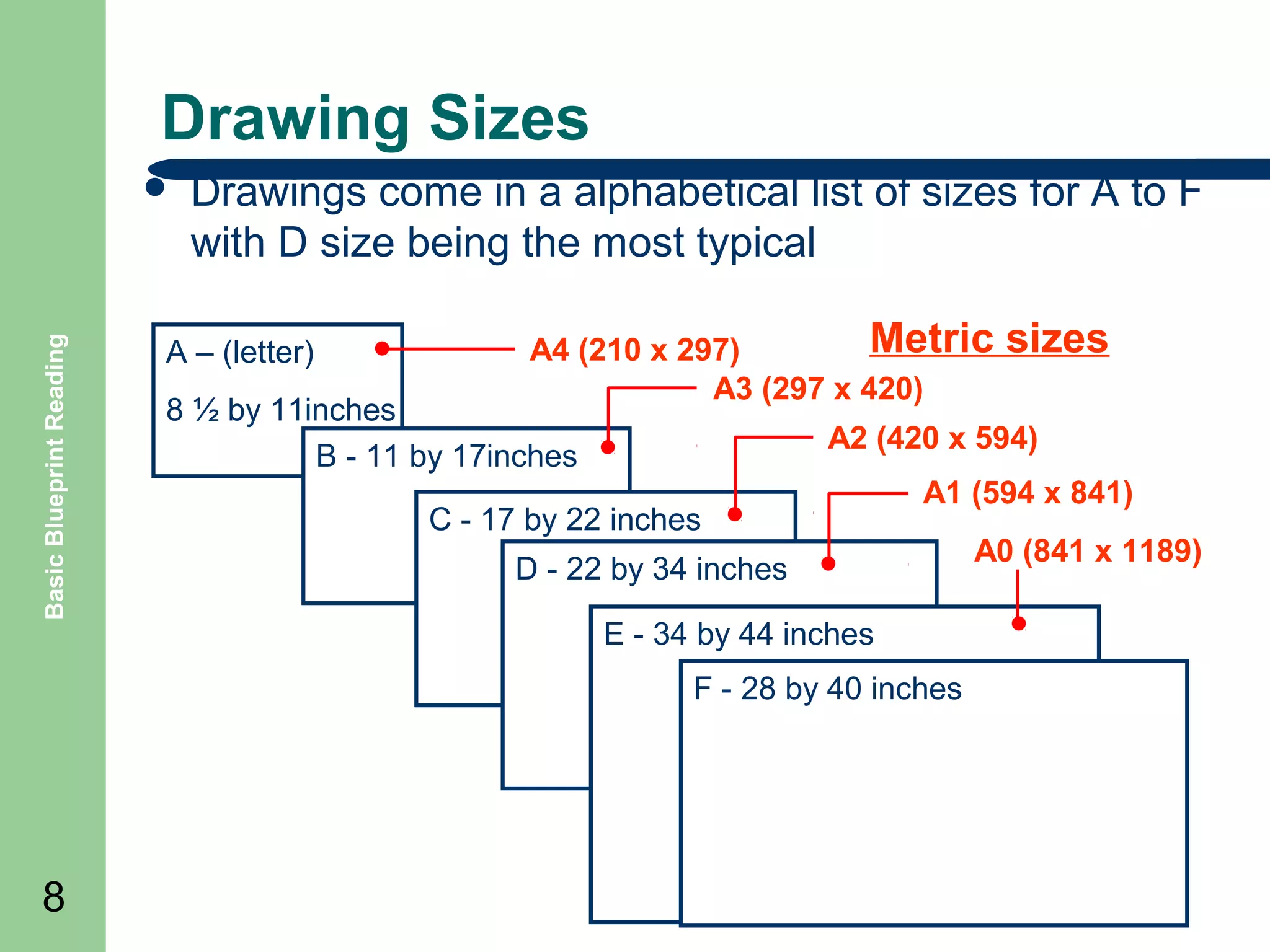

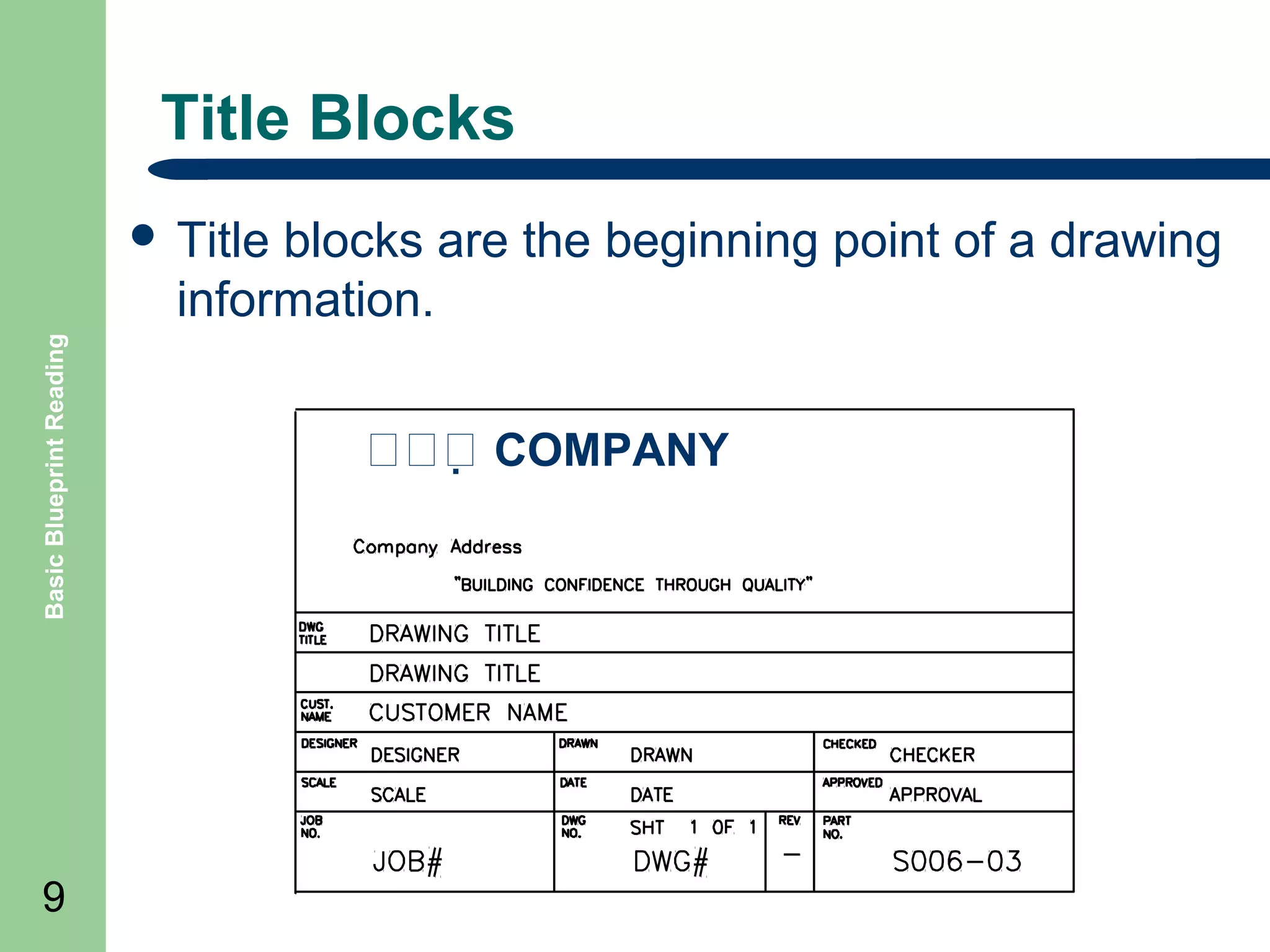

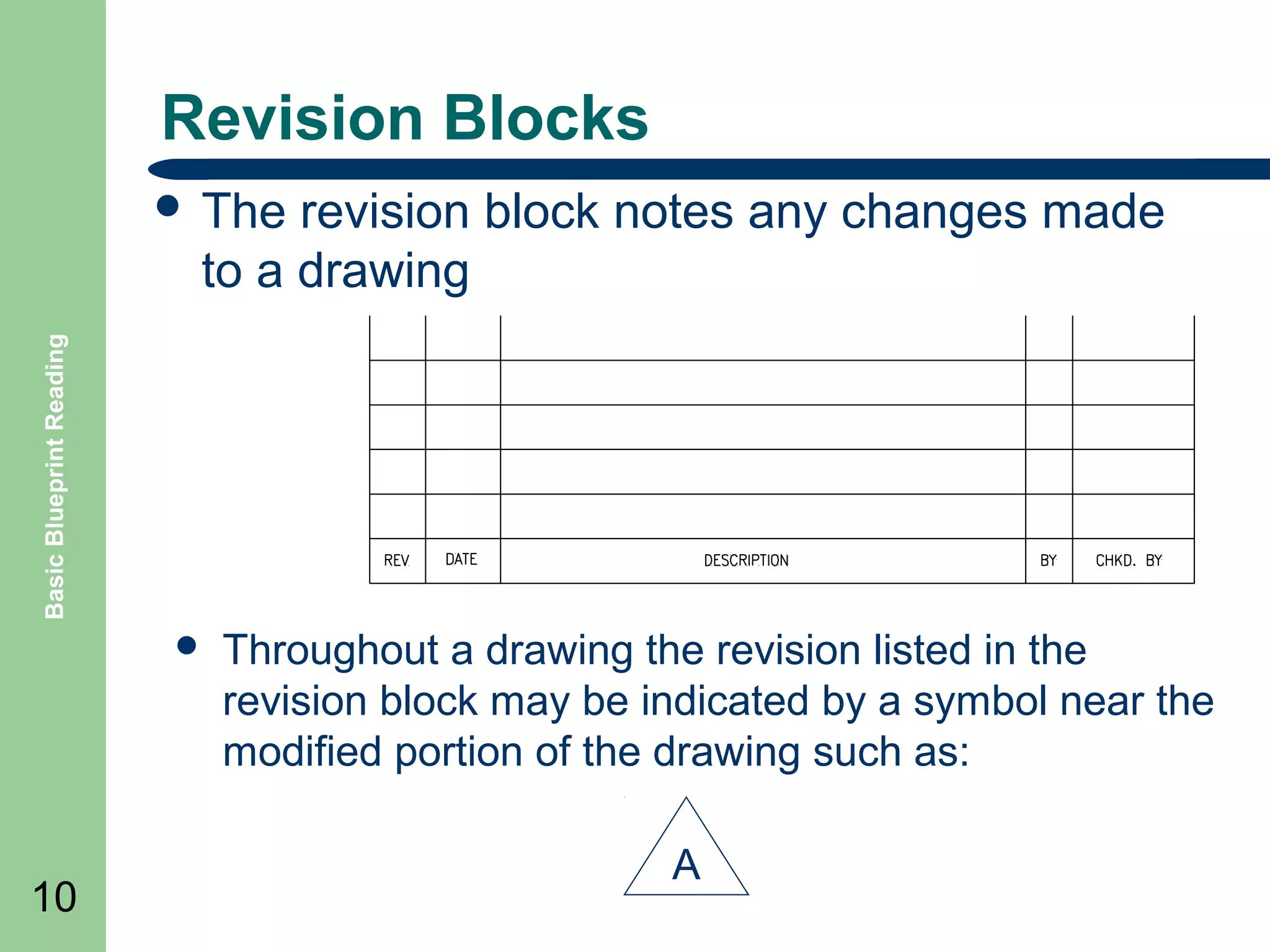

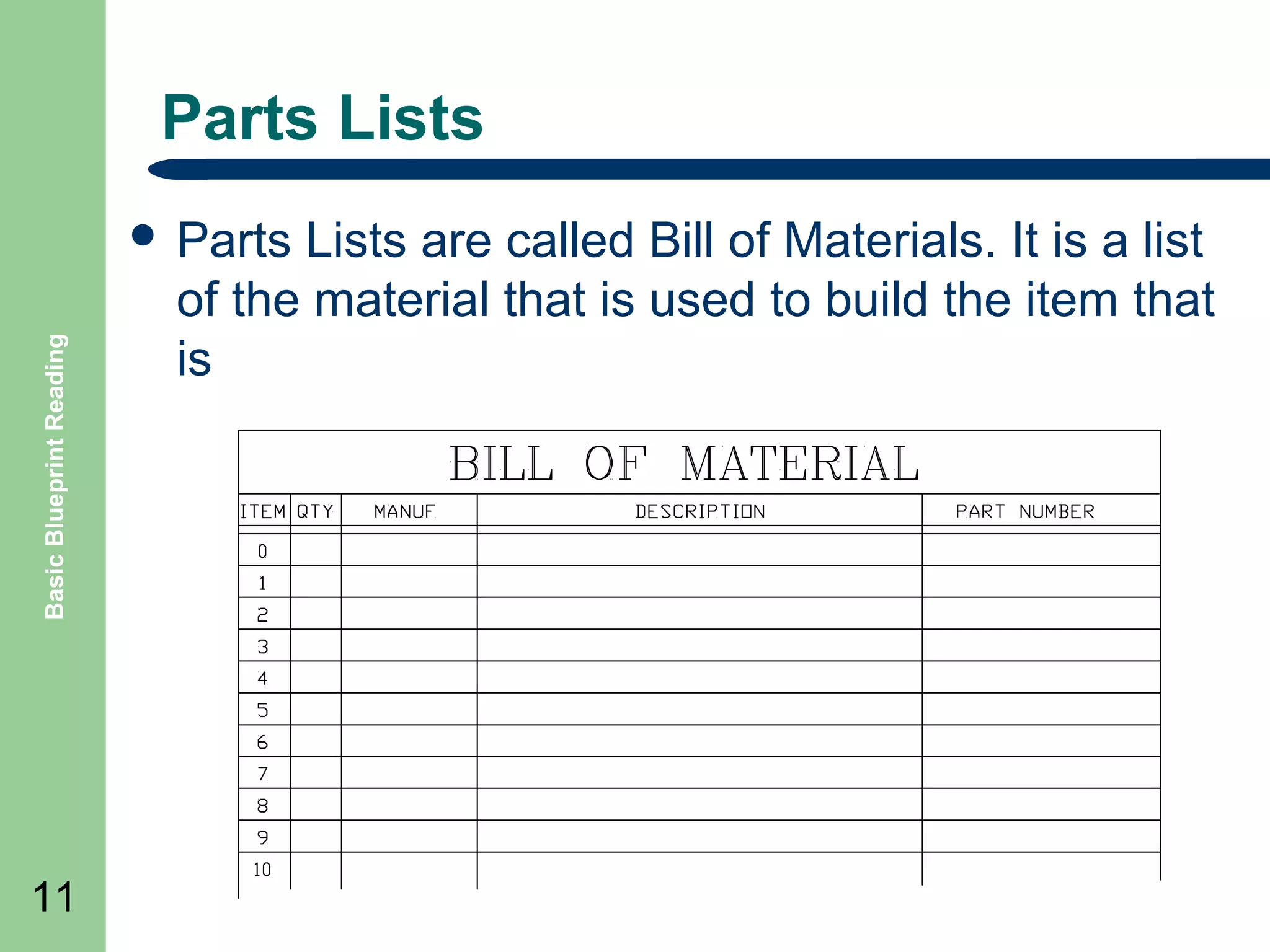

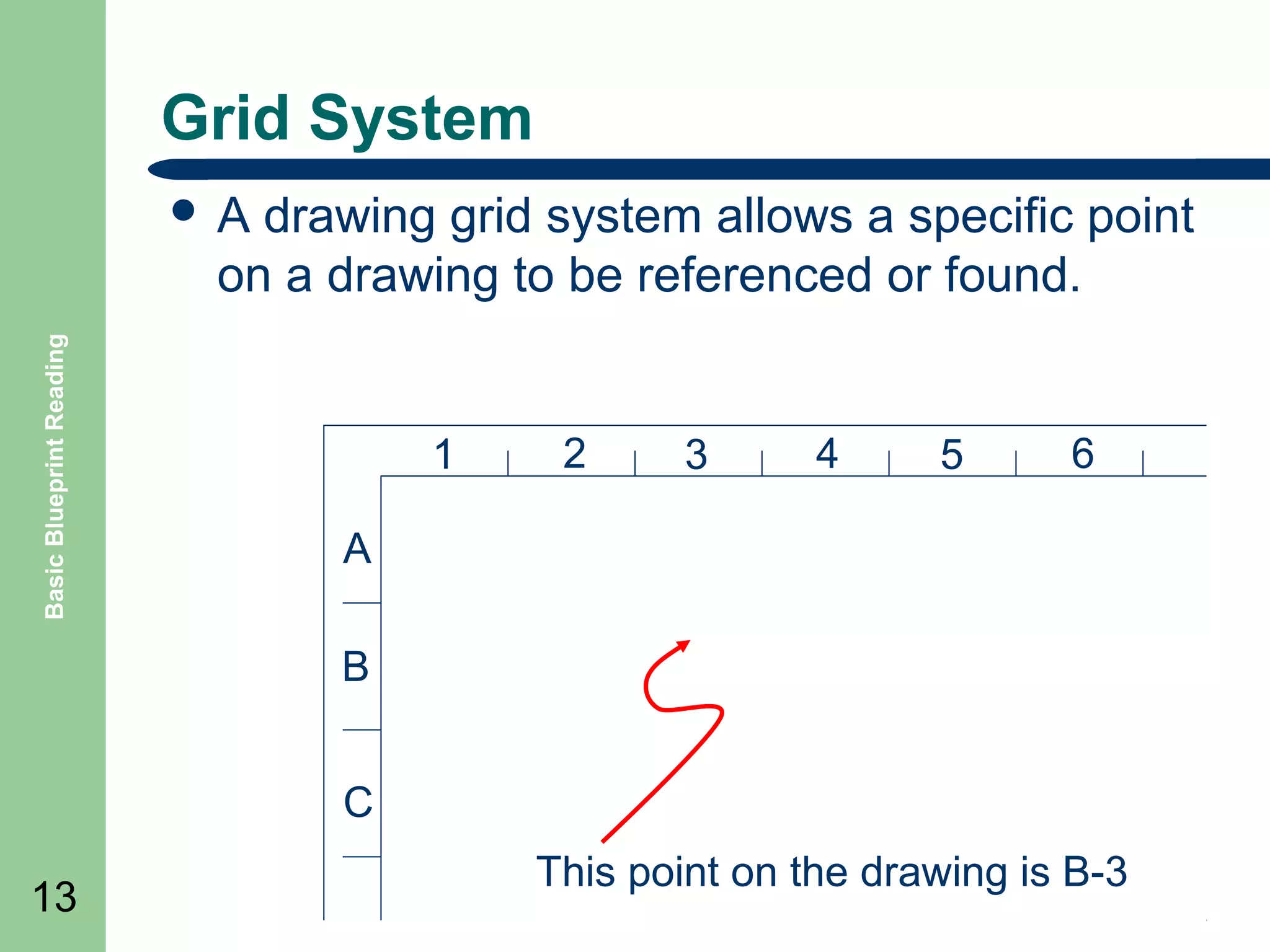

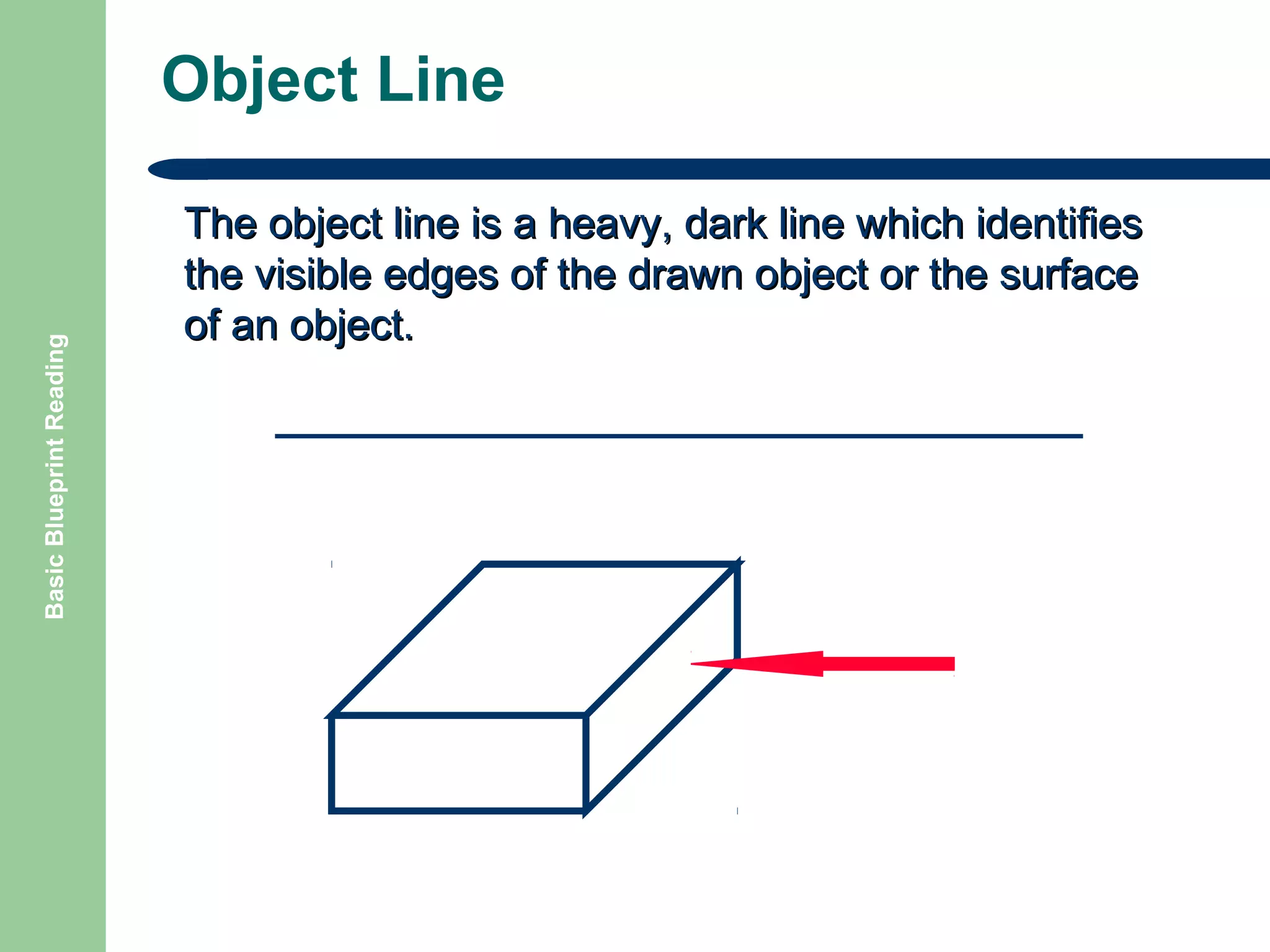

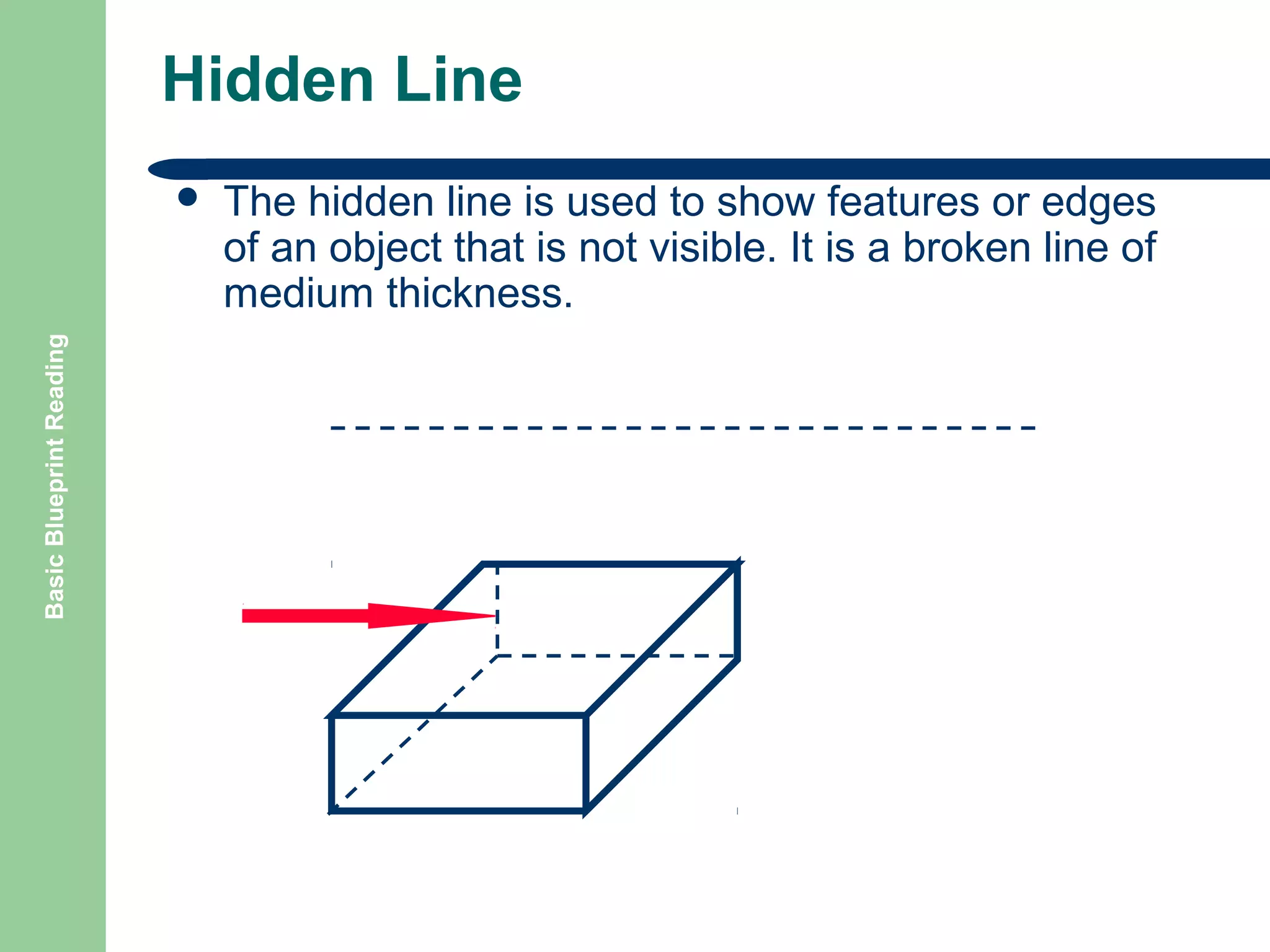

