13 Initial Project Site Office Set-up Risk Assessment Templates.docx

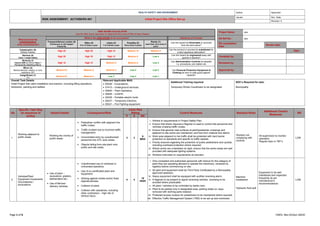

- 1. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Initial Project Site Office Set-up Issued: Rev. Date: Revision: 0 Page 1 of 6 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 1 Working adjacent to public areas Working the vicinity of public areas; Pedestrian conflict with adjacent live traffic routes; Traffic incident due to incorrect traffic management; Uncontrolled entry by unauthorized personnel into ATC work areas; Objects falling from site plant onto public and site roads; 3 3 9 MED i. Adhere to requirements in Project Safety Plan; ii. Ensure that where required a flagman is used to control site personnel and vehicles crossing traffic routes; iii. Ensure that general road surfaces at plant/pedestrian crossings and adjacent to site works are maintained, and free from material and debris; iv. Work area adjacent to live traffic shall be protected with hard barrier protection to standards and specific to traffic speeds; v. Priority ensured regarding the protection of public pedestrians and cyclists, including overhead protection where required; vi. Where works are undertaken at night, ensure that the works areas are well provided with adequate lighting systems; vii. Workers instructed on requirements at induction. Workers not complying with controls All supervision to monitor operation; Regular topic in TBT’s LOW 2 Vehicles/Plant Equipment movements Groundworks / excavations Use of plant – excavators, graders, telehandlers etc.; Use of flat-bed delivery vehicles; Unauthorised use of untrained or unlicensed operators; Use of un-certificated plant and equipment; Striking against mobile and/or fixed objects/vehicles; Collision of plant; Collision with operatives, including other contractors – high risk of serious injury; 4 4 16 HIGH i. Only competent and authorised personnel with licence for the category of plant they are operating allowed to operate the machinery, reviewed by logistics before commencing on site; ii. All plant and equipment shall be Third Party Certificated by a Municipality approved assessor; iii. Heavy equipment shall be equipped with audible reversing alarm; iv. A flagman to be present to signal reversing vehicles, reversing to be avoided where practicable; v. All plant / vehicles to be controlled by banks man; vi. Plant to be parked only in designated area, parking brake on, keys removed with working parts lowered; vii. Protected access route(s) for pedestrians to be maintained where required; viii. Effective Traffic Management System (TMS) to be set up and monitored Machine breakdown Hydraulic fluid spill Equipment to be well maintained and inspected frequently as per manufacturer’s recommendations LOW Project Name: xxx RA Ref No.: xxx RA compilation Date: Review date: Date: Compiled by: Reviewed by: Approved by: Overall Task Details Initial Project Site cabin installation and erection, including lifting operations, blockwork, painting and welfare Relevant Applicable MAS: 00246 – Excavations; 01413 – Underground services; 00940 – Plant Operators; 00939 – CoSHH; 00238 – Portable electric tools; 00237 – Temporary Electrics; 00241 – Fire Fighting equipment. Additional Training required: Temporary Works Coordinator to be designated NOC’s Required for task: Municipality RISK SCORE CALCULATOR Use the Risk Score Calculator to Determine the Level of Risk of each Hazard What would be the CONSEQUENCE of an occurrence be? What is the LIKELIHOOD of an occurrence? Hierarchy of Controls Frequent/Almost certain (5) Continuous or will happen frequently Often (4) 6 to 12 times a year Likely (3) 1 to 5 times a year Possible (2) Once every 5 years Rarely (1) Less than once every 5 years Can the hazard be Eliminated or removed from the work place? Catastrophic (5) Multiple Fatalities High 25 High 20 High 15 Medium 10 Medium 5 Can the product or process be substituted for a less hazardous alternative? Serious (4) Class 1 single fatality High 20 High 16 High 12 Medium 8 Low 4 Can the hazard be engineered away with guards or barriers? Moderate (3) Class2 (AWI or LTI) or Class 1 Permanently disabling effects High 15 High 12 Medium 9 Medium 6 Low 3 Can Administration Controls be adopted I.e. procedures, job rotation etc. Minor (2) Medical attention needed, no work restrictions. MTI Medium10 Medium 8 Medium 6 Low 4 Low 2 Can Personal Protective Equipment & Clothing be worn to safe guard against hazards? Insignificant (1) FAI Medium10 Medium 4 Low 3 Low 2 Low 1

