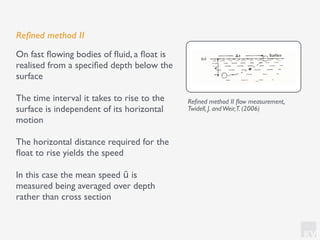

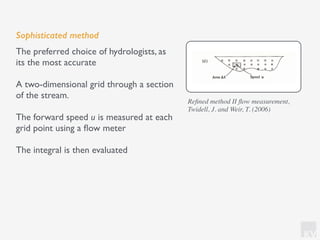

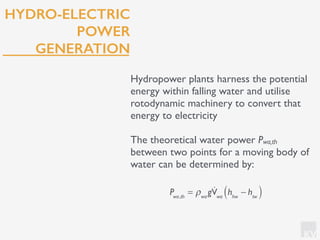

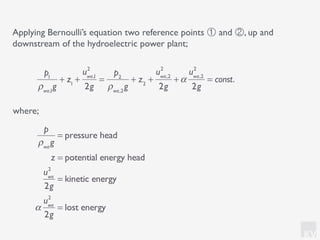

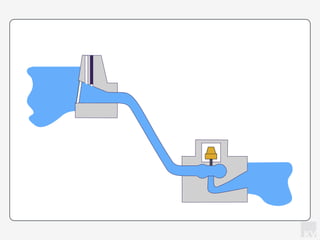

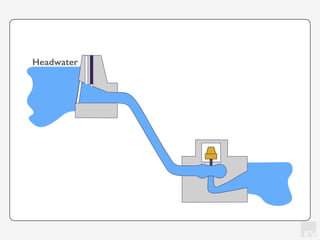

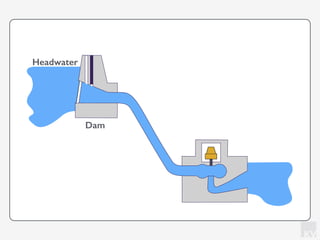

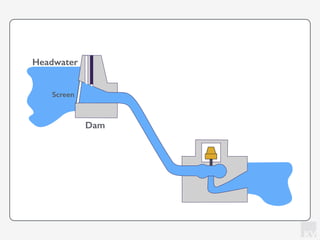

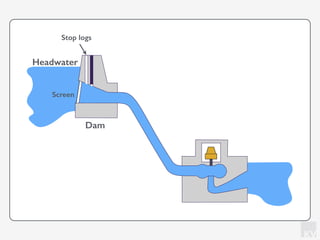

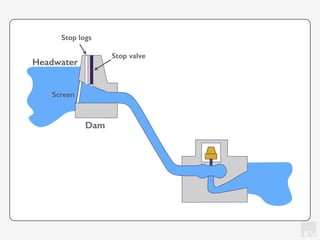

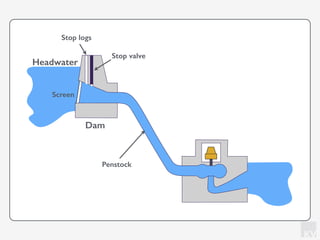

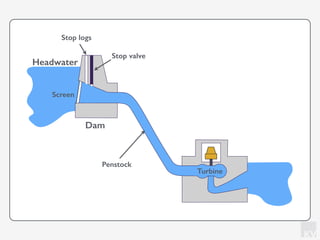

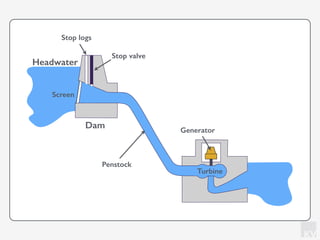

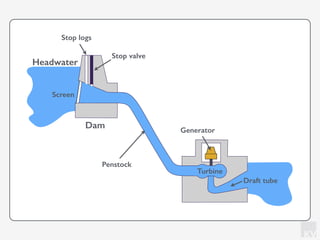

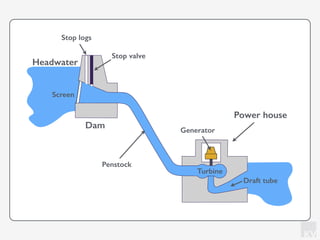

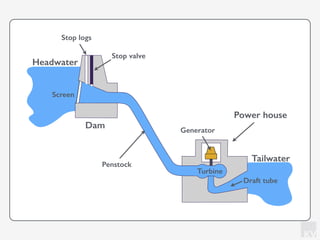

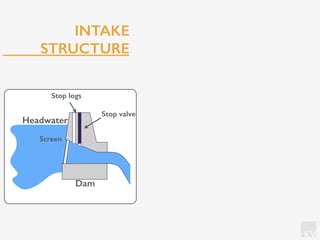

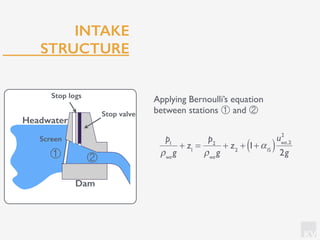