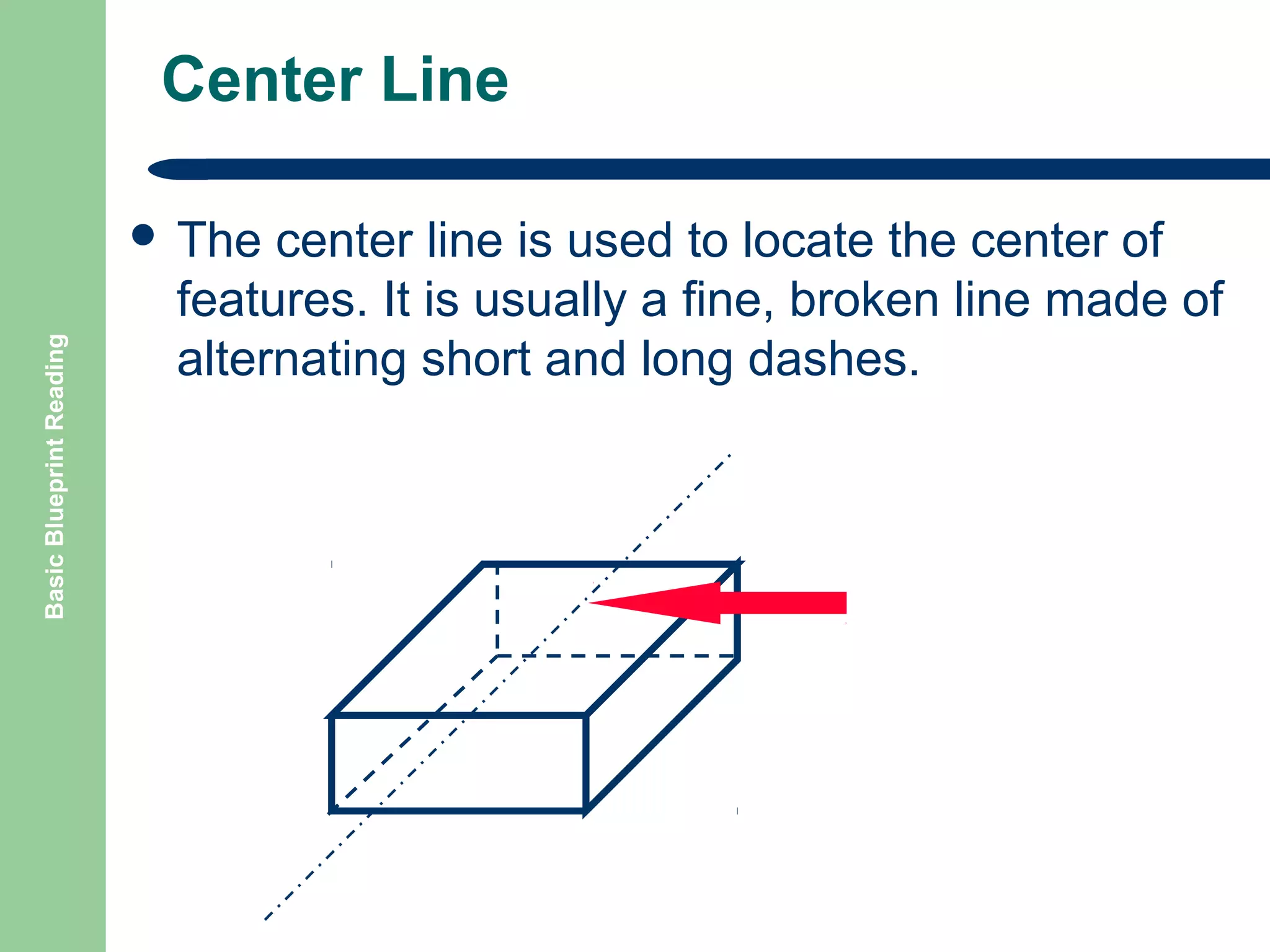

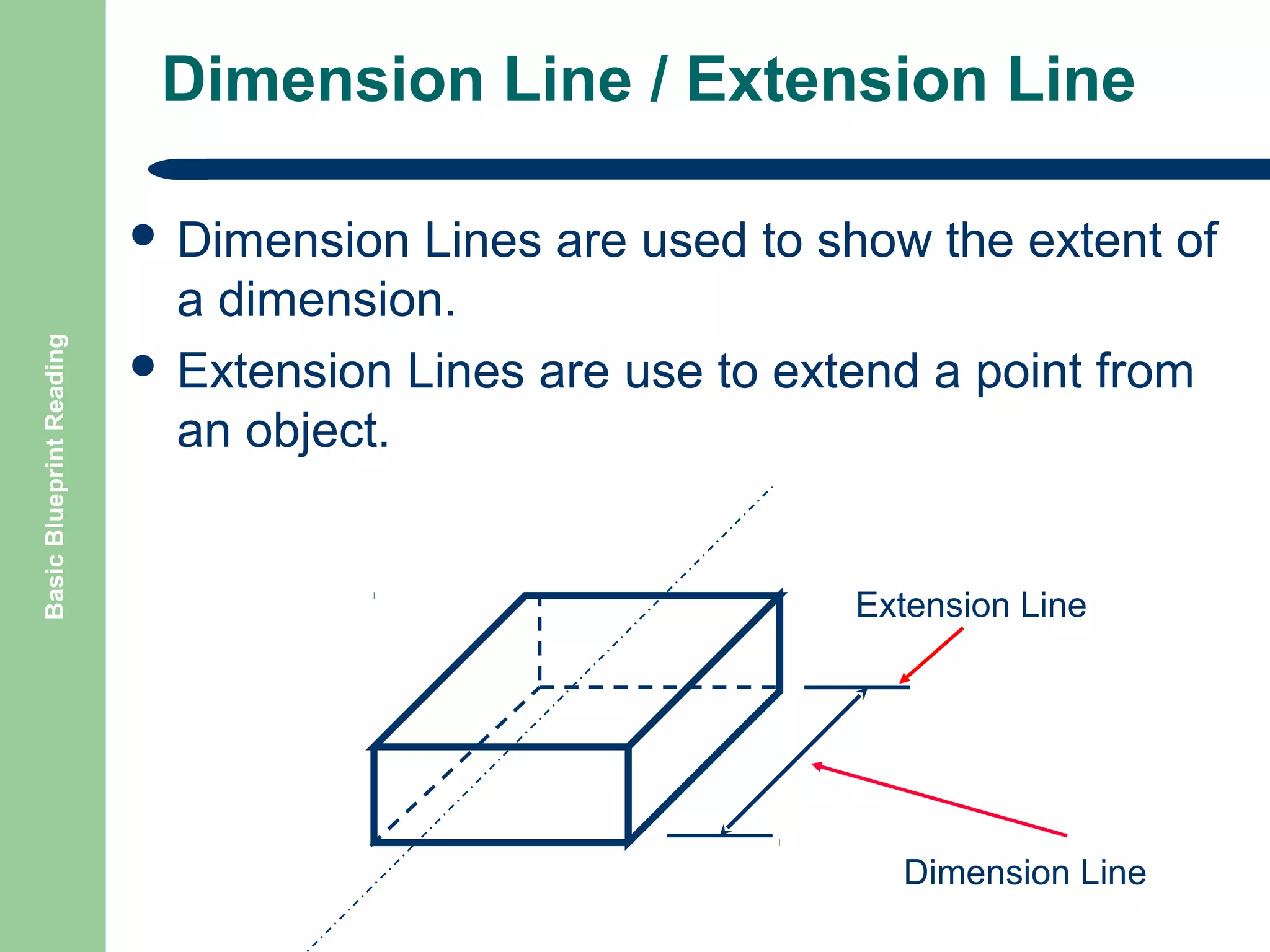

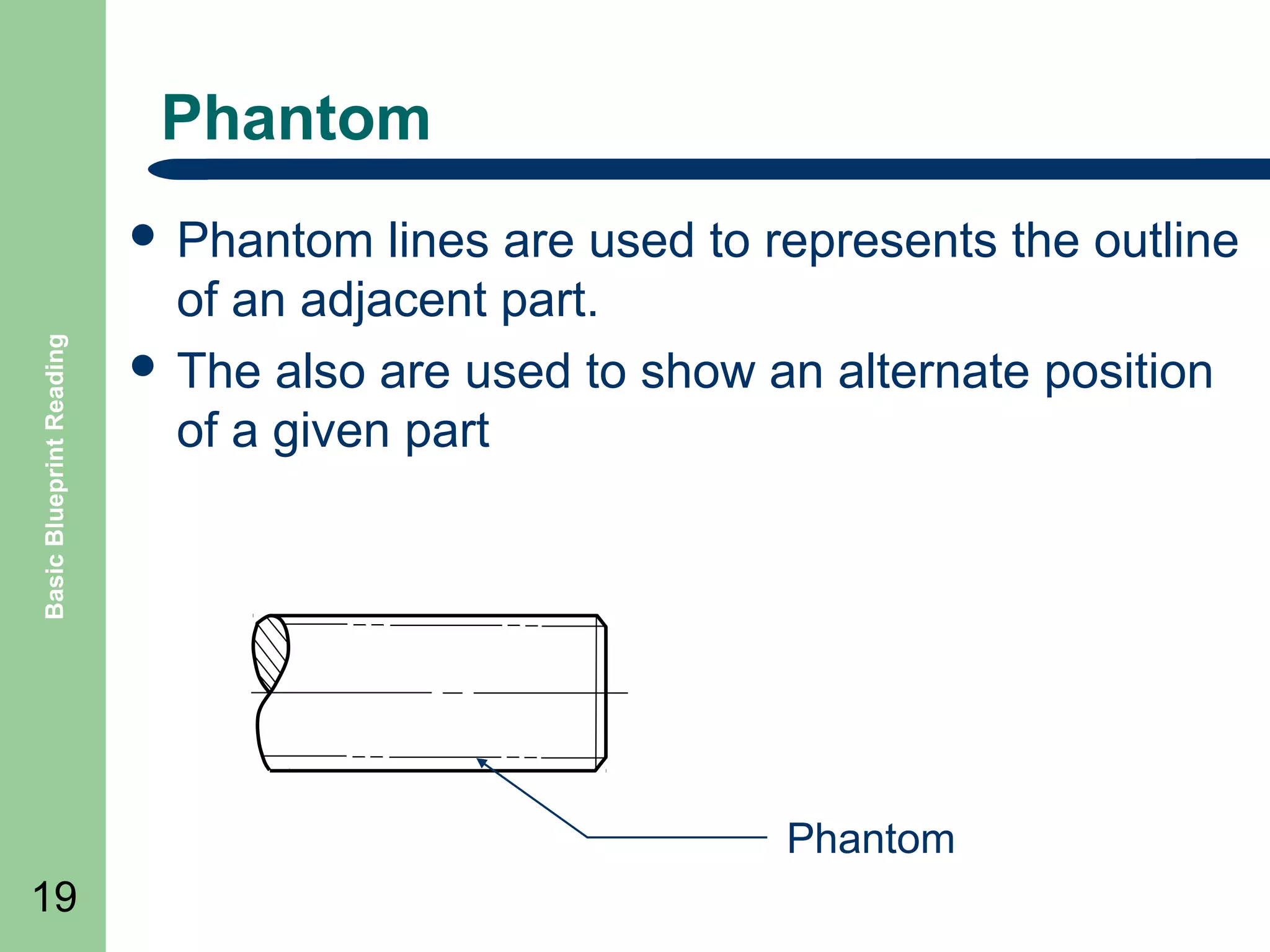

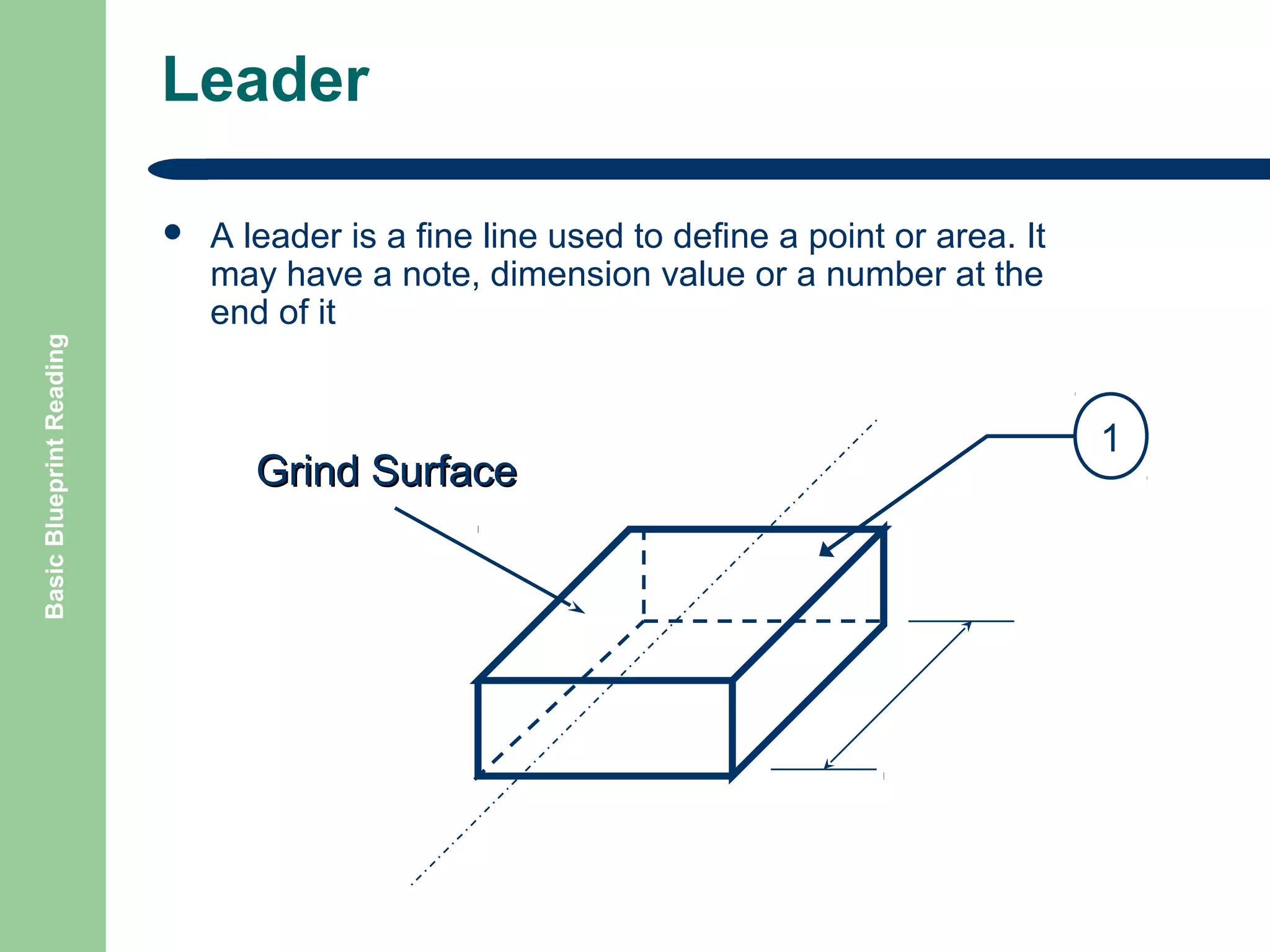

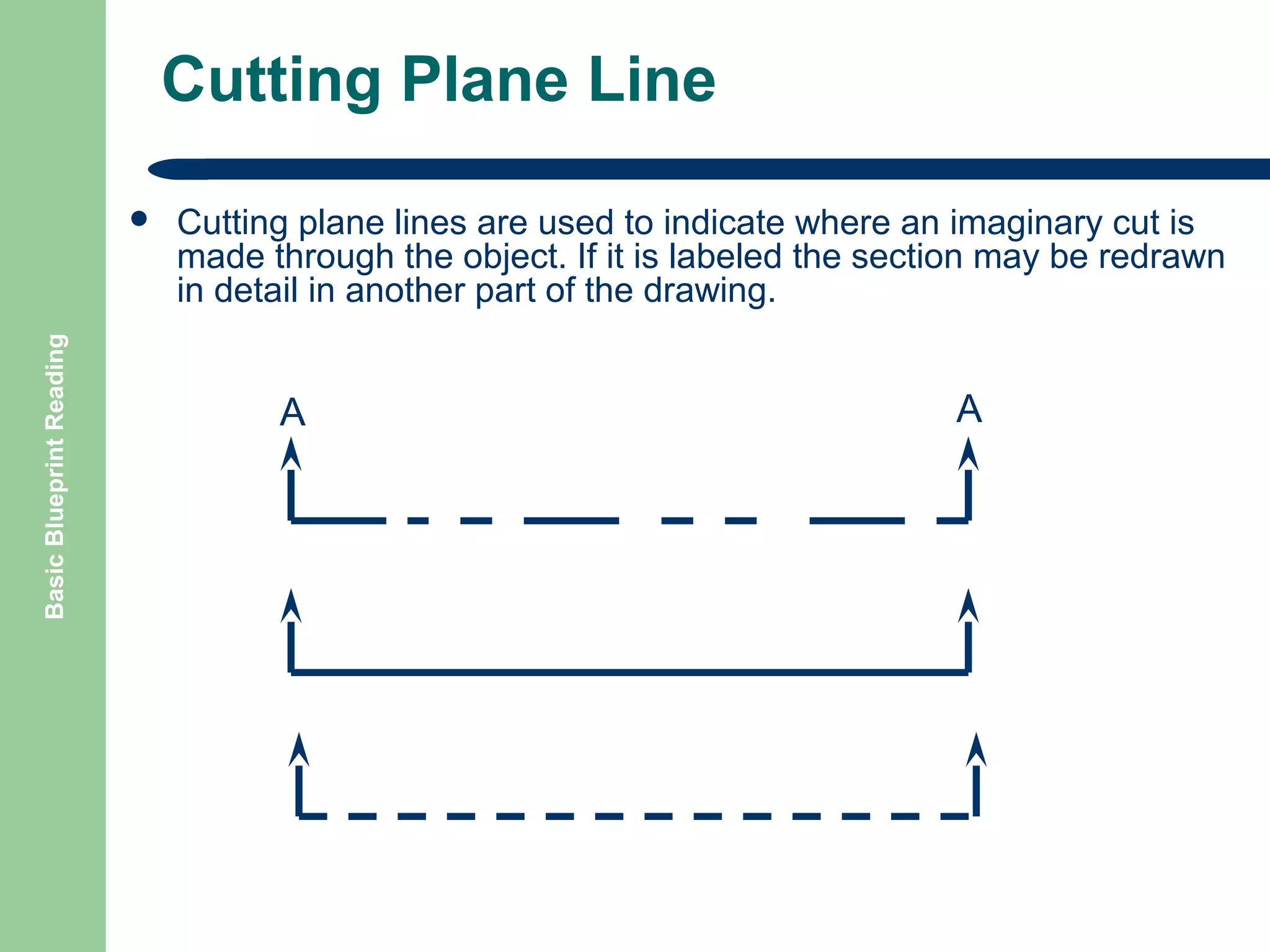

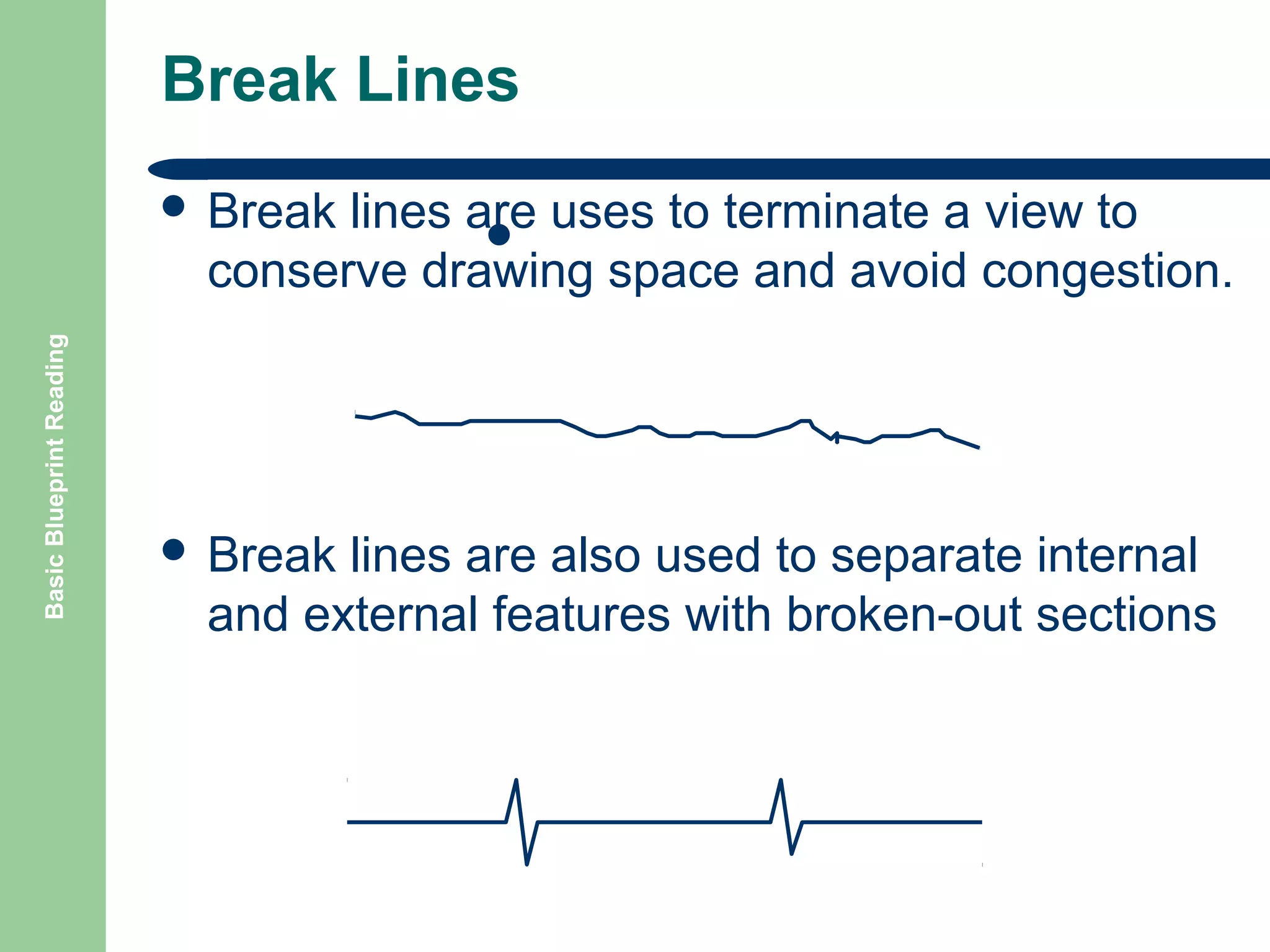

