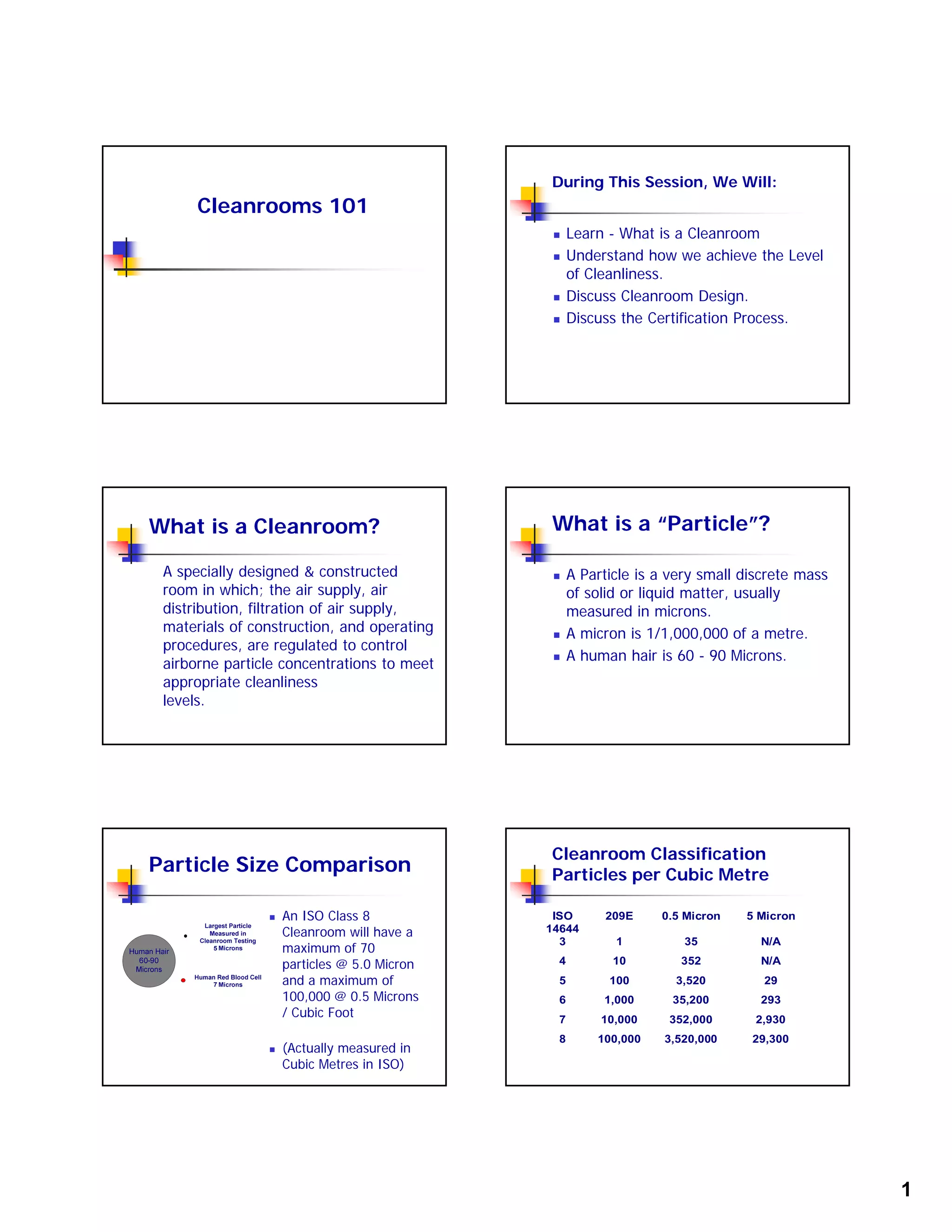

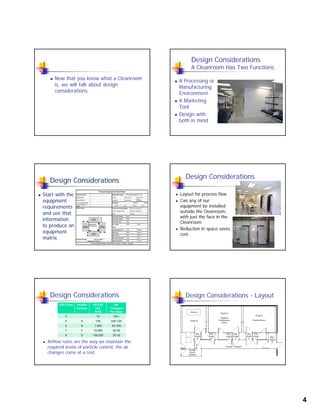

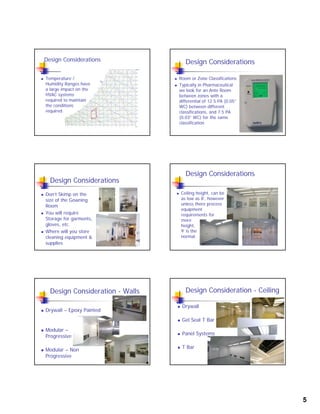

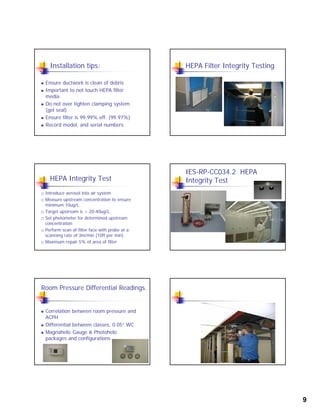

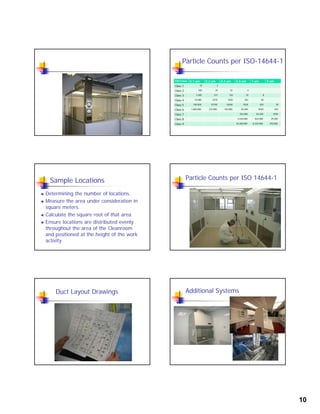

This document provides an overview of cleanrooms, including their purpose of controlling airborne particle concentrations, classifications based on particle levels, sources of contamination, and design considerations. Cleanrooms aim to maintain cleanliness levels through isolation of contamination sources, filtration of air supplies, and regulating air flow, temperature, and humidity. Particle testing and certification ensure cleanrooms meet standards like ISO 14644-1.