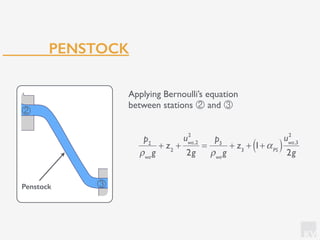

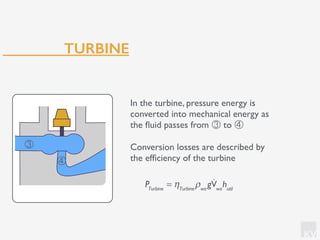

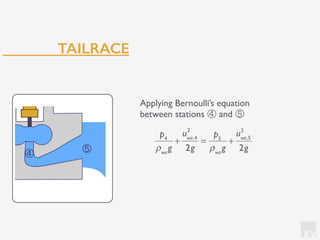

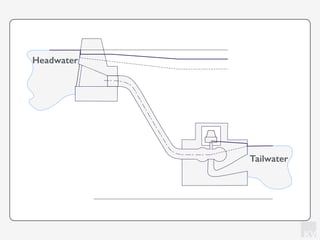

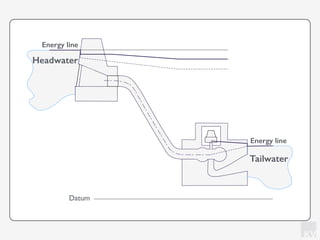

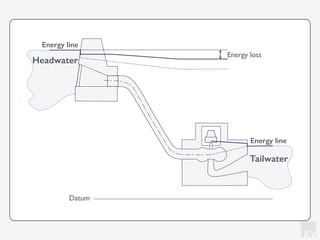

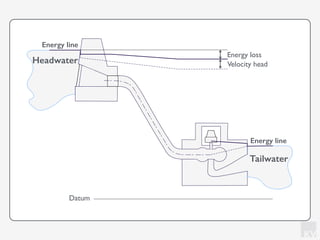

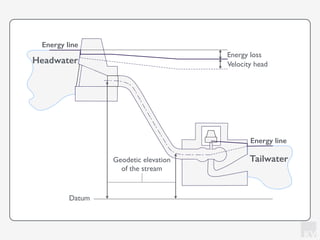

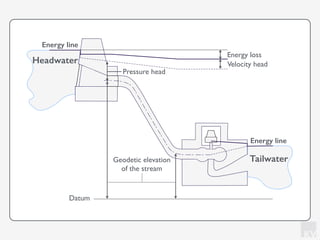

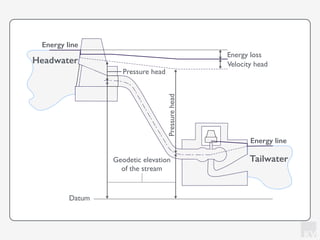

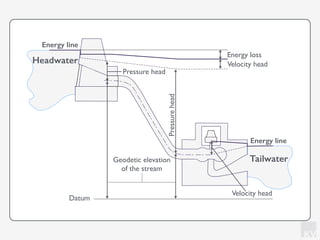

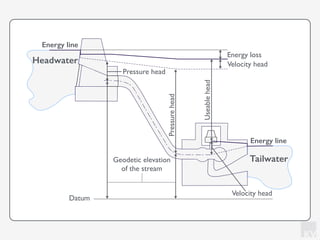

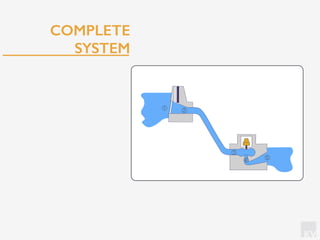

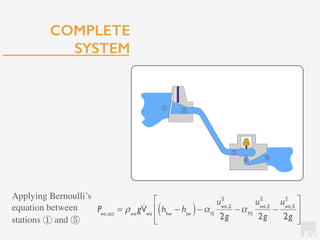

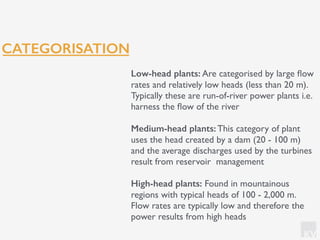

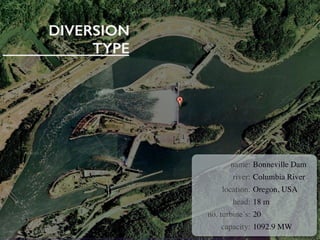

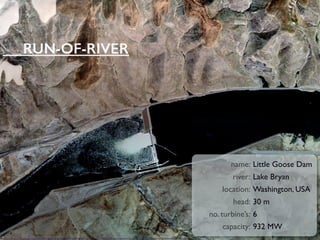

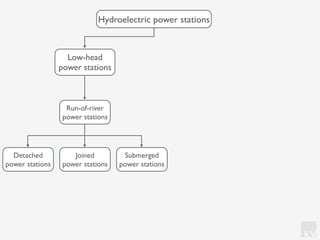

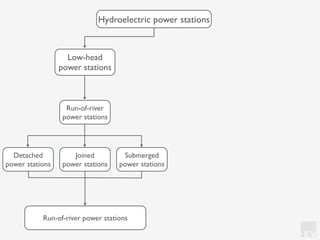

