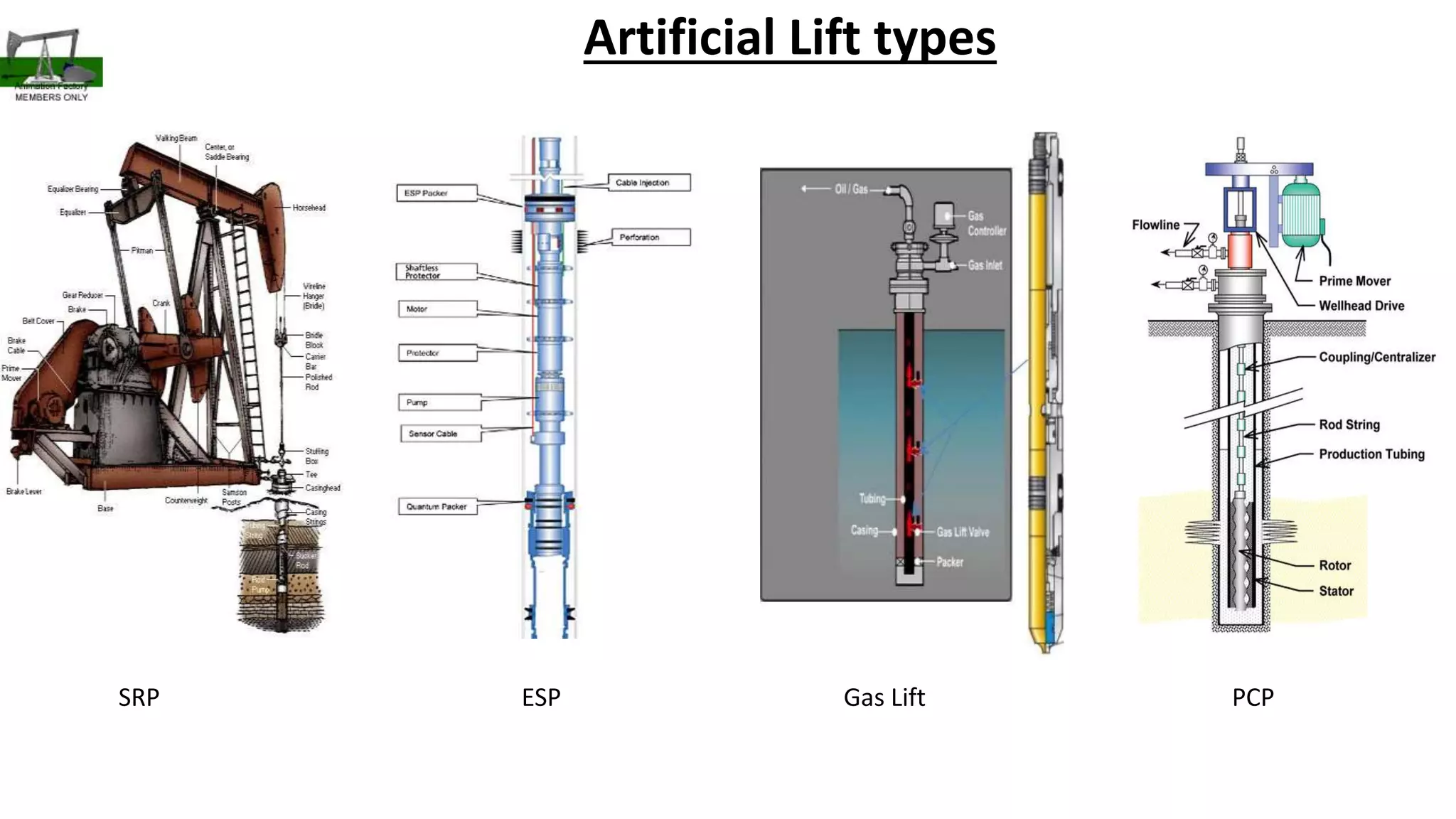

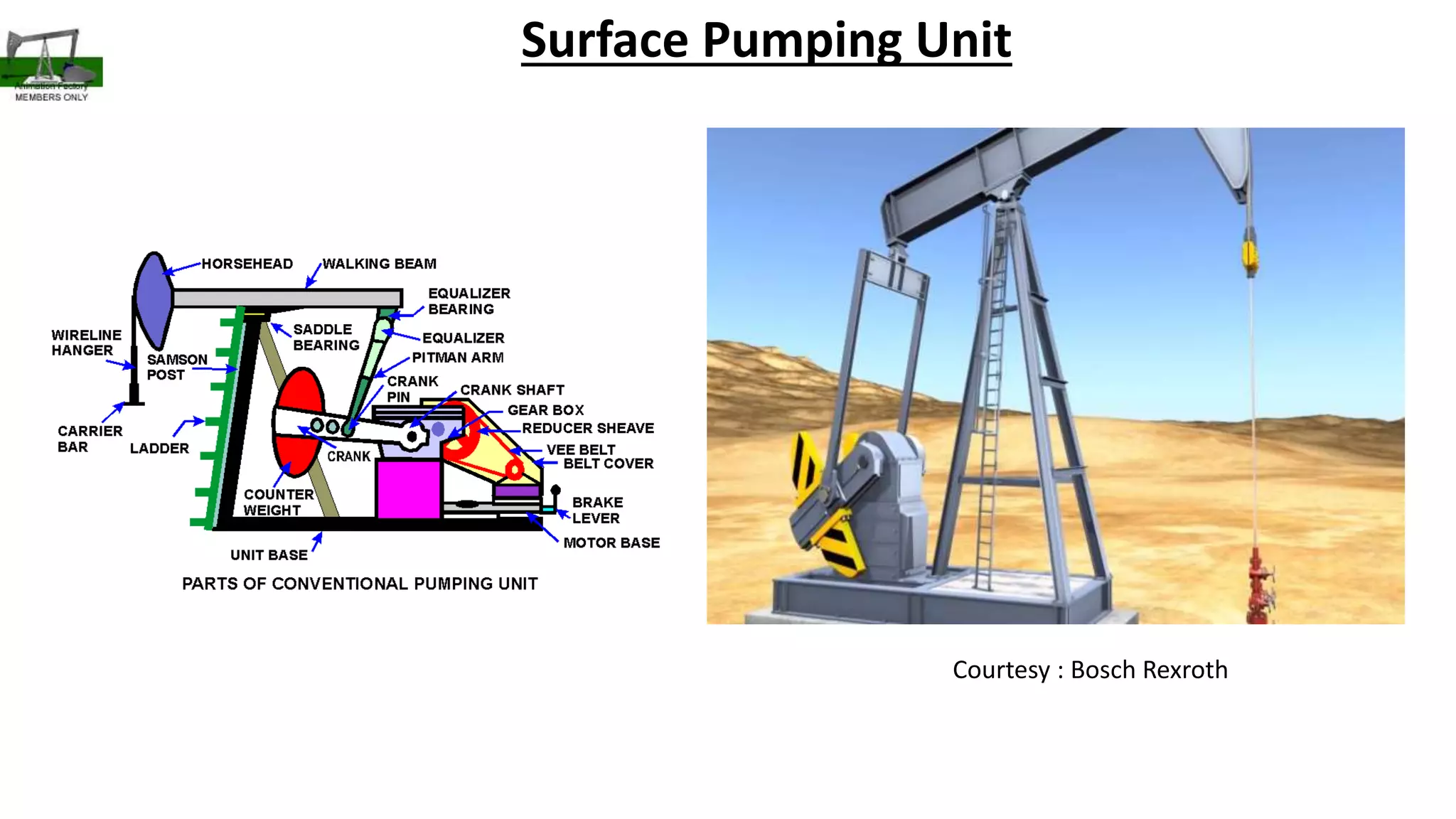

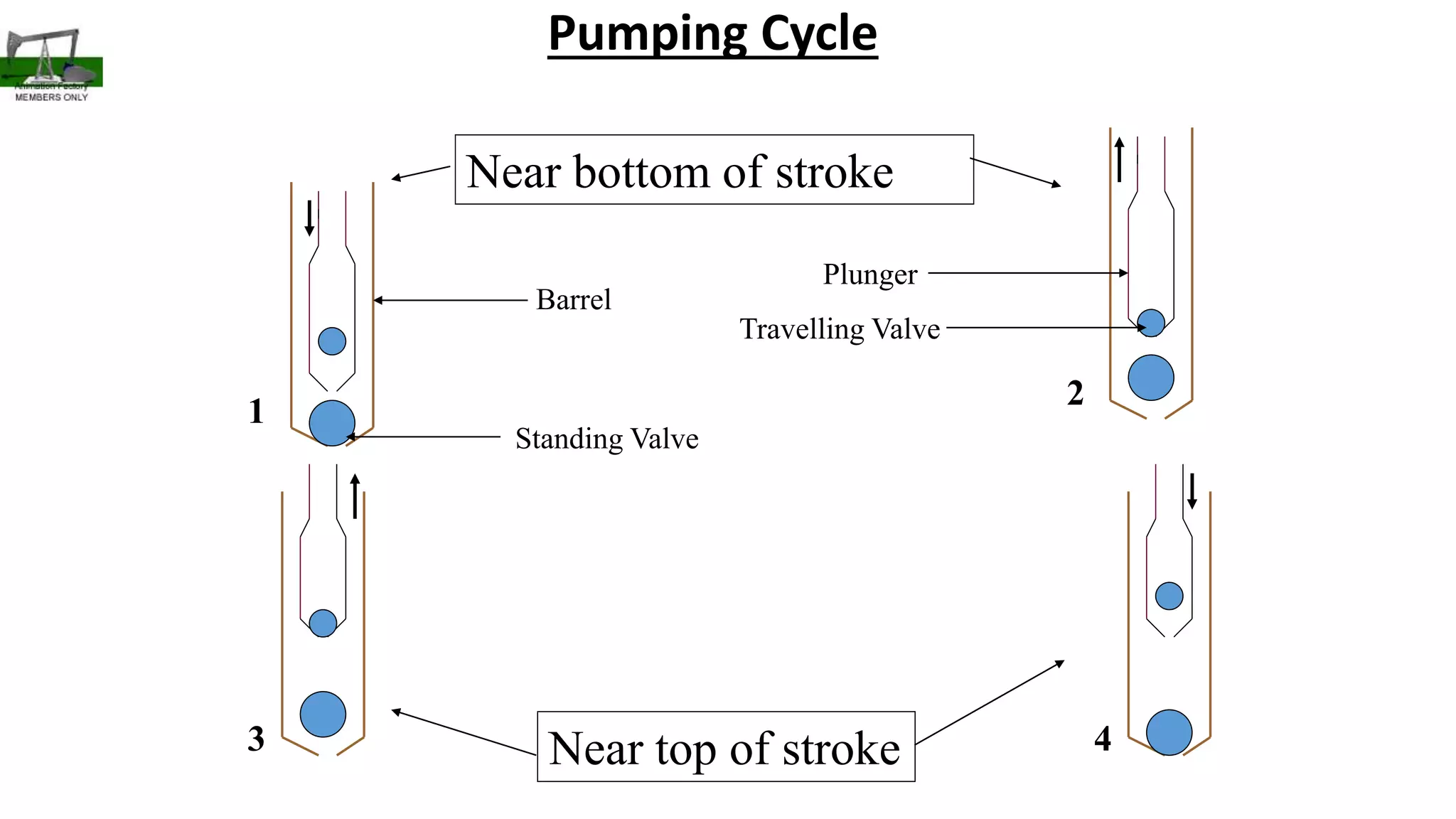

