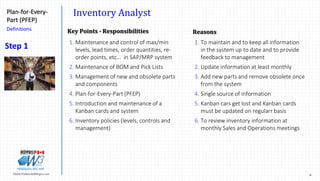

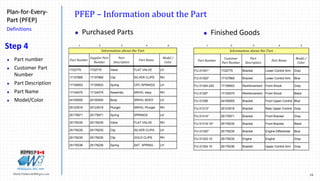

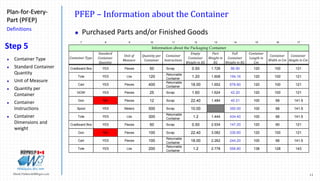

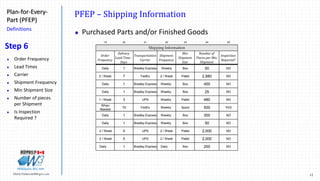

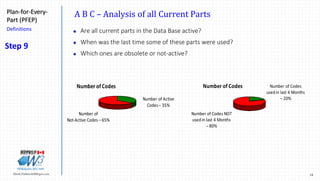

This document provides information and guidance on developing a Plan for Every Part (PFEP) database. It recommends establishing an Inventory Analyst role to be responsible for the PFEP database. It describes collecting information for the database on parts, containers, shipping, and developing a plan based on the data. The goal is to gather and maintain updated information on all material used in processes to facilitate planning and inventory management.