- 2. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Initial Project Site Office Set-up Issued: Rev. Date: Revision: 0 Page 2 of 6 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 3 Excavation in site area Trial trenches, septic tank excavation etc. Excavation in working areas with live traffic movements and pedestrians; Unprotected excavation area; Excavation not to approved design; Damage to exposed existing live underground services; Trench/excavation collapse; Falling/slipping into trenches; Overturning of Truck / machinery into excavation; Incident due to poor illumination; Incident due to hazardous gas/fumes entering excavation; Collapse/damage of structures due to undermining; Difficulty rescuing injured or collapsed worker from deep excavation; 4 4 16 High i. Temporary Works Coordinator / Construction Team to ensure Permit to Excavate has been issued, communicated and signed by personnel prior to any excavation work; ii. Excavation safety buffer, protection, design and traffic signs to be to ATC Minimum Acceptable Standard, RTA Manual Chapter 3 requirements (as applicable) and DM Code of Practice -Section 9; iii. Any exposed services to be protected and adequately supported to avoid damage; Any unidentified services discovered to be immediately communicated to management and work stopped; iv. All spoil to be maintained at least 2m from excavation; v. Trench boxes to be used where practicable, backfilled behind; vi. All shoring, trench sheet supports etc. to be as per approved design, following correct working procedures; vii. Temporary Works Coordinator to ensure excavation design adhered to at all times; viii. Provide access ladders or ramps that suitable to the size and location of excavation. Access and egress ladders/steps to be secured, every 20m on long runs, or steps dug into soil, suitably supported; ix. All excavations below 1.2m depth to be benched/battered back to MAS standards; x. Excavation to be inspected daily with written inspection report weekly by Temporary Works Supervisor; Daily briefings to workers on working in excavations requirements by supervision; xi. Use of stop blocks, barriers and other suitable means of protection used to prevent vehicles entering excavations, warning tape is not to be used as primary protection; xii. Where practicable, access roads and pedestrian walkways to be established away from excavations; Suitable and sufficient signage introduced to excavations; xiii. Backfilling of trenches/excavations to be undertaken as soon as possible after verification or completion of works; xiv. Excavation to be suitably illuminated during night times; xv. No changes to excavations without re-submittal of design reviewed by the TWC, NOC and Permits; Vehicle entering excavation Excavation collapse Incident due to barrier removal Emergency services called, area cleared Secure area No removal of protection barriers without prior approval from management. LOW 4 Works at Height (Office cabin set-up) Use of Ladders and stepladders Working at height; Injury from Fall from Heights; Injury from falling objects; Unsafe use of ladder; Not securing ladder properly; Unsuitable handhold at the top of the ladder or at landing; Using defective ladders; Inadequate planning of task to be completed; 4 4 16 High i. Edge protection to be erected at all work areas where the potential of injury from fall exists, regardless of height but compulsory above 2m; ii. Where due to the constraints of the work area fall protection is not possible safety harness and lanyard are to be used and hooked off to a secure anchor point; iii. No shock lanyard to be used below 6m in height; iv. All hand tools to be tied off when working at height; v. Ensure good standard of lighting, at night, for the work area; vi. Employees are to be given training in the use of ladders; vii. Supervisors must ensure that all ladders are correctly angled, tied or footed. A suitable base must also be provided for ladders; viii. A ladder must extend at least 1 meter above the landing unless a suitable handhold is present; ix. All defective ladders are to be removed off site once defect has been observed; Painting of ladders is prohibited; x. Ladders should be checked before being put into use and on a regular basis thereafter; xi. Ladders only be used where the duration of the use is short and where other methods cannot be used due to physical constraints on site; xii. Do not stand on top three rungs of ladders. Supervision to constantly monitor workers; Regular TBT’s & Trainings to be given on working Confined space; Low

