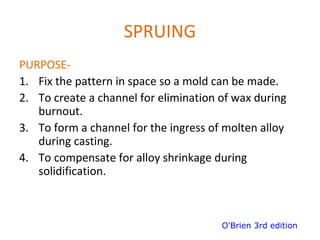

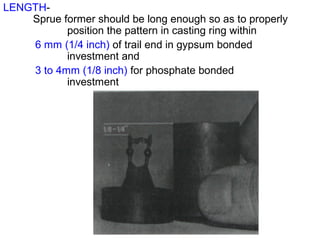

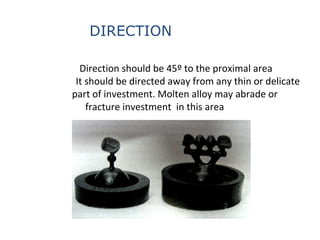

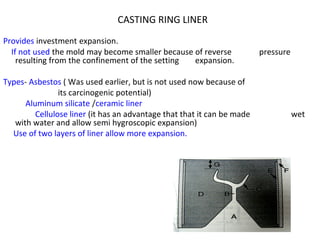

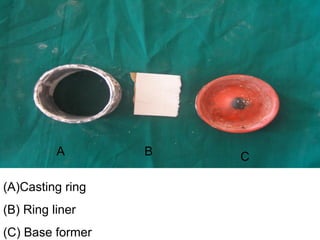

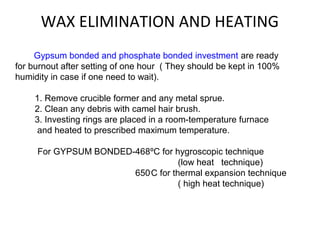

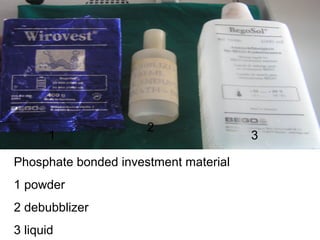

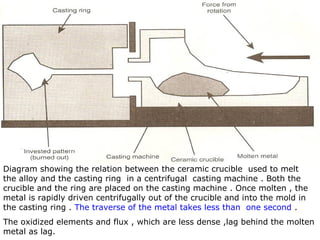

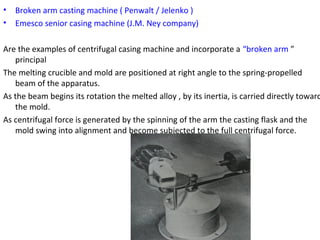

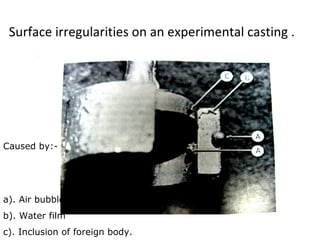

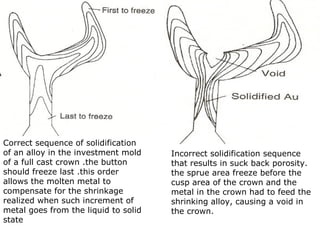

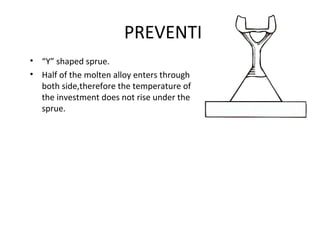

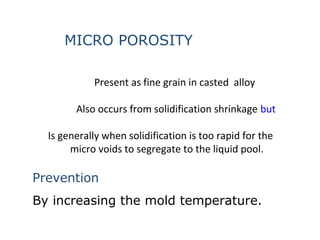

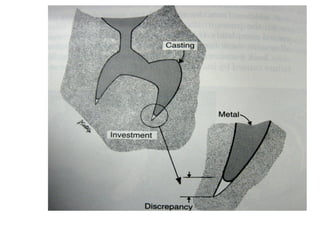

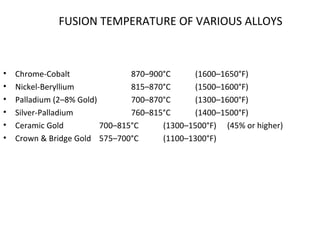

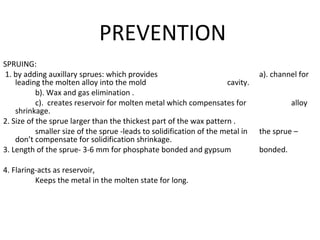

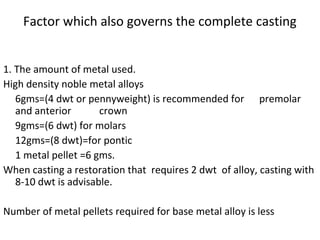

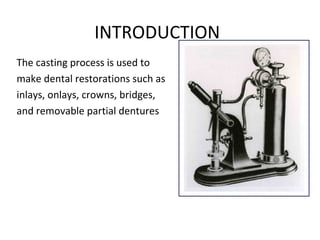

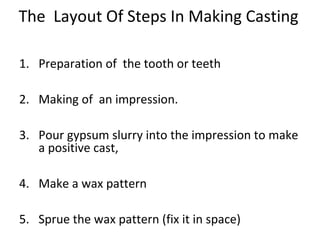

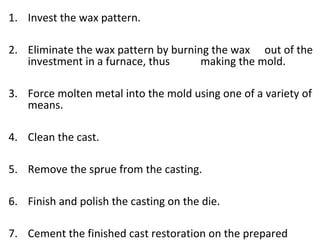

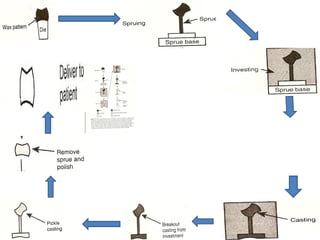

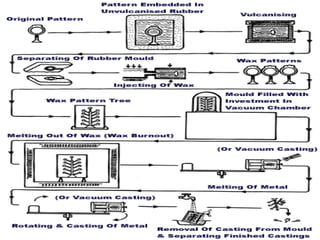

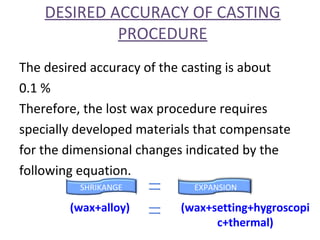

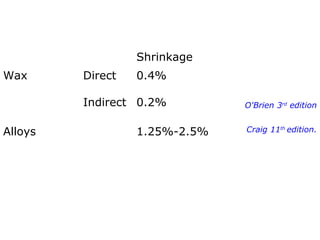

