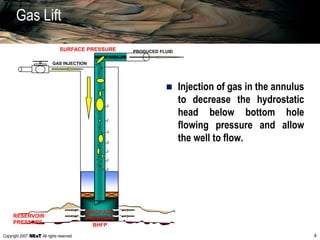

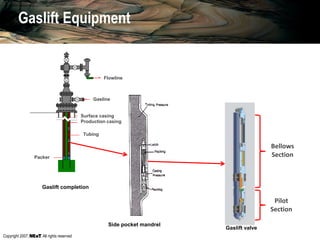

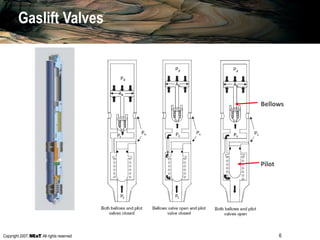

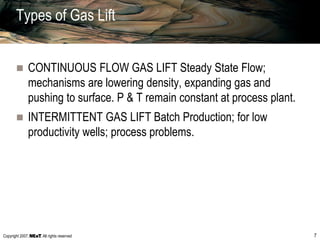

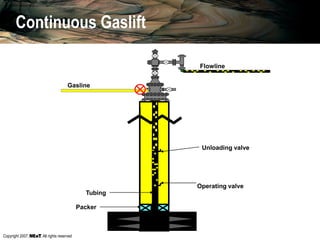

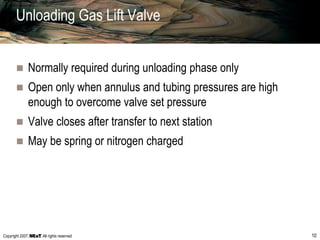

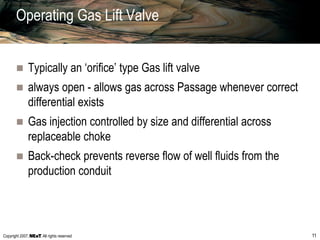

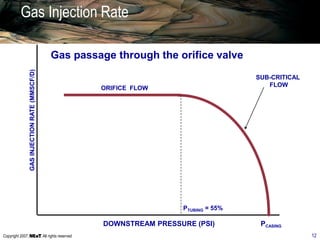

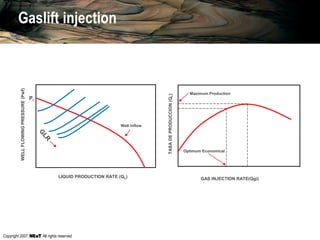

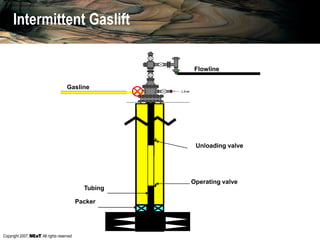

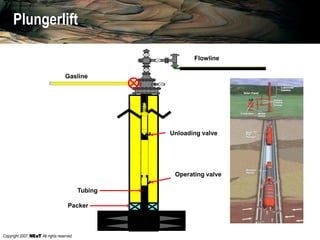

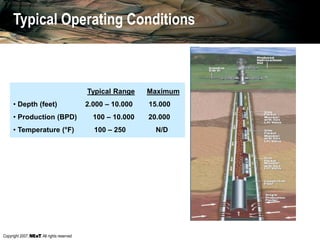

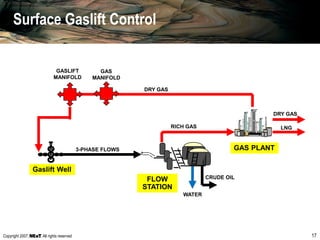

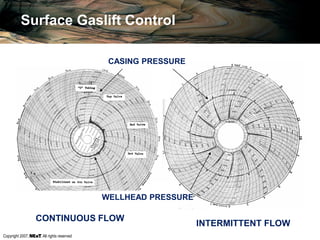

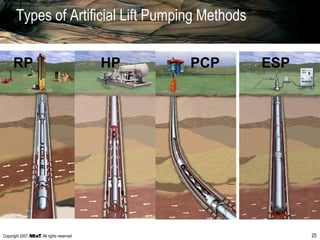

This document discusses gas lift, a method of artificial lift used in oil production. It describes how gas lift works by injecting gas into the wellbore to reduce fluid density and allow the well to flow. The key components of a gas lift system include the gasline, tubing, packer, and gas lift valves. Continuous and intermittent gas lift methods are examined. Advantages include flexibility and ability to handle high production rates, while disadvantages include needing a gas source and potential high installation costs. Troubleshooting techniques and factors that influence gas lift design are also overviewed.