- 3. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Initial Project Site Office Set-up Issued: Rev. Date: Revision: 0 Page 3 of 6 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 5 Mobile Crane operation (Cabin/unit placing) Use of Mobile Crane Unauthorised operation of the mobile crane; Failure due to use of un-certificated crane; Overturning due to incorrect siting; Incident due to use of defective lifting gear / equipment; Load striking moving and/or stationary structures; Crane collapse due to lifting loads beyond SWL; Persons underneath load struck by materials; Load swinging / spinning uncontrolled. 4 4 16 High i. Logistics and construction team to ensure the correct type and size of crane for the task is ordered; ii. Crane Supervisor / HSE Officer to undertake visual checks of crane and operator certificates when arriving on site; iii. All cranes to be Third Party Certificated by a DM approved inspector; iv. Minimum Acceptable Standard ATC/OHS/MAS/00941 to be adhered to; v. Ensure crane is set up/rigged out correctly, is on firm level ground as per crane plan with outriggers fully extended with spreader pads; vi. Ensure all lifting equipment have valid test certificate before use (6 monthly 3rd party insp.); vii. Method statements and risk assessments to be submitted and adhered to for technical and/or non-routine lifts; Lift Plan to be completed prior to any lift taking place by crane supervisor and engineer; viii. Riggers to undertake visual inspection of all lifting equipment daily; ix. Crane load indicator to be functioning, not to be overridden; x. Operator to adhere to crane safe working load limits, weight of load established before lifting; xi. Lift controlled by designate rigger/banks man using approved hand signals; xii. Tag lines shall be used to guide materials while lifting, 2 lines minimum 10m in length; xiii. No personnel under loads, avoid over-sailing of personnel if practicable; xiv. No lifts when wind speed exceeds 40kph; Mechanical failure of crane; Failure of lifting equipment during operation; Daily visual inspection and Pre- start check of the lifting equipment & lifting gears to be conducted. Low 6 Temporary electrics - offices Electrical connections and terminations Use of untrained electricians for electrical works; Use of substandard electrical fixtures and fittings; Use of substandard connections; Non-adherence to colour coding of wiring; Incorrect earthing; Tripping hazard; Damage to unprotected cables; Use of incorrectly rated fuses; 3 4 12 High i. All electricians to be suitably trained and experienced in the works; ii. All wiring, connections and terminations inspected prior to connection to live supply; iii. All wiring to follow colour coding standards; All fuses shall be to correct rating for electrical system or equipment; iv. All junction boxes and sockets fixed securely to structure; All electrical junction boxes, sockets and fittings to be of suitable quality; v. Insulation tape shall not be used for cable connections, correct junction boxes to be used; vi. All earth connections shall be to standards; vii. No cables shall trail on the floor; all securely clipped clear of damage or posing a trip hazard; viii. Armoured cable used for cables set below ground; Armoured cable shall be correctly fitted and protected at junction boxes; All cables to be fed through securely fixed conduit; ix. SMDB’s and DB’s used on site shall be sound, minimum IP54 rated, and mounted on secure frames. Doors shall be lockable with correct warning signage; x. SMDB’s and DB’s shall be subject to regular inspections, any damaged units removed from service; Rain entering DB’s Remove from site Low 7 Site generators – offices and site Temporary supply Generator fires; Incident due to incorrect earthing; Fuel leakage – environmental risk; Fuel storage; Noise; i. Generators to be suitable size and capacity for the task, with maintenance record; ii. Generators to have suitable earth rod connected at all time; iii. Fire extinguishers to be located close to generators; iv. Generators to be fitted with drip trays; v. Fuel tanks to be bunded to 110% capacity, bunds to be sealed with delivery hoses retained inside bund; vi. Generators to be subject to regular inspection regime; Units monitored for excessive exhaust fumes; Low

