Curriculum Vitae Insights

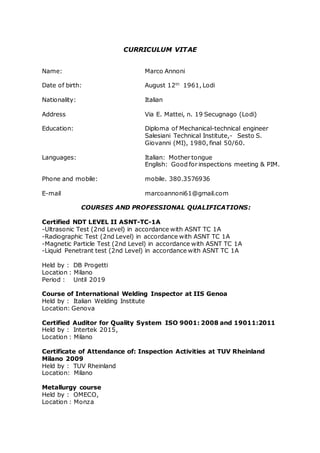

- 1. CURRICULUM VITAE Name: Marco Annoni Date of birth: August 12th 1961, Lodi Nationality: Italian Address Via E. Mattei, n. 19 Secugnago (Lodi) Education: Diploma of Mechanical-technical engineer Salesiani Technical Institute,- Sesto S. Giovanni (MI), 1980, final 50/60. Languages: Italian: Mother tongue English: Good for inspections meeting & PIM. Phone and mobile: mobile. 380.3576936 E-mail marcoannoni61@gmail.com COURSES AND PROFESSIONAL QUALIFICATIONS: Certified NDT LEVEL II ASNT-TC-1A -Ultrasonic Test (2nd Level) in accordance with ASNT TC 1A -Radiographic Test (2nd Level) in accordance with ASNT TC 1A -Magnetic Particle Test (2nd Level) in accordance with ASNT TC 1A -Liquid Penetrant test (2nd Level) in accordance with ASNT TC 1A Held by : DB Progetti Location : Milano Period : Until 2019 Course of International Welding Inspector at IIS Genoa Held by : Italian Welding Institute Location: Genova Certified Auditor for Quality System ISO 9001: 2008 and 19011:2011 Held by : Intertek 2015, Location : Milano Certificate of Attendance of: Inspection Activities at TUV Rheinland Milano 2009 Held by : TUV Rheinland Location: Milano Metallurgy course Held by : OMECO, Location : Monza

- 2. APPROUVED BY COMPANY: CPECC, ENPPI, PETROFAC HITACHI, ADCO, ZADCO, Kuwait Gulf Oil Company (K.S.C.), K.O.C, CCED, Arabian Power C0.(UAE), CCC, QCLNG PIPELINE PTY LIMITED (Queensland – Australia), ENI OIL, MELLITAH OIL & GAS BV, DOLPHIN ENERGY. COMPONENTS KNOW: Forgings, Plates, Pipes, Piping, Fittings, Induction bends, flanges, Heat exchangers, - Heater and cooling equipment, Pig launcher/receiver, chiller Pressure vessels, Strainers, Separators, Steel structures, Tanks, Valves: manual and motor operated (Gas-over-oil, electric,); Instruments Cables, Power Cables, Safety valves and ControlValves, Skid for CO2 performing MAIN EXPERIENCES Forged components for Ball Valves, Filters, Vessels, Pig Launcher, etc.; Follow the production and Inspection of NDT, Laboratory test, PMI, visual & dimensional, Material Test Certificate and packing. Main Supplier: FORGITAL, SIDERFORGE, FORGEROSSI, F.M.A., FORGIA di BOLLATE, FACS FUCINE, FOMAS, RING MILL, ASFO, FORG. VIENNA. Casting components for valves, strainers, etc.(NDT, Mechanical test, PMI, visual & dimensional); Follow the production for expediting and Inspection of NDT, Laboratory test, PMI, visual & dimensional, Material Test Certificate and packing. Main Supplier: INOSSMAN, FONDINOX, FAREM, FLAG, LUCCHINI, Coatings: polyethylene, resins, bitumen, etc.; Inspection on oil & gas components for cleanness, sand-blasting, roughness, application parameters, protection for shipment Main Supplier: RIVESTUBI, RIVECO, SIGMA, SAVI, LENA,

