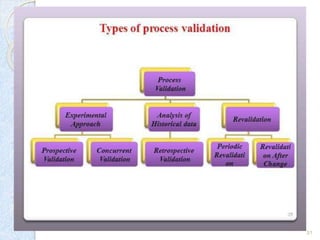

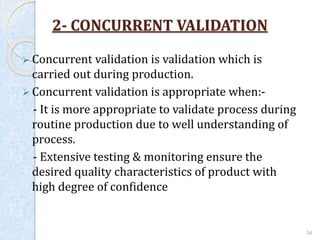

The document outlines the process validation in pharmaceutical manufacturing, emphasizing its regulatory requirements, life cycle, and significance in ensuring product quality and compliance. It details various types of validation, including analytical method, cleaning, and equipment validation, and describes the phases involved in process validation. Furthermore, it addresses the roles of the FDA and specific regulations impacting validation procedures.