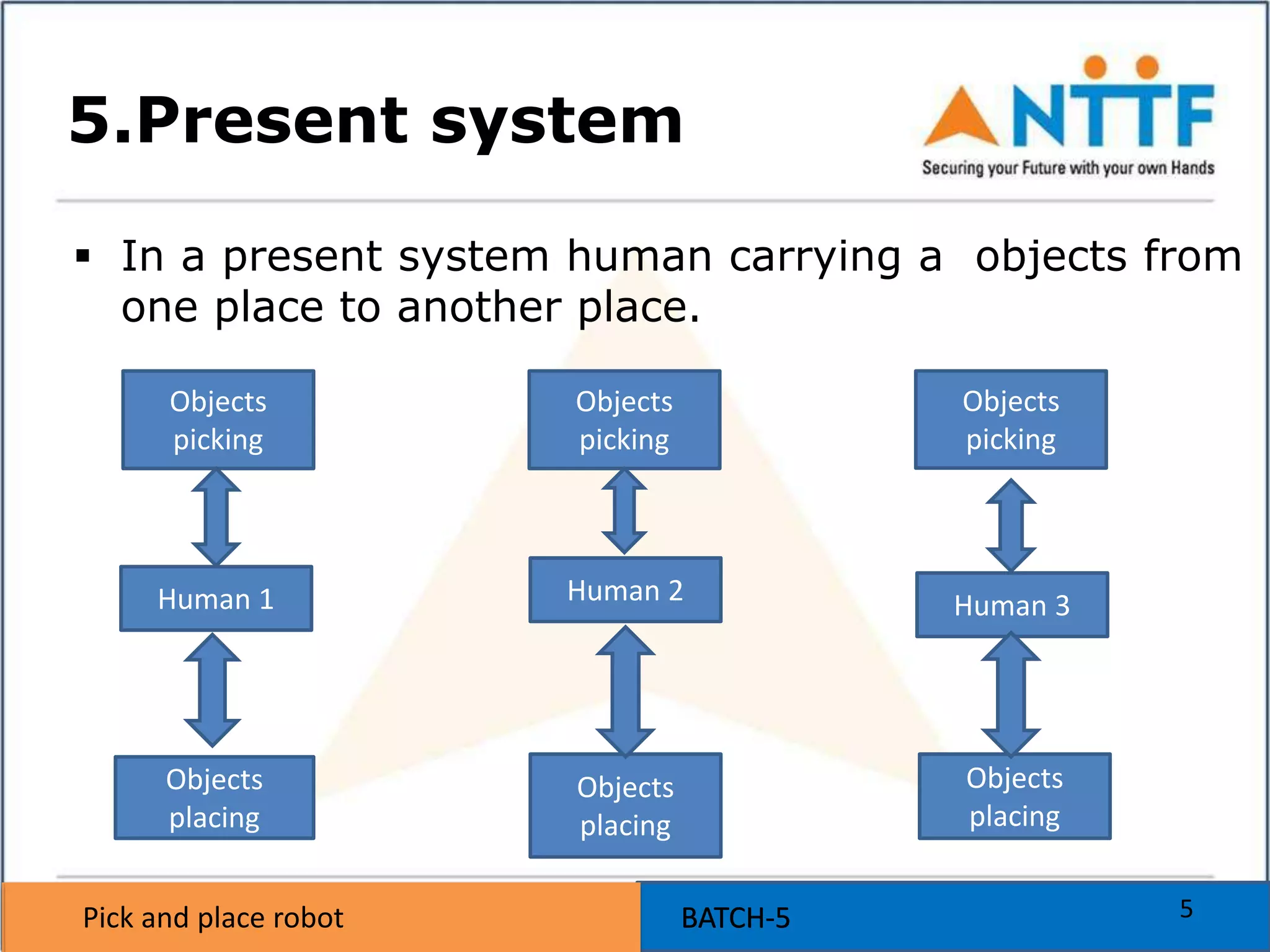

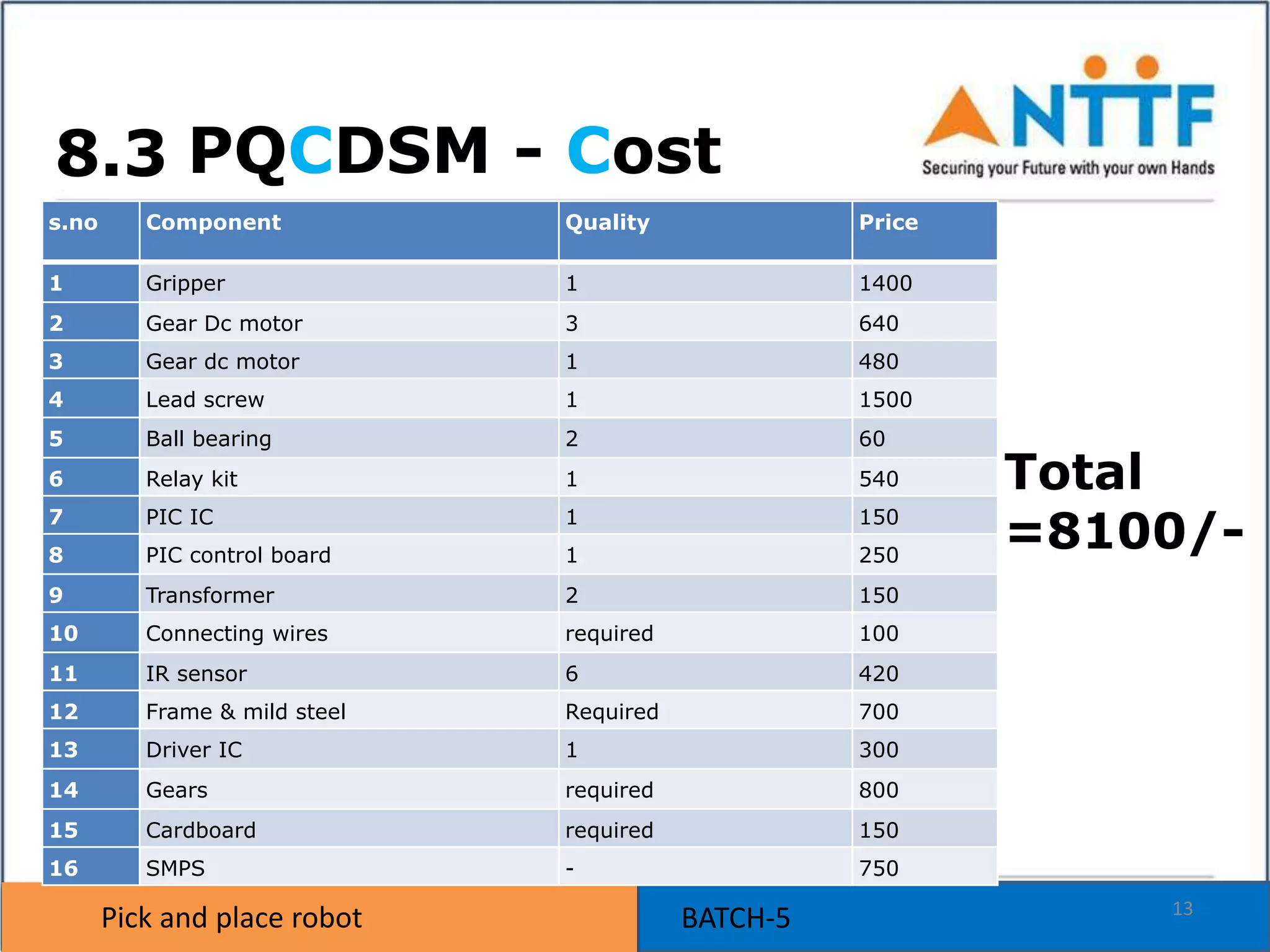

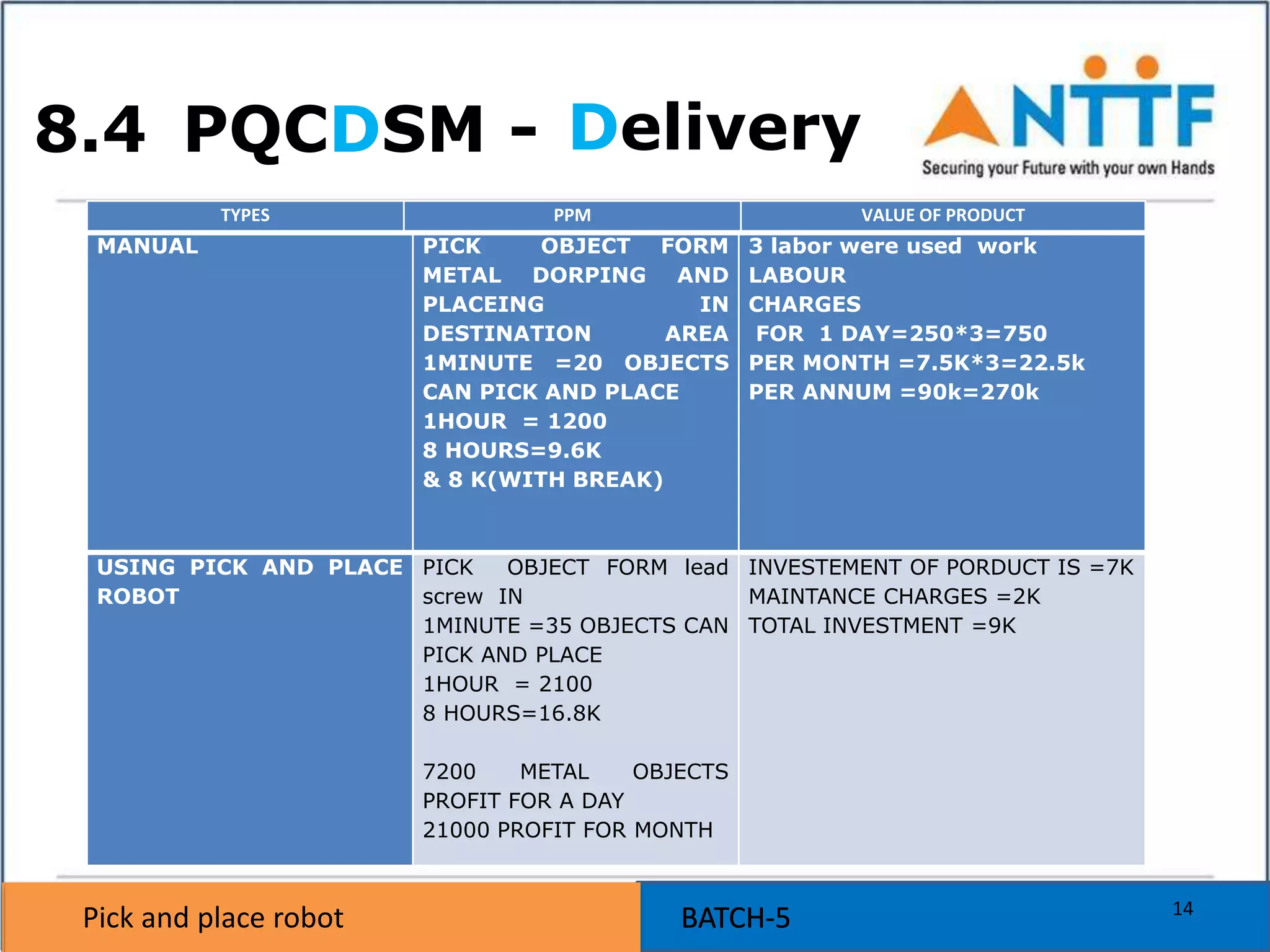

