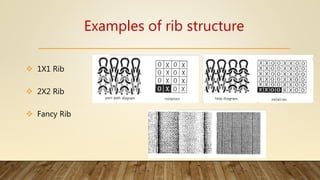

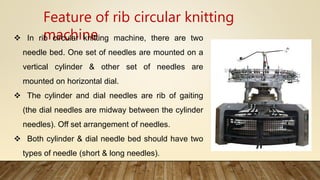

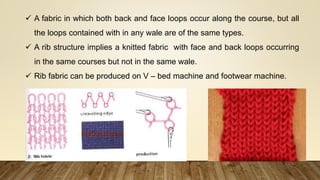

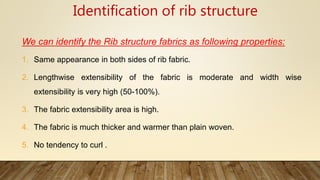

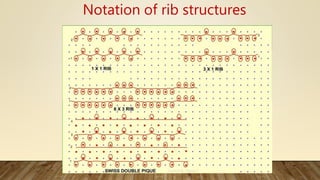

Rib structure is the second family of knit structures where wales of face stitches and back stitches are knitted alternatively on each side of the fabric. Rib fabrics are produced on machines with two sets of offset needles. The 1x1 rib structure has perfectly balanced stitches with high elastic recovery in the width direction. The 2x2 rib structure has 2 technical face loops and 2 back loops per repeat, making it popular for cuffs and waistbands. Rib fabrics have the same appearance on both sides with moderate lengthwise and very high widthwise extensibility, thickness, and no tendency to curl.