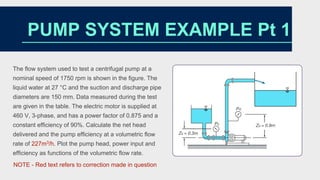

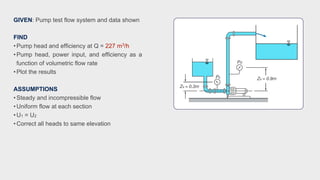

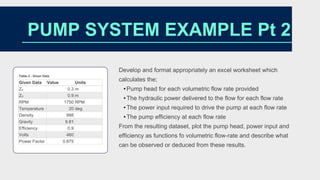

The document summarizes a test of a centrifugal pump. Key details include:

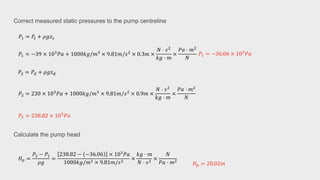

- The pump was tested at 1750 rpm with water at 27°C flowing through 150 mm pipes.

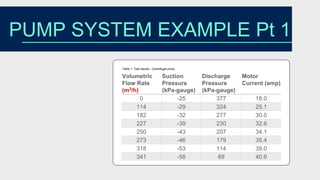

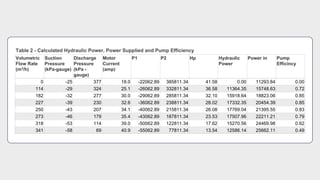

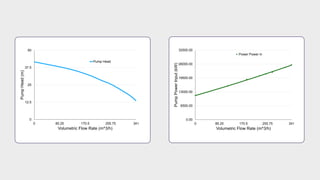

- Test data on flow rate, suction/discharge pressures, and motor current were provided.

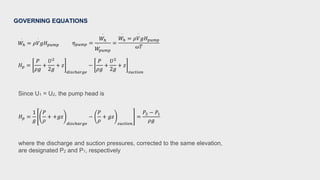

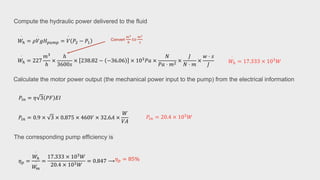

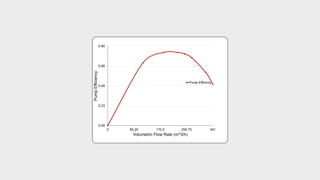

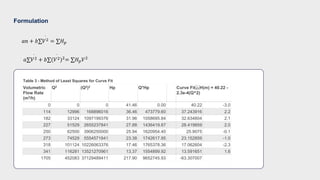

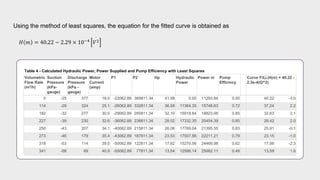

- Calculations were shown to determine the pump head and efficiency at 227 m3/h flow.

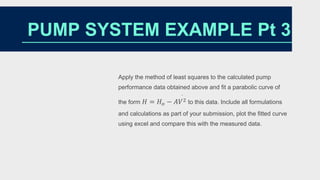

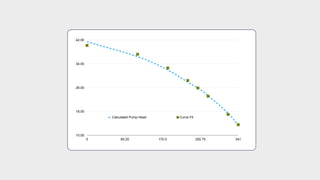

- Additional calculations fitted the performance data to a curve and compared to measurements.