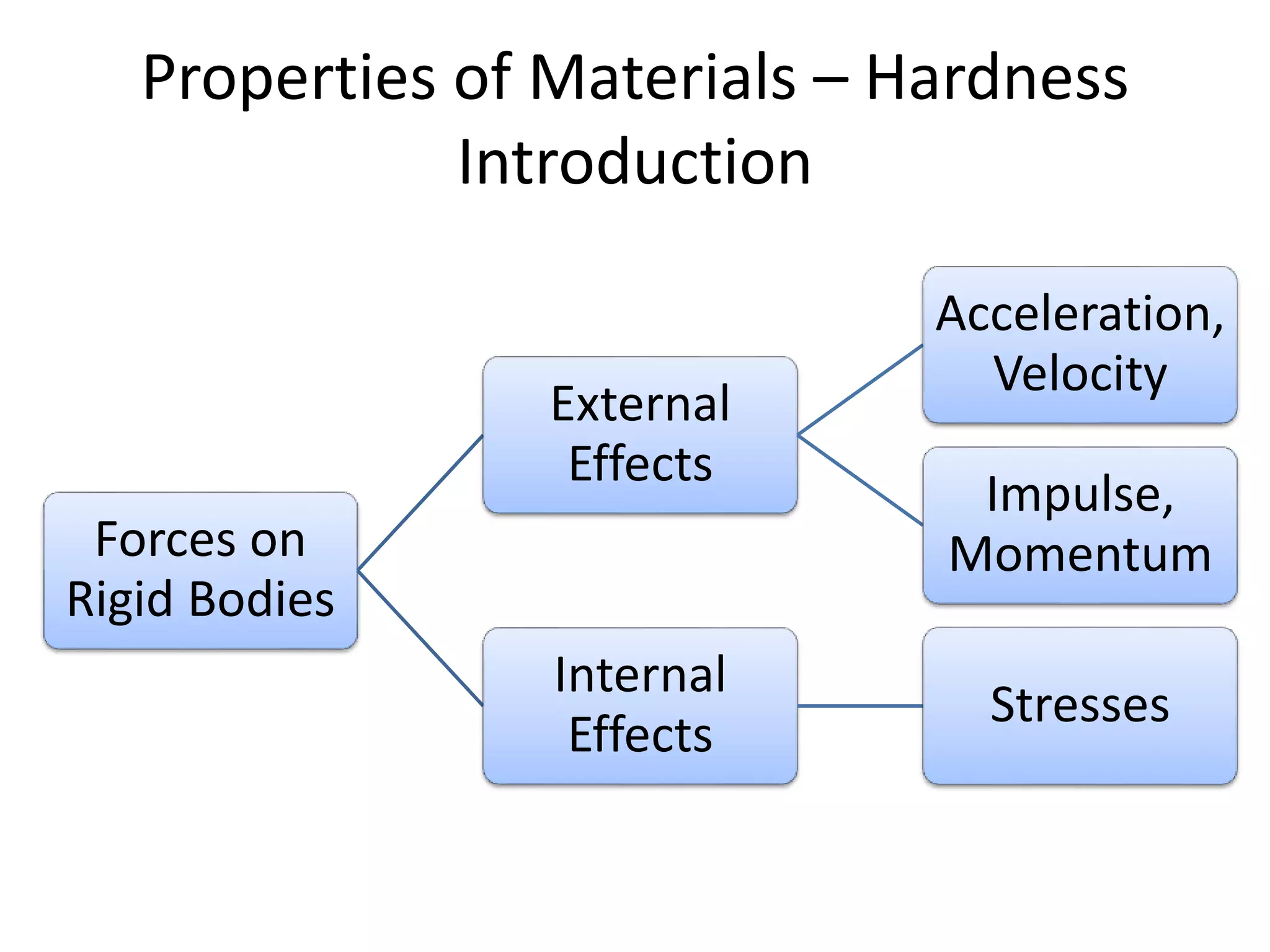

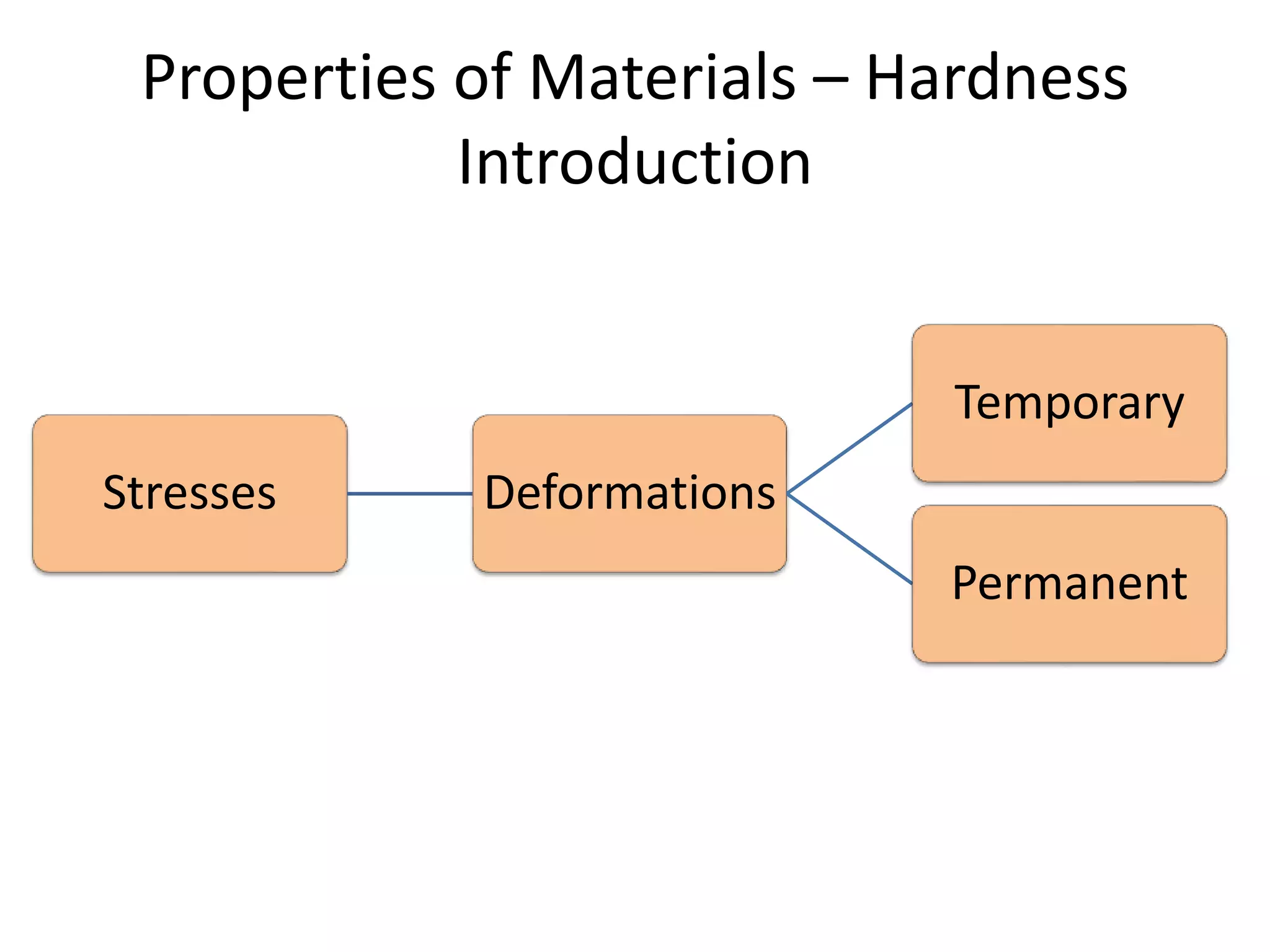

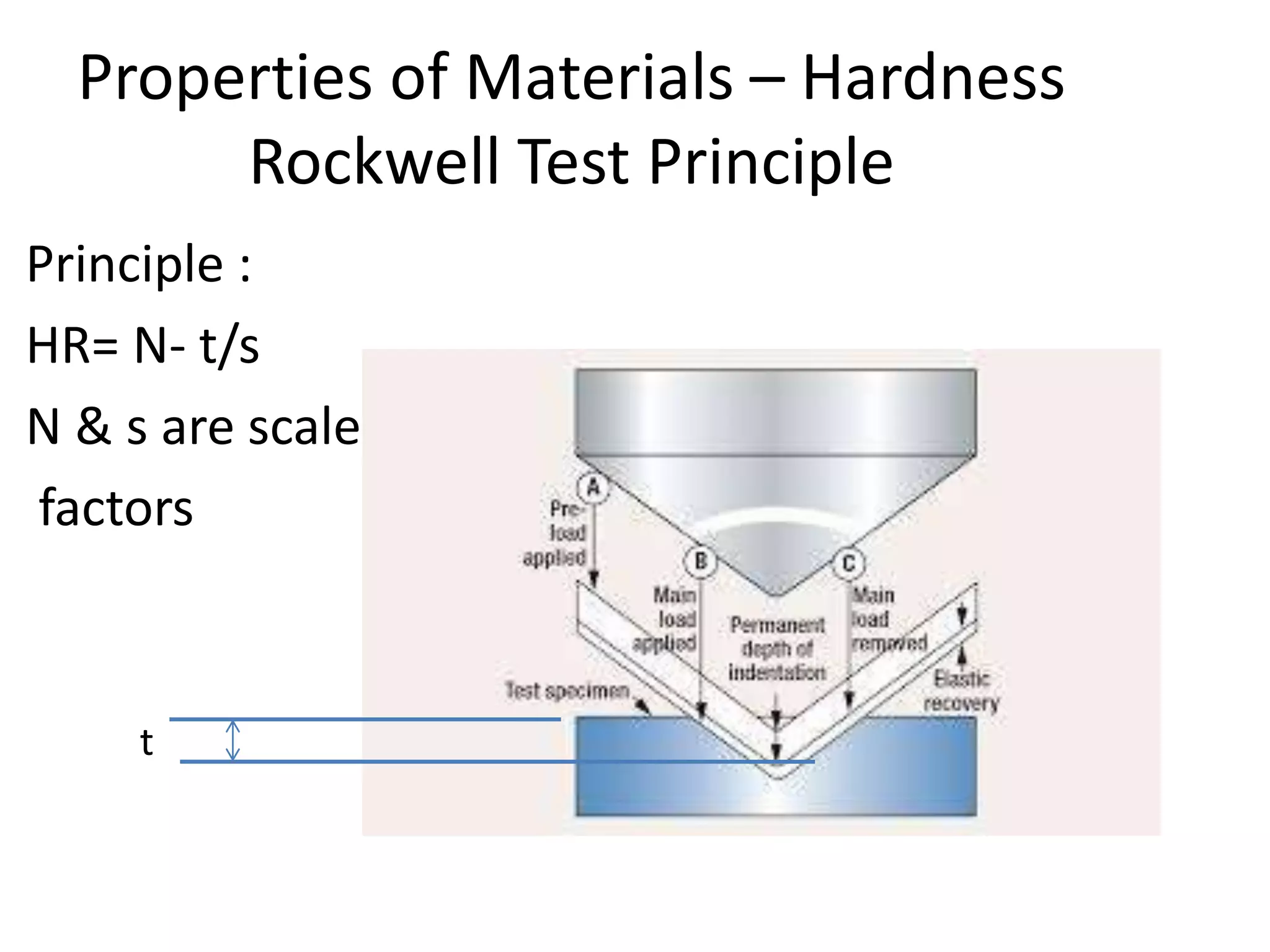