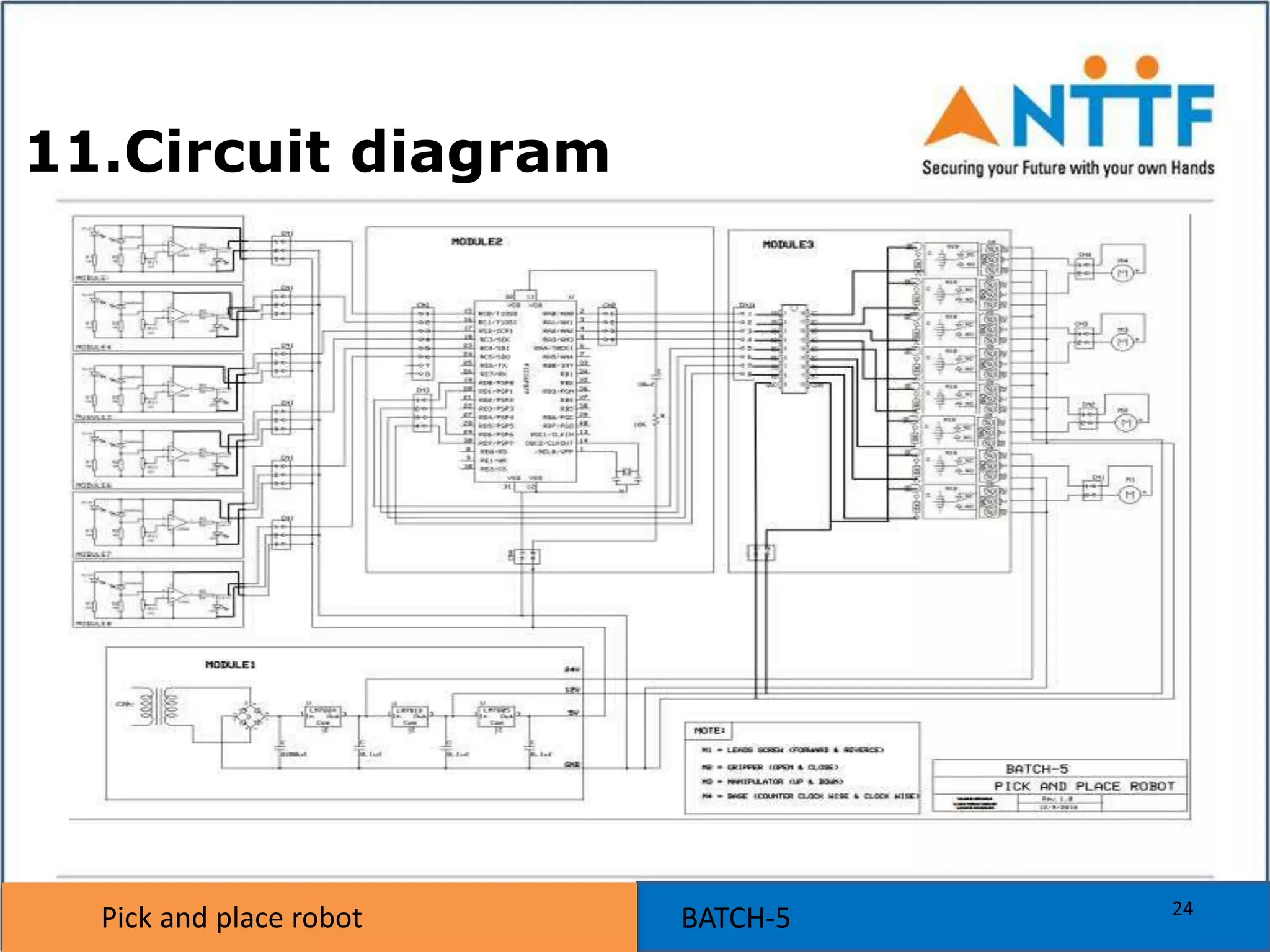

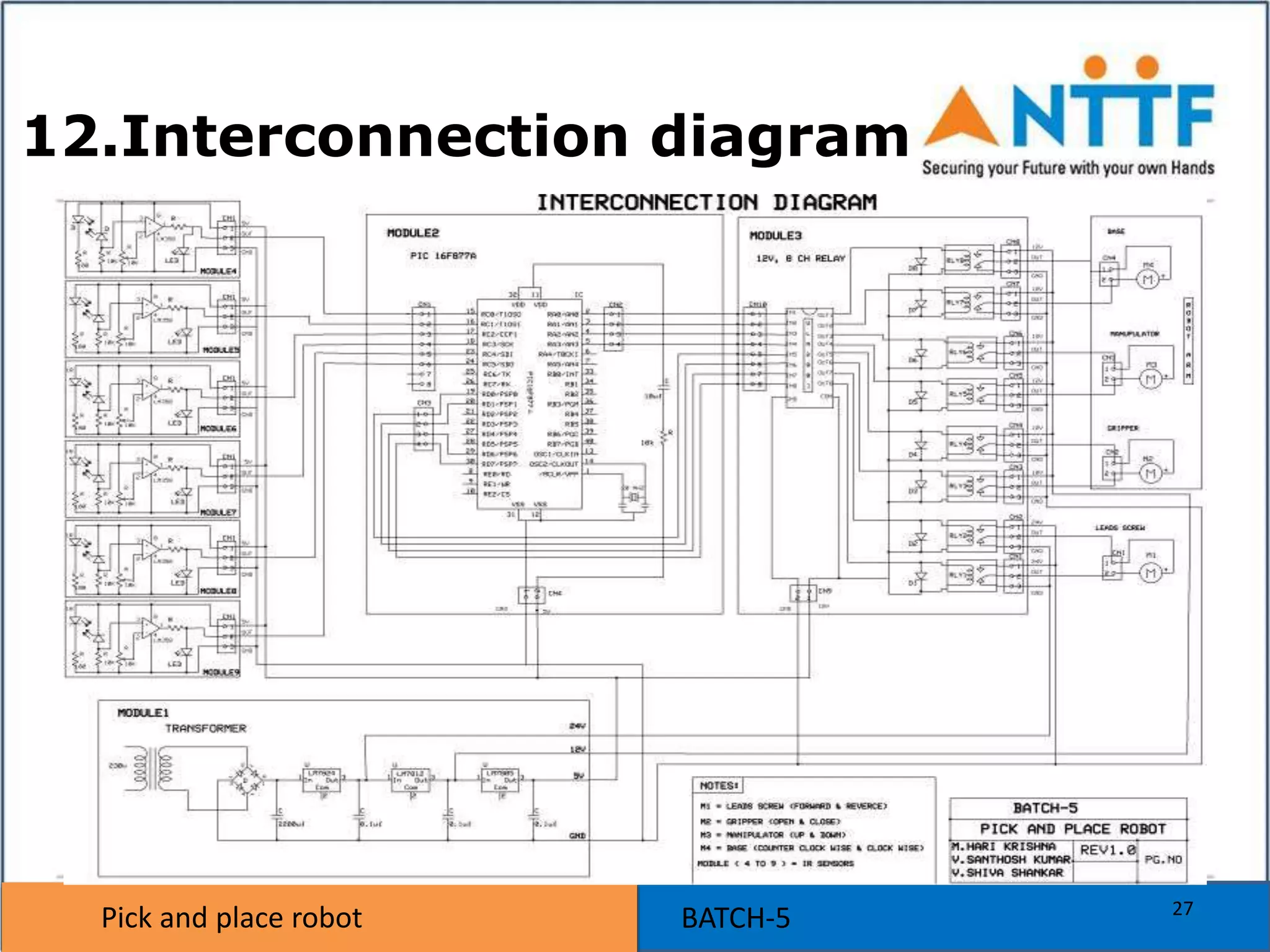

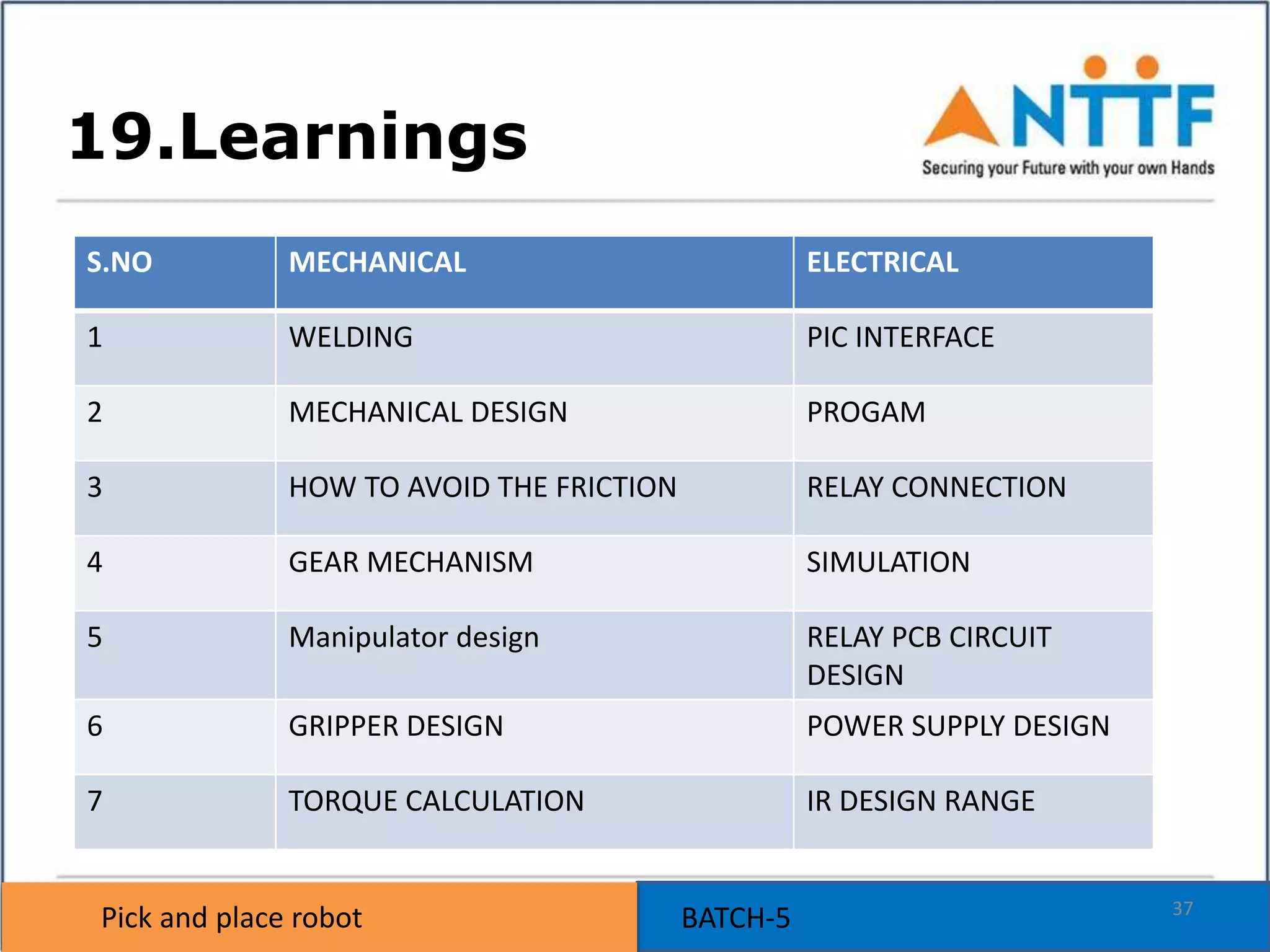

This document describes the design of an automatic pick and place robot created by students. The robot uses a robotic arm with a gripper to pick objects from one box and place them in another box moving along linear guide ways. It analyzes how the robot can increase productivity over manual labor by working faster and without breaks. Diagrams and descriptions explain the mechanical and electrical components of the robot including the lead screw, ball bearings, gripper, manipulator, power supply, and PIC microcontroller used to control the robotic movements.