- 4. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Initial Project Site Office Set-up Issued: Rev. Date: Revision: 0 Page 4 of 6 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 8 Office installation Electrical equipment – grinders, cutters, drills etc. Electric shock due to damaged equipment; Ear damage through excessive noise; Use of untrained operators resulting in incident; Hand Arm Vibration injury through prolonged use of equipment; Eye injury from flying debris; Incident due to adapted/modified equipment; incident due to machine guard removal; 3 3 9 Med i. All electrical equipment, drills, grinders, cutters etc., to be tested, inspected and sound, no damaged leads, connectors etc. To be removed from service and quarantined if damaged; ii. No guards to be removed from grinders or cutting equipment at any time; iii. No handles shall be removed from electrical hand tools at any time; iv. No electrical hand tools shall be adapted for use other than as designed by the manufacturer; v. Manufacturers power tool speed rating and cutting disc max speed to be matched to prevent bursting of wheels; vi. Grinding / cutting wheels shall only be changed by trained personnel; vii. 110v tools to be used, unless exempted by risk assessment; viii. Splitter boxes shall not be used for multiple connections; ix. All Emergency Stop buttons to be present and working on all machinery, if not, machine will be quarantined until repaired to standards; x. Equipment to be subject to regular electrical inspection regime, and especially when returned to the stores; xi. Hot works permit required if cutting through steel, aluminum etc. where a spark can be formed, fire extinguishers and fire watch in place as per permit requirement; xii. Ear protection and face mask to be worn by all workers in area, not just tool operators. Eye protection to be worn; xiii. When using vibrating tools such a jack-hammers etc., workers shall be rotated to avoid Hand Arm Vibration. Refer to chart for recommended use in 8hour period; xiv. Workers shall be advised of the symptoms of HAV via briefings, toolbox talks etc.; xv. Works from ladders, see section 4; Use of sub- contractors Sub-contractors will be informed at tender stage regarding site requirements Low 9. Site offices Fire prevention and emergency procedures Fire Poor emergency response procedures; Insufficient fire-fighting equipment; Poor housekeeping; 4 4 16 High i. Offices to be fitted with smoke detectors; ii. Hose reels to be installed before personnel allowed to occupy, fire pumps subject to inspection regime; iii. Extinguishers to be placed in clear areas and subject to weekly inspections; iv. Emergency exits to be established and clearly marked with signage. To be communicated at Induction; v. Fire drills to be routinely undertaken, at least every 6 months; vi. Muster points also clearly identified at induction, and kept clear of storage areas; vii. Reverse parking deployed in parking areas; viii. Designated smoking areas established, clear of the offices, with sand trays and fire extinguishers; ix. Waste skips to be at least 10m from offices, and not allowed to overflow. Regular removal from site by licensed contractor; x. Double stacked offices to be fitted with steel emergency exit stairs, at least 2 at opposing ends; xi. Flammable liquids, fuel, paints, chemicals shall not be stored in offices; xii. No gas cylinders to be stored inside offices, but in area clear of offices in signed cages; xiii. Waste paper etc. to be removed daily and not allowed to build up; Muster points relocated due to site development New muster points to be effectively communicated to site staff Low

- 5. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Initial Project Site Office Set-up Issued: Rev. Date: Revision: 0 Page 5 of 6 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR 10 Loading out blocks / materials in work area Blockwork (cabin supports, septic tank walls etc.); Slip, trip or fall; Fall from ladder; Fall from trailer bed; Manual Handling strain injury to body; Cuts to exposed body parts; Hit by vehicle; Use of electrical cutting equipment; i. Walkway to be available for access around area. Rubbish to be cleared regularly to prevent slip/trips; ii. Do not lift over people with truck Hiab or fork lift; Hiab outriggers fully extended and Third Party test available for review; iii. When handling components wear gloves, cover all exposed body parts; iv. Follow correct Manual Handling procedures, use aids if available; v. Stored materials to be laid on flat ground and not stacked more than 2 pallets high; vi. Access to trailer beds to be via footed ladder. When lifting do not climb over trailer bed on unsecured materials; vii. Blocks to be stored on pallets if they are to be moved to another location. Blocks to be positioned as close as possible to the work area; viii. Loading out can be done by stacking on pallet and placing with fork lift of manually stacking individual blocks adjacent to the work station; ix. Care must be taken to prevent overloading of any work platform with blocks. Supervision will monitor loading out, ensuring blocks are loaded safely, and distributed along the length of work platform, no point loading; x. Blocks will be stacked on platforms no more than 3 high and never above the height of installed hand rails; Low 