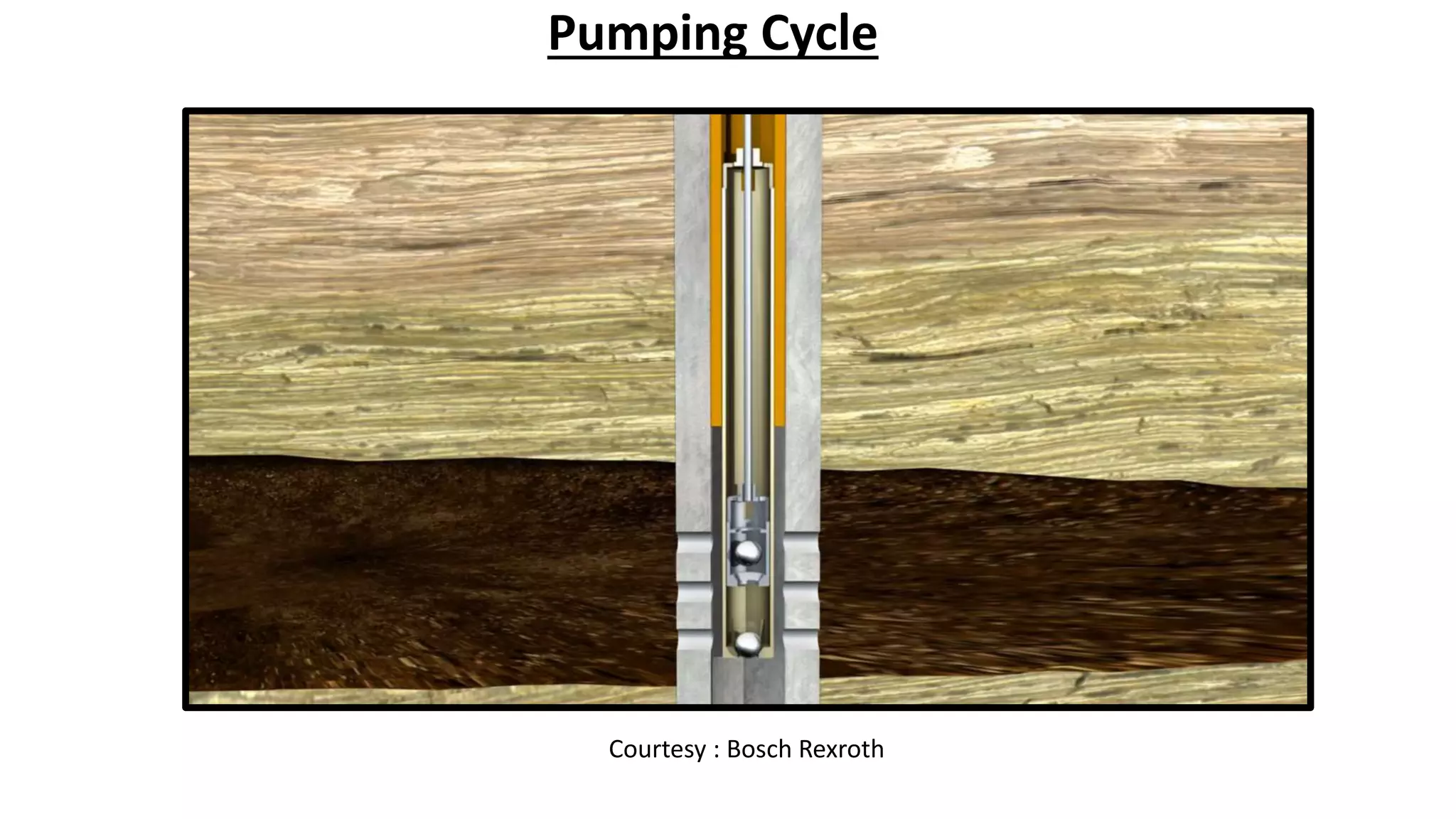

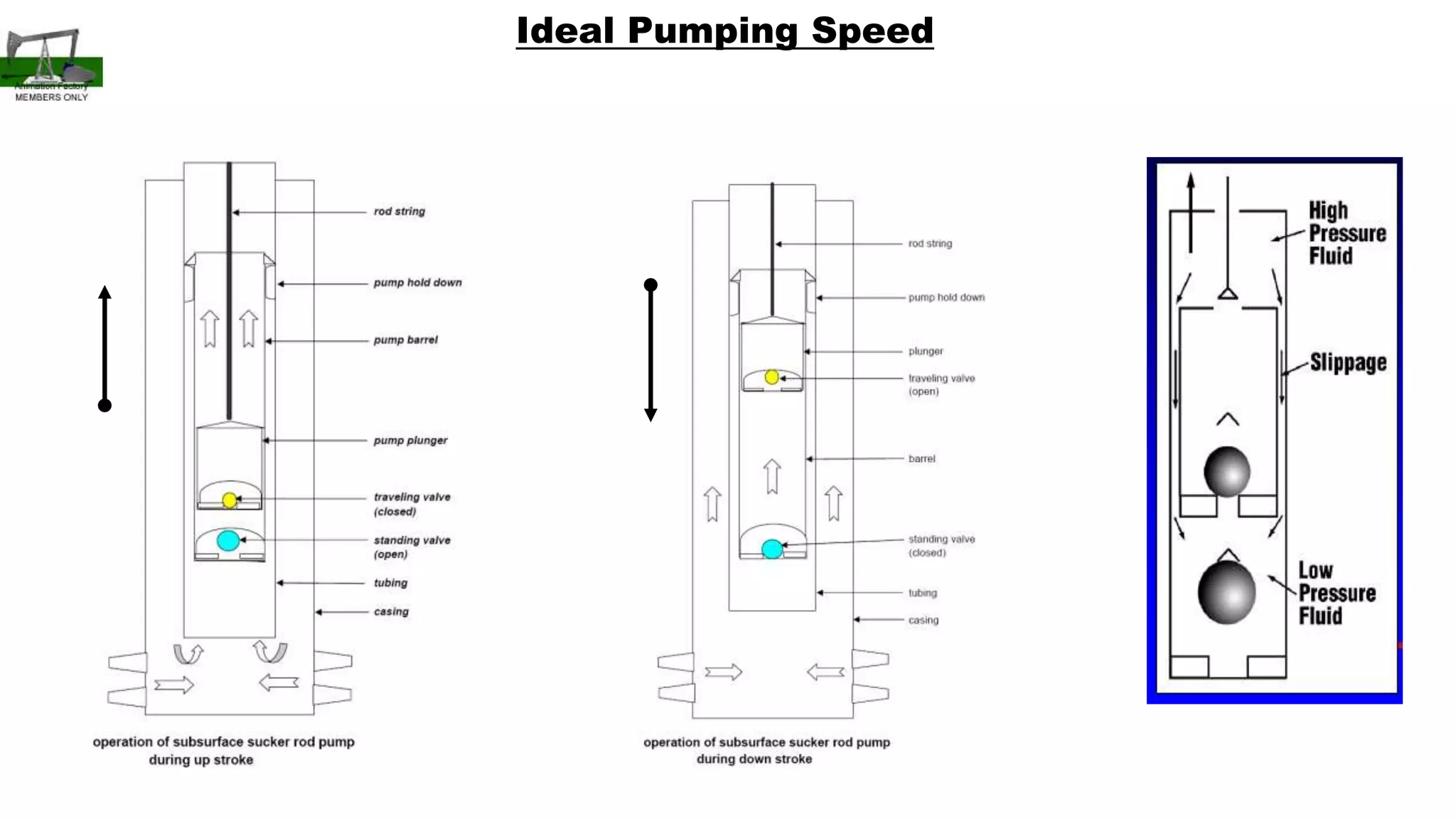

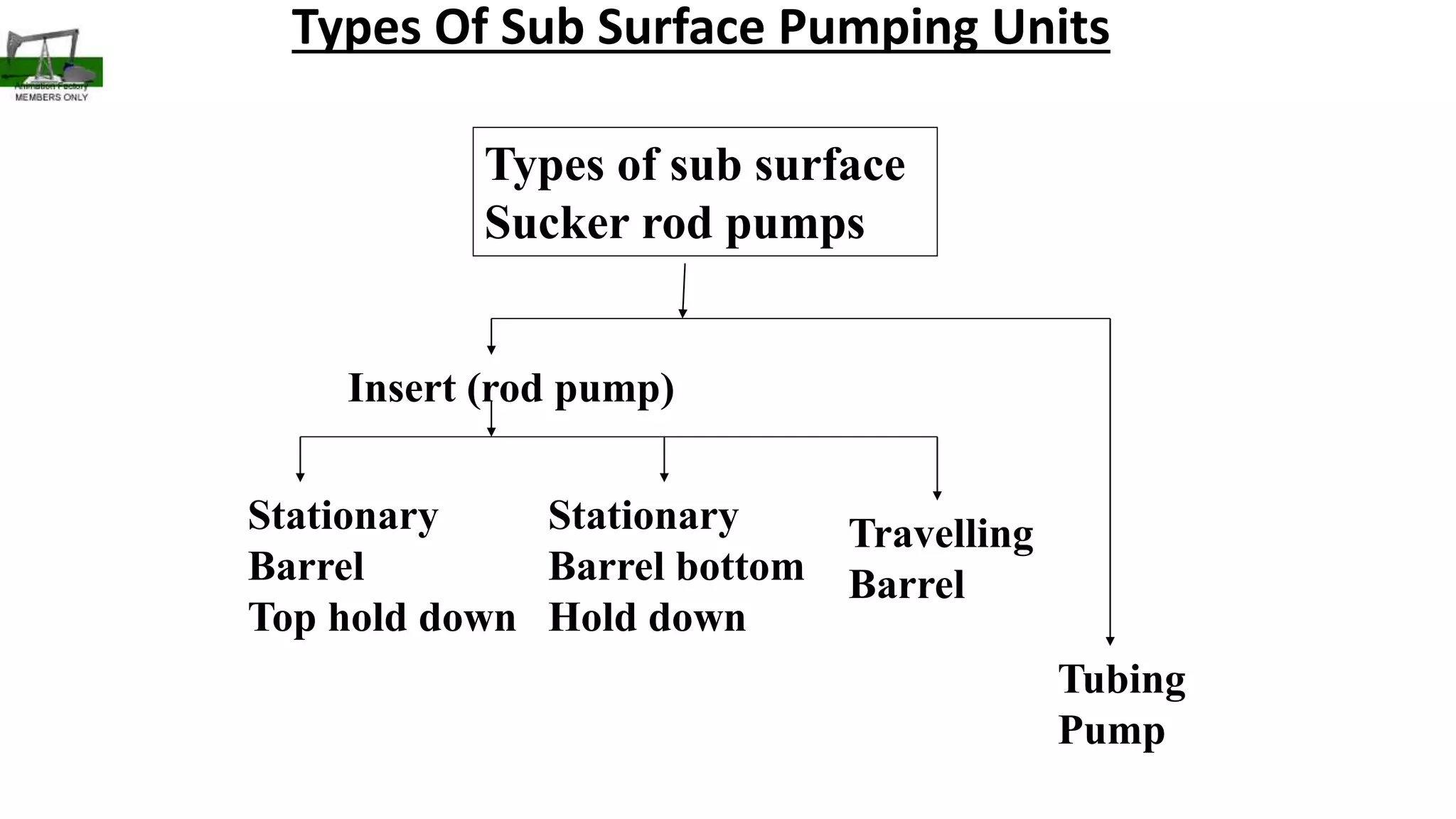