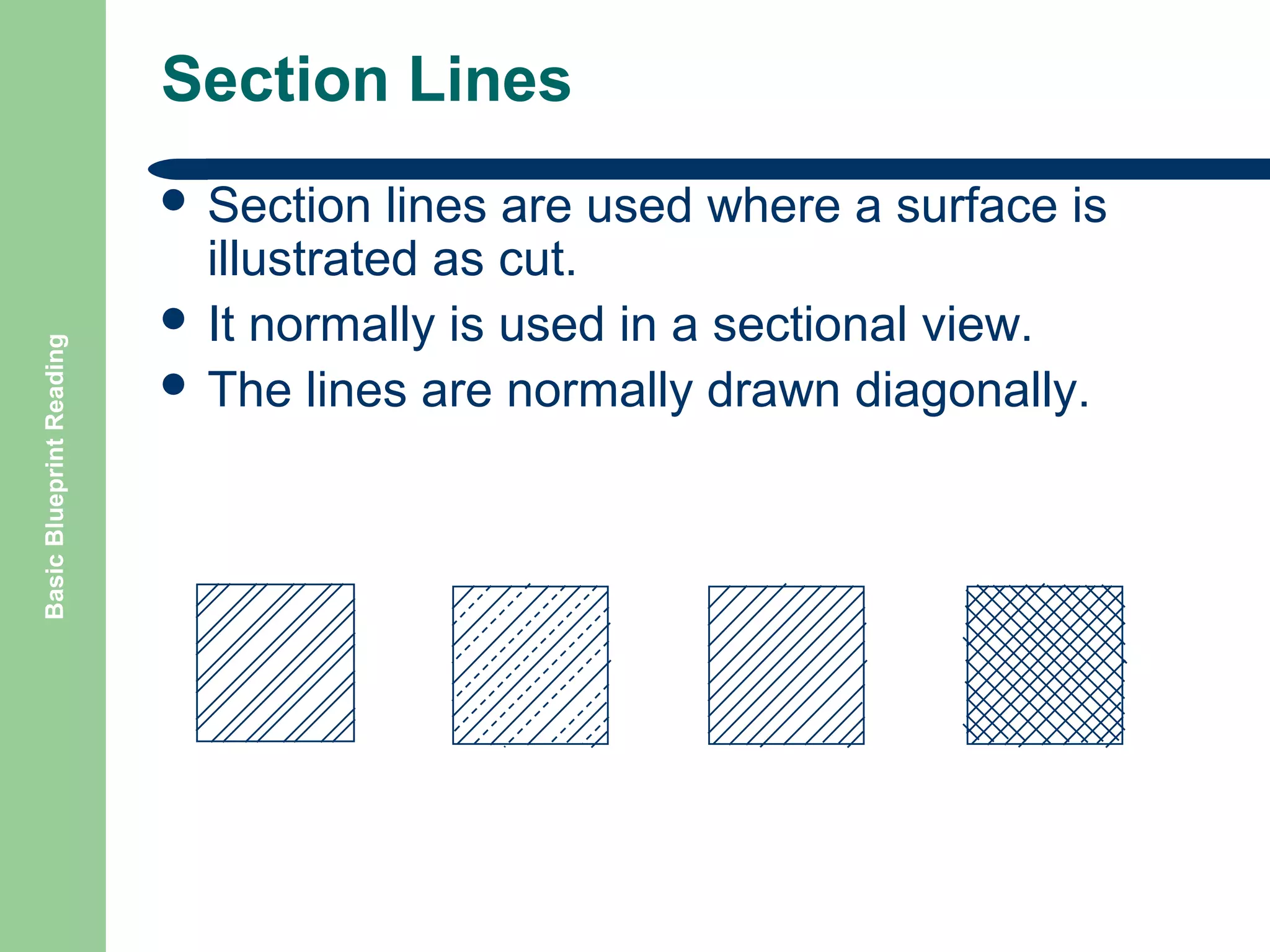

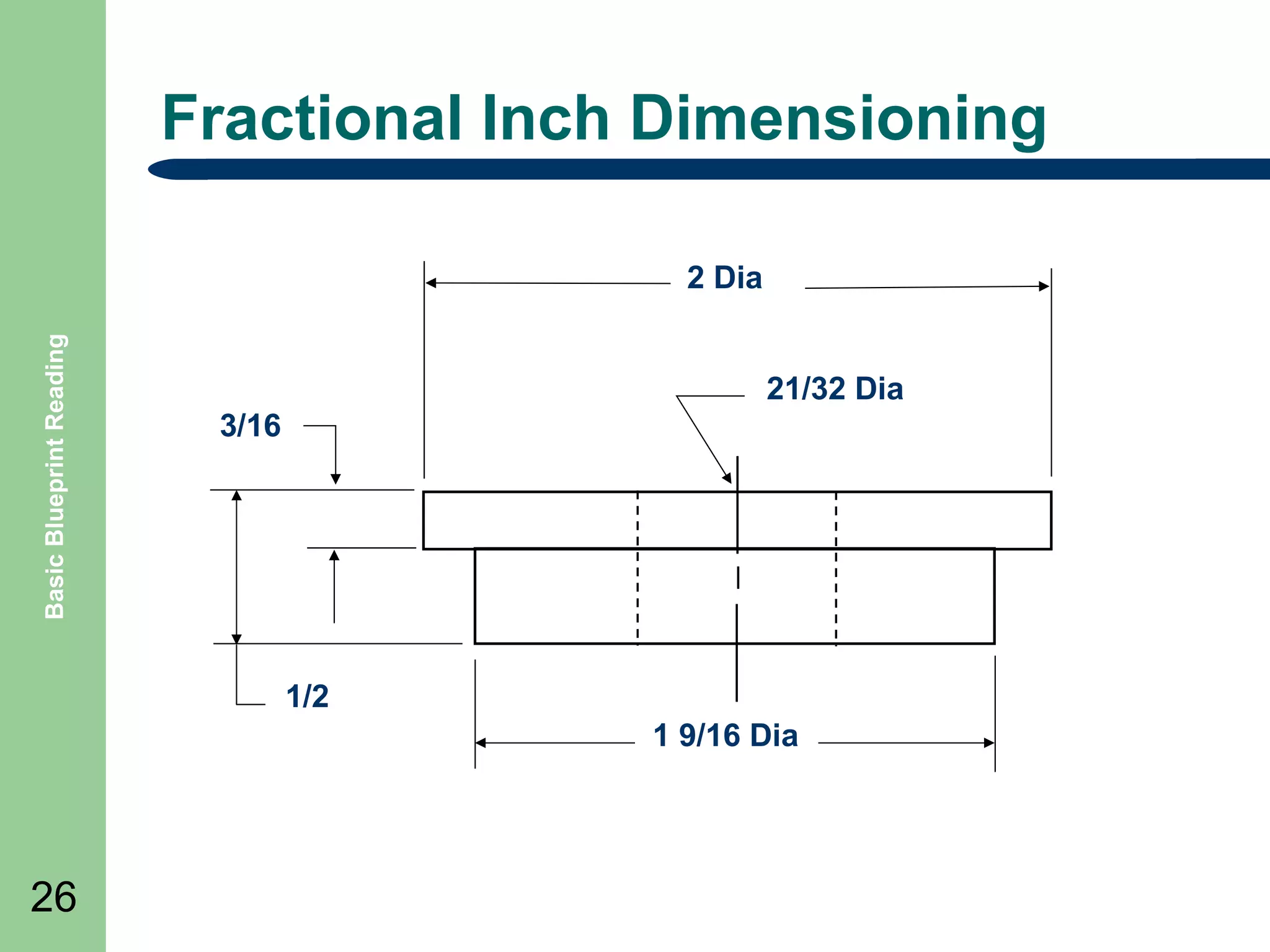

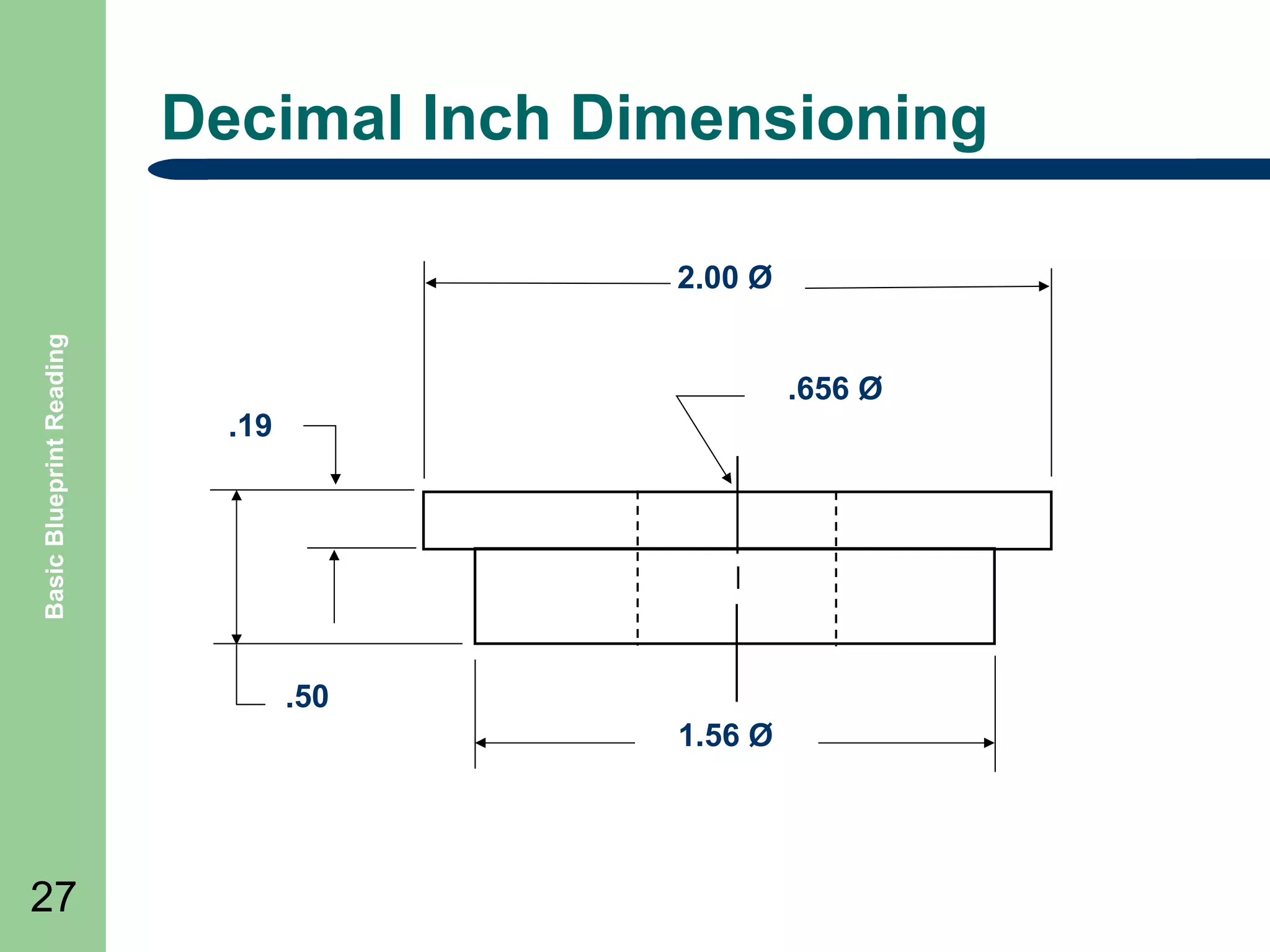

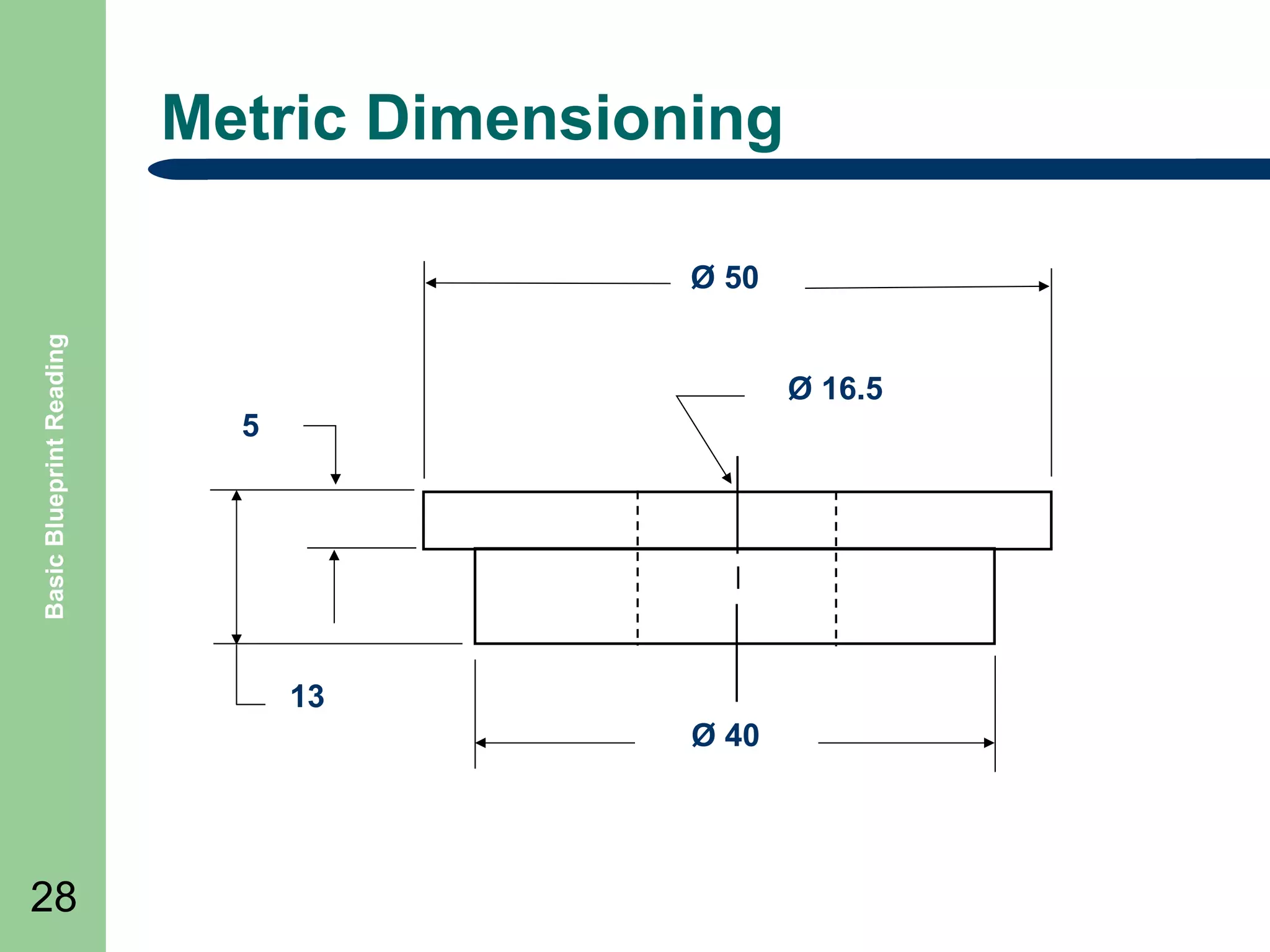

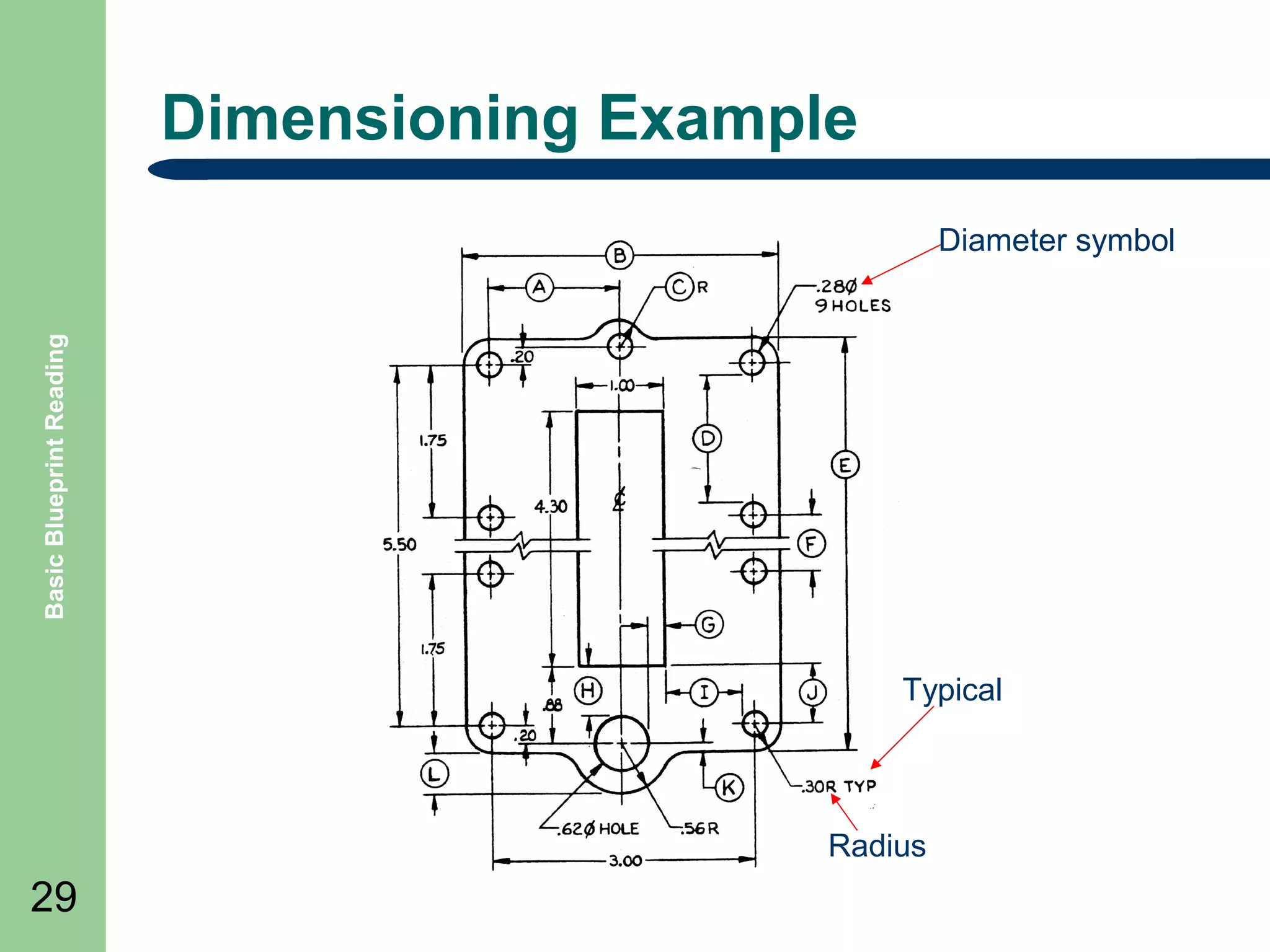

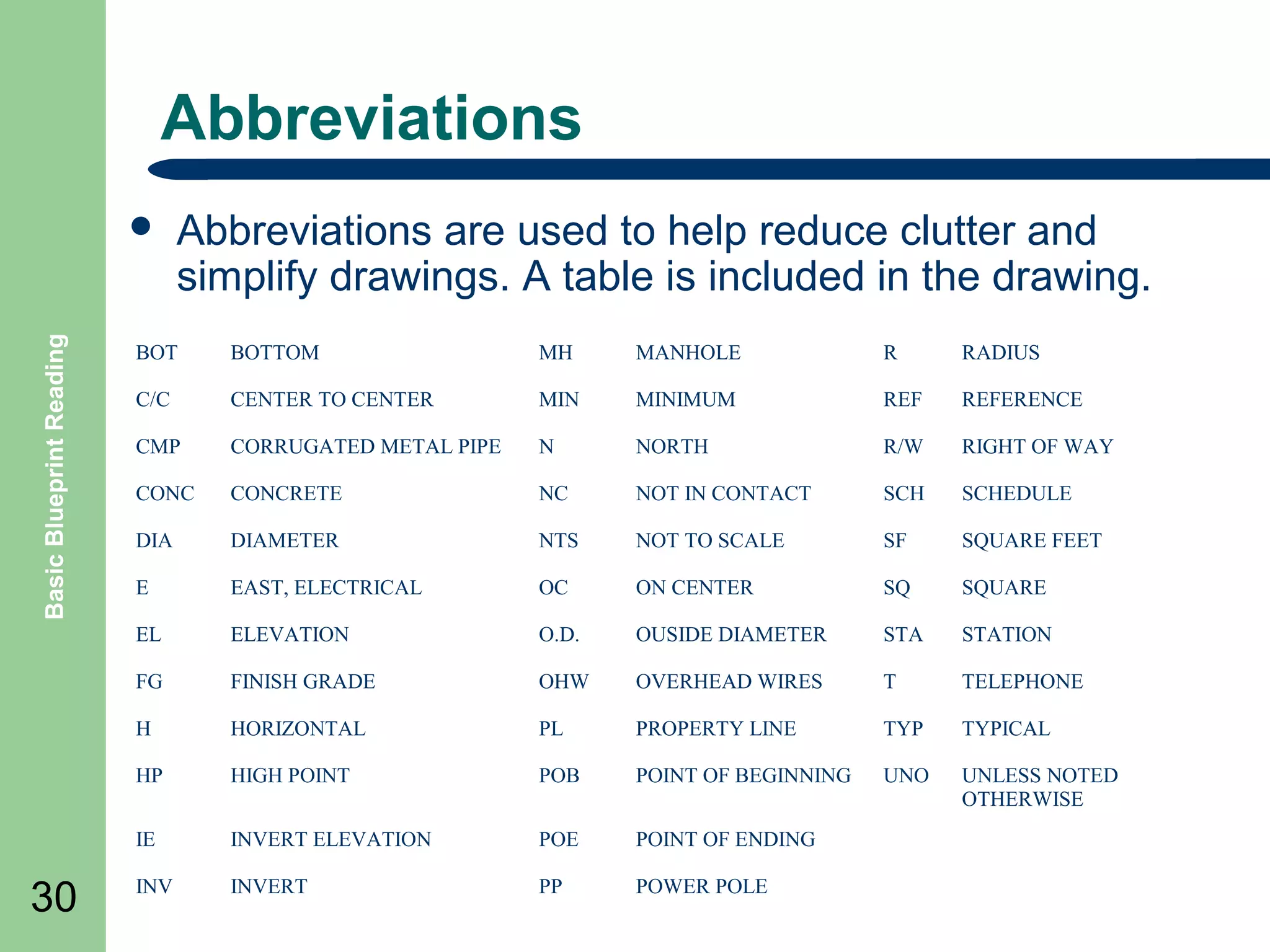

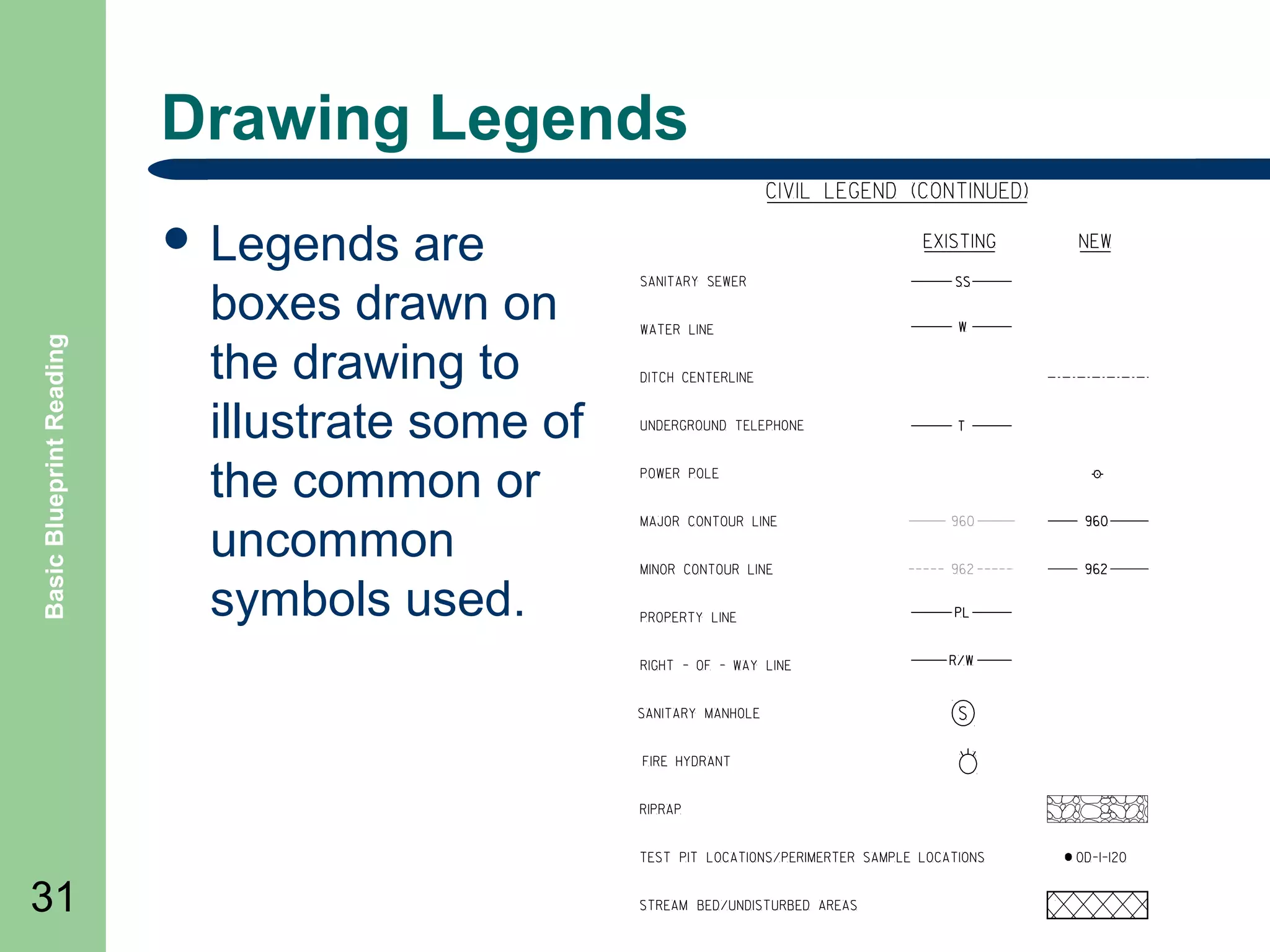

