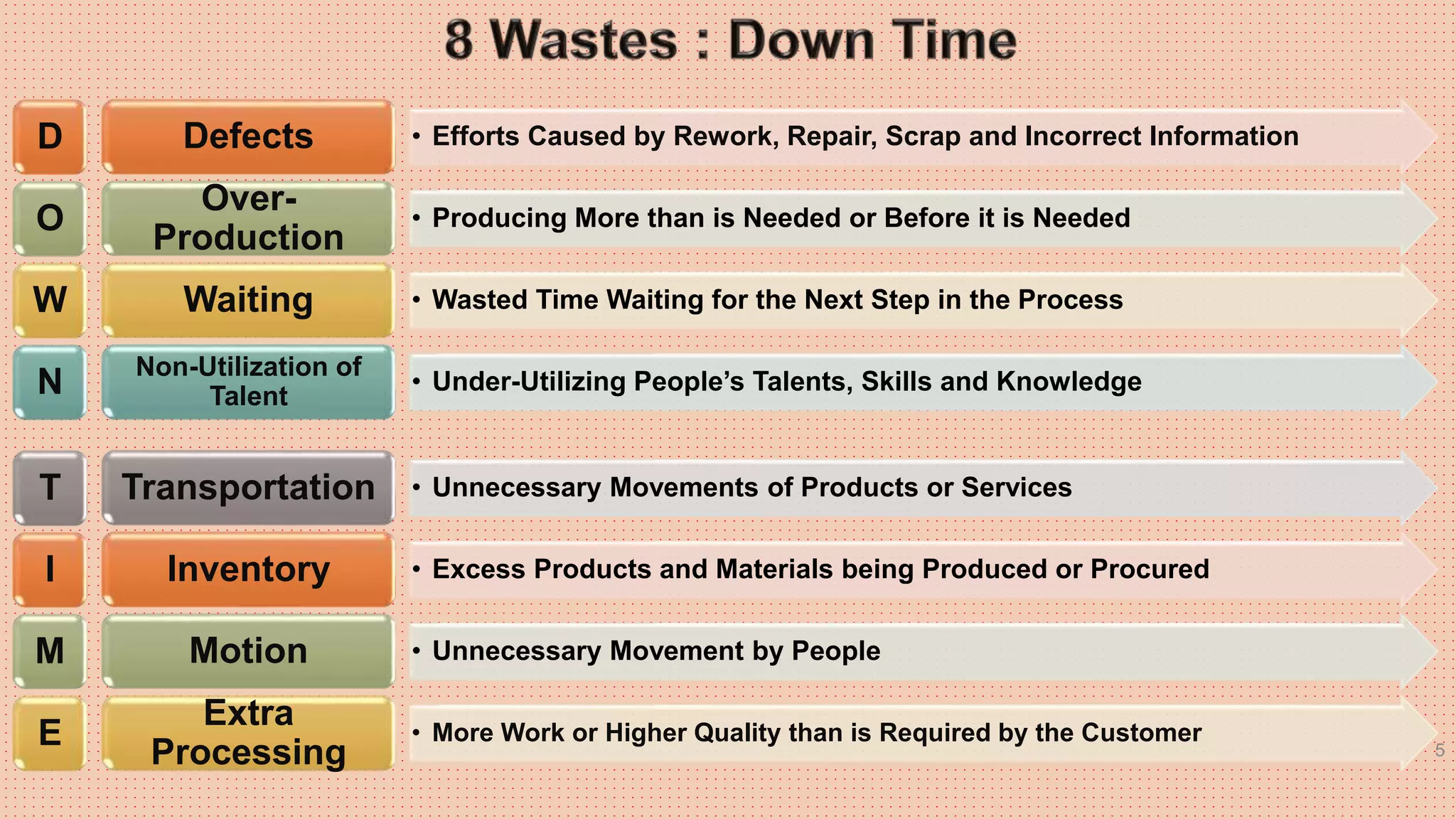

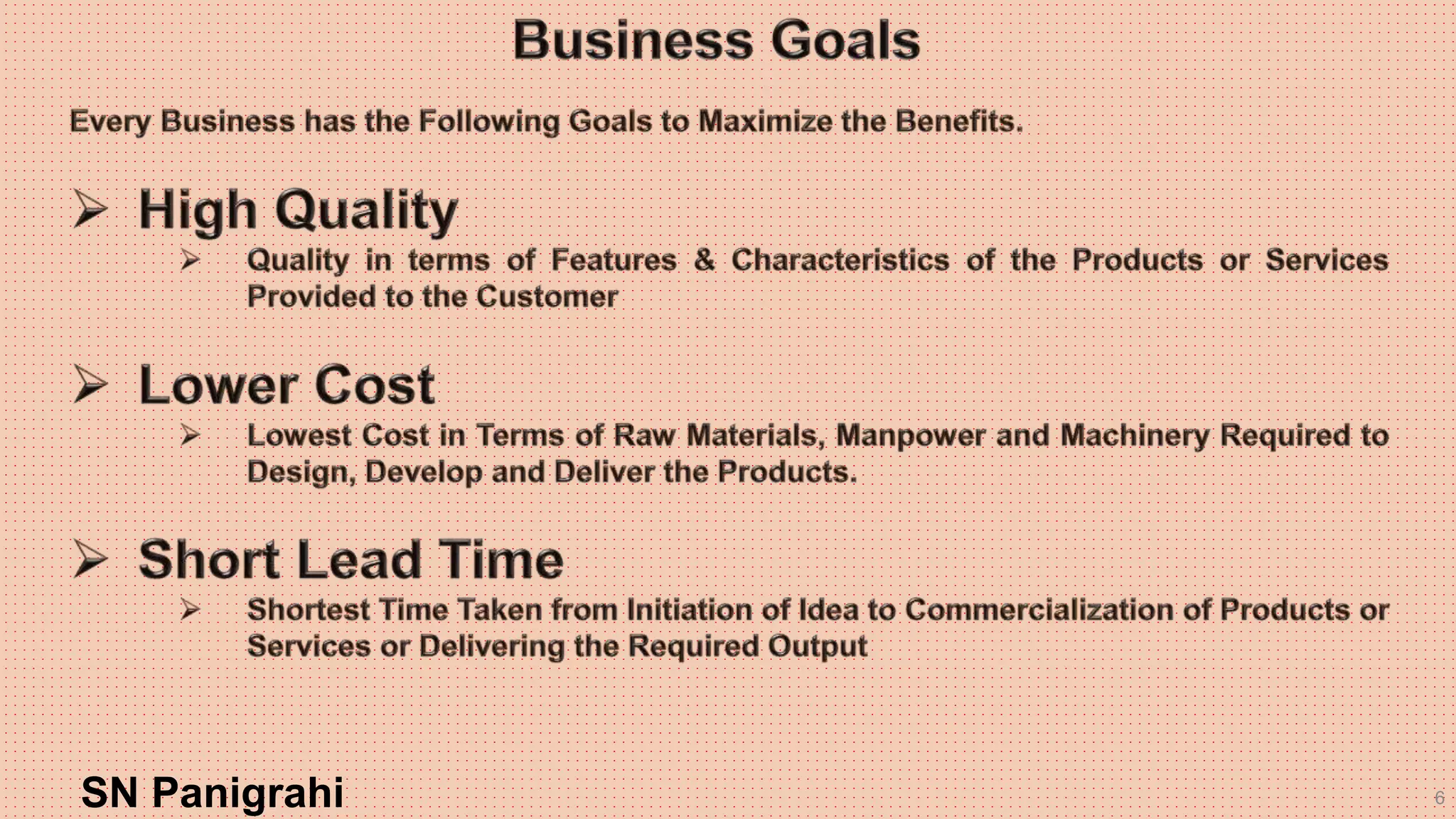