- 3. Valves: (Ball, Gate, Check, Plug, Butterfly, Swing, Safety valves) Inspection on raw materials(forging/casting), NDT test on components, NDT on welding overlay, pressure test, functional test, qualification test, heat treatments valve-pup piece, Visual & Dimensional check, coating, packing. Main Supplier: PERAR, CAMERON, BREDA, VALVITALIA, FASANI, TYCO, MIBB, PETROLVALVES, PIBIVIESSE, FIORENTINI, PARCOL, KSB, NUOVO PIGNONE, RINGO O VALVE, SIMER, TAI, ORTON, VALVOMECCANICA, GALLI & CASSINA, OMB, STARLINE, DELLA FOGLIA, INVALVES, Pressure vessel, strainers, filters, pig launcher, Inspection of single components, mechanical test c/o laboratory, pressure test, visual & dimensional check against approved DWG, functional check(quick closure), coating check, MRB review, packing and shipping. Main Supplier: OMSA, SIRZ, F.B., GRANZIERO, NICOLA & ALBIA, FULGOSI, TECNOSPECIAL, CELLA, ANGIOLETTI, ORMIS, DELTA Engineering, FAI, CDB. GENERAL INSTRUMENTS. Valves operator, gas-over-oil, spring return, electrical, pneumatic. Inspection on raw components, torque performance on test bench, pressure test, visual & dimensional against DWG, visual & dimensional check, coating, MRB, packing. Main Supplier: BIFFI, LEDEEN, VALVITALIA, BETTIS, etc. Activity on Test Laboratory Certification 3.2 on test laboratory for Mechenical test, Corrosion test, NDT. Main Laboratory: OMECO, SIDER TEST, QUALITY CONTROL, LPM, VALVITALIA, etc. Induction bends Inspections on mother pipes, check of production parameters, NDT, Mechanical Test, visual & Dimensional check, coating, packing. Main Supplier: MANNESMANN, SIMAS, VALVITALIA, Pipes Supervision and inspection of, SAW, HFW, SS, pipe production, check of production parameters, NDT, Mechanical Test, Visual & Dimensional check, coating Main Supplier: EUROPIPE, ILVA, VALLOUREC, TENARIS, ARVEDI, GENERAL SIDER, TPCO. Fittings cold formed and forging formed Inspection on mother pipes and plate, NDT on welding and base metal, Heat Treatment check, Mechanical test on welding and base material, Visual & Dimensional check, low stress marking check, coating, packing. Main Supplier: ALLIED, TECNOFORGE, BASSI, MUNRO & MILLER OMR, PETROLRACCORD, GAM RACCORDI, VALVITALIA, CHERO PIPING, RACCORTUBI, OMR,

- 4. Loading Arms for Cryogenic methane: Inspection on raw materials, test of welding procedure, test of emergency double ball valves, installation check and functional test with remote control. Main Supplier: FMC. Centrifugal Pump: Inspection NDT on casting case, pressure test, performance test, dimensional check, coating, packing, Main Supplier: TERMOMECCANICA PUMPS, KSB; Engineering Skid: Manage PIM, check of DWG, analyze ITP, construction procedure, attend to pressure test, functional test, performance check, visual & dimensional check against DWG, follow P&ID, coating and packing. Main Supplier: FORAIN, METANO IMPIANTI, REPCO, PREMABERGO, BEA FILRI, SIIRTEC, SICON OIL, JOHN ZINC, WTD. MV- HV Electric Cable: Inspection on Type Test, Performance test, Dimensional check, control of drum marking, Main Supplier: PRISMIAN Electrical Heater: Inspection on Pressure test, Functional test, coating, MRB MASTERWATT; LIST OF MAIN PROJECTS MANAGED Jebel Dhanna Replacement Of Unidirectional By Bi-Directional Meter Prover System– Adco; Satah Facilities Replacement Of Main Diesel Generators At Arzanah Power House - (Zadco); Two Eocene Tanks and Two Chemical Storage Tanks at mgc Project - Saudi Arabian Chevron inc.+ Kuwait Gulf Oil Company (K.S.C.); New Export Transit Pipelines From New Bs-171 To Agrp At Mina Al-Ahmadi – K.O.C./K.S.C.; EPF and Main Production Facilities and Pipelines and future Development - CCED Oman; EPC 12” Pipeline from Takreer to Umn al Nar Power Station - Arabian Power CO (UAE); Construction of new Pipelines at Mina Ahmadi - KOC Kuwait; Export Pipeline & Gas Collection Header - QCLNG PIPELINE PTY LIMITED (Queensland-AUSTRALIA); Bu Hasa Shuhaiba Unit “H” - Water Injection Enhancement - ADCO UAE; A-100 Low Pressure Facilities & Arrival Manifold - MELLITAH OIL & GAS BV; EGDS Upgrade - EPC Works For East & West Systems - Dolphin Energy.

