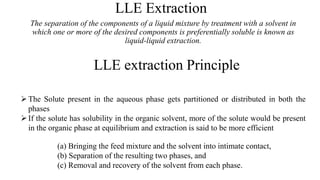

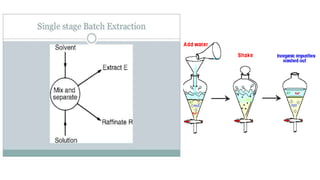

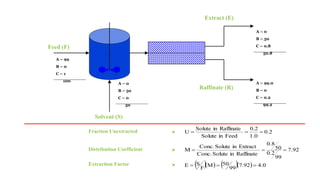

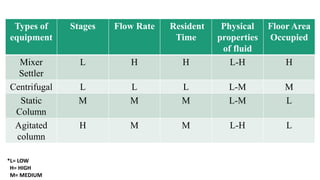

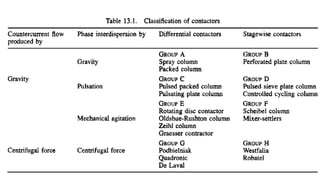

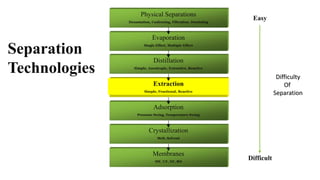

The document details various liquid-liquid extraction techniques and their applications across multiple industries, including pharmaceuticals, petrochemicals, and food processing. It emphasizes the principles and parameters affecting extraction efficiency, as well as the necessary equipment and operational modes for effective separation. Additionally, it compares extraction methods to distillation and provides data on different organic compounds used in these processes.

![Distillation vs. Extraction

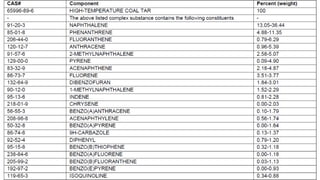

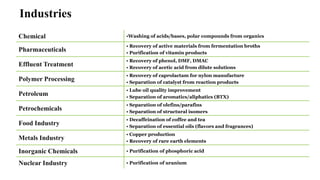

Organic Compound BP [°C]

Water Solu.

[%]

Azeotrope

B.P. [°C]

Azeotrope

Water [%]

Typical Reduction Level

Methylene Chloride 40 2.0 38.1 1.5 < 50 ppb

Acetone 56.2 Infinite Non Azeotropic < 50 ppb

Methanol 64.5 Infinite Non Azeotropic < 50 ppb

Benzene 80.1 0.18 69.4 8.9 < 50 ppb

Toluene 110.8 0.05 85.0 20.2 < 50 ppb

Formaldehyde -21 Infinite Non Azeotropic < 1,000 ppm

Formic Acid 100.8 Infinite 107.1 22.5 < 500 ppm

Acetic Acid 118.0 Infinite Non Azeotropic < 500 ppm

Pyridine 115.5 57 92.6 43 < 10 ppm

Aniline 181.4 3.60 99.0 80.8 < 10 ppm

Phenol 181.4 8.20 99.5 90.8 < 10 ppm

Nitrobenzene 210.9 0.04 98.6 88.0 < 10 ppm

Dinitrotoluene (2,4) 300.0 0.03 99 – 100 > 90 < 10 ppm

Dimethyl Formamide 153.0 Infinite Non Azeotropic < 10 ppm

Dimethyl Acetamide 166.1 Infinite Non Azeotropic < 10 ppm

n-Methylpyrrolidone 202.0 Infinite Non Azeotropic < 10 ppm

ExtractionDistillation](https://image.slidesharecdn.com/liquid-liquidextraction-190205091504/85/Liquid-liquid-extraction-6-320.jpg)