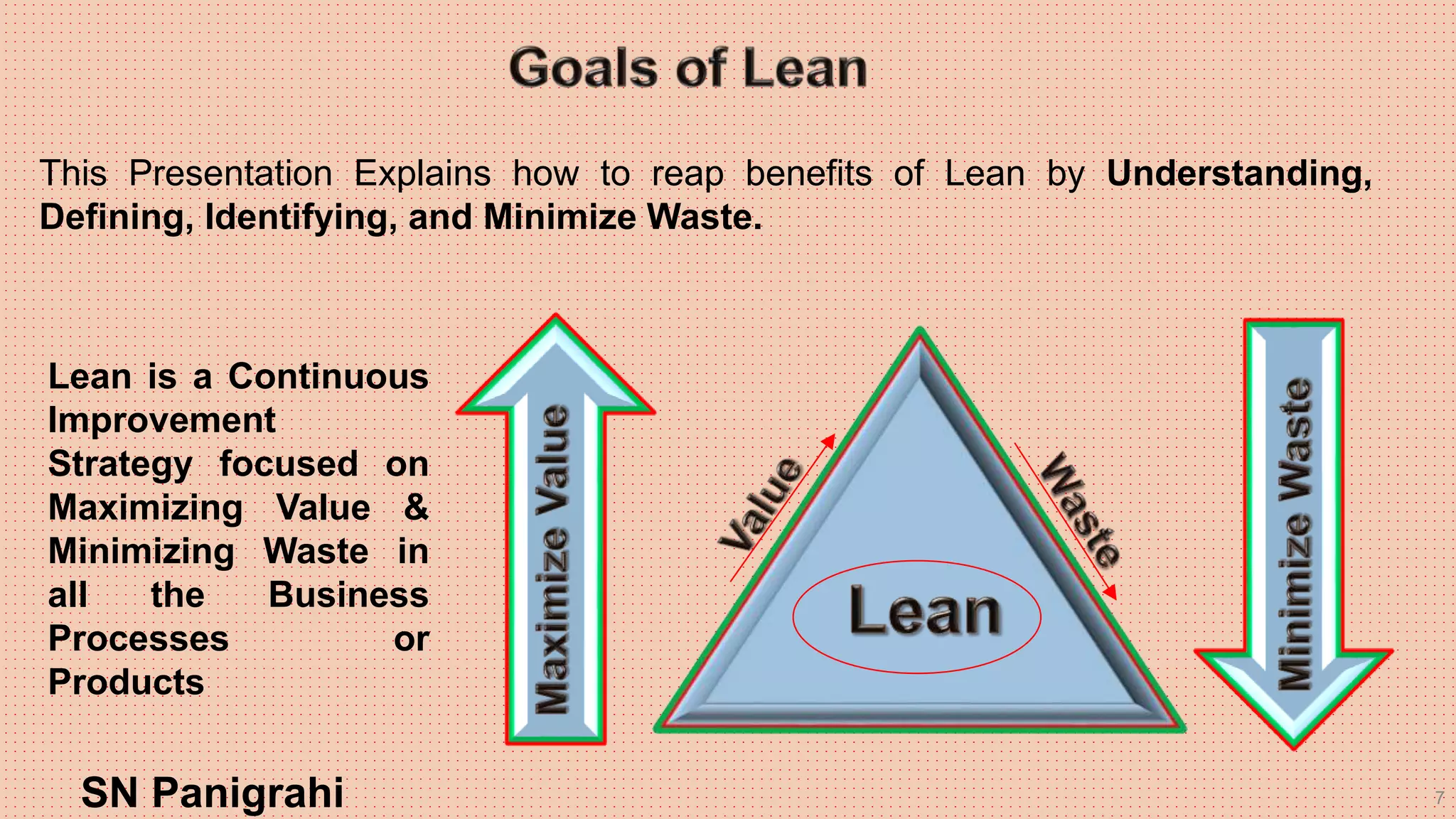

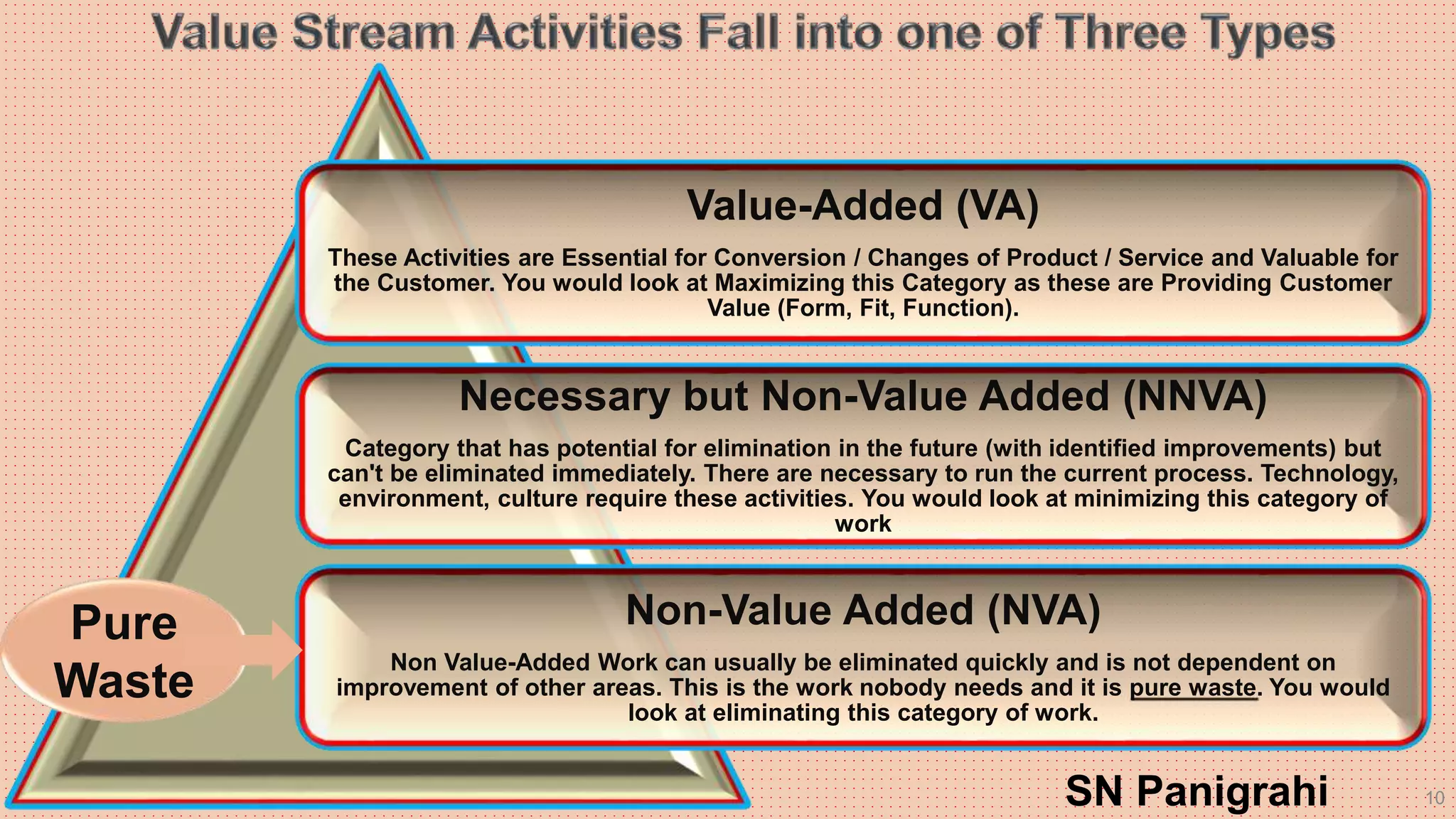

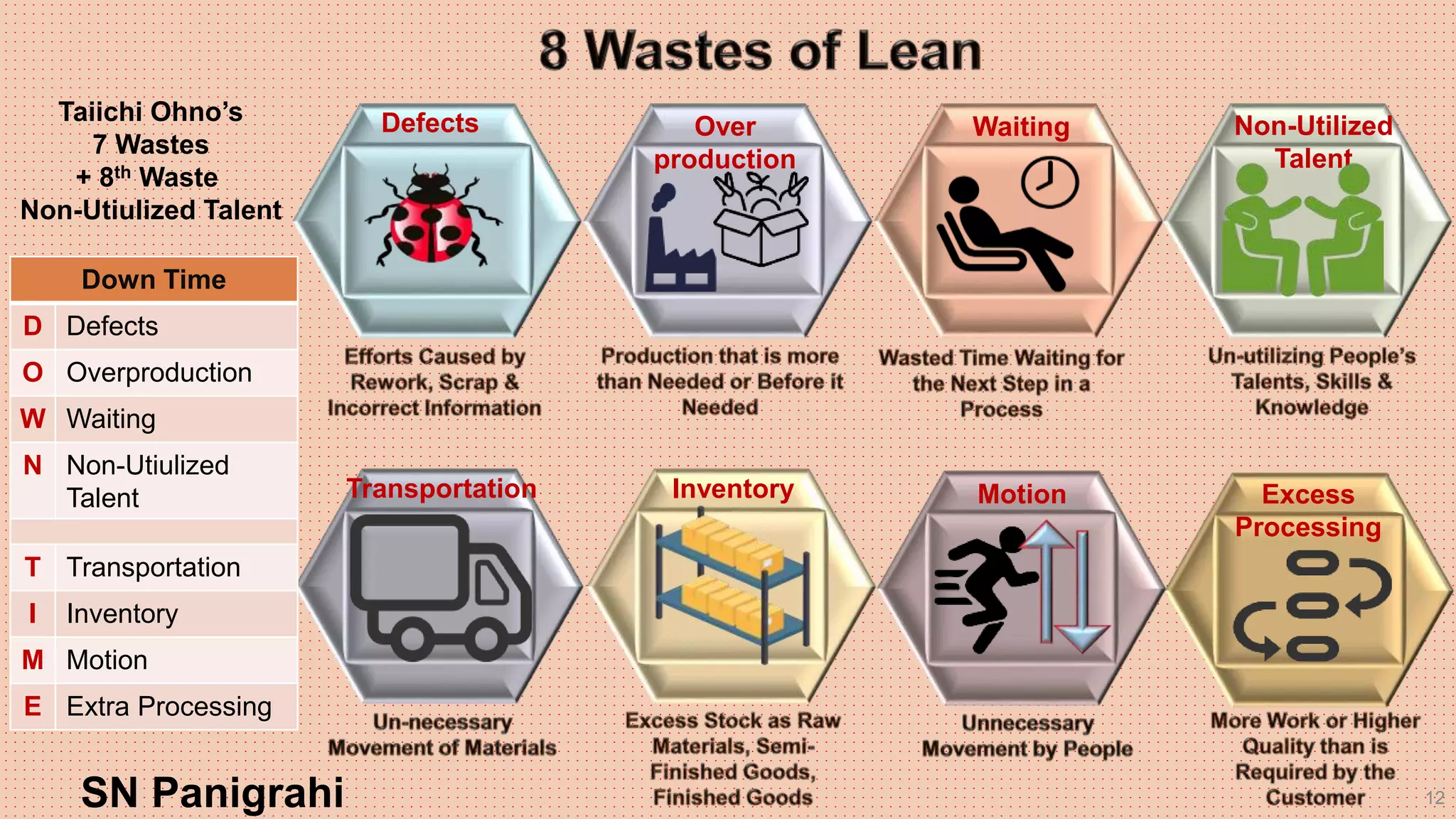