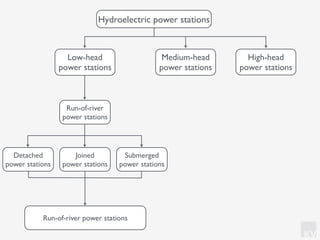

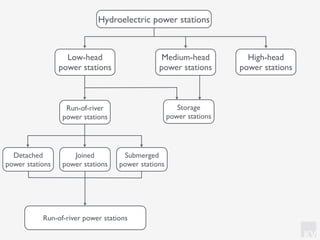

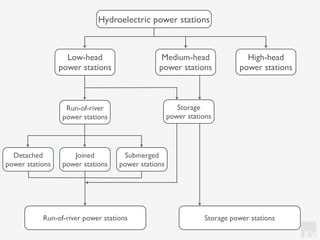

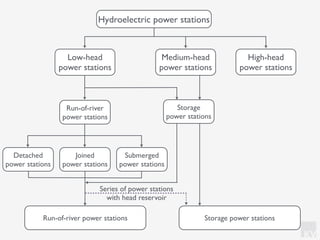

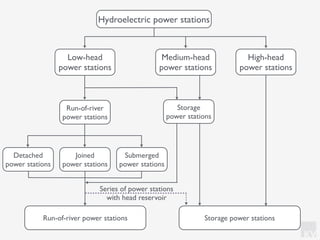

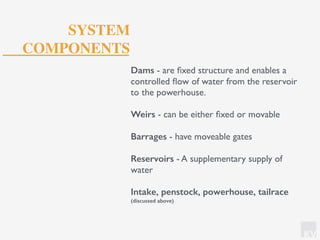

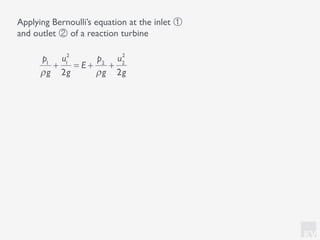

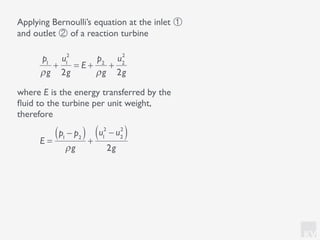

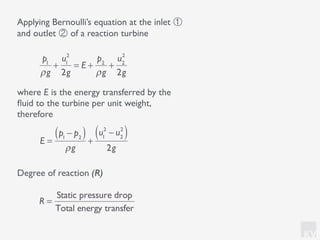

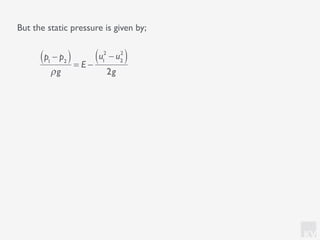

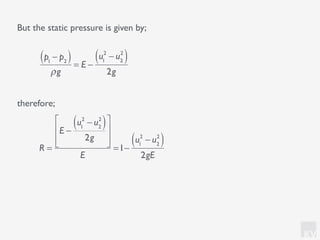

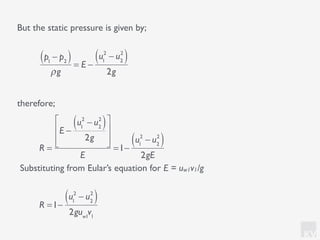

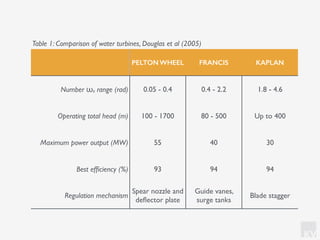

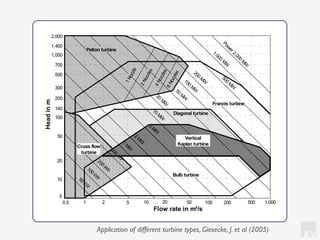

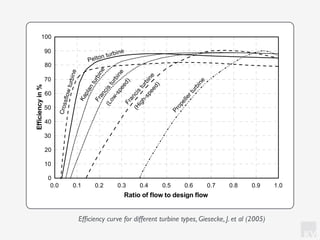

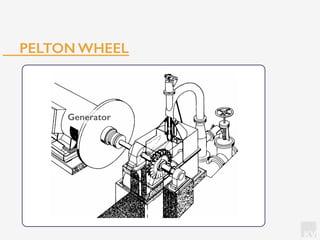

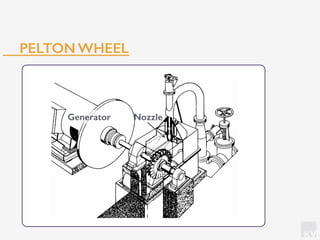

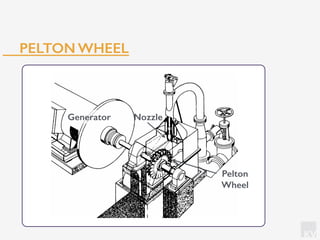