11 Blockwork. Use of Concrete; Laying blocks; Use of cement mixer and mechanical saw, entanglement or shock; Splash from concrete into eyes; Dermatitis and skin burns to body; Concrete soaking boots, overalls, and other clothing. Vibration. - Cement burns; Waste build up; i. Washing facilities shall be provided; Contact with the skin is to be minimized and eye protection is to be worn, soaked overalls to be removed immediately; ii. Chemical resistant gloves shall be worn by anyone whose hands may contact with the wet concrete mixes; Wellington boots to be worn when pouring concrete; iii. Guards to be in place over moving machinery, cover is to be kept over hopper during operation and cleaning activities; iv. Mortar is to be delivered from the mixer in a bucket or wheel barrow and placed on spot boards next to the work station; v. Used cement bags are to be disposed of as produced in designated area and not left to blow around site; vi. Glasses or goggles and dust mask may be required to be worn when loading the mixer to prevent cement particles from blowing into eyes, mouth/nose; vii. Exposed body parts are to be kept covered, if cement/mortar splashes occur they are to be washed off immediately; viii. Cement mixer and mechanical block saw to be operated by trained competent persons only, all guards present on machines always, electrical connections/wiring sound and undamaged; ix. At no time, will personnel use hands, shovels etc. inside rotating machine, mixer will be isolated and stopped rotating before cleaning out machine; Lay blocks at a comfortable level. Do not over reach or build higher than the working platform either on the ground or from hop ups and scaffold; x. Blockwork will be laid with stability in mind, mortar will be allowed to cure in sections before proceeding too high. Engineers and Supervision will monitor blockwork tie rods are fitted and secured during the task as specified; xi. Block saw blades only to be changed by trained personnel; xii. Wear PPE at all time especially nitrile gloves to protect hands from sharp corners and cement burns. Wash any spillage off hands or clothing immediately; xiii. Care must be taken to prevent overloading of any work platform with blocks. Supervision will monitor loading out, ensuring blocks are loaded safely, and distributed along the length of work platform, no point loading; Low

- 6. HEALTH SAFETY AND ENVIRONMENT Author: Approved: RISK ASSESSMENT: ACT/HSE/RA 001 Initial Project Site Office Set-up Issued: Rev. Date: Revision: 0 Page 6 of 6 HSEQ -Rev-01(Jan-2023) No Specific Task Step (In sequence of works) Hazard Details Consequence/Risk Initial Risk Rating Control Measures Residual Risks Additional Control Measures RR P S RR xiv. Clear up waste regularly, do not allow to build up; 12 Painting task offices etc. CoSHH Storing, handling and using Hazardous materials (Paints and Thinners); Cleaning of equipment and disposal of cleaning agents and hazardous liquids Fire; Environmental hazard; Exposure of chemicals with skin, risk of dermatitis etc. Accidental ingestion of hazardous liquids; Inhalation of harmful vapour; Poor disposal of waste; 3 3 9 Med i. Ensure that Material Safety Data Sheets (MSDS) are made available at the site and users are aware of the hazards involved while using and storing these chemicals; ii. Personnel must be issued with required P.P.E. and work to be carried out under supervision; iii. Where practicable water based paints to be used; iv. Thinners and cleaners to only be used in well ventilated areas; v. Ensure all painting equipment is cleaned in designated area; vi. Area to be well ventilated; vii. All wash-off to be stored in designated tanks for removal by licensed contractor; viii. Strict no smoking policy enforced; ix. Use of disposable equipment where practicable. Nitrile gloves to be worn; x. Operatives to be instructed on identifying symptoms of skin disease and related illness; xi. All empty paint cans to be removed from site using designated skips; All paint, thinner and other hazardous liquids to be stored in designated, marked containers, plastic bottles etc. are not to be used; Paint or chemical spillage Spill kits to be available in all areas where a risk exists. Staff trained in environmental actions in the event of a spill Low 13 Welfare facilities Workers on site requiring Welfare Inadequate welfare facilities; Risk of poor health to workers; Non-compliance with requirements; 3 3 9 Med i. All welfare facilities will be established as per approved Worker Welfare Plan for the duration of the project; ii. Welfare areas shall be kept clean at all time, regular housekeeping, removal of waste and ablution cleaning daily; Low