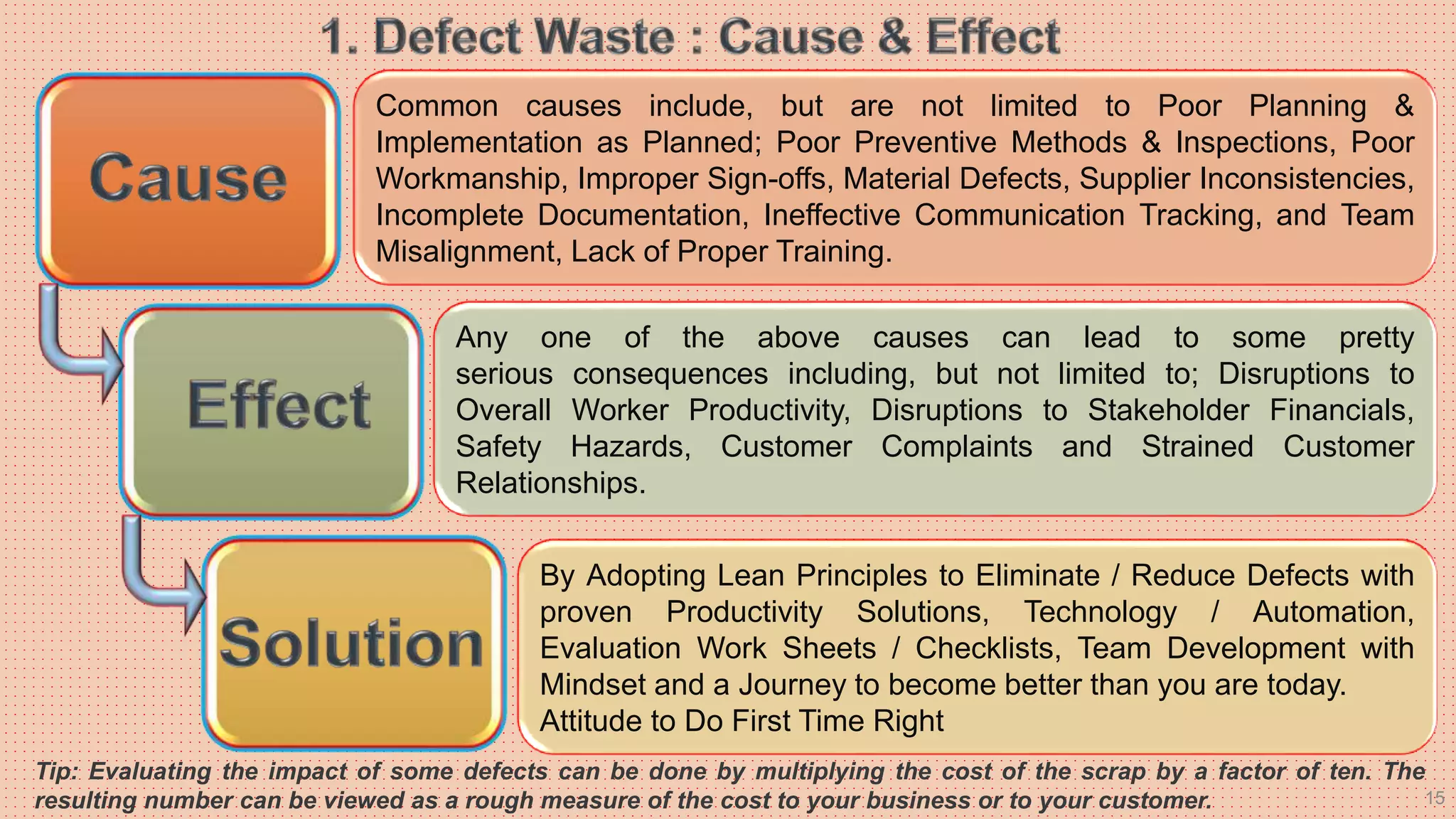

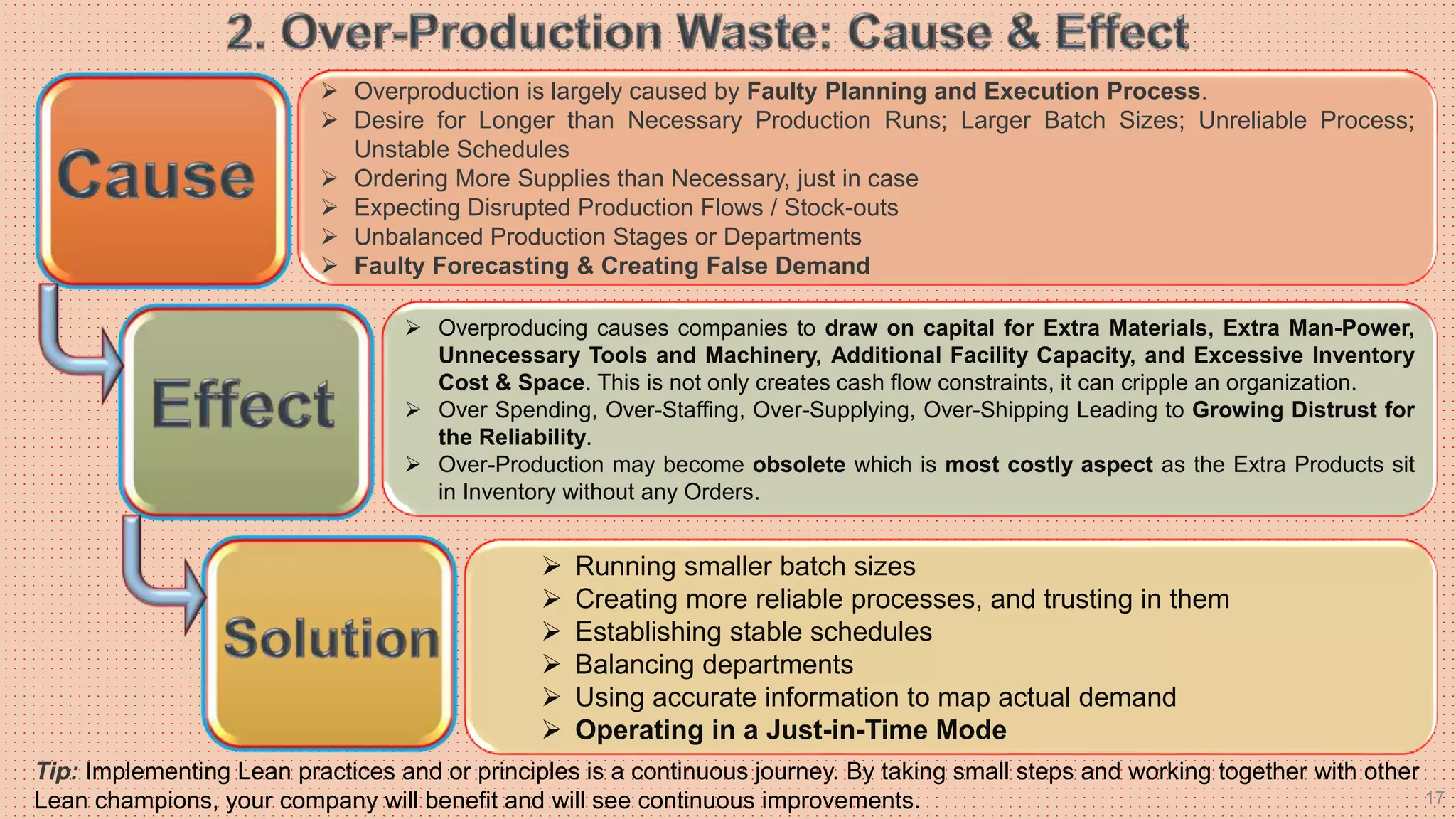