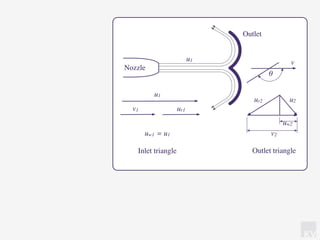

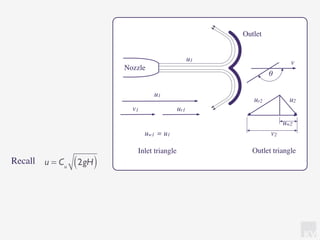

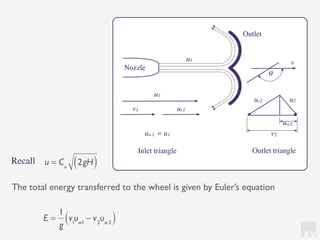

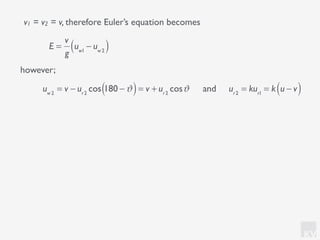

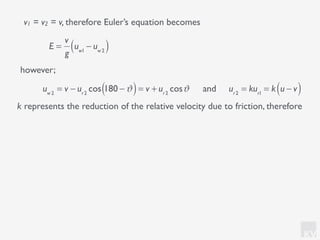

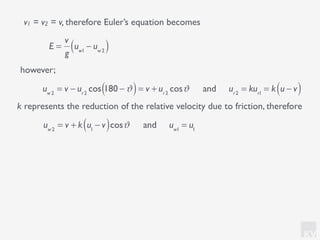

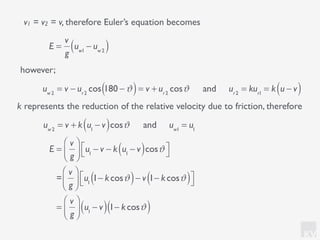

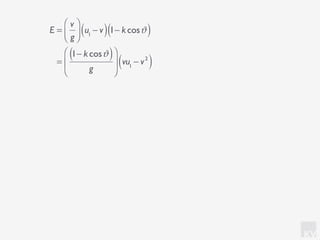

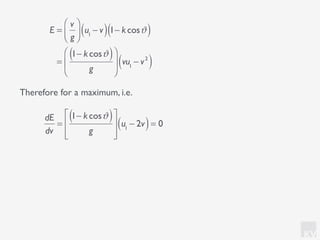

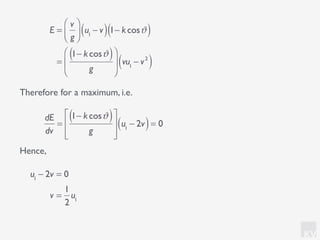

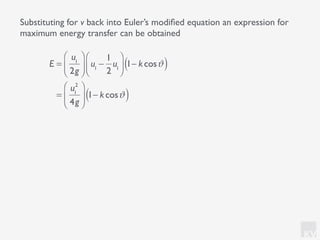

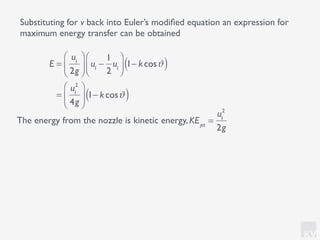

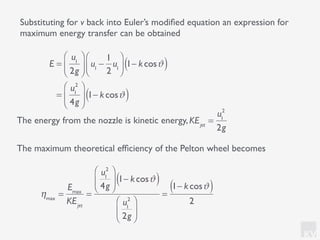

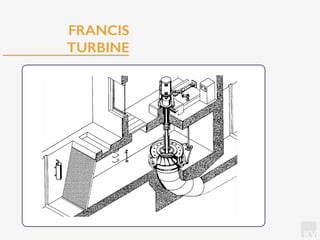

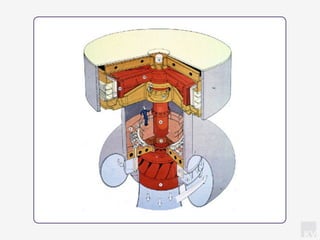

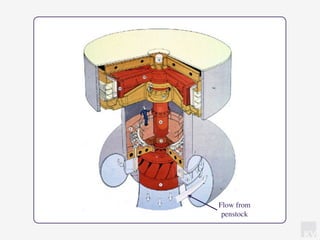

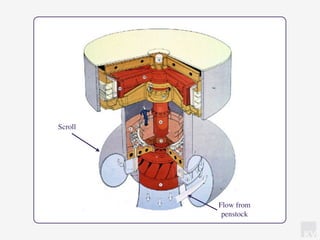

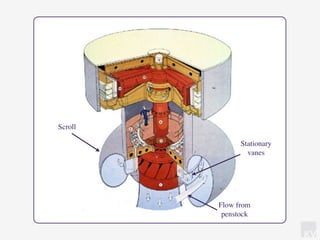

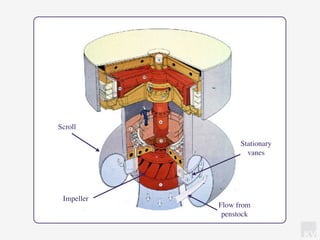