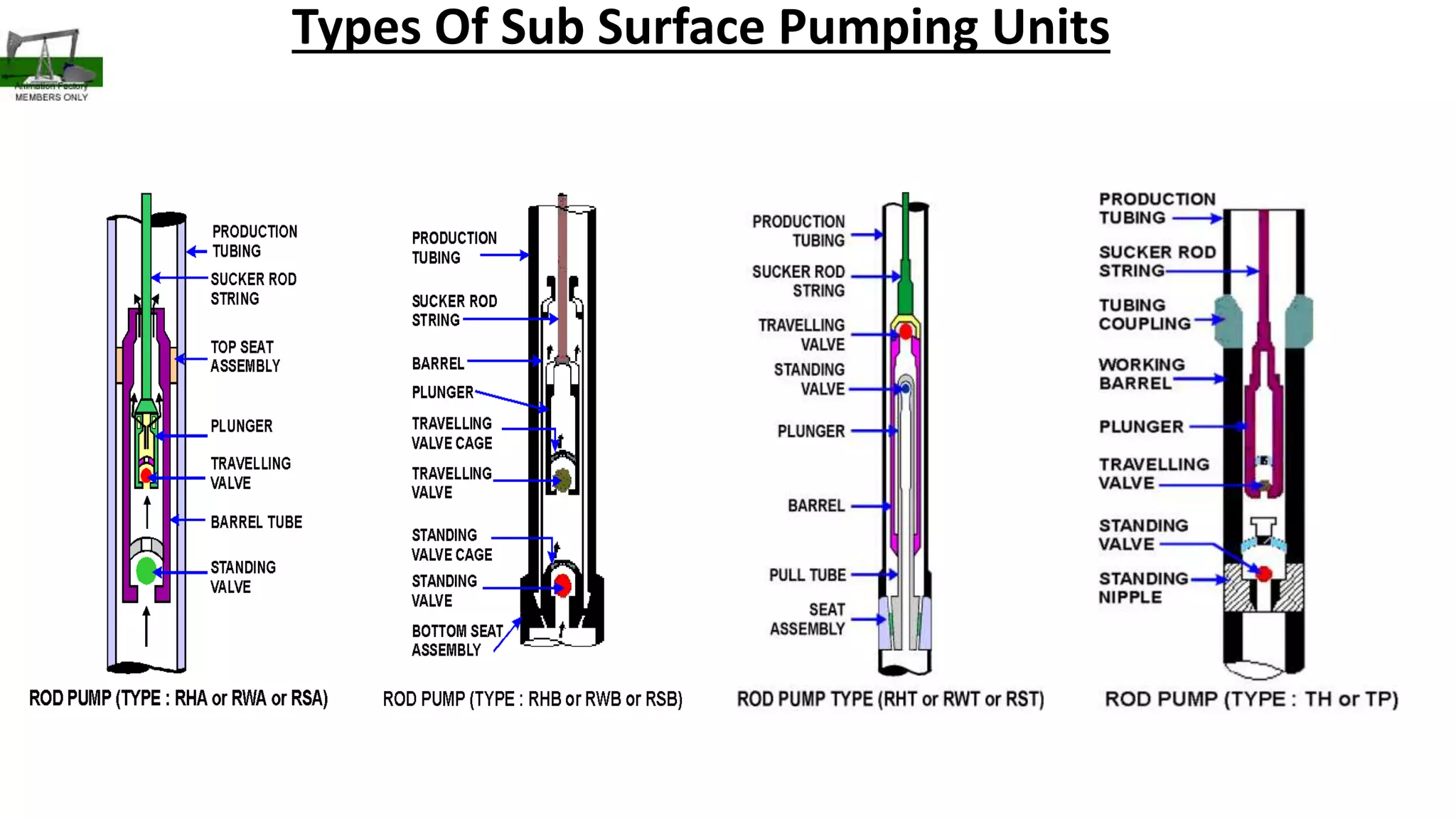

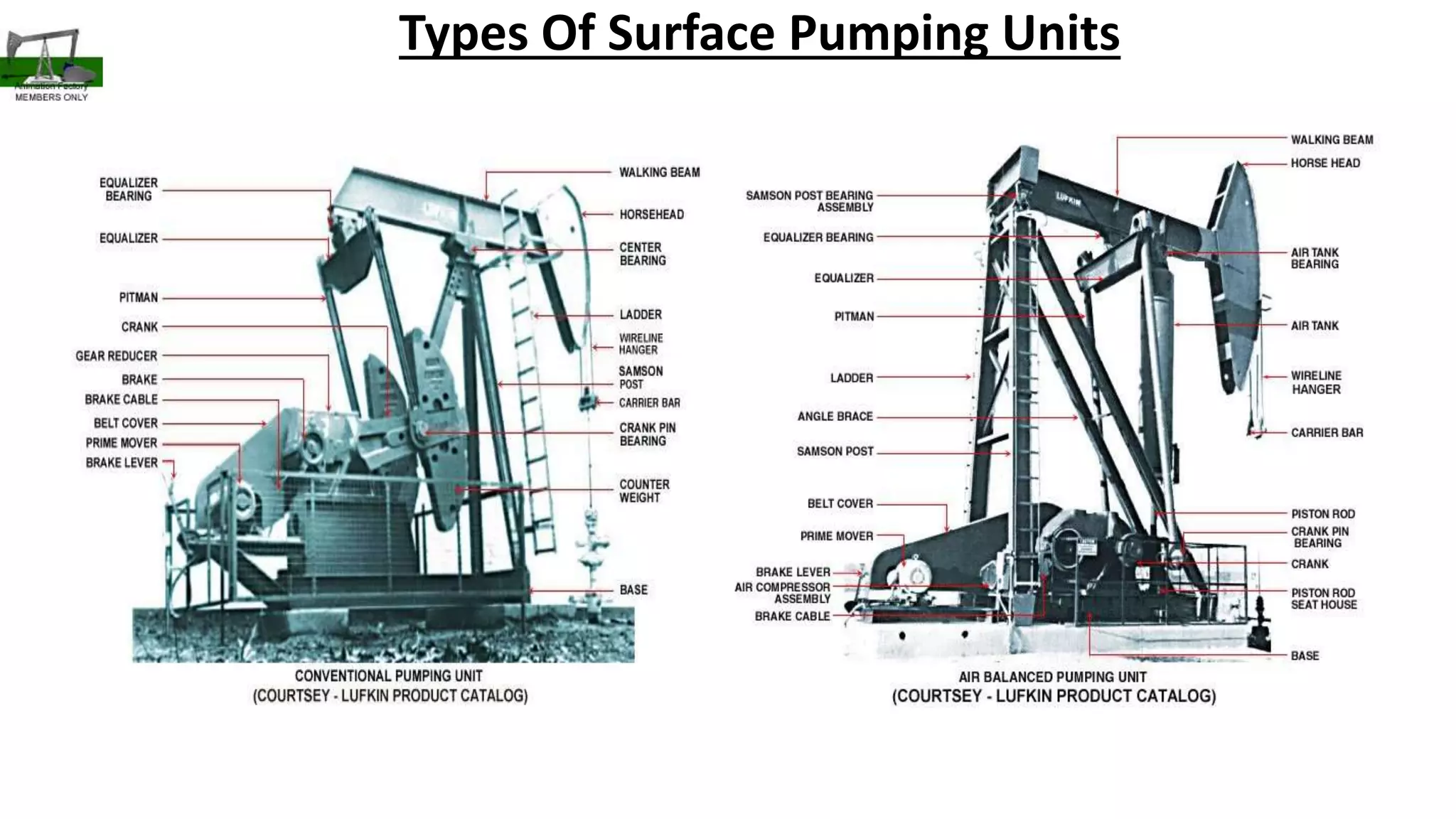