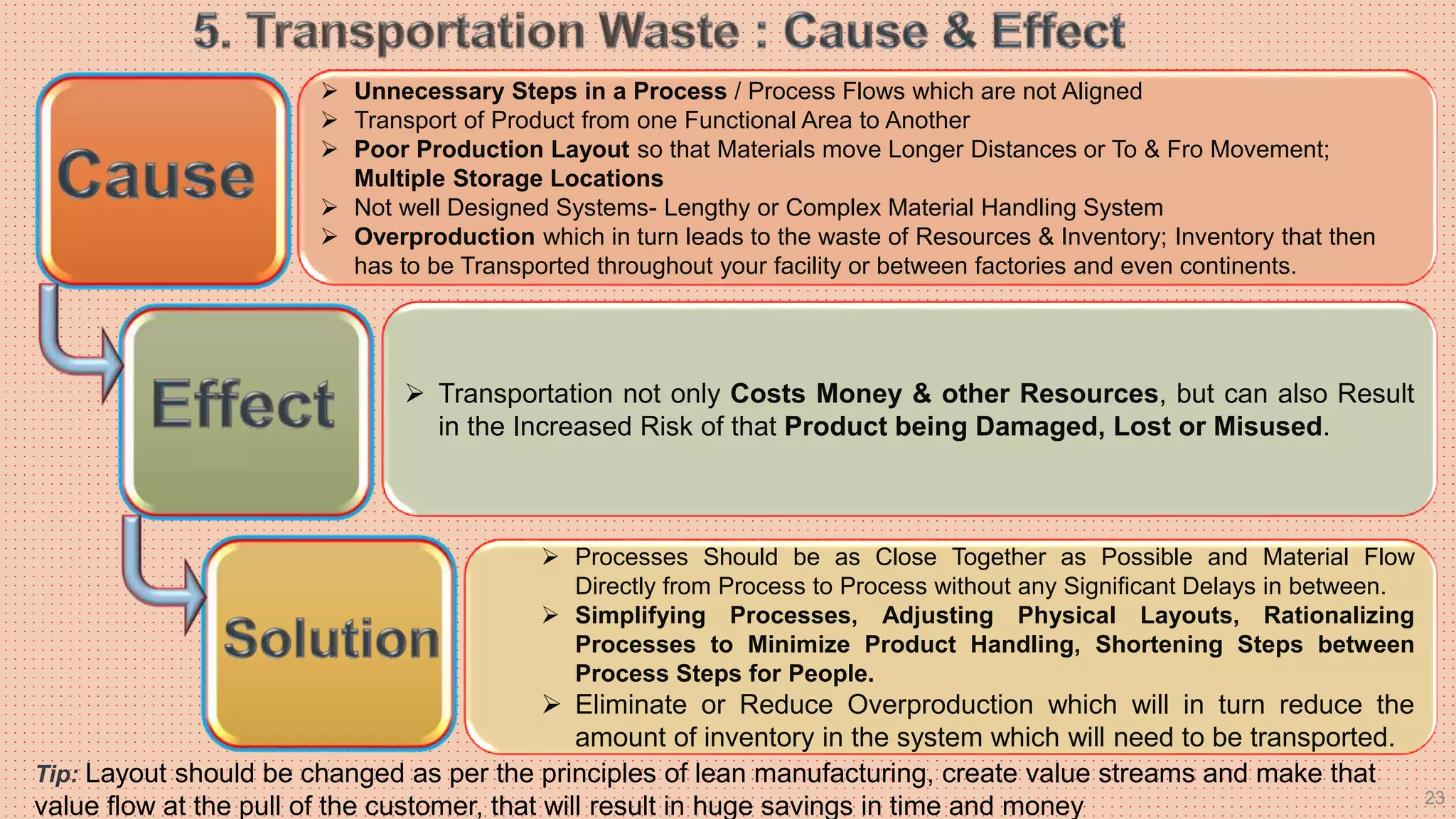

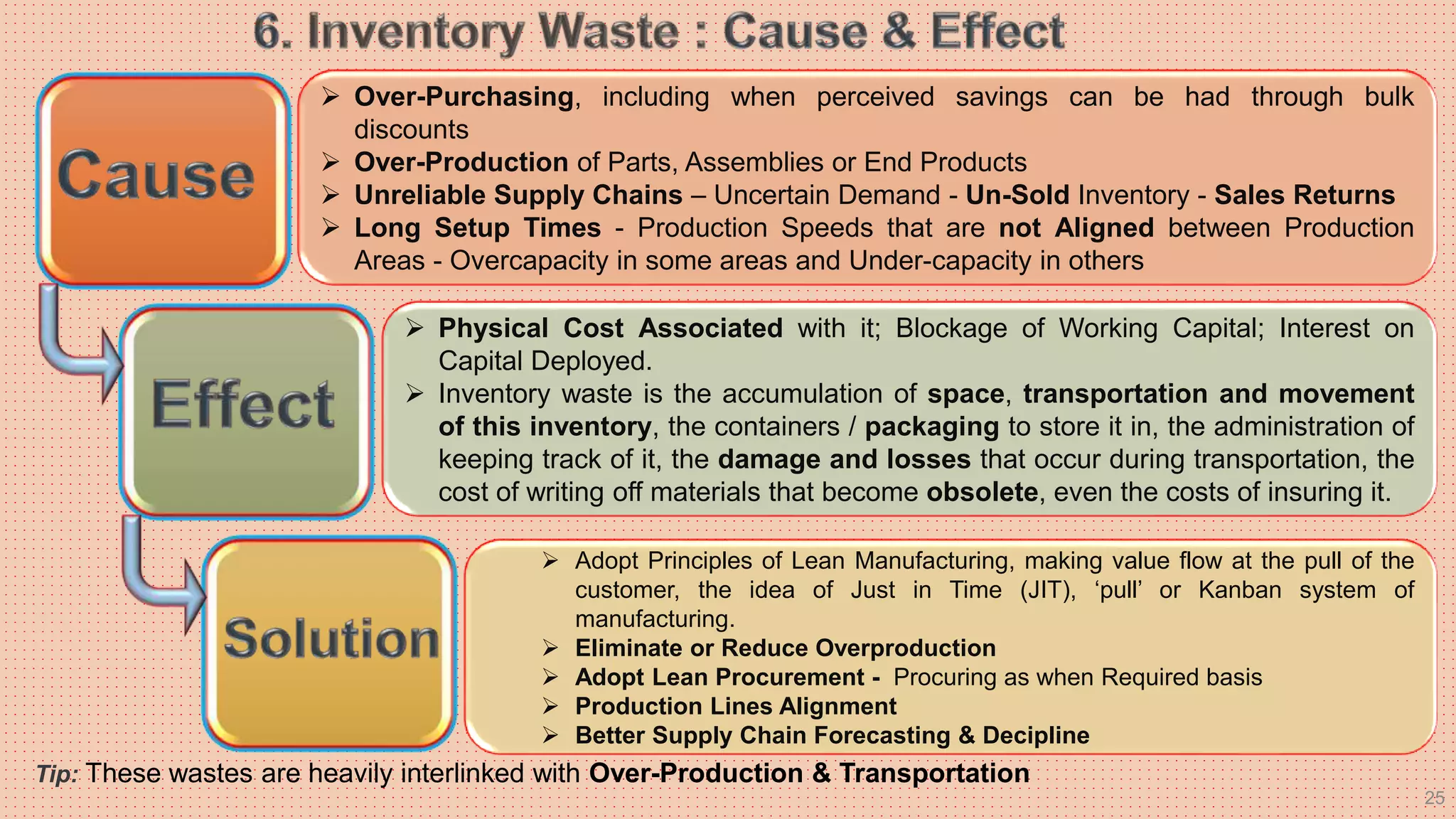

The document outlines the lean manufacturing methodology, emphasizing waste reduction and efficiency improvement in production systems. It describes the origins of lean principles, particularly from the Toyota Production System, and identifies the eight types of waste (muda) that hinder productivity. Key elements include continuous improvement, employee involvement, and minimizing non-value-added activities to enhance overall business performance.