- 5. MAIN ACTIVITIES MANAGED Inspection of welded pipes for pipeline and qualification the new ultrasonic plant in ILVA mill (Taranto), coordinate the team of assigned inspectors (Moody). Inspection of production of weld pipes in Vallourec in Sedan (F), coordinate the team of assign inspectors (Scoop). Inspection of production of bends in Munro & Miller (Edimburg). Inspection of loading arms for liquid methane in FMC France(Sens) for ENI port in La Spezia, inspection the relevant construction, Inspection of 48” x 56” pig launch in SIRZ (Padova), hydraulic test, RT, UT, and functionality. Tests on cryogenic valve in Vanessa plant (Fiorenzuola PC). Inspection of 24” ANSI 600 plug valve in Cameron/Grove (Voghera) . Inspection of plug and ball valves manufacturer by Valvitalia factory (Rivanazzano PV) . Inspection on EUROPIPE rohrwerke for qualification of API X80 SAW weld pipes and inspection the production. Inspection on SALZGITTER plant for Mannesmann induction bend API X80 material. Manage of pre-inspection meetings for verification and confirmation of the contract documents, drawings, specifications and procedures; Among all: -Tianjin Pipe Corporation (CHINA), -WARTZILA Diesel Engine (FINLAND), -CAMERON Valve (ITALY), -Zunt (ITALY); Review the SNAM specification for fittings to extend to API X80 material. Review the SNAM specification for gas heather in remote control and start. inspection for Ansaldo Nuclear division in Criotec plant in Chivasso by fugitive emission on experimental nuclear components for Paul Sergie Institute (CERN). inspection for MED.OIL/SIRTE OIL COMPANY(Libya) on replacement of tube-bundle on SS heat exchanger. Editing of new API X100 material specifications for pipes and bends for ENI’s experimental Sardegna pipeline project, PREVIOUS WORK EXPERIENCES: October 2007 to 2016 SICON OIL & GAS – E.P.C. of CCC Group Project Quality Manager, Supplier Quality Coordinator, Analysis and approval of quality documents, Inspections of Pressure Equipment and Machinery, Expediter and Inspections on main components, Interface for Quality Department in Audit ISO 9001, Qualifications of new suppliers by mean Audit, test on components and check the procedures, equipment and, manufacturing. Definition the final quality dossier for each equipment’s QRB (Quality Record Book). Manage the quality of projects on the suppliers chain, solve client claims, ensure the conformance of equipment’s to the Client specifications; Analysis of quality control plans, ITP and construction/control procedures of Vendor prior to start the production to verify that they meet with requirements of customer specifications;

- 6. February 2005 to September 2007: TÜV NORD Inspections, Expediting, Qualification as Third Parts on Components and Welding procedure and welding operator. Inspection Activity on behalf of ANSALDO NUCLEARE on components for NUCLEAR PLANTS in CAORSO & CERNAVODA. Inspection & expediting of pressure equipment’s on behalf of Mc Dermott on Q.GAS project, NDT inspections on welding overlay on 48”, class 1500, top entry valve Cameron for Q.GAS project, • Inspection on behalf of SIRTE OIL COMPANY of pressure vessels and heat exchanged laugh; • Inspection & Qualification test on laboratory on welding processes and the welding operators. • Inspection for Qualification of "Fire Test" on Ball Valve • Inspection for upgrade the components in the facilities of the Caorso (PC) nuclear power station, • Supervision & Inspection by Fugitive emission on experimental components for nuclear-Institute for CERN (Swisse), Audit of ISO 9001 for Qualification of new suppliers, new materials and testing of prototypes; • Inspection on components for nuclear power plants in Cernavoda(ROM) Lisega, Idrosapiens (expansion joints), Flowserve(Laboratory valves). Criotec (experimental vessel for CERN), March 1985 to January 2005: SNAM RETE GAS • Strategic material inspections, site and prototypes testing, • Functional and Non Destructive Inspection. • Qualifications of Strategic Components and new Suppliers. • Quality system Audit of suppliers. • Issue and review of specifications for strategic materials. Purchaser Order Management of Strategic material, verification of ITP, site inspection for verification of the causes and restore failures; Functional and Non Destructive Inspection of components for gas site, pipelines and pressure reduction stations, Attending to Tests and Controls, on productions Pipe, Fittings, Bends, vessels, (NDT) to the manufacturer to verify the performance and accuracy of the materials with the data sheet, drawings, control plans, client specification, and the correctness of Certification (Test Reports, MTC); Preparation and review of specifications for strategic materials; November 1984 to February 1985: MASERATI Cars • QC on main components before admit on assembling line; • Check the problems on main components on assembling line in order to solve it.