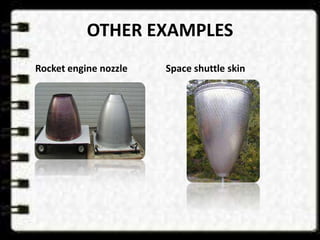

Explosive forming is a metal shaping technique that uses an explosive charge to generate high forming pressures. There are two main methods - the stand off method places a metal plate over a die and positions an explosive above the plate, while the contact method places the explosive in direct contact with the workpiece. The rapid conversion of the explosive to gas produces a shock wave with pressures up to several million psi that can form metal sheets into complex shapes in a single operation, making it suitable for aerospace applications requiring large or low-quantity customized parts.