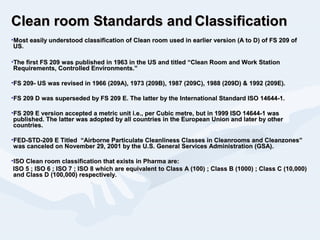

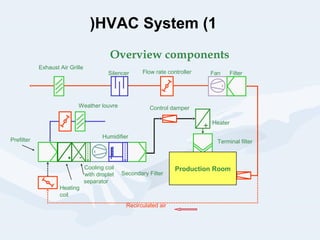

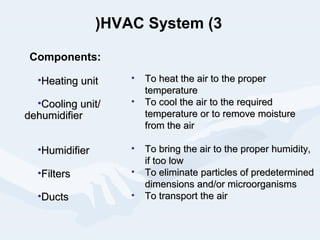

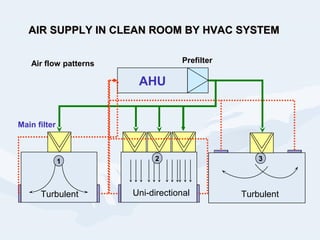

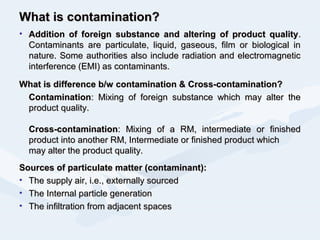

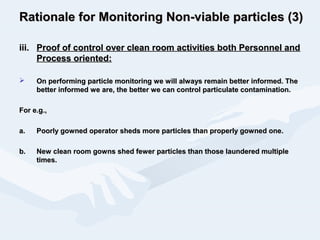

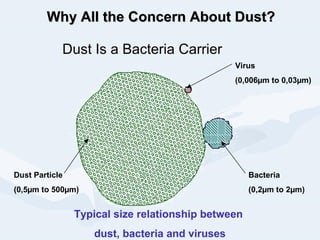

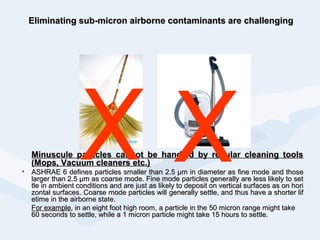

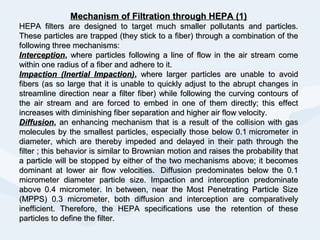

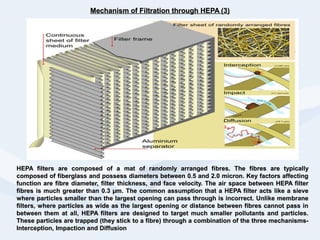

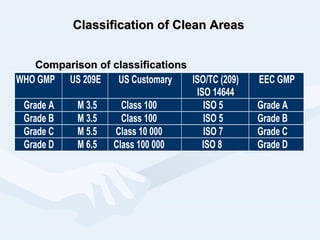

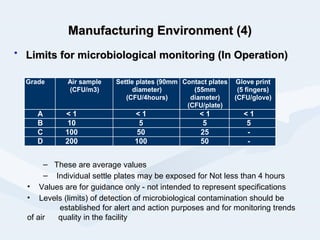

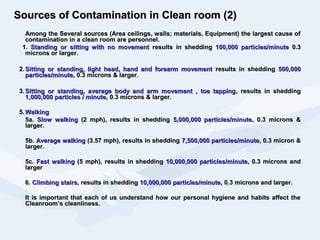

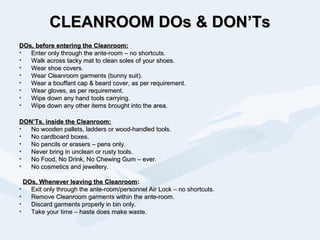

The document provides an overview of clean rooms, including their purpose, key components, classification standards, and importance in the pharmaceutical industry. A clean room is a controlled environment designed and maintained to reduce contamination through strict control of particulate matter and other pollutants. Clean rooms are classified based on standards like ISO and use HEPA filters to purify air circulation. Proper clean room certification and validation is important for ensuring safety and quality in pharmaceutical manufacturing as required by cGMP guidelines.