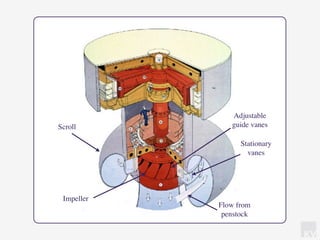

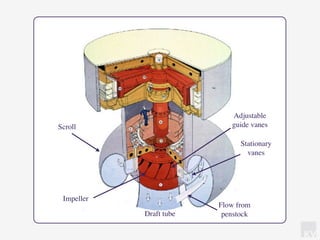

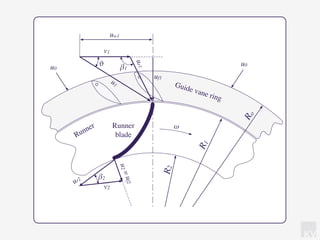

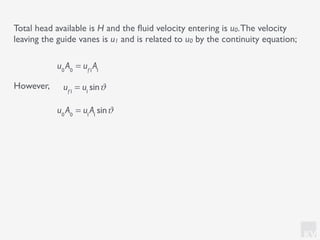

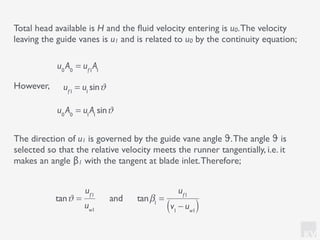

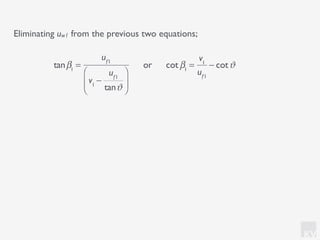

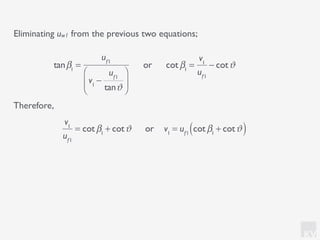

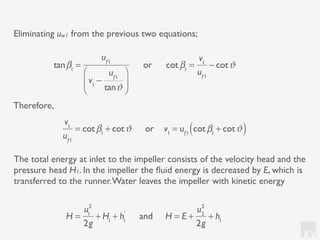

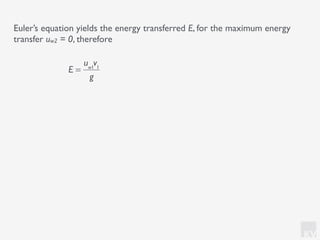

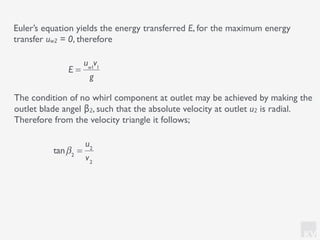

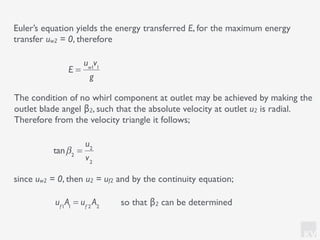

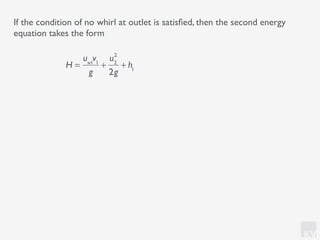

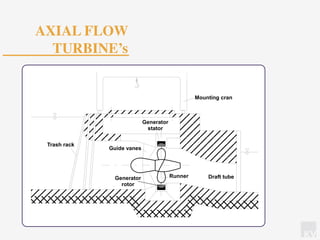

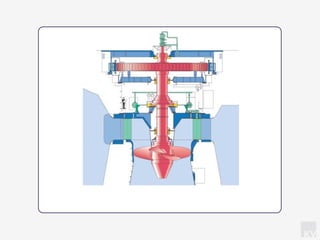

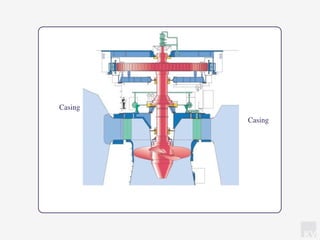

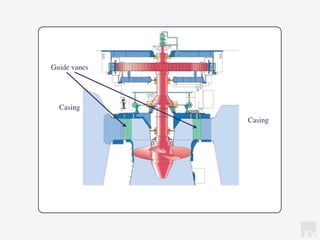

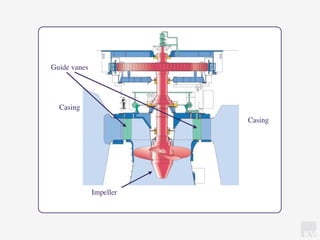

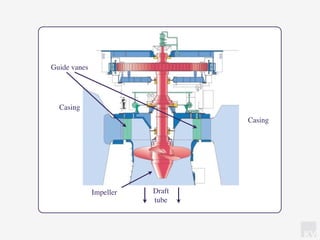

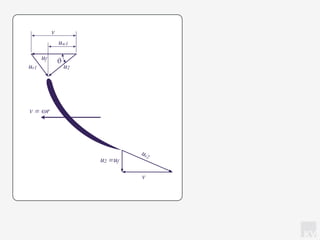

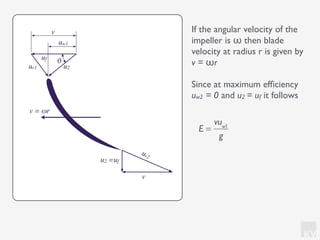

This document discusses hydroelectric power generation and the components involved. It begins by outlining the objectives of understanding the vocabulary, workings, configurations, and components of hydroelectric power plants. It then discusses various methods for measuring water flow rates, including basic, refined, and sophisticated methods. The document goes on to explain the principles of hydroelectric power generation using Bernoulli's equation. It describes intake structures, penstocks, turbines, tailraces, and categorizes different types of power plants. Finally, it discusses the components involved in hydroelectric systems and different types of turbines, including impulse and reaction turbines.