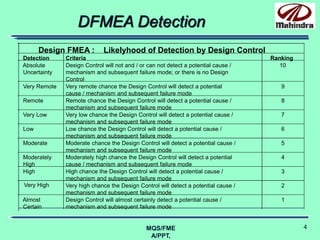

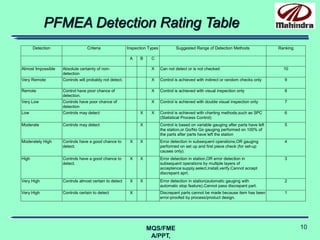

The document provides tables for rating the severity, occurrence, and detection of potential failures in Failure Mode and Effects Analysis (FMEA). The severity table ranks effects from hazardous without warning to none. The occurrence table ranks likelihood of failures from very high (>100/1000 items) to remote (<0.01/1000 items). The detection table ranks likelihood of detection from absolute uncertainty to error-proofed design. The tables provide guidance for numerically scoring these factors in FMEA.