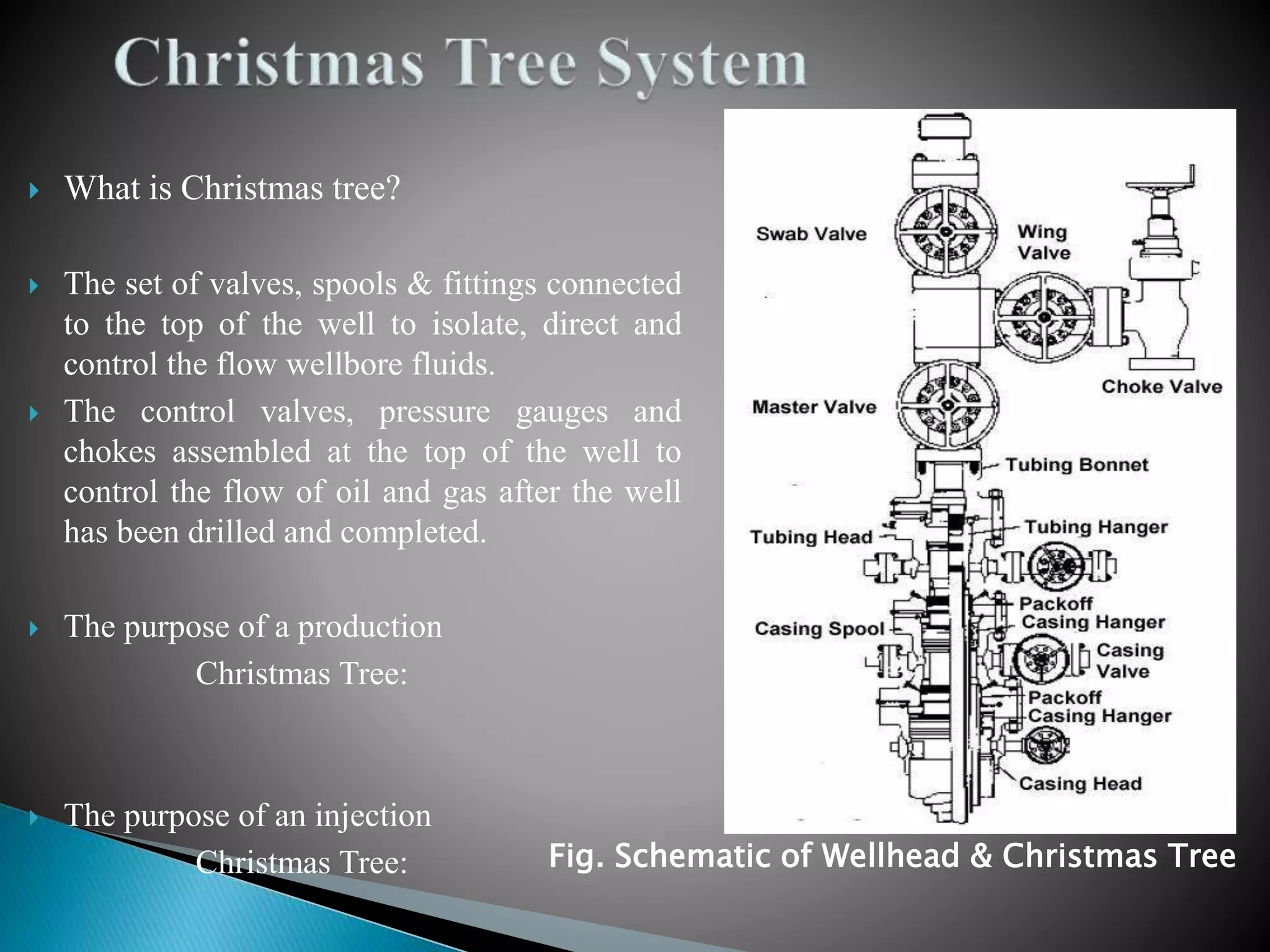

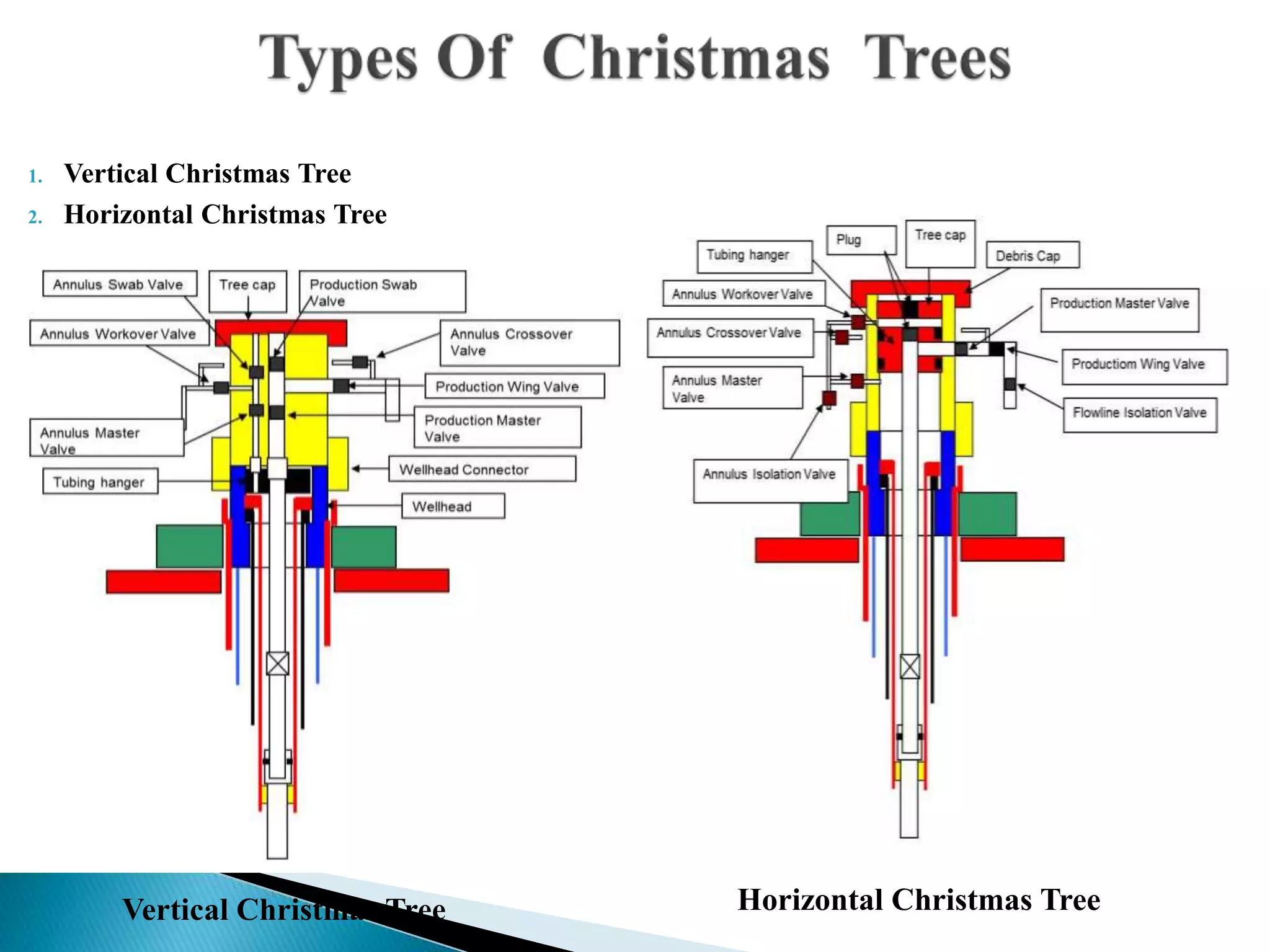

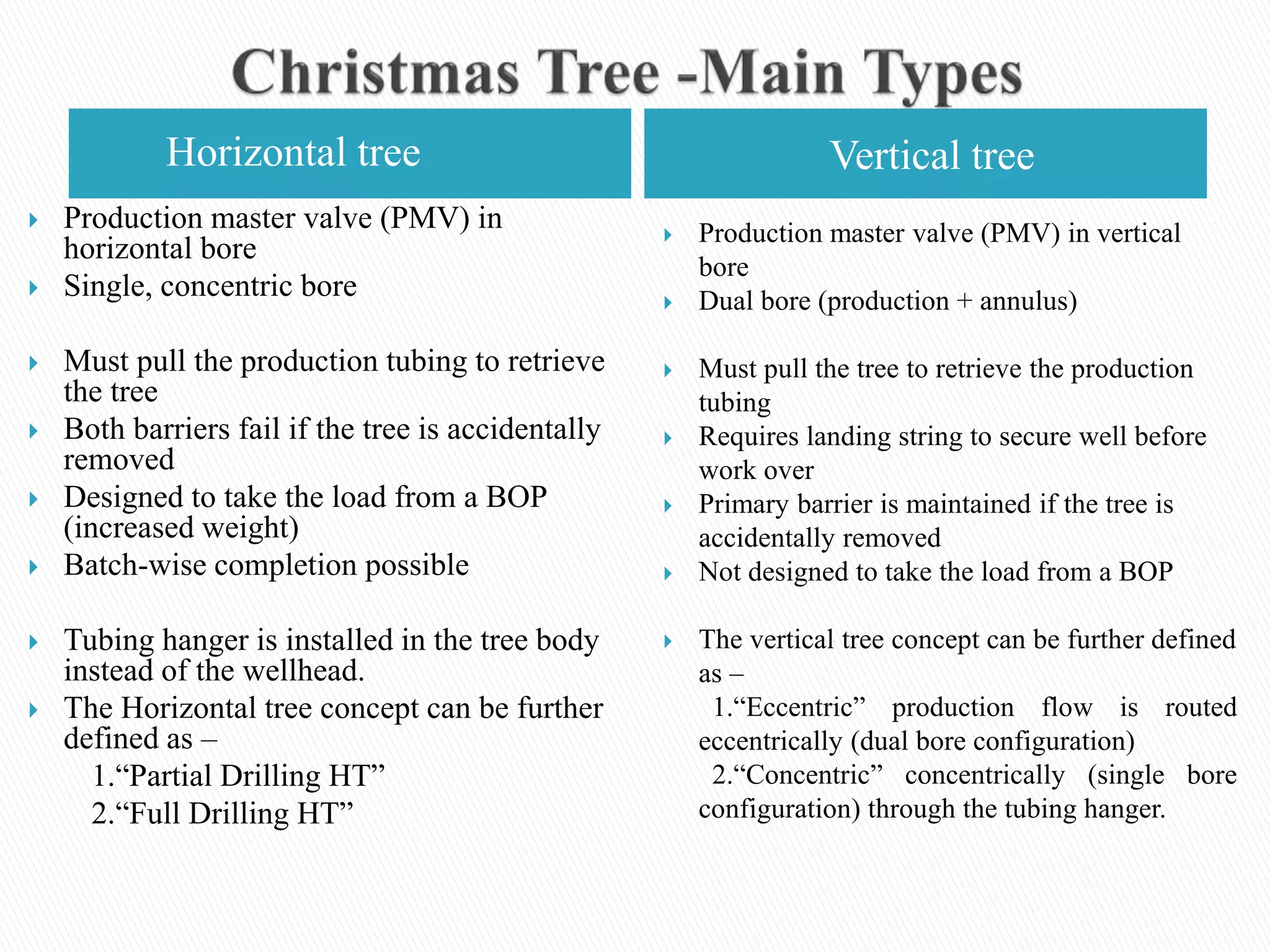

