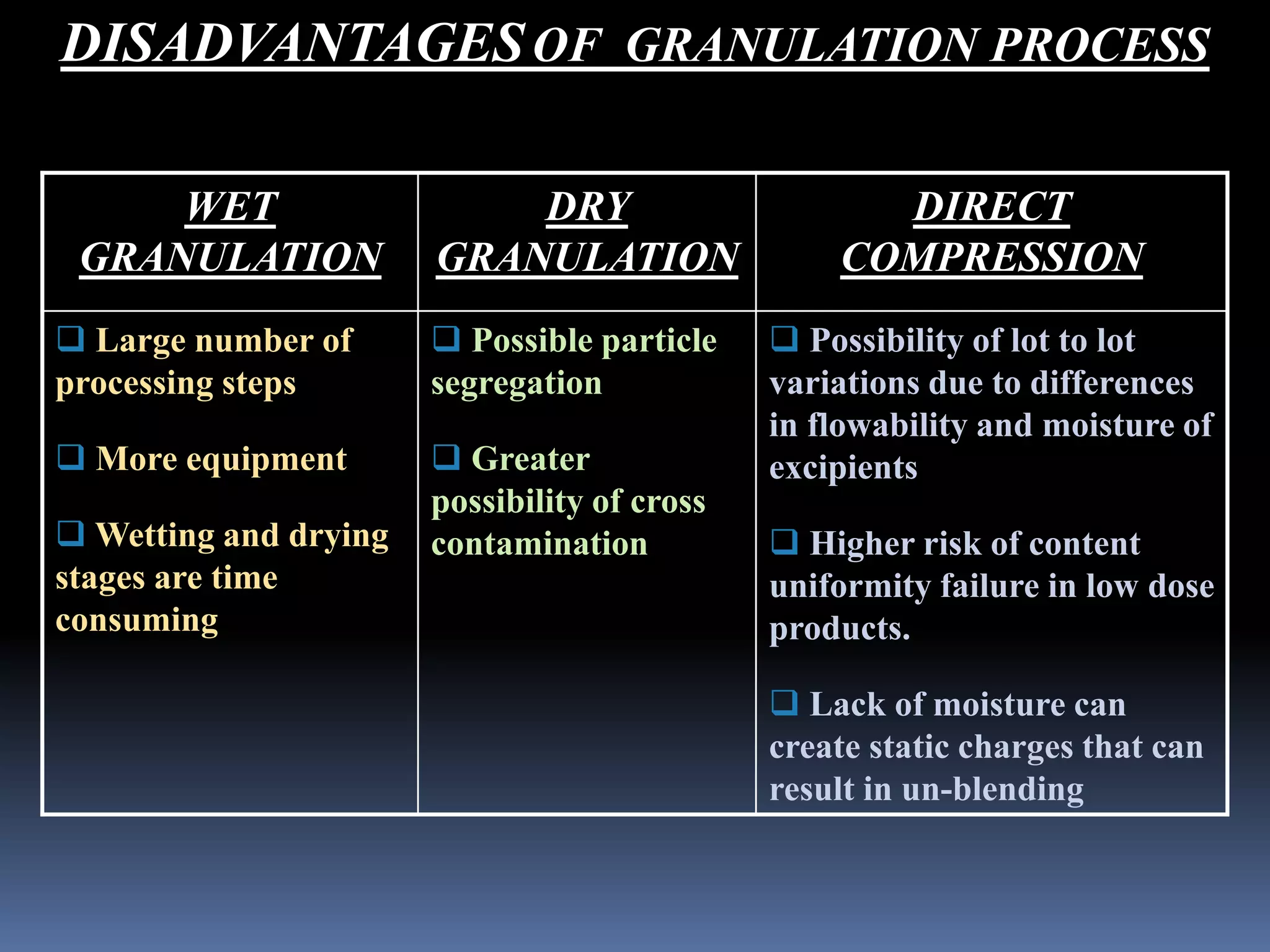

Granulation is the process of binding powder particles together to form larger multi-particle granules. It is done to improve powder flow properties, enhance content uniformity, and eliminate segregation issues. The main granulation techniques are wet granulation, dry granulation, and direct compression. Wet granulation involves mixing powders with a liquid binder to form granules, then drying the granules. Dry granulation compresses powders directly into tablets. Direct compression tablets are made by compressing blended powders without granulation. Granulation improves flow, content uniformity, and compression properties.