This document details the casting process in conservative dentistry, outlining definitions and steps involved in creating dental restorations. It highlights techniques such as lost-wax casting, spruing, and the use of gypsum and phosphate bonded investment materials, alongside casting machines and their operation. The document also addresses desired accuracy, defects prevention, and the types of investments and machines used in the casting procedures.

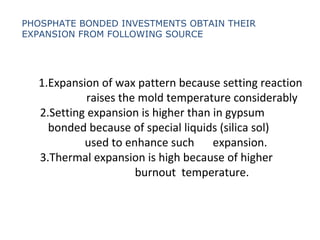

![Hi-Temp Carbon-free

investment for high

fusing alloys

1.2%

TE at

1300-1800°F

(700-900°C

.7% Setting

Expansion

Cera-Fina Carbon-free fine

grained investment for

high fusing alloys

1.3% TE at

1300-1800°F

(700-900°C)

.3% Setting

Expansion

WiroFine partial denture

investment material

Linear thermal

expansion [%]

0,8

Bellavest® SH

Graphite-free,

phosphate-bonded

precision casting

investment material

rapidly or

conventionally

heatable casting

investment material

for crowns and bridges

made of precious

metal, non-precious

metal alloys and press

ceramic

50% BegoSol®

1.7% (total

expansion)

80% BegoSol®

2.2%(total

expansion)

Expansion in Phosphate Bonded Investment

Material](https://image.slidesharecdn.com/castingprocedureanddefects-150827073459-lva1-app6892/85/Casting-procedure-and-defects-22-320.jpg)