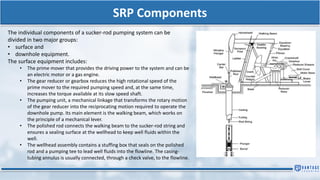

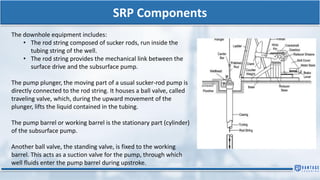

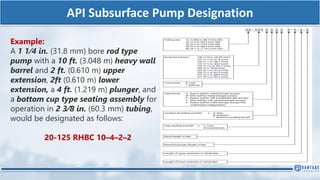

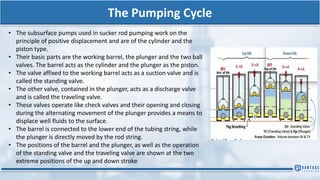

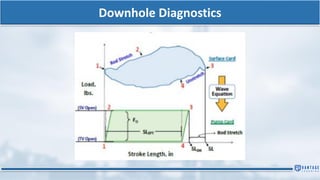

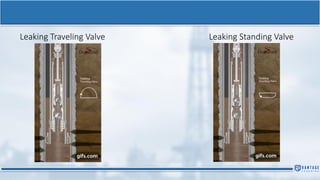

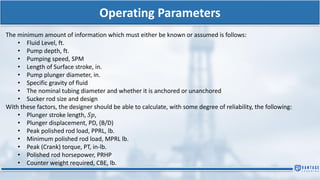

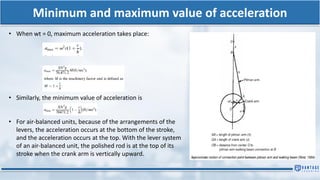

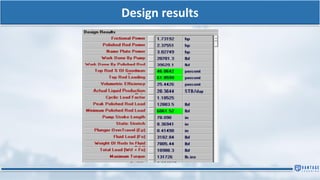

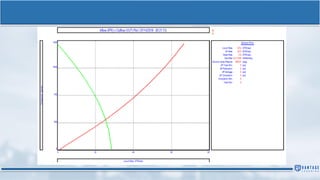

Sucker rod pumps are commonly used to lift oil from wells. They consist of downhole equipment like a pump barrel and plunger, as well as surface equipment like a prime mover and walking beam. The pump operates through a reciprocating cycle where the plunger lifts fluid on the upstroke and releases it on the downstroke. Key parameters that must be calculated for pump design include the maximum and minimum polished rod loads, plunger displacement, torque requirements, and needed counterweight. Issues like fluid pound, gas interference, and leaky valves can be identified from analysis of load versus position cards measured at the surface.