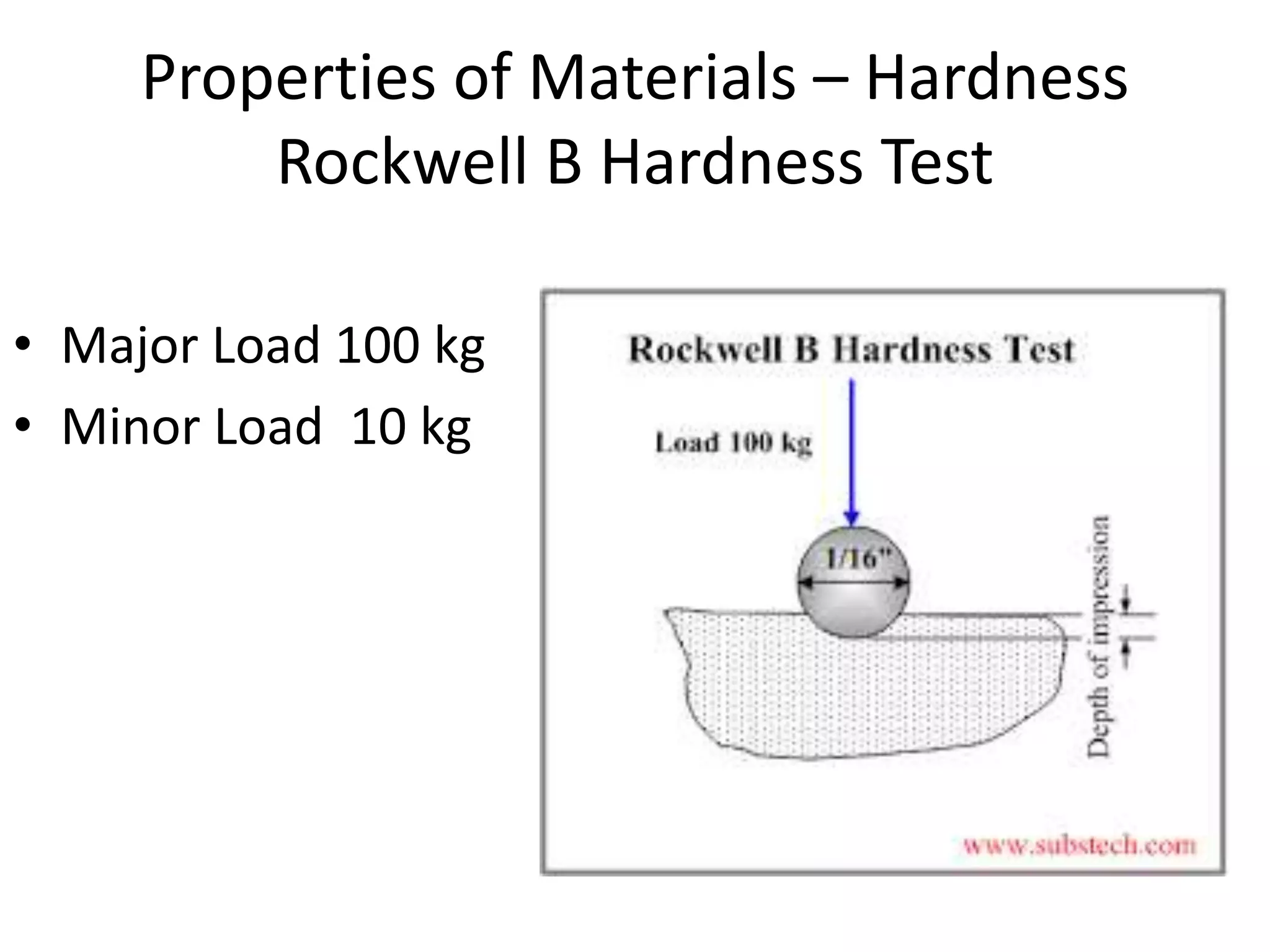

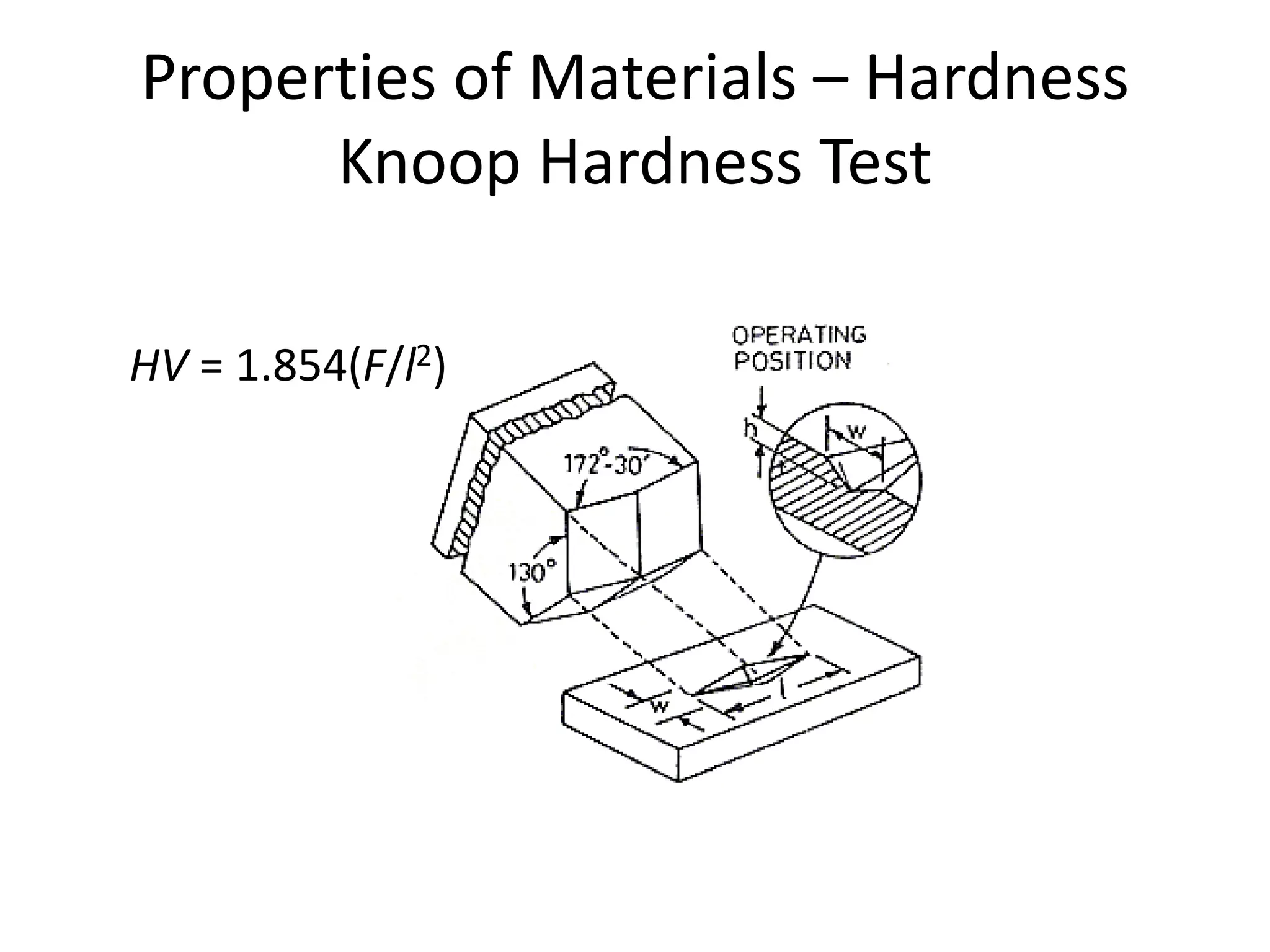