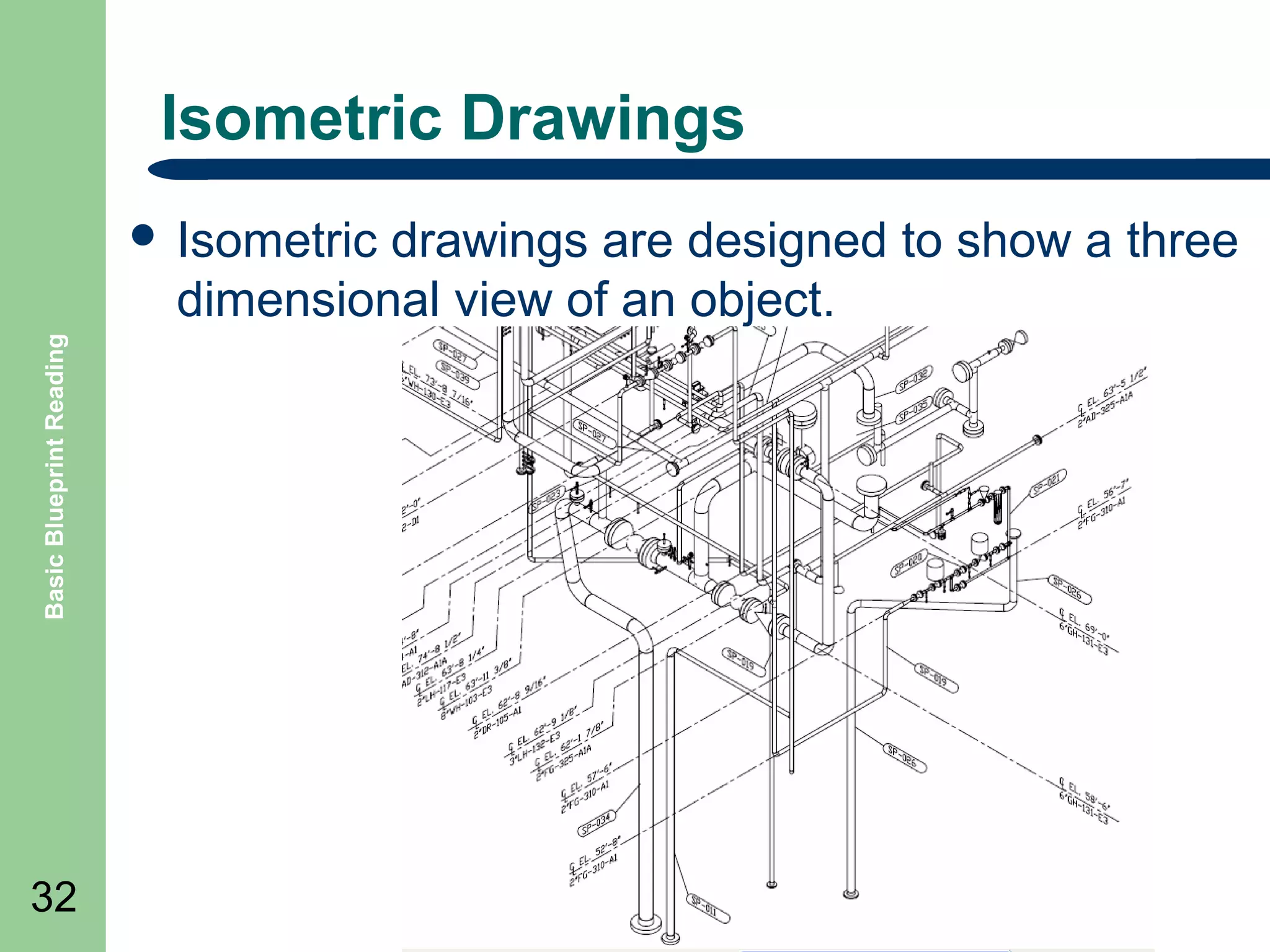

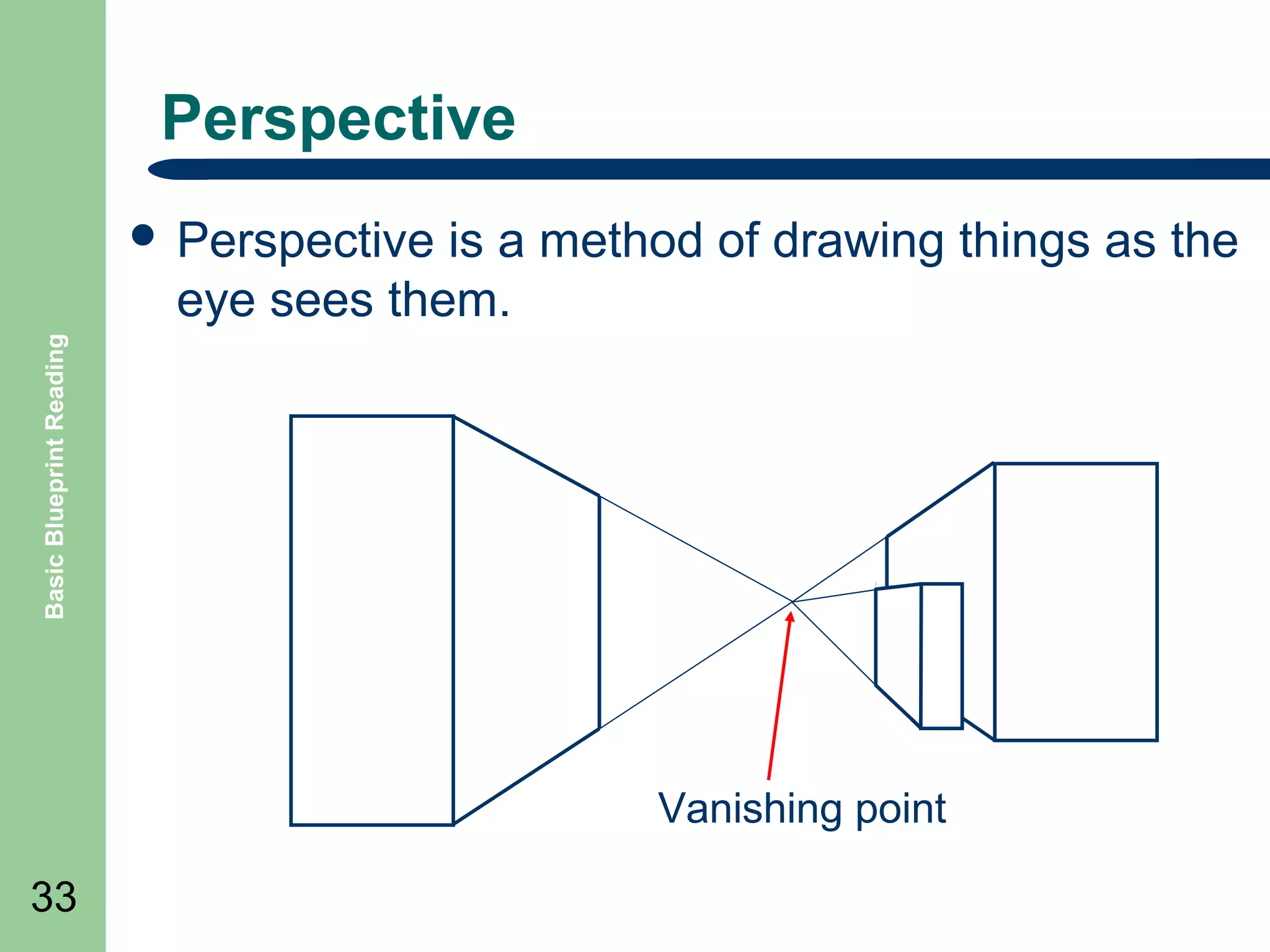

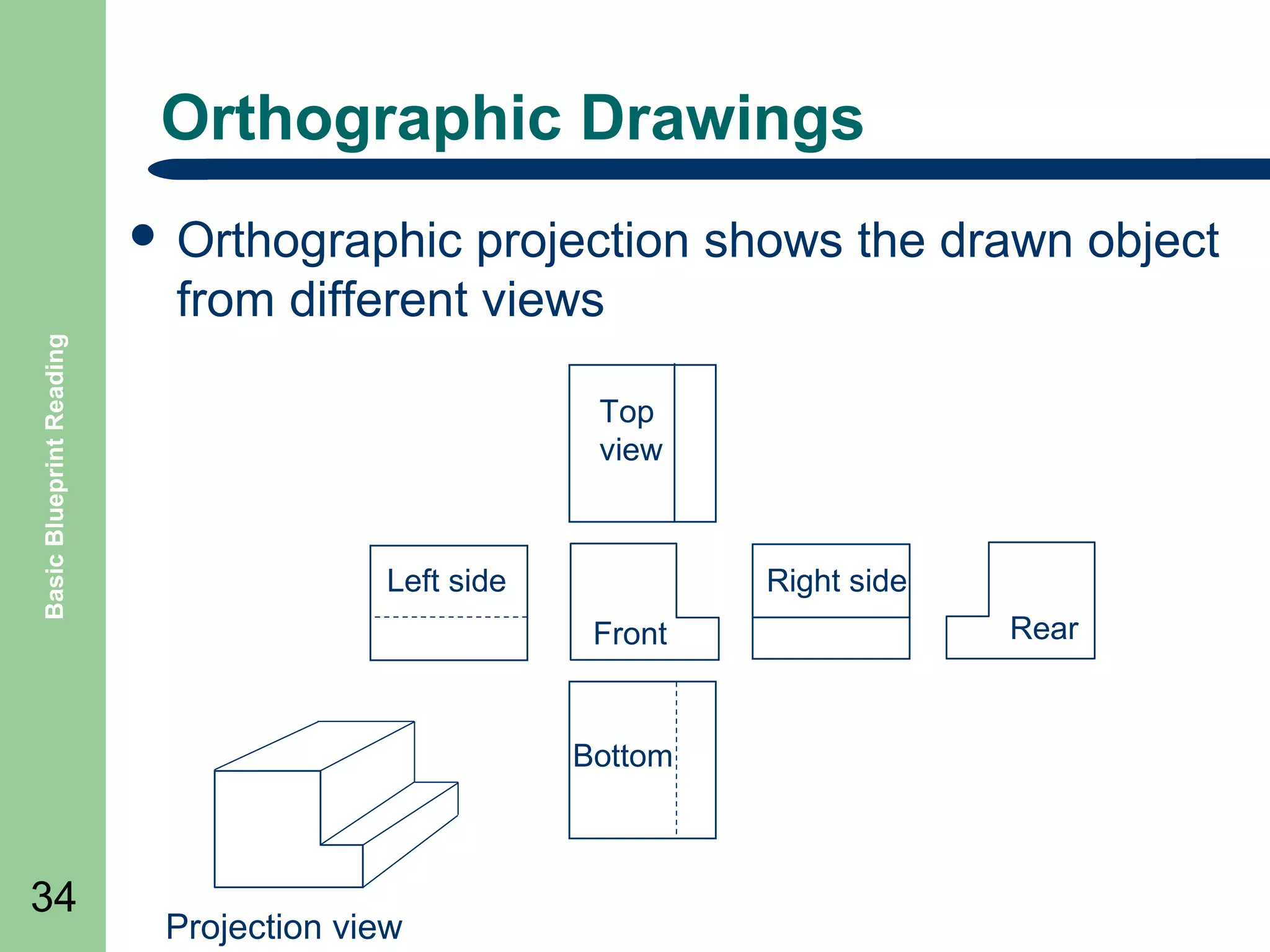

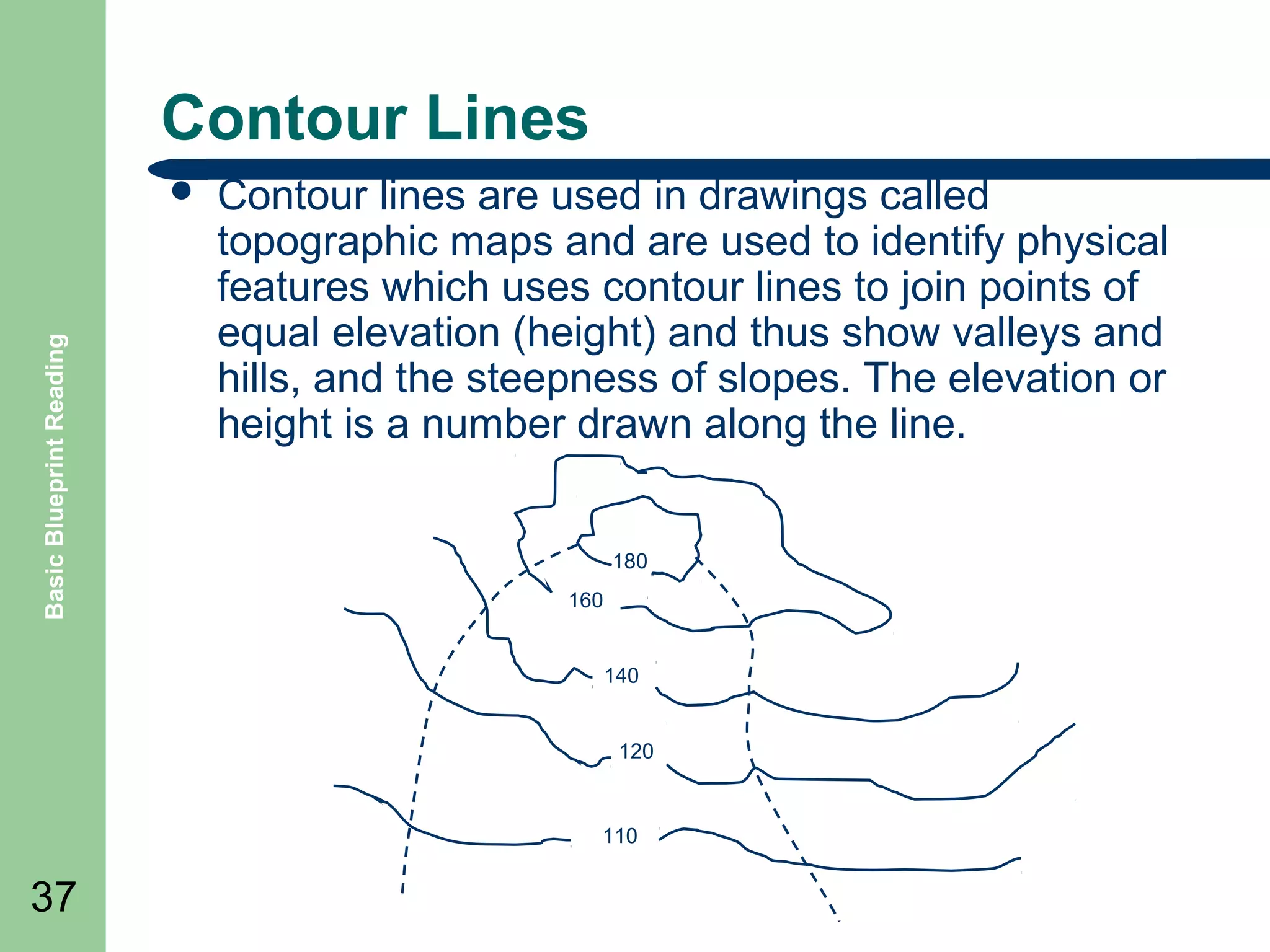

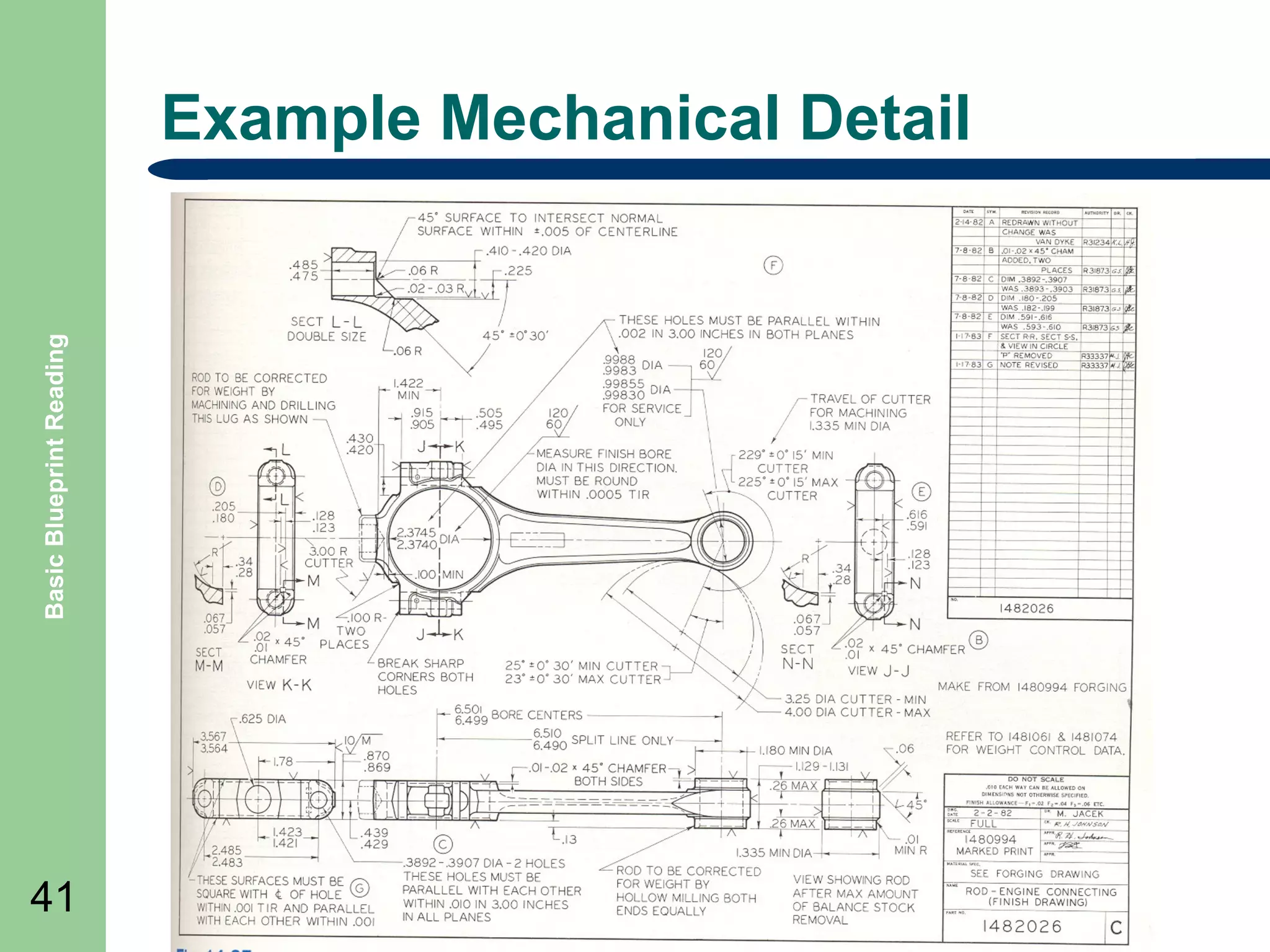

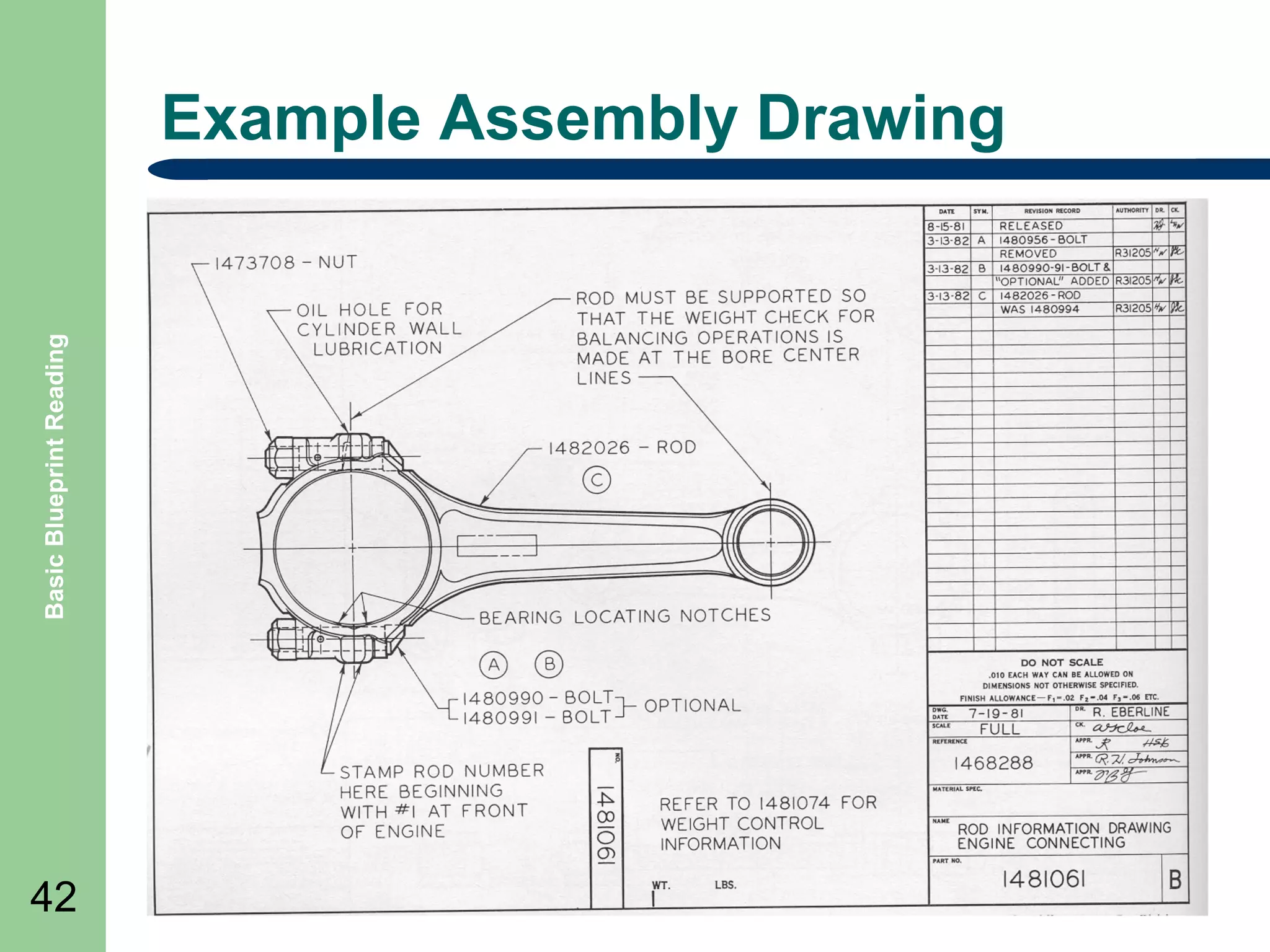

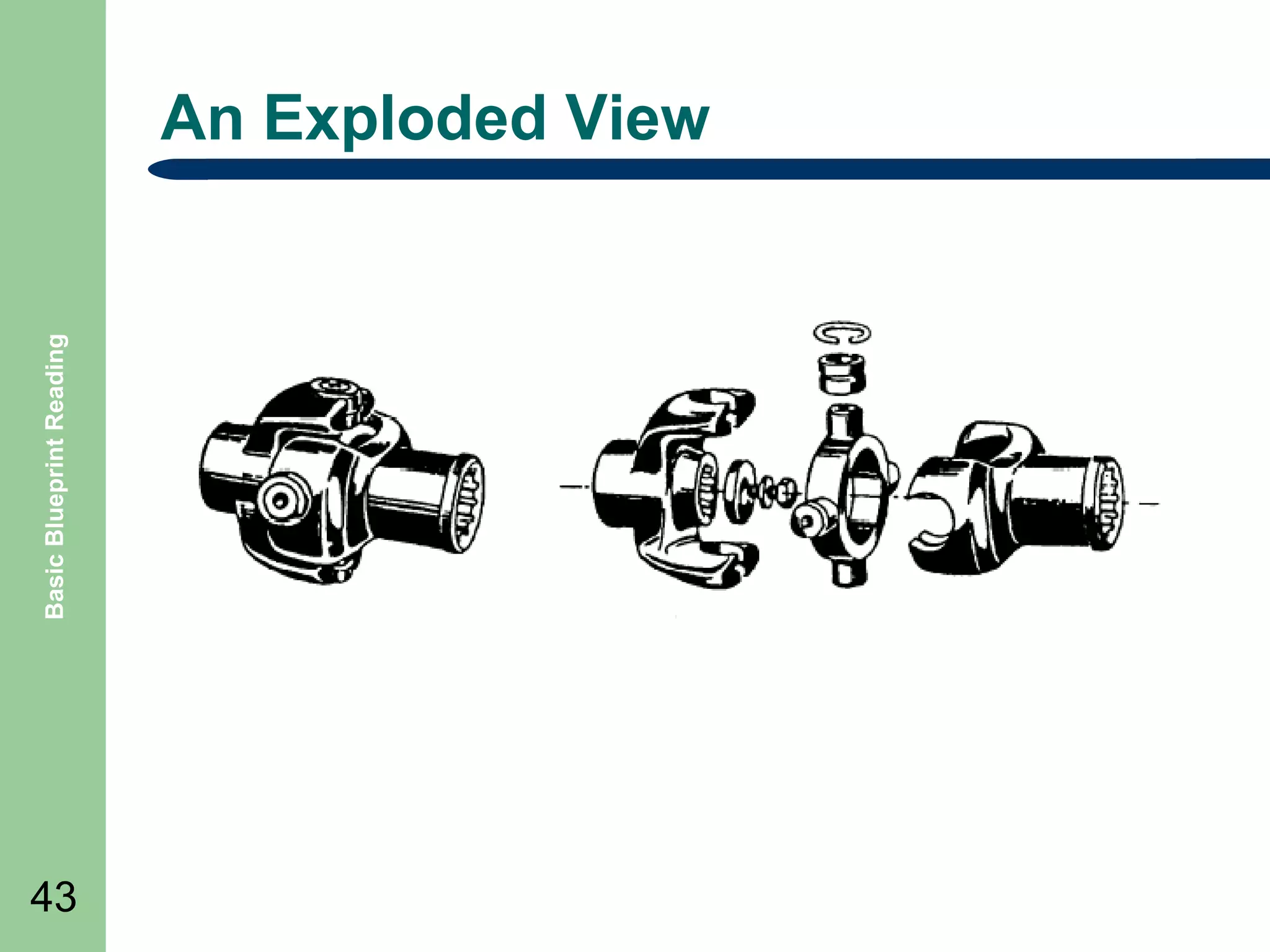

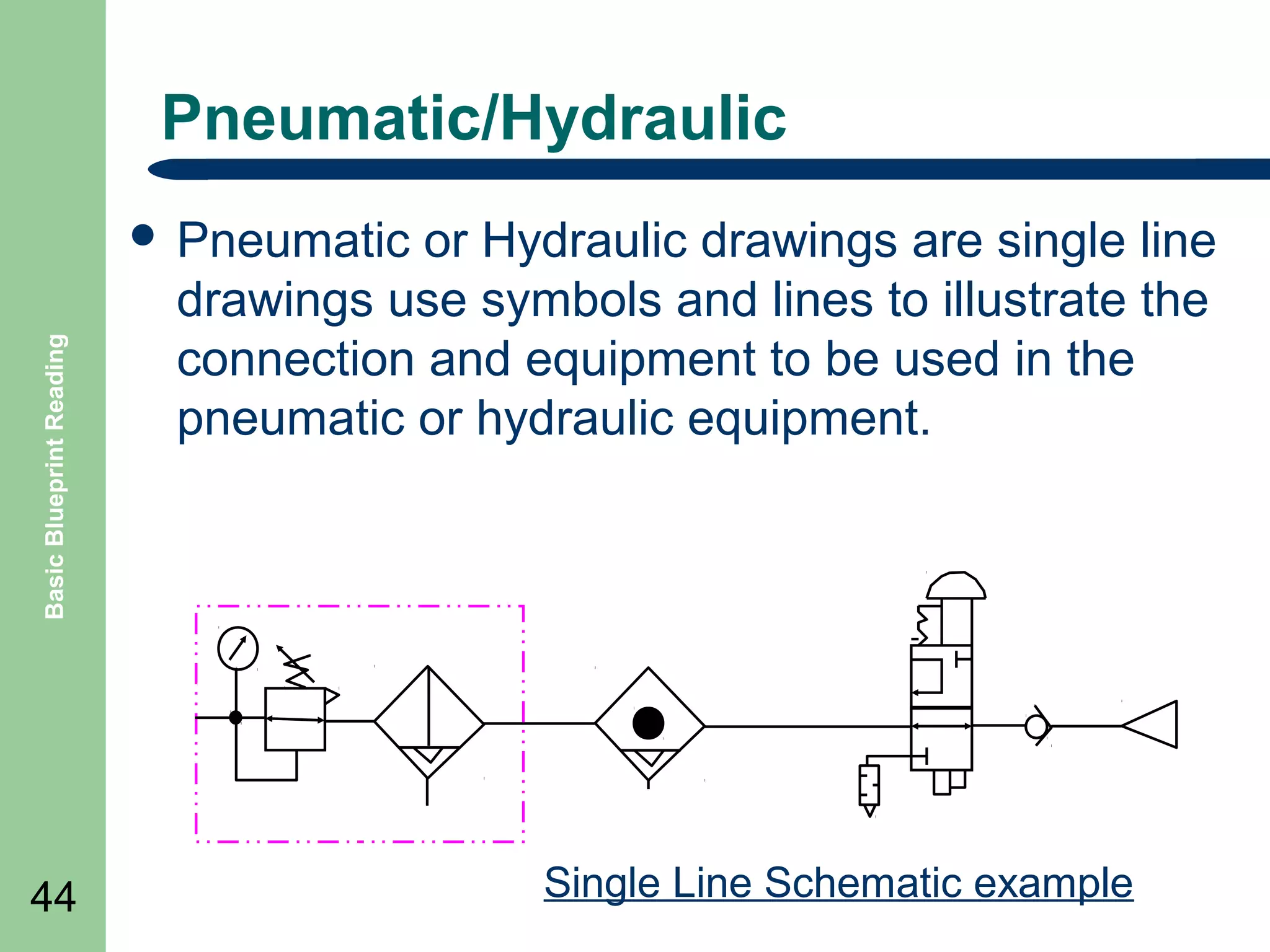

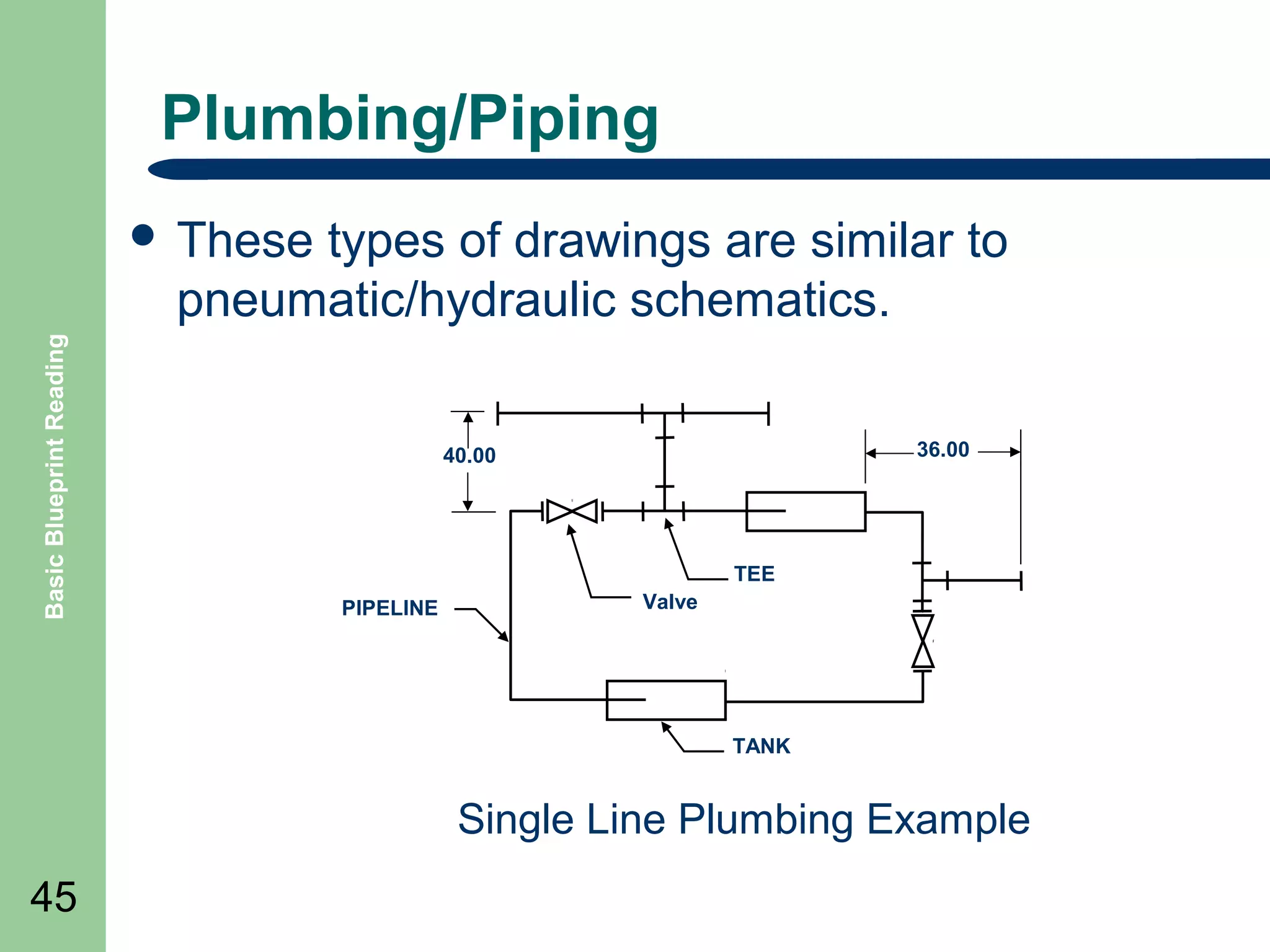

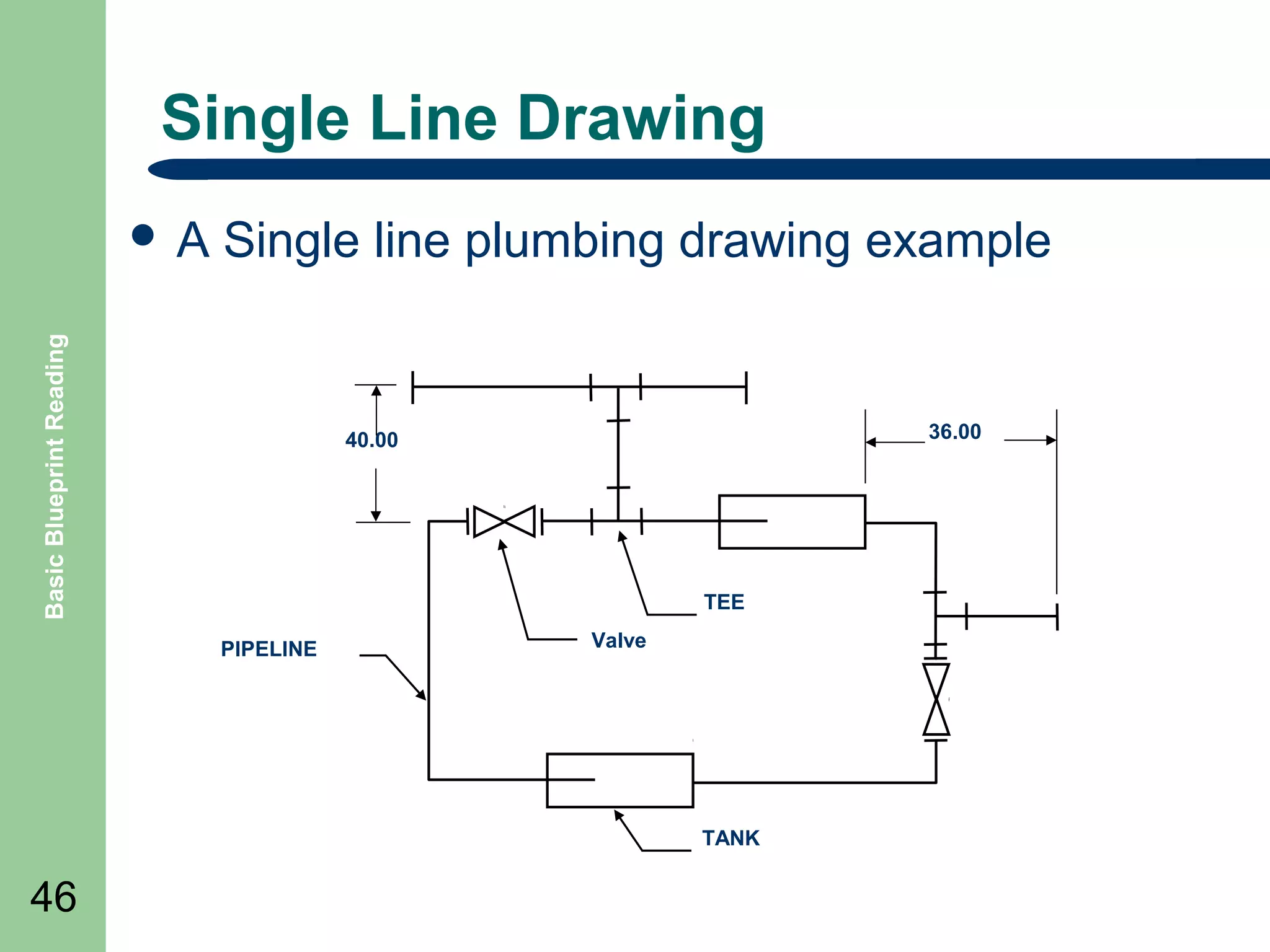

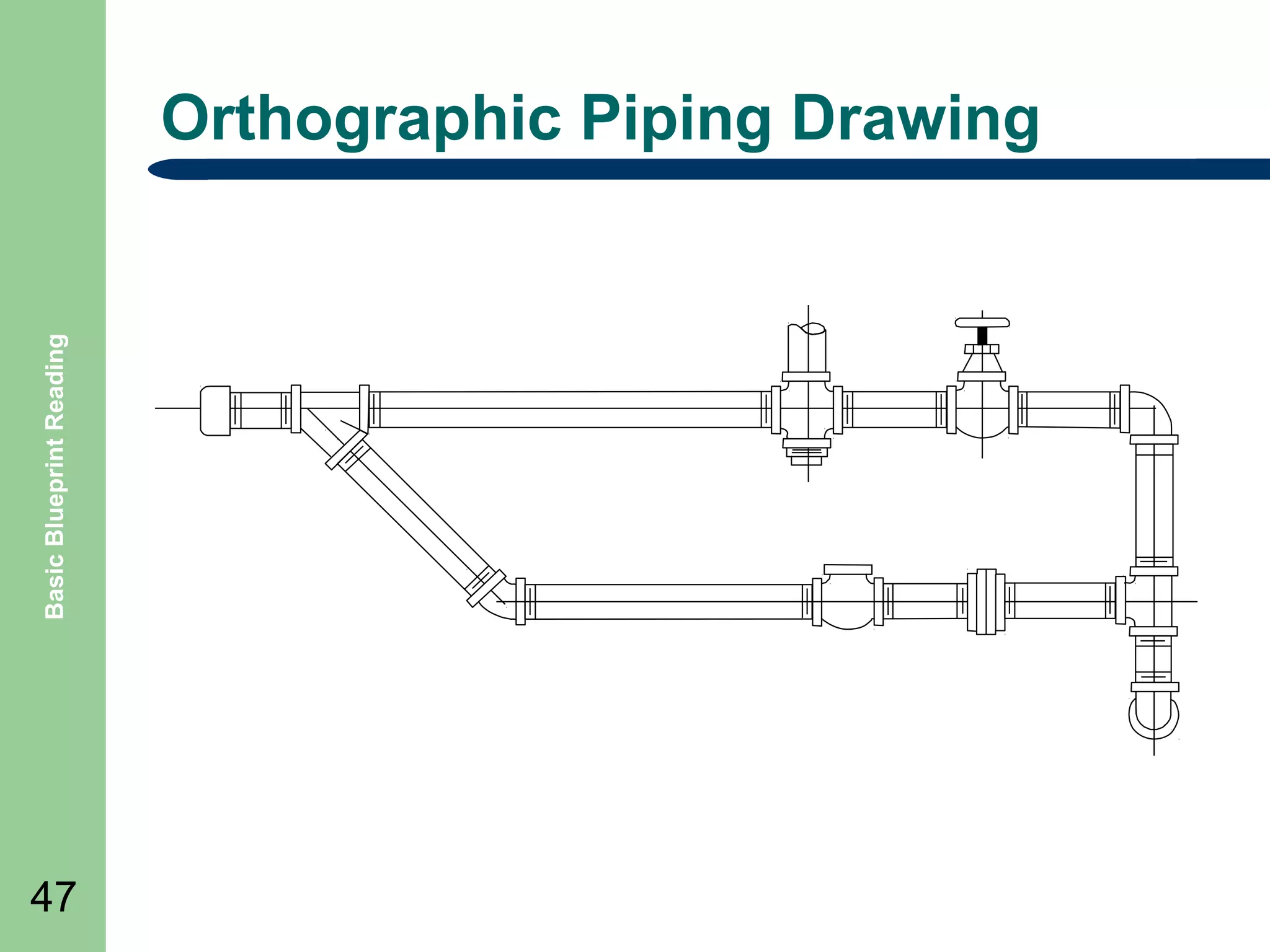

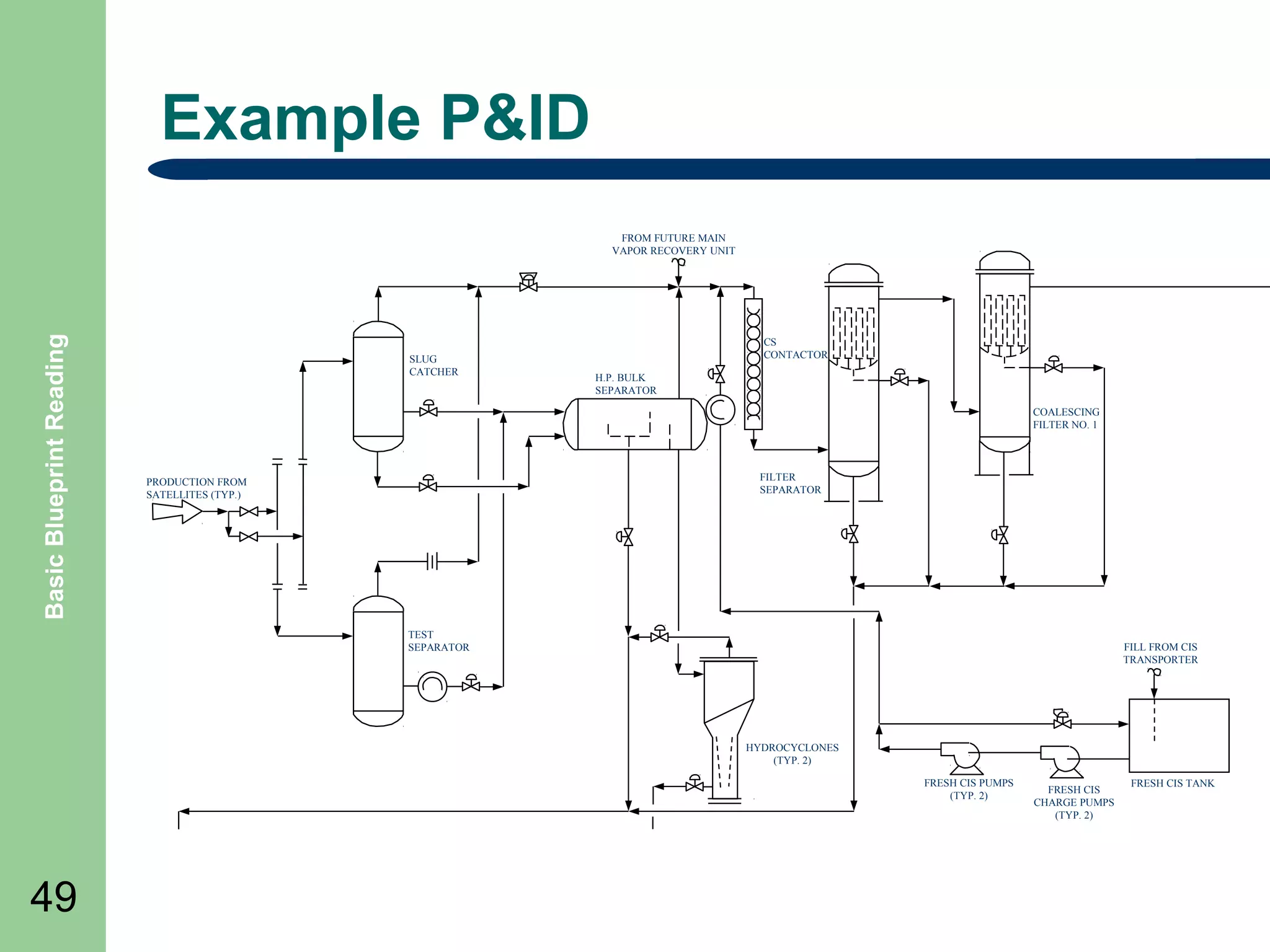

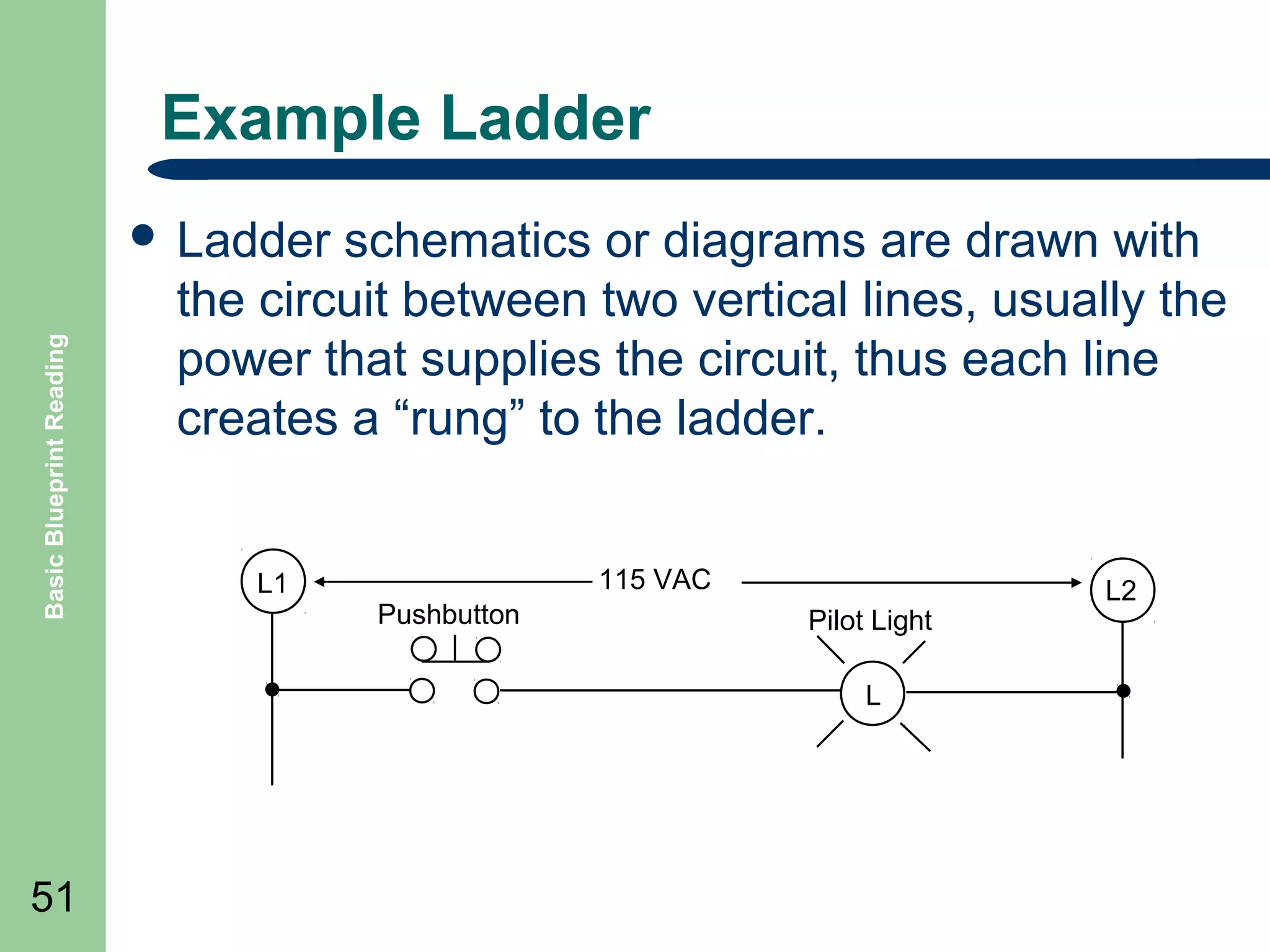

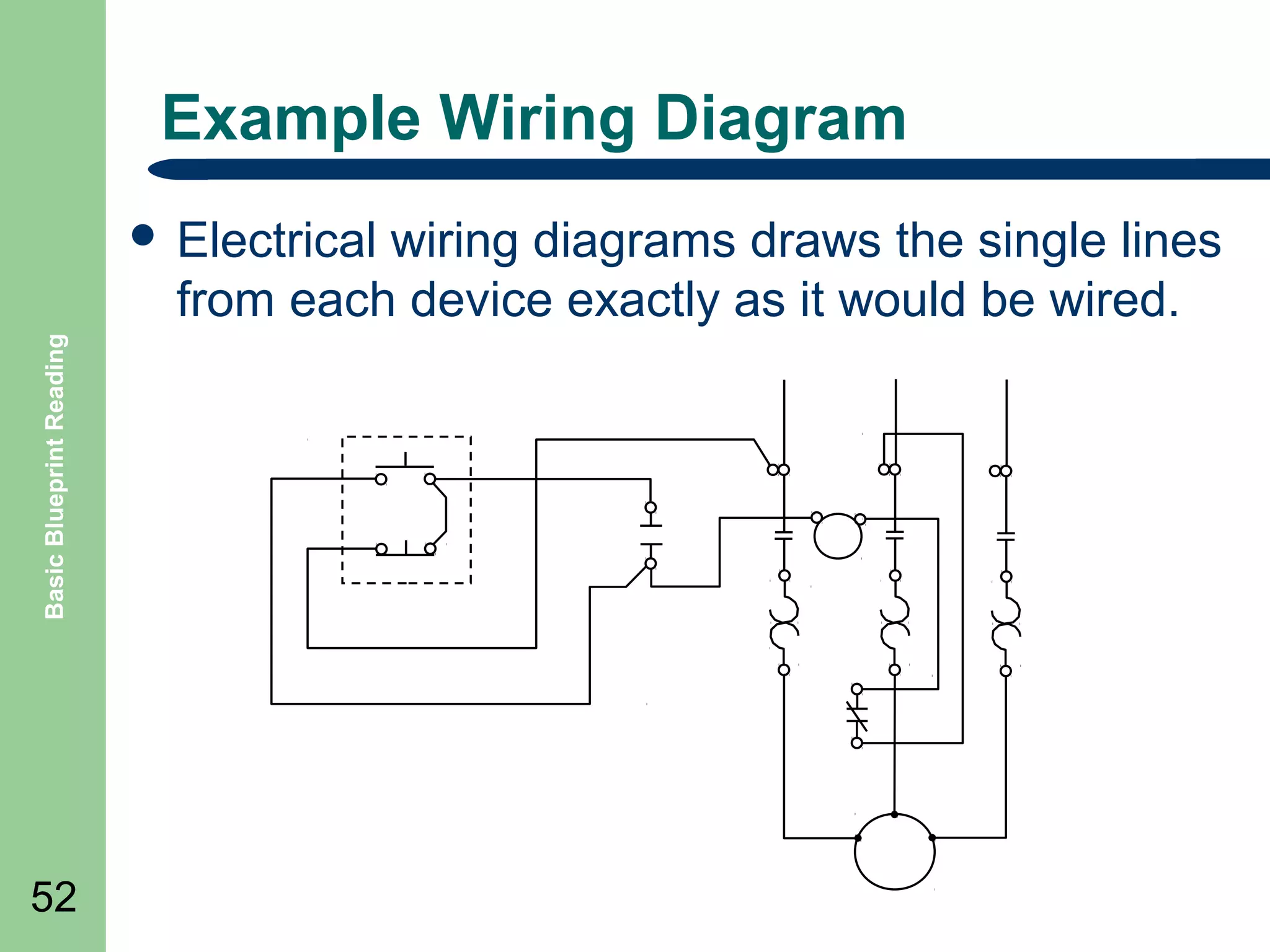

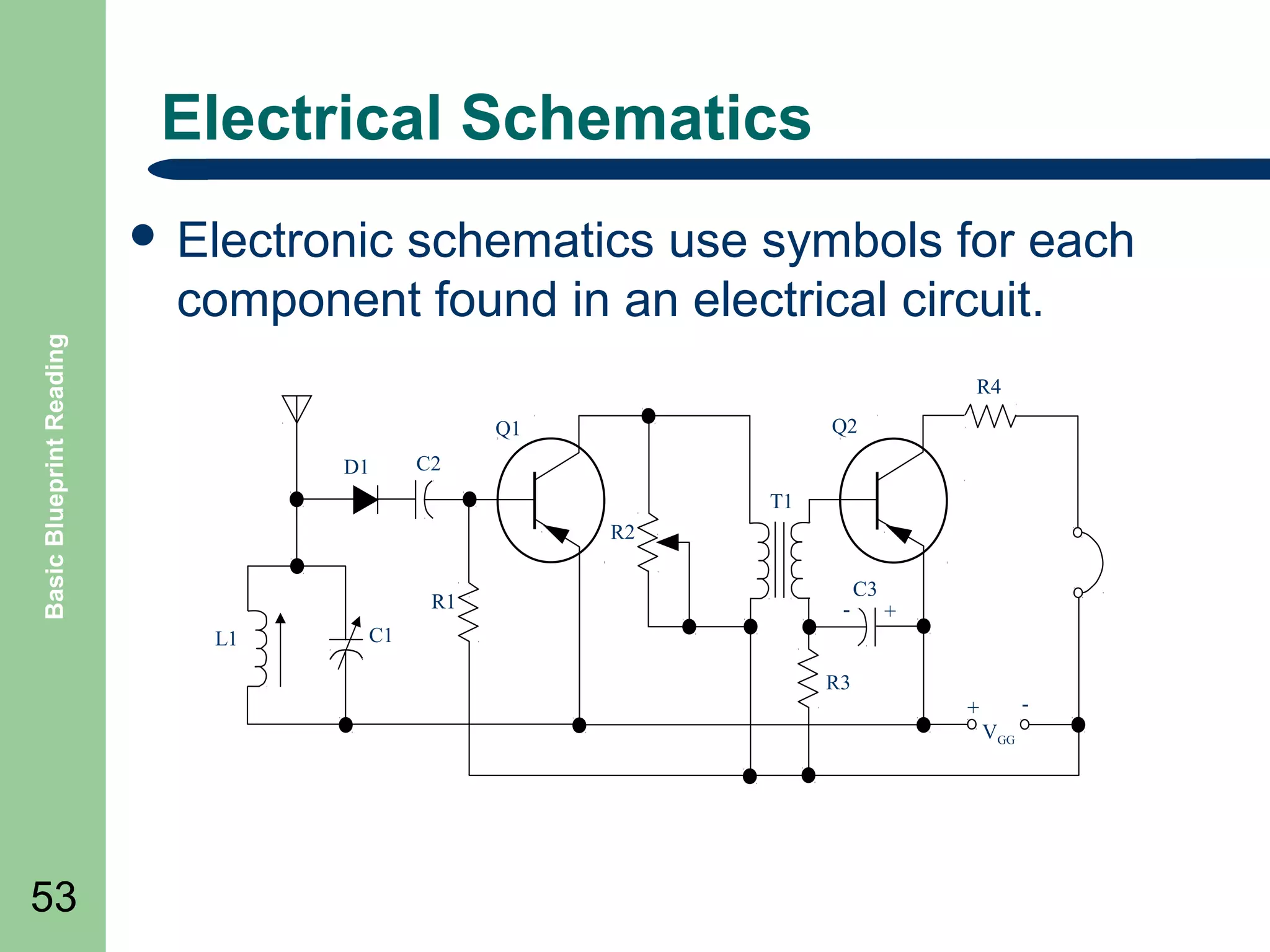

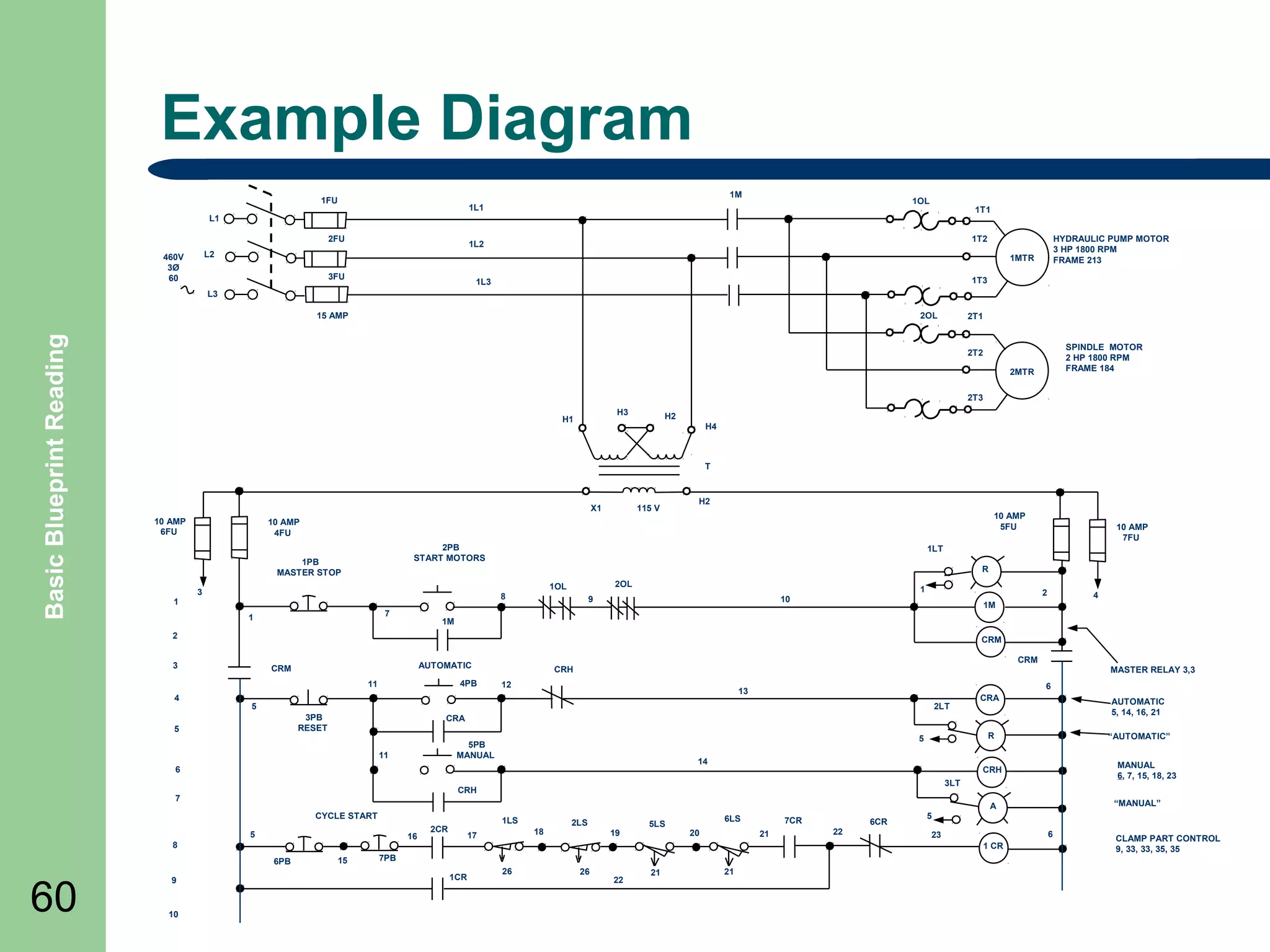

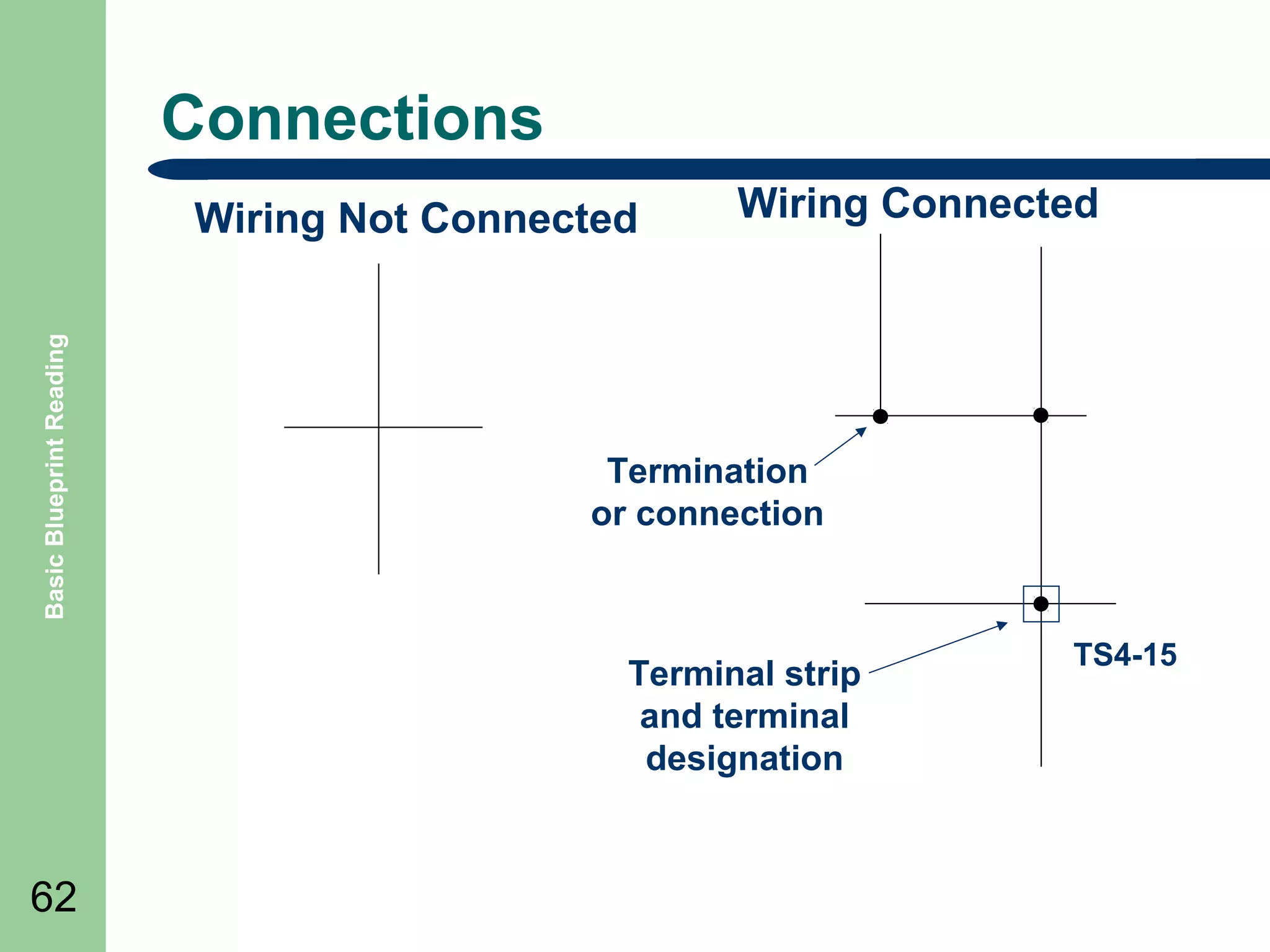

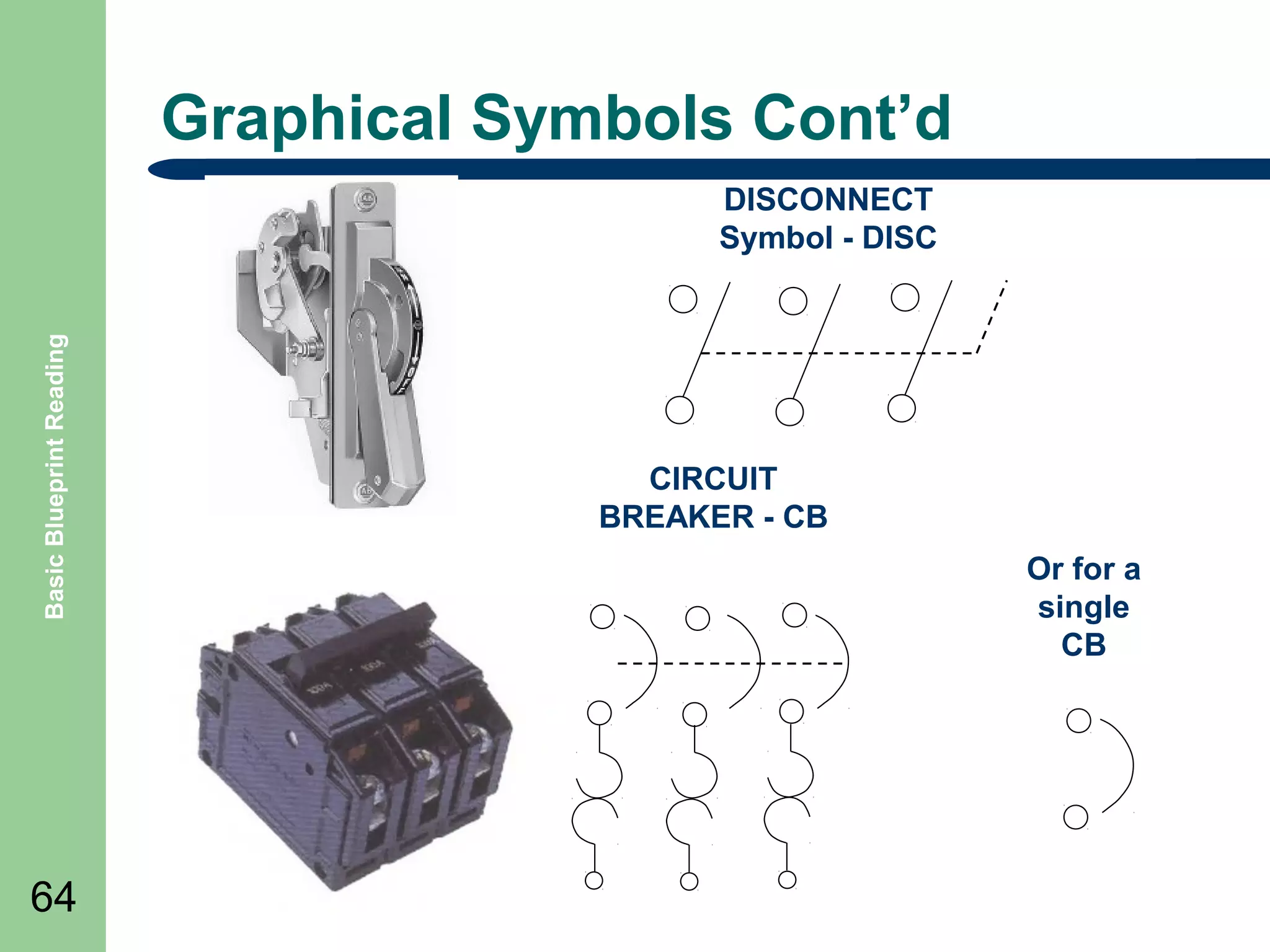

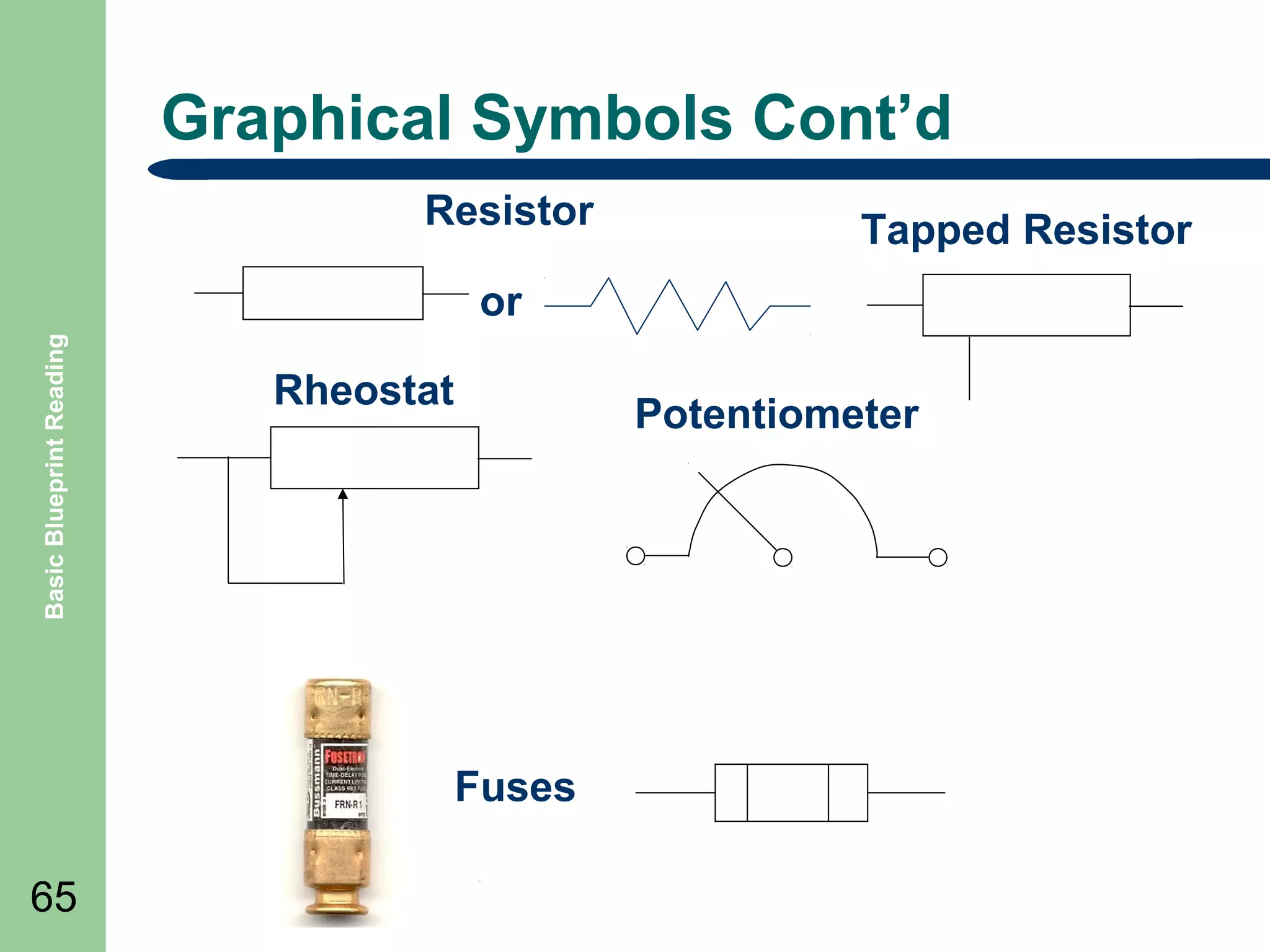

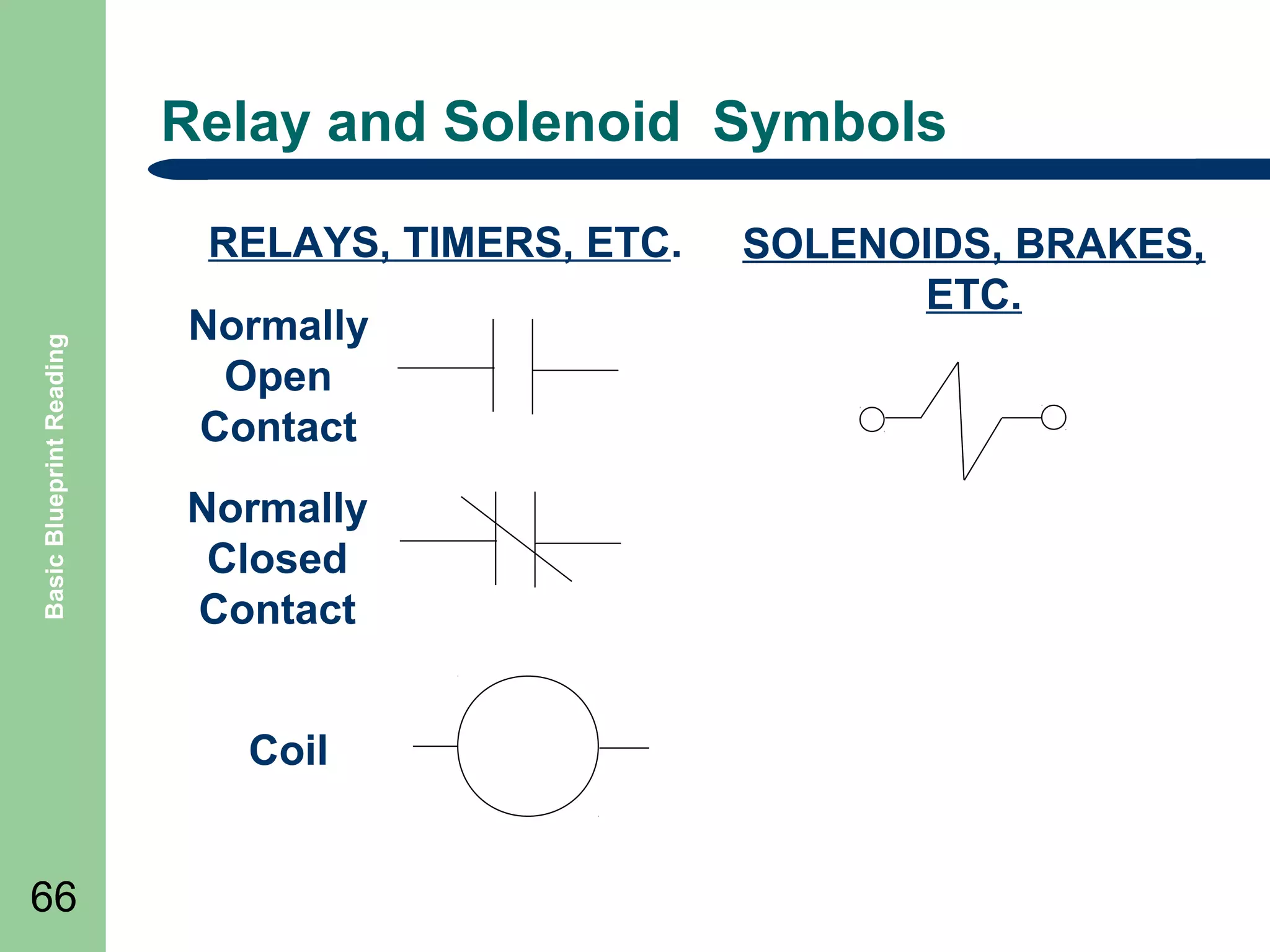

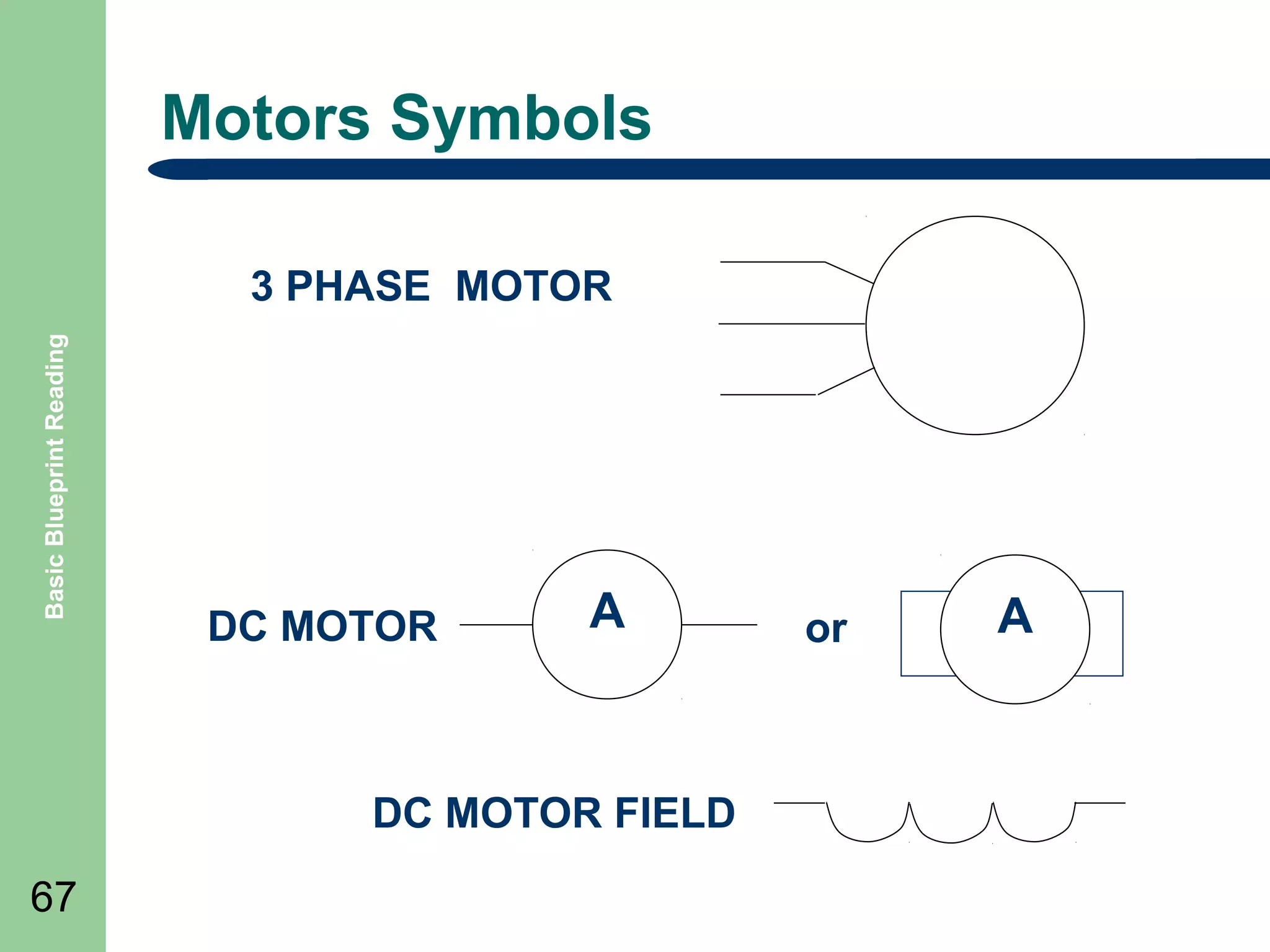

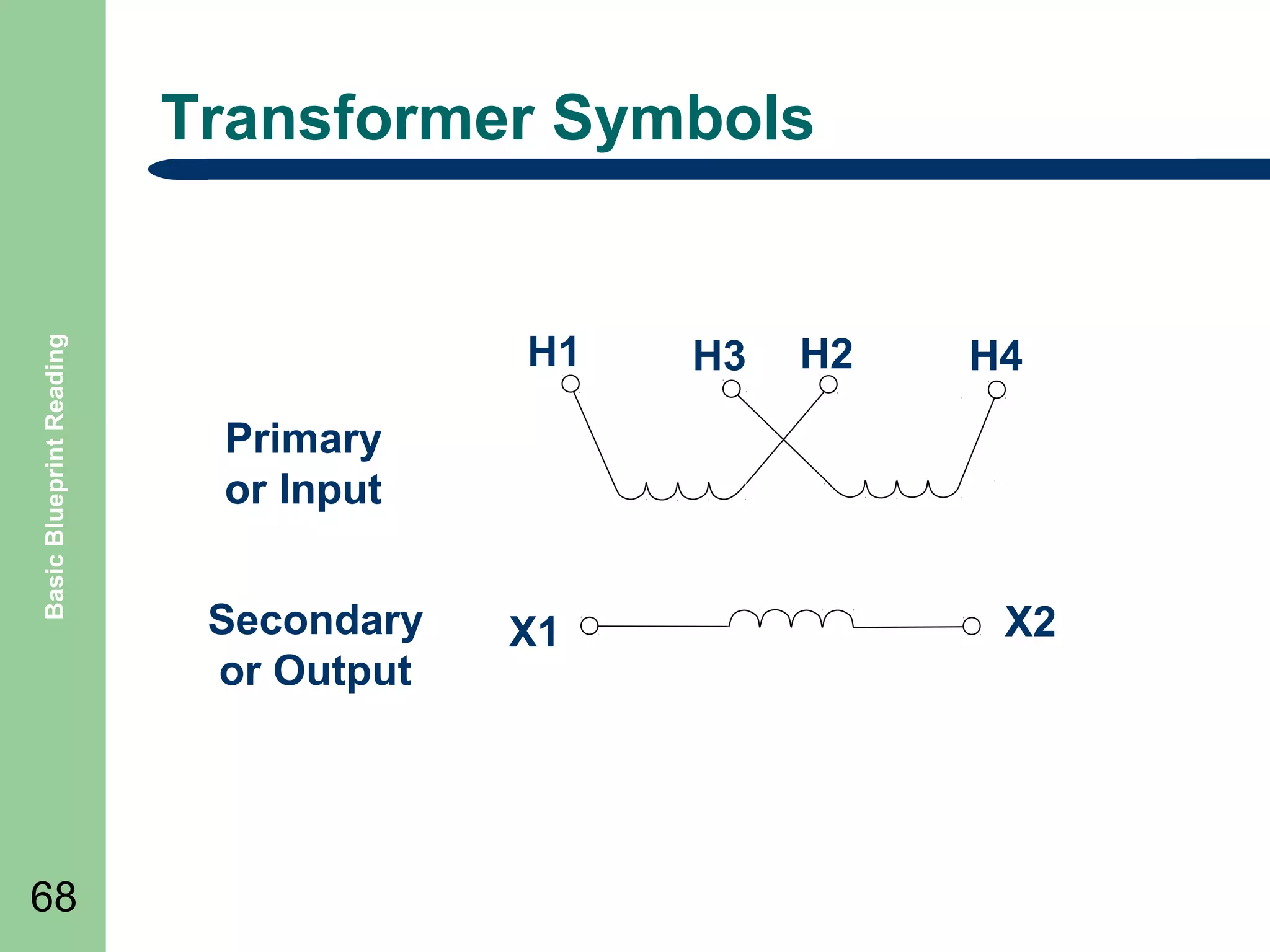

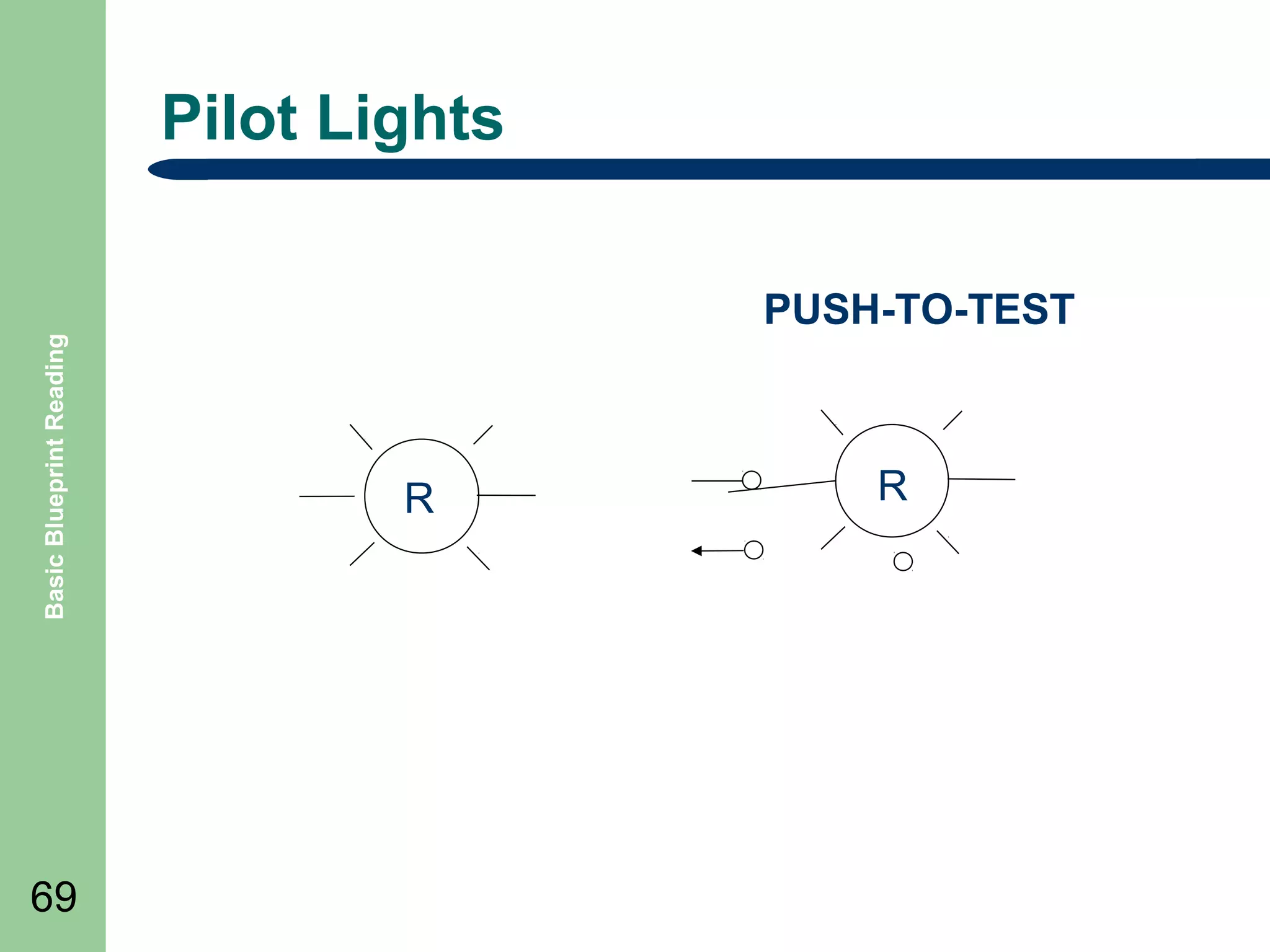

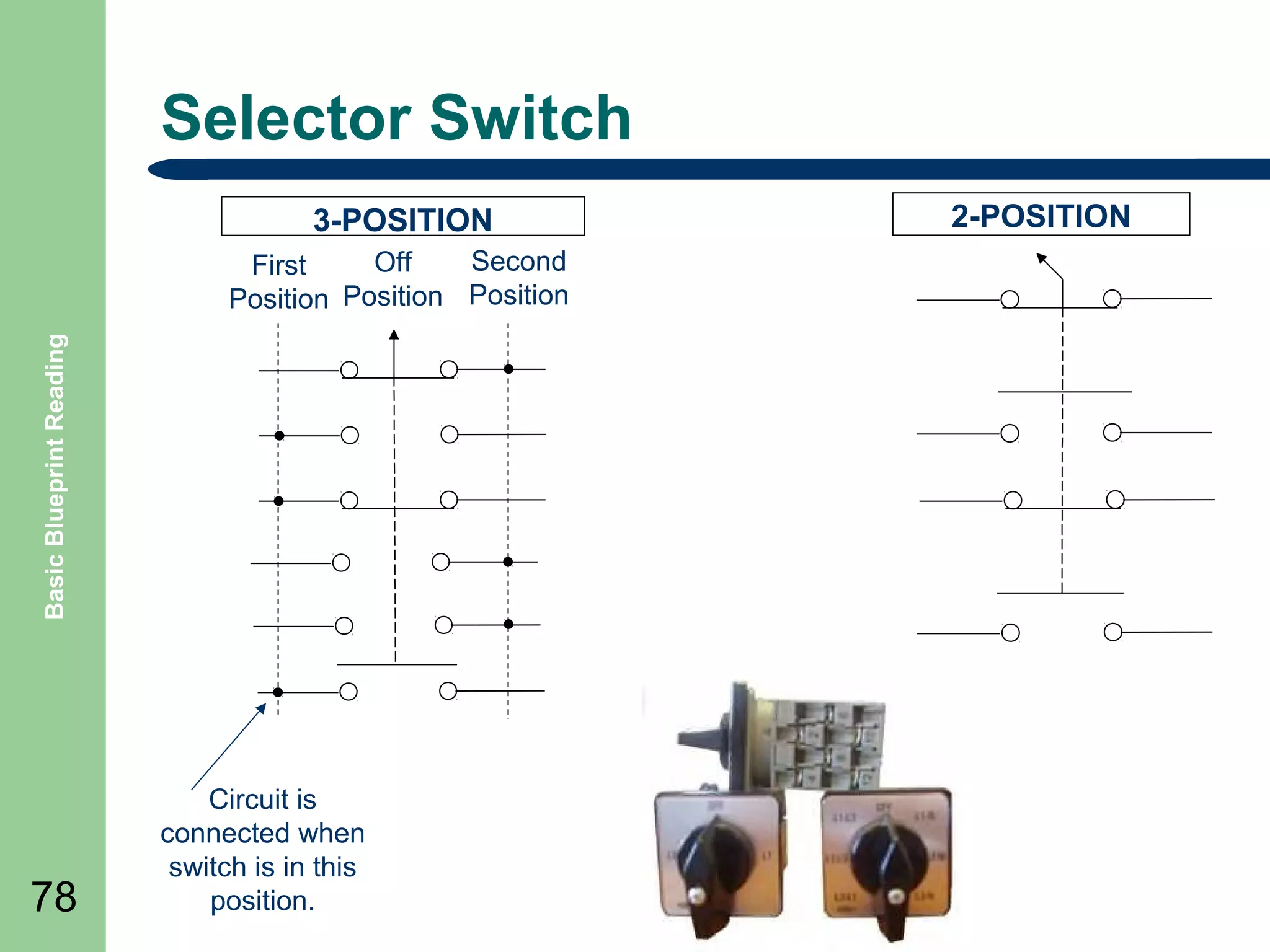

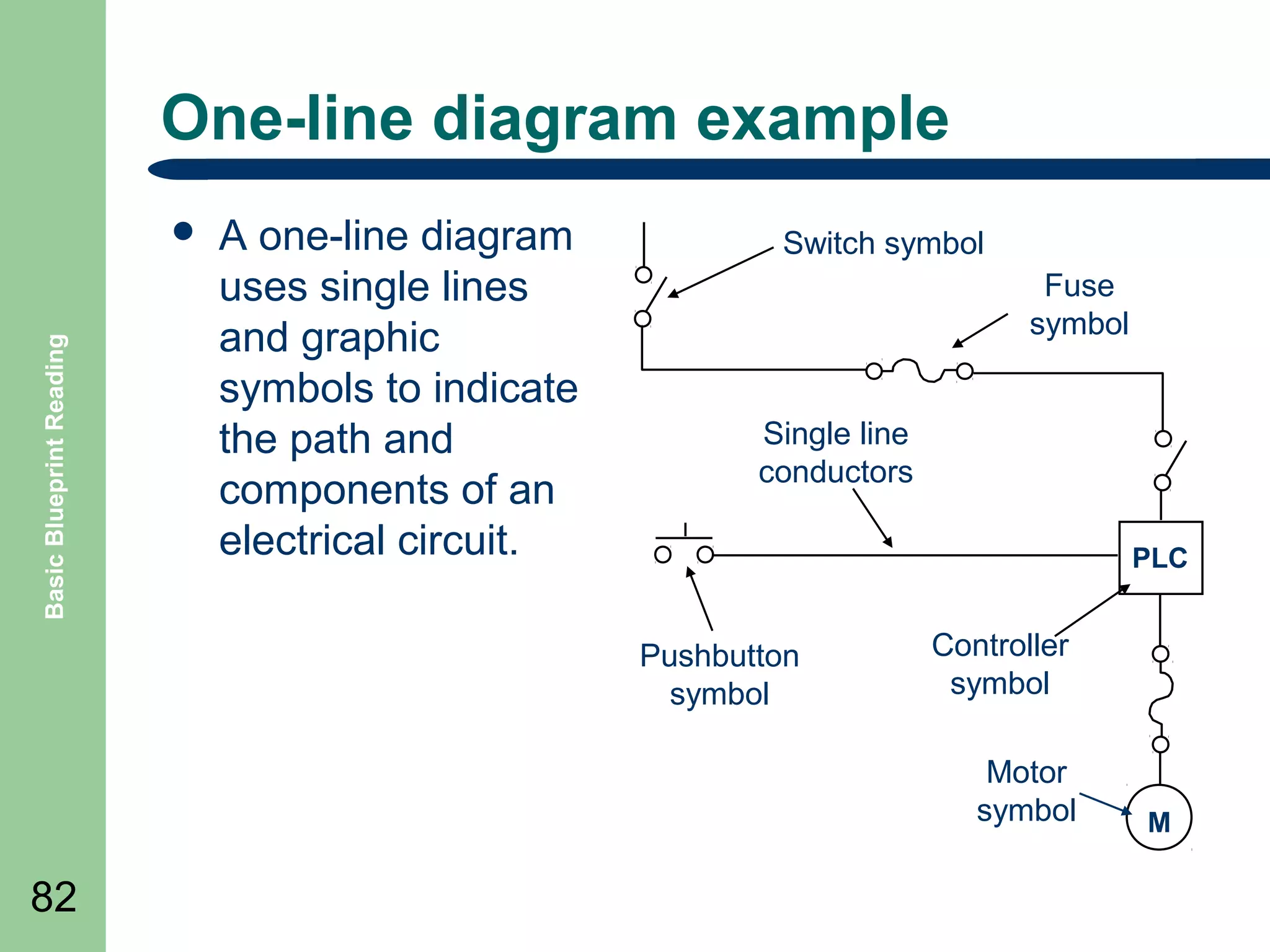

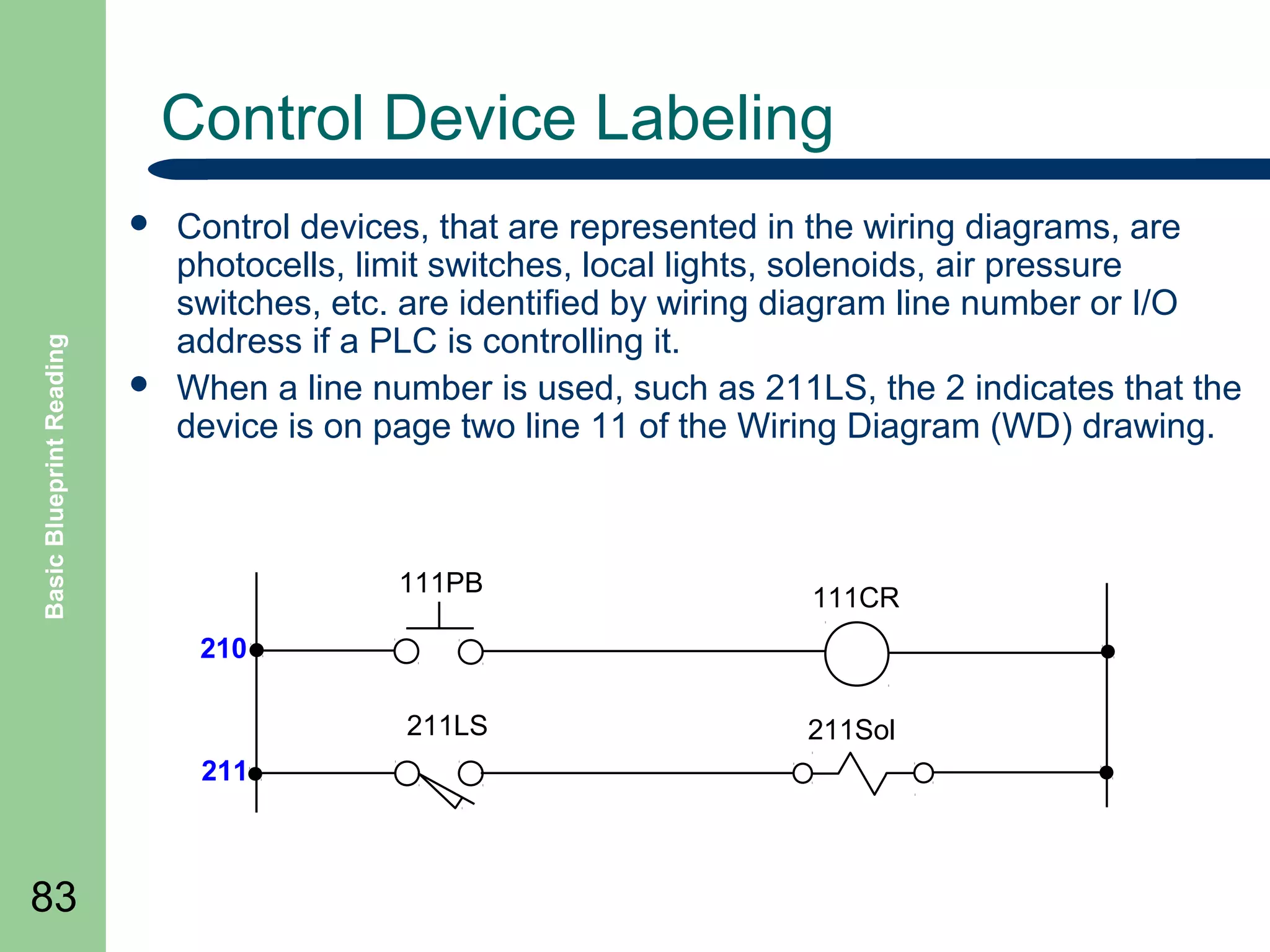

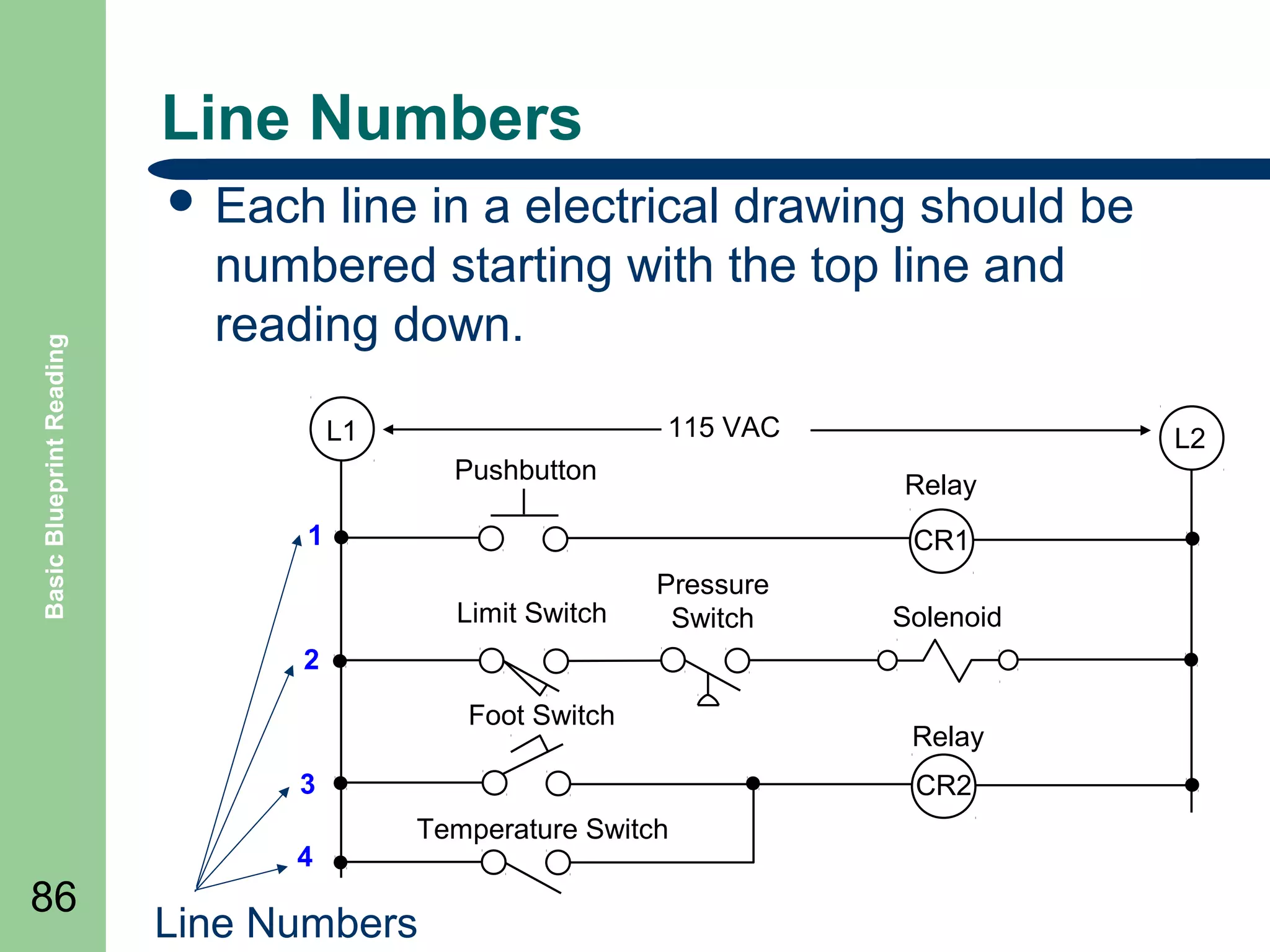

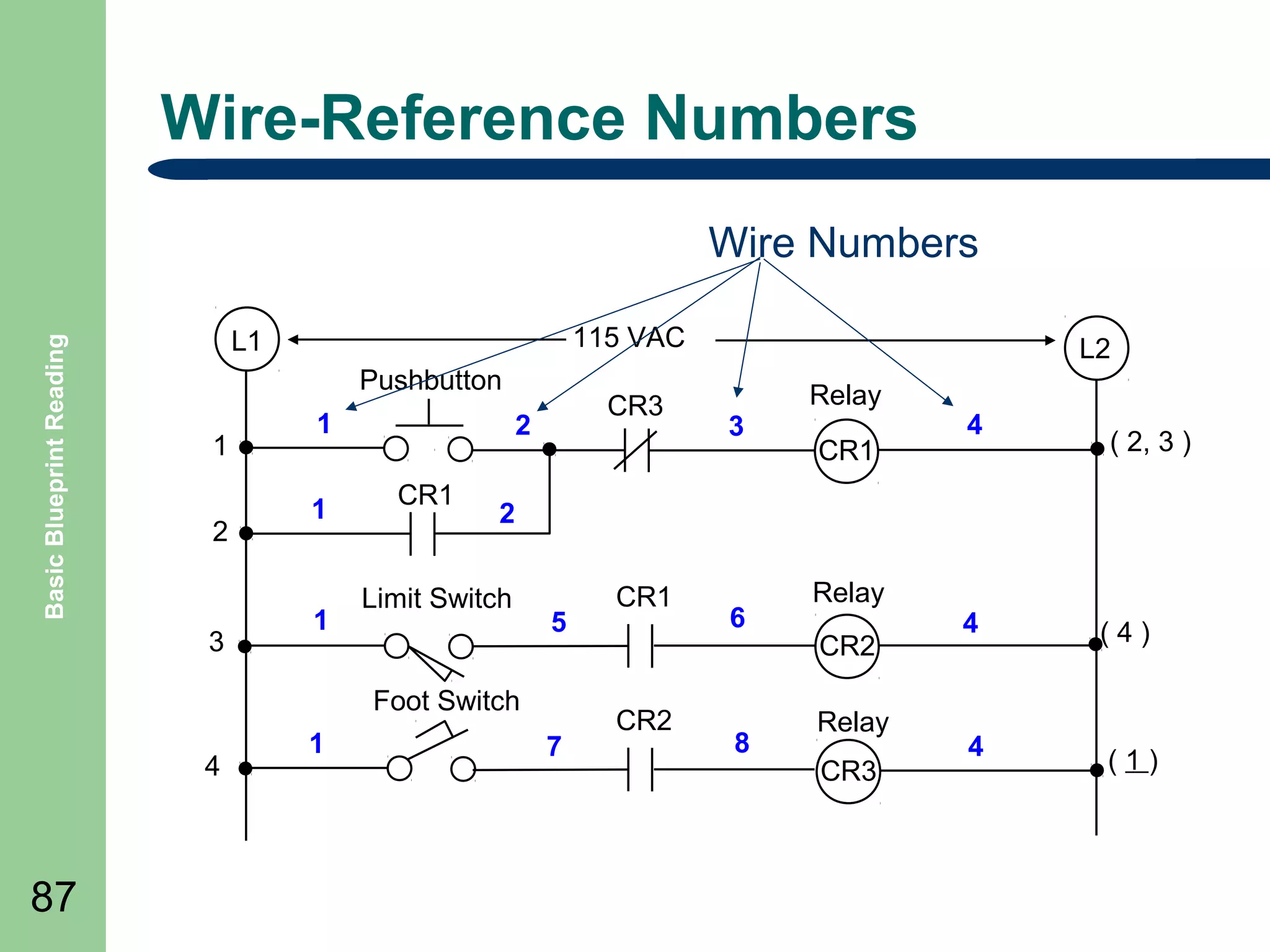

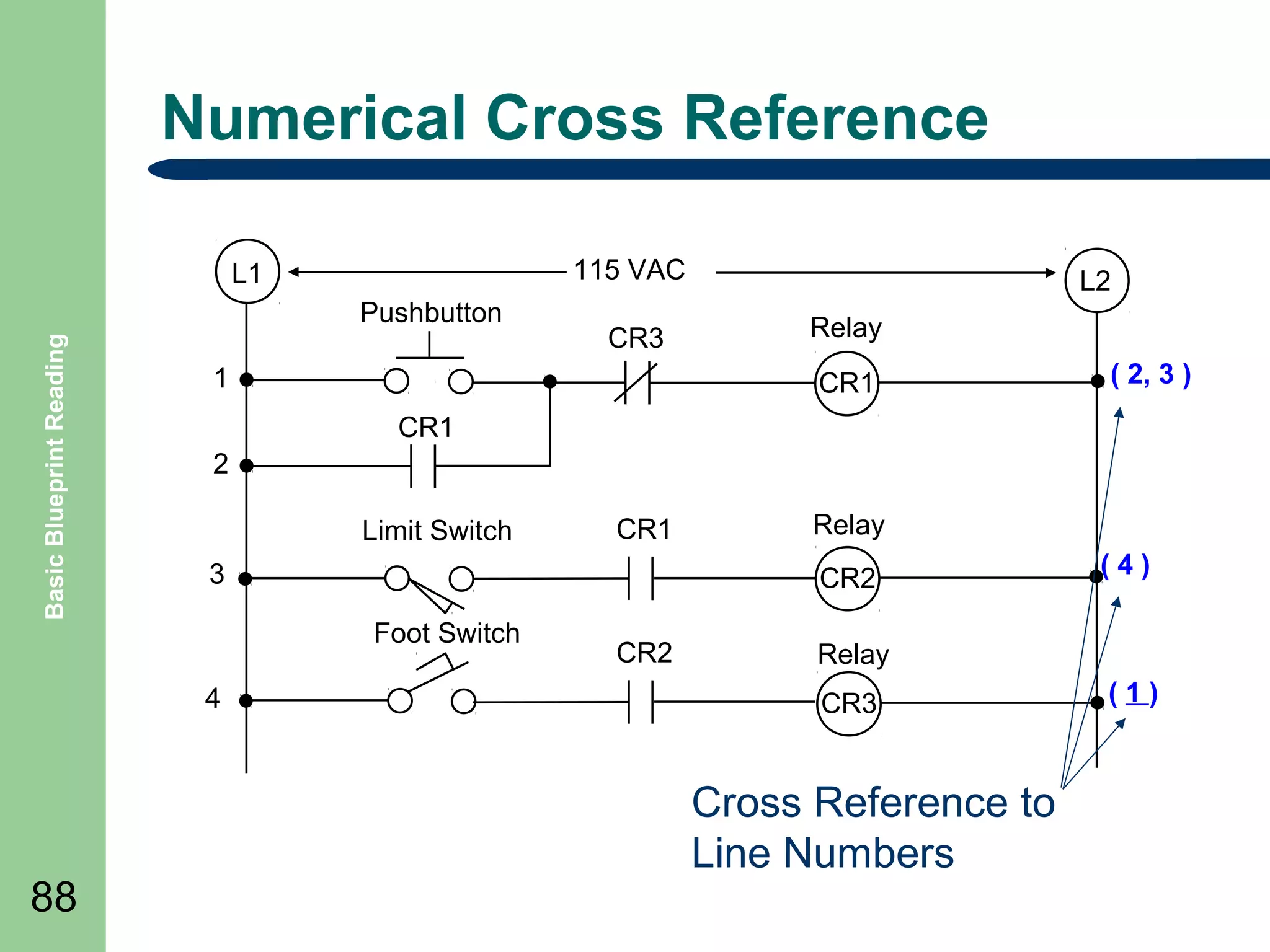

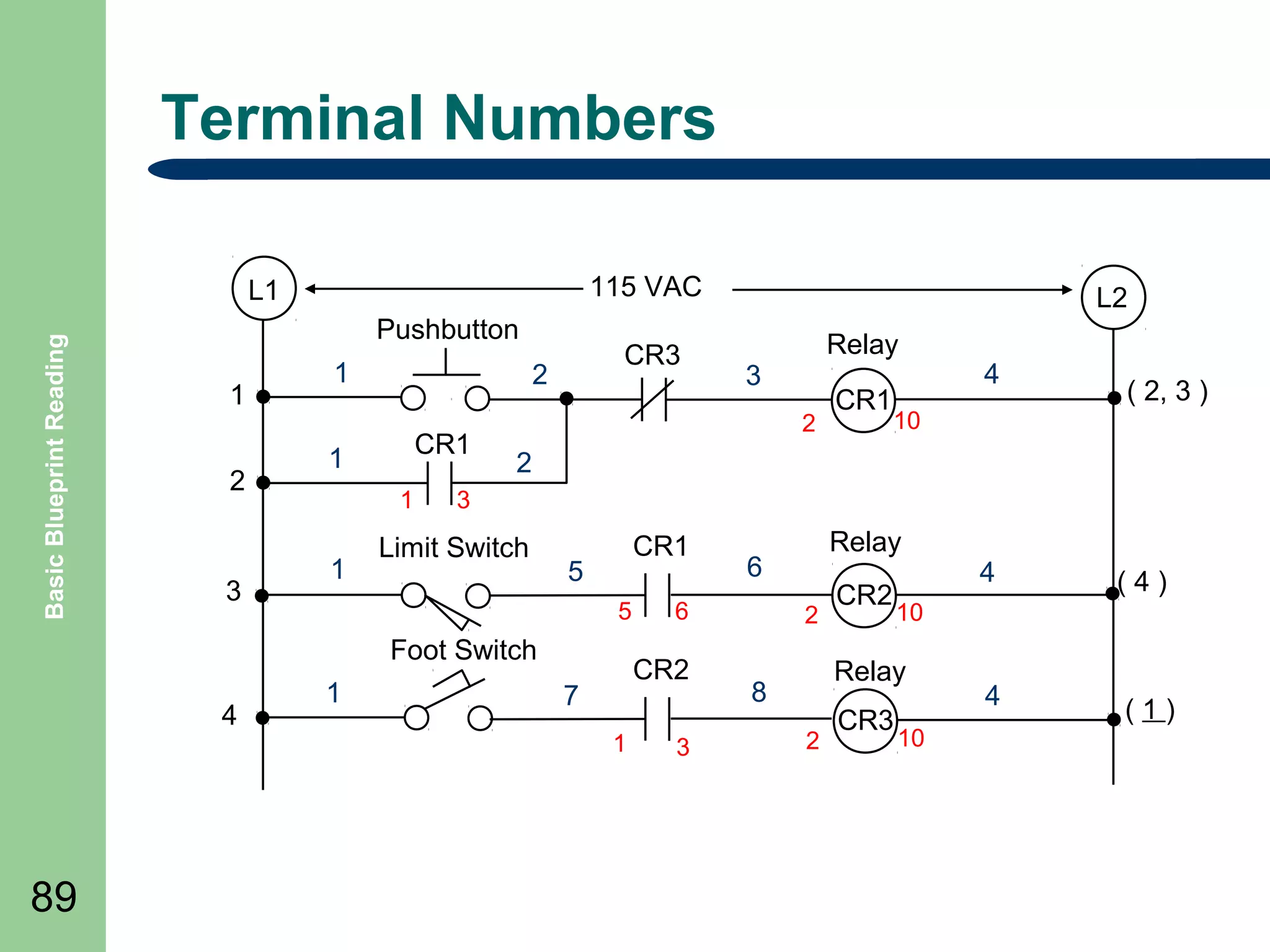

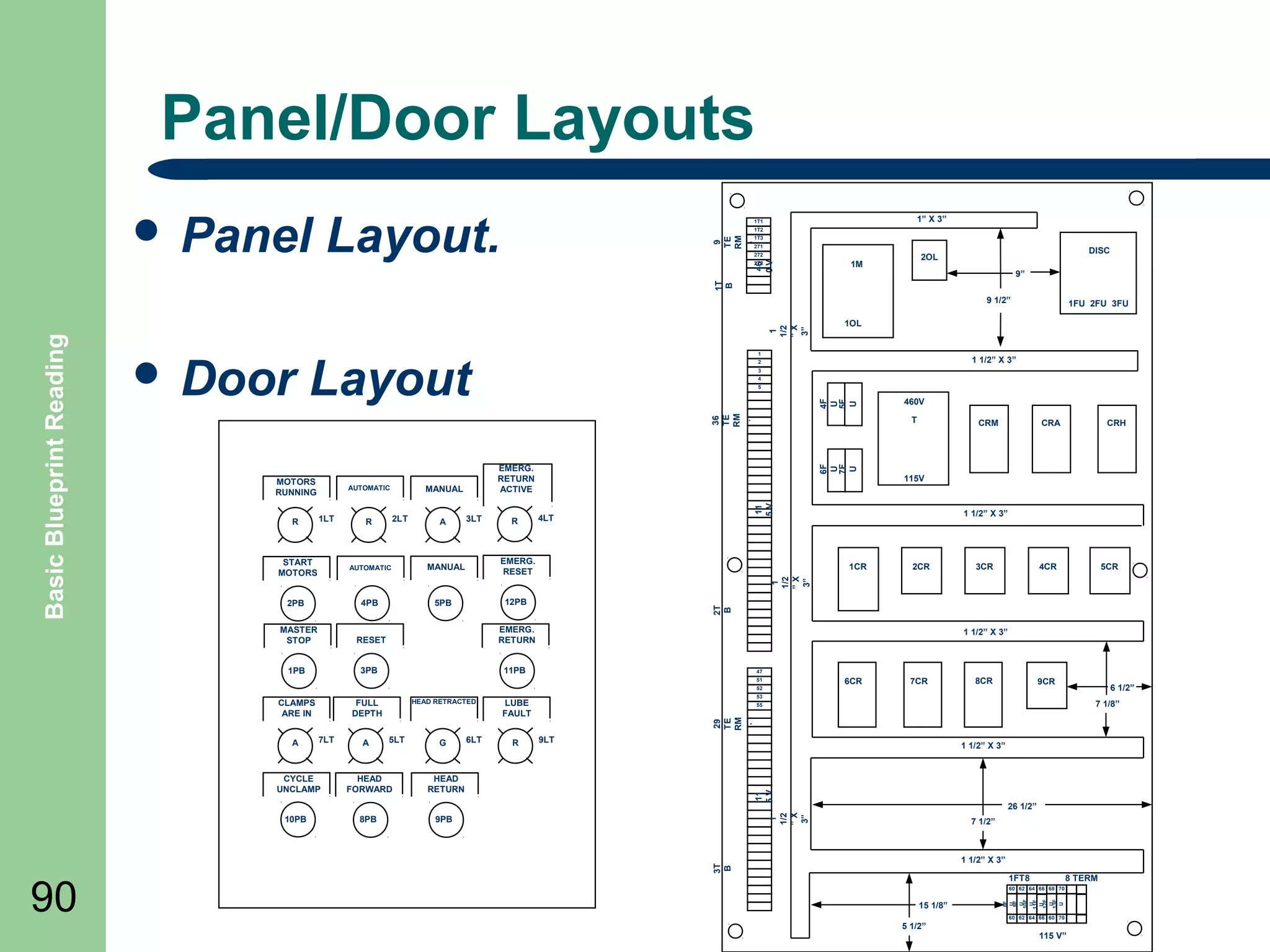

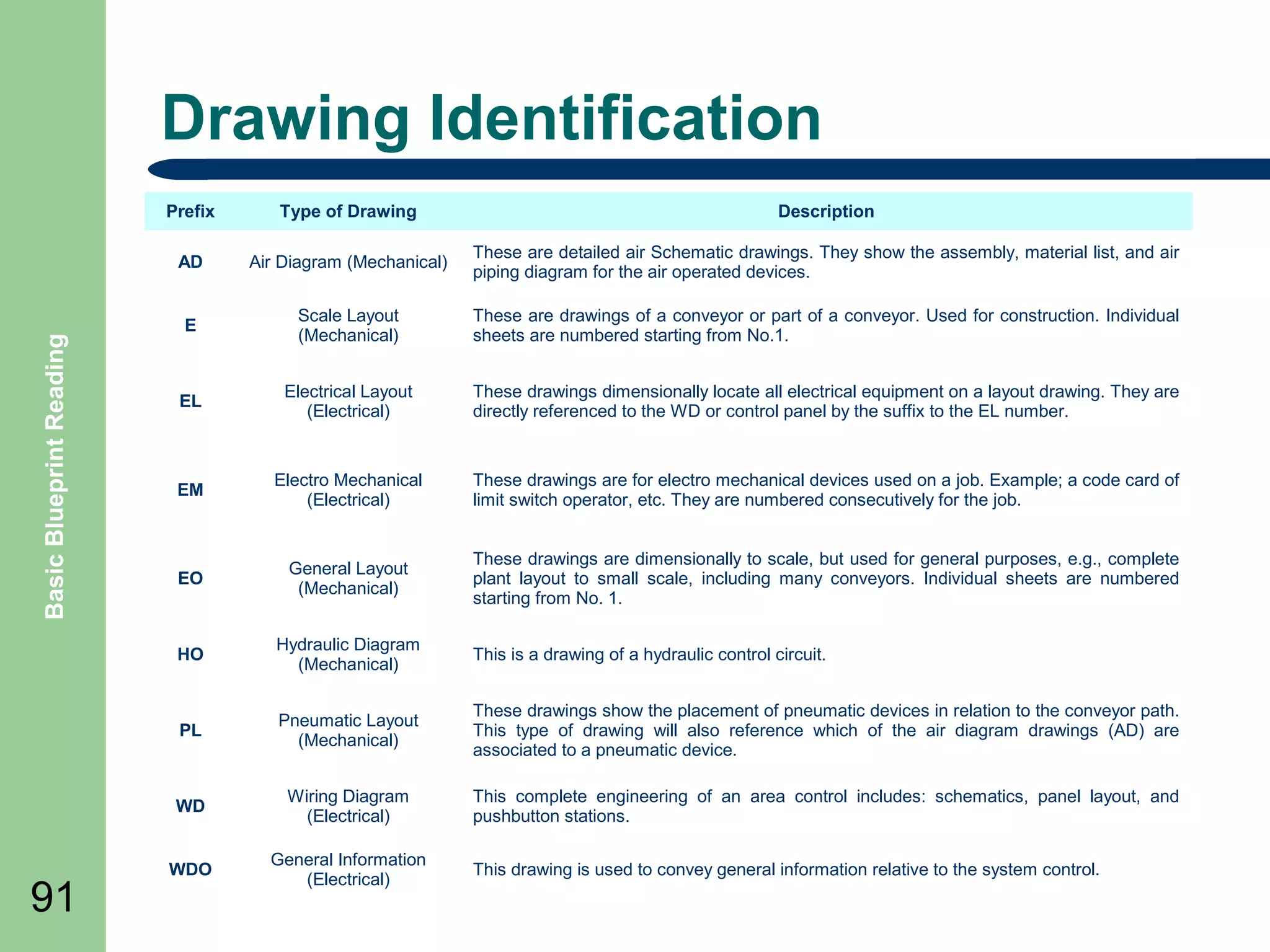

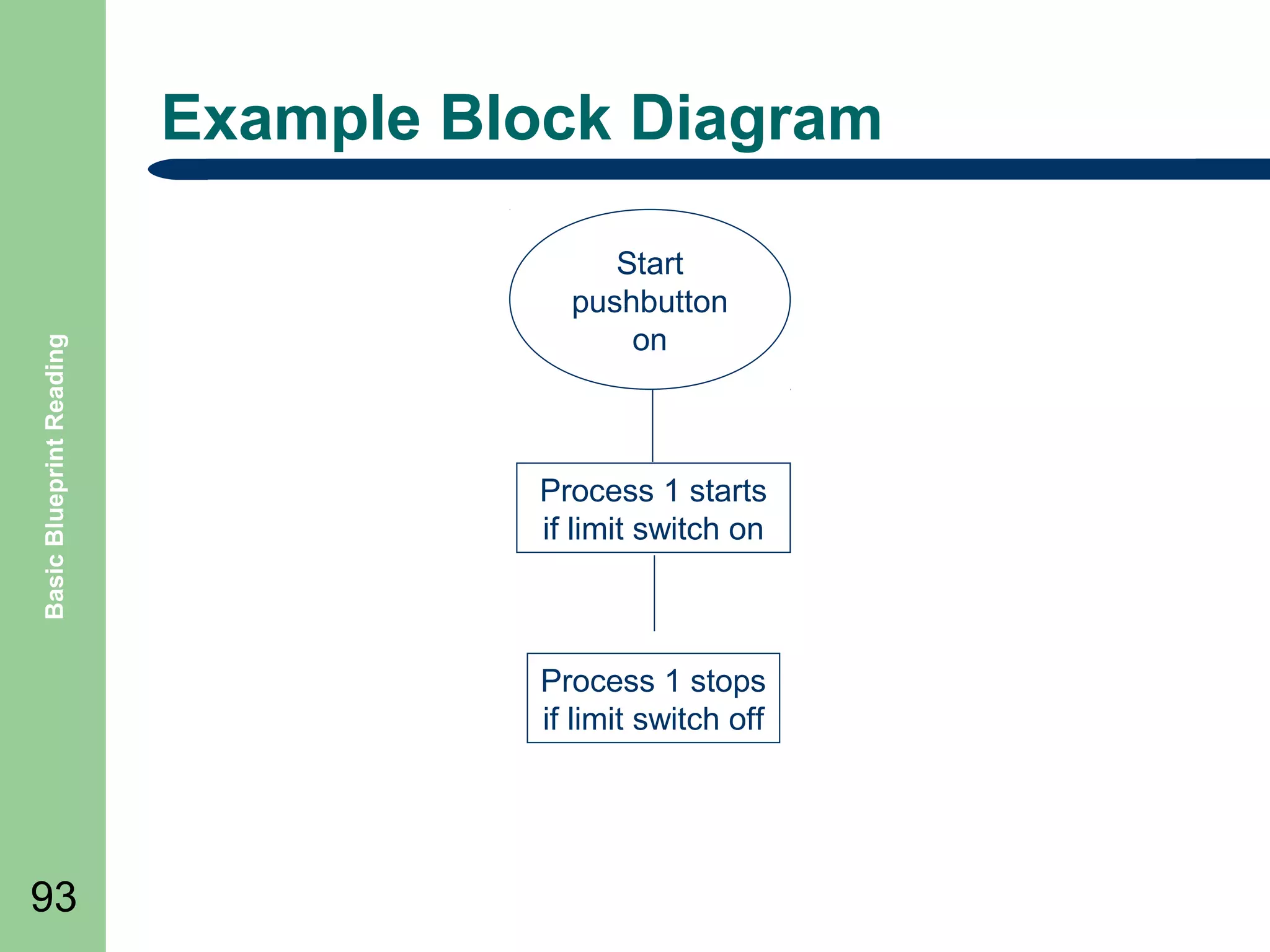