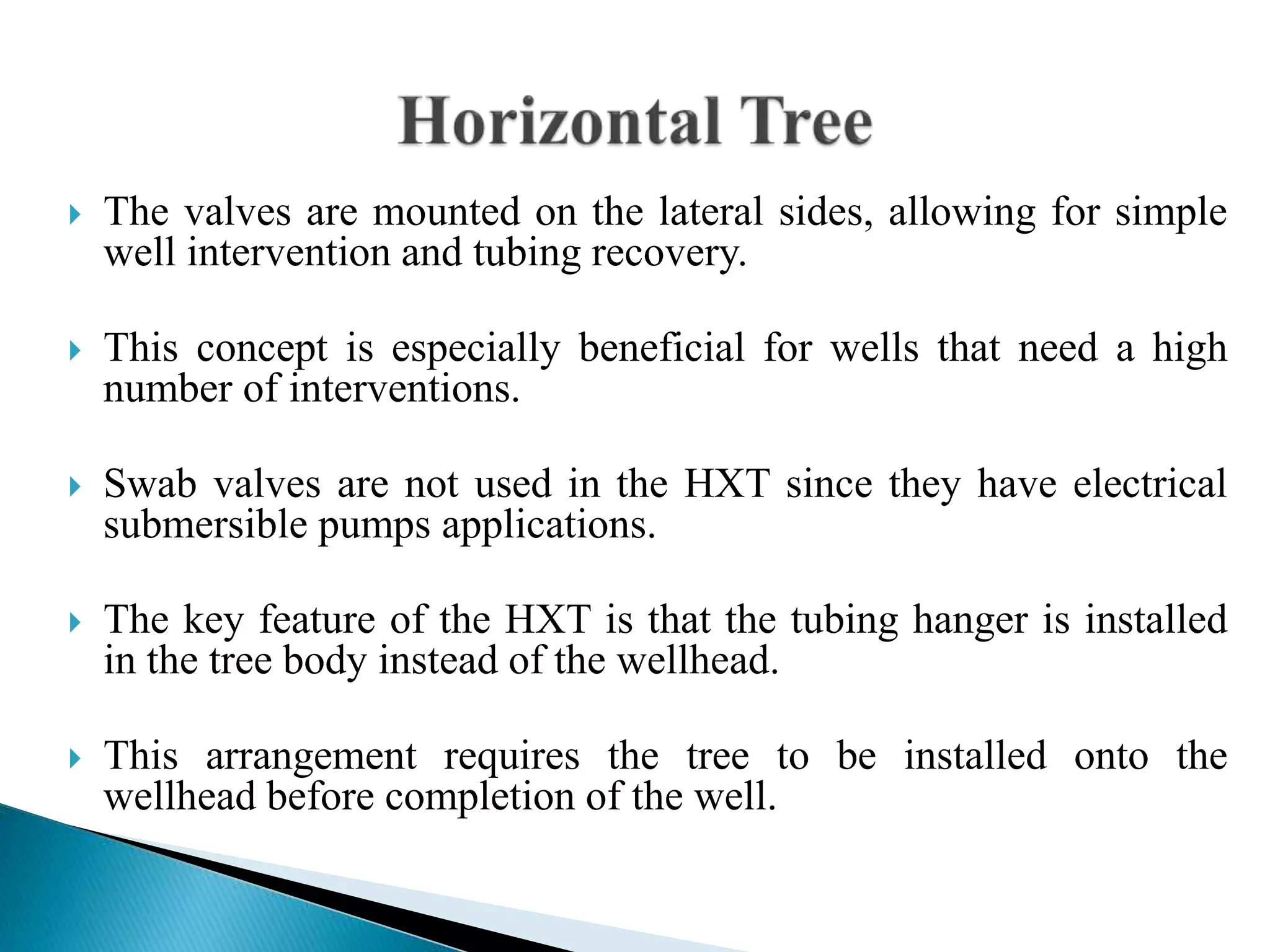

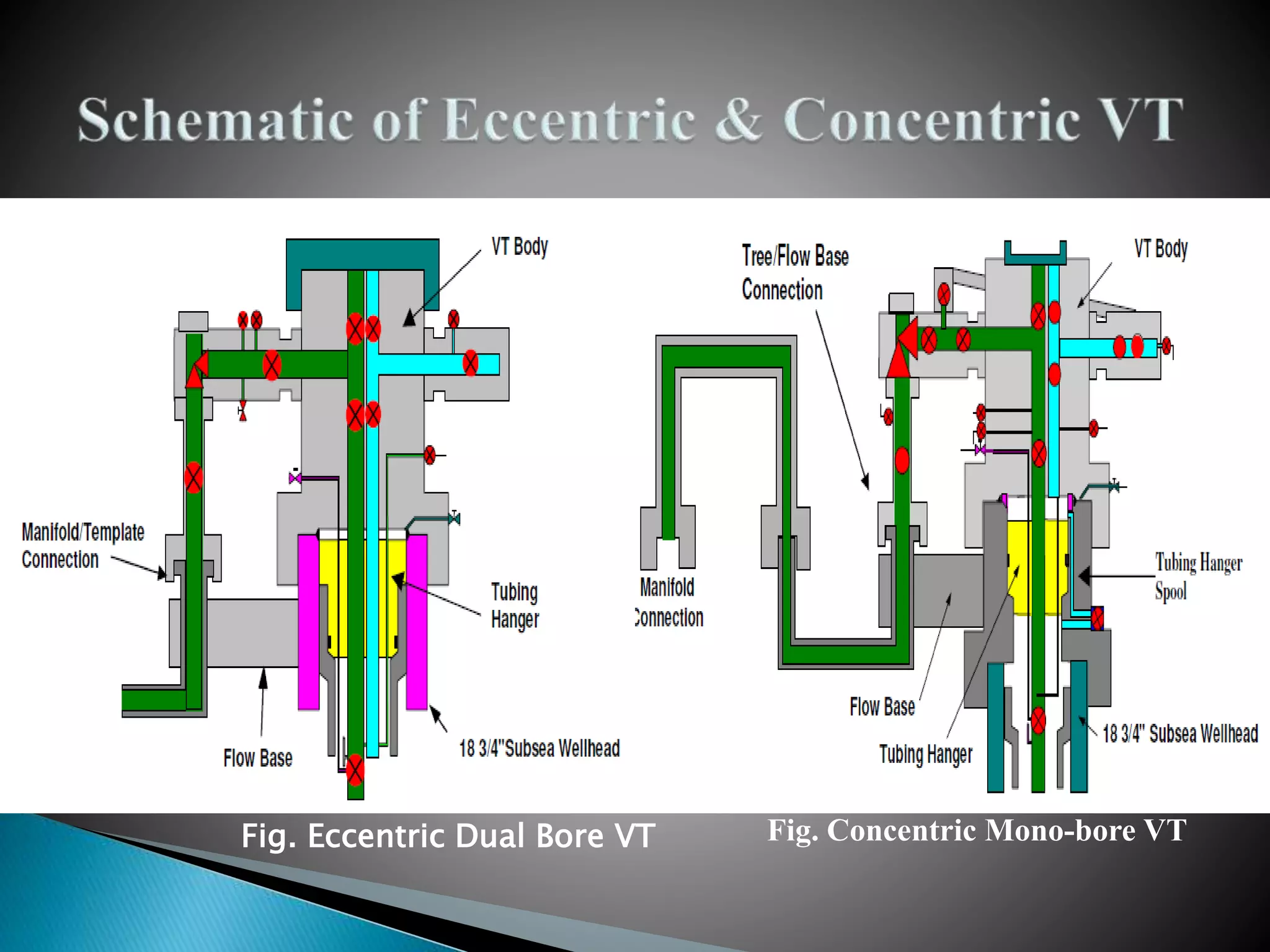

The document provides an overview of Christmas trees in petroleum engineering, describing their purpose, components, and types, including vertical and horizontal configurations. It details their functionality in controlling wellbore fluid flow, including various safety features and specifications pertaining to industry standards. Additionally, it discusses the advantages and limitations of each type concerning well completion, intervention needs, and costs associated with installation.