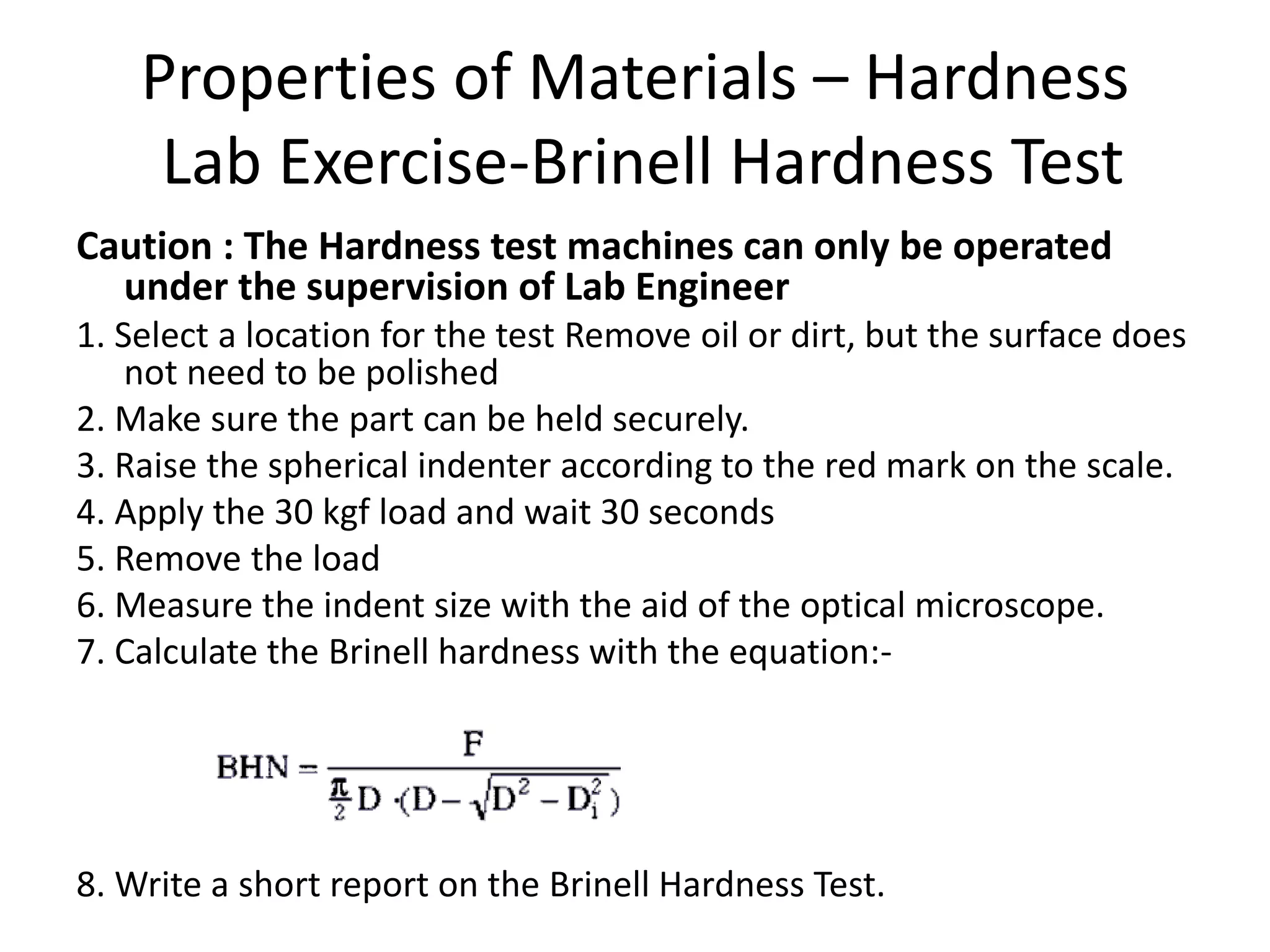

The document provides an overview of material hardness, including its definition, importance, and various testing methods. It details historical techniques for measuring hardness, such as the Mohs, Brinell, Rockwell, Vickers, and Knoop hardness tests, along with typical hardness values for various materials. Additionally, it includes instructions for a lab exercise on conducting a Brinell hardness test.