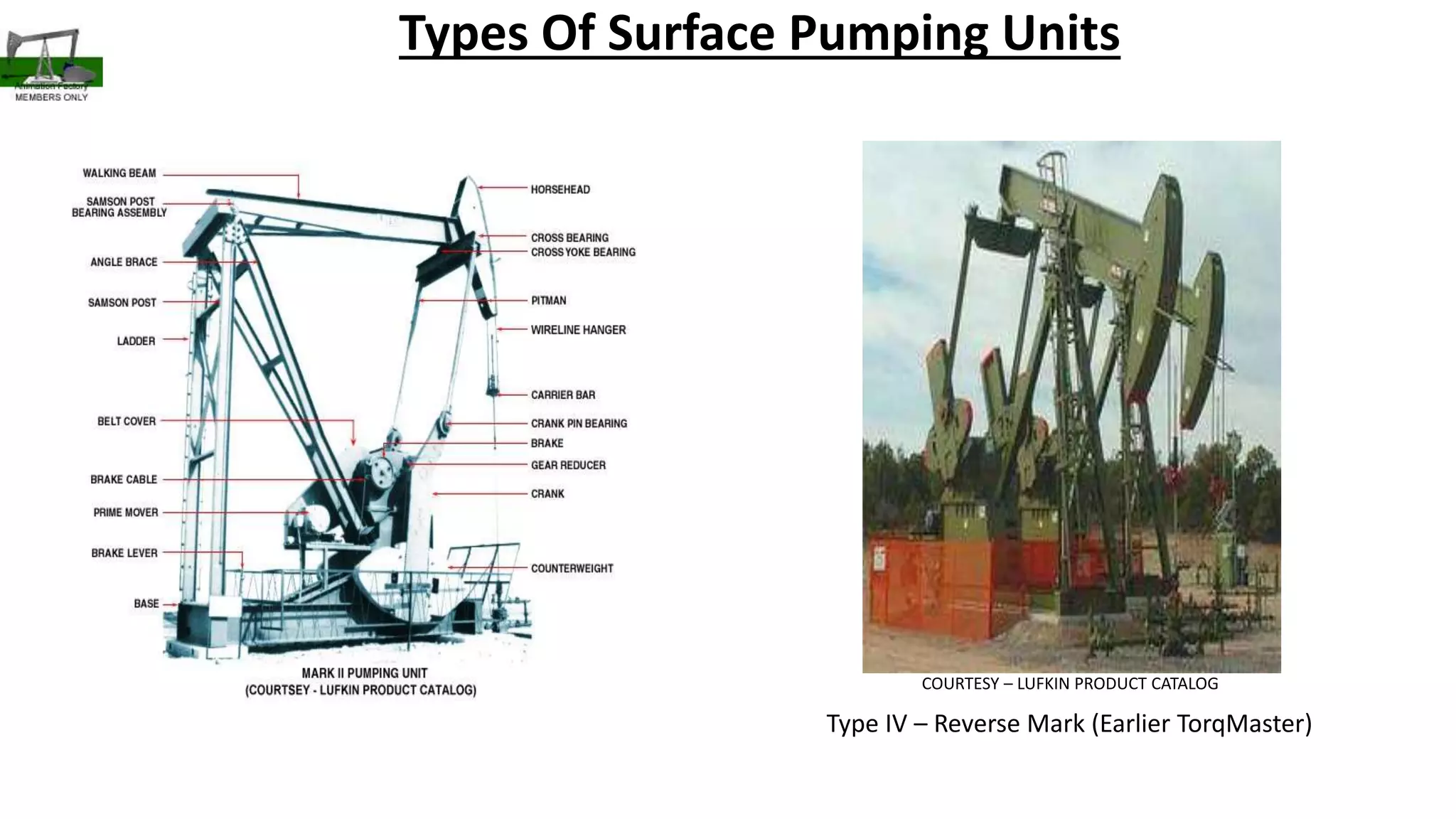

Sucker rod pumps are a type of artificial lift used in oil wells that involves components both above and below ground. The surface pumping unit is connected via sucker rods to the subsurface pump located downhole. The pumping cycle involves the plunger moving up and down inside the barrel, using the traveling or standing valves to draw fluid into the barrel on the upstroke and push it up on the downstroke. Sucker rod pumps are suitable for shallow wells producing 10-1000 bbl/day but become less effective at greater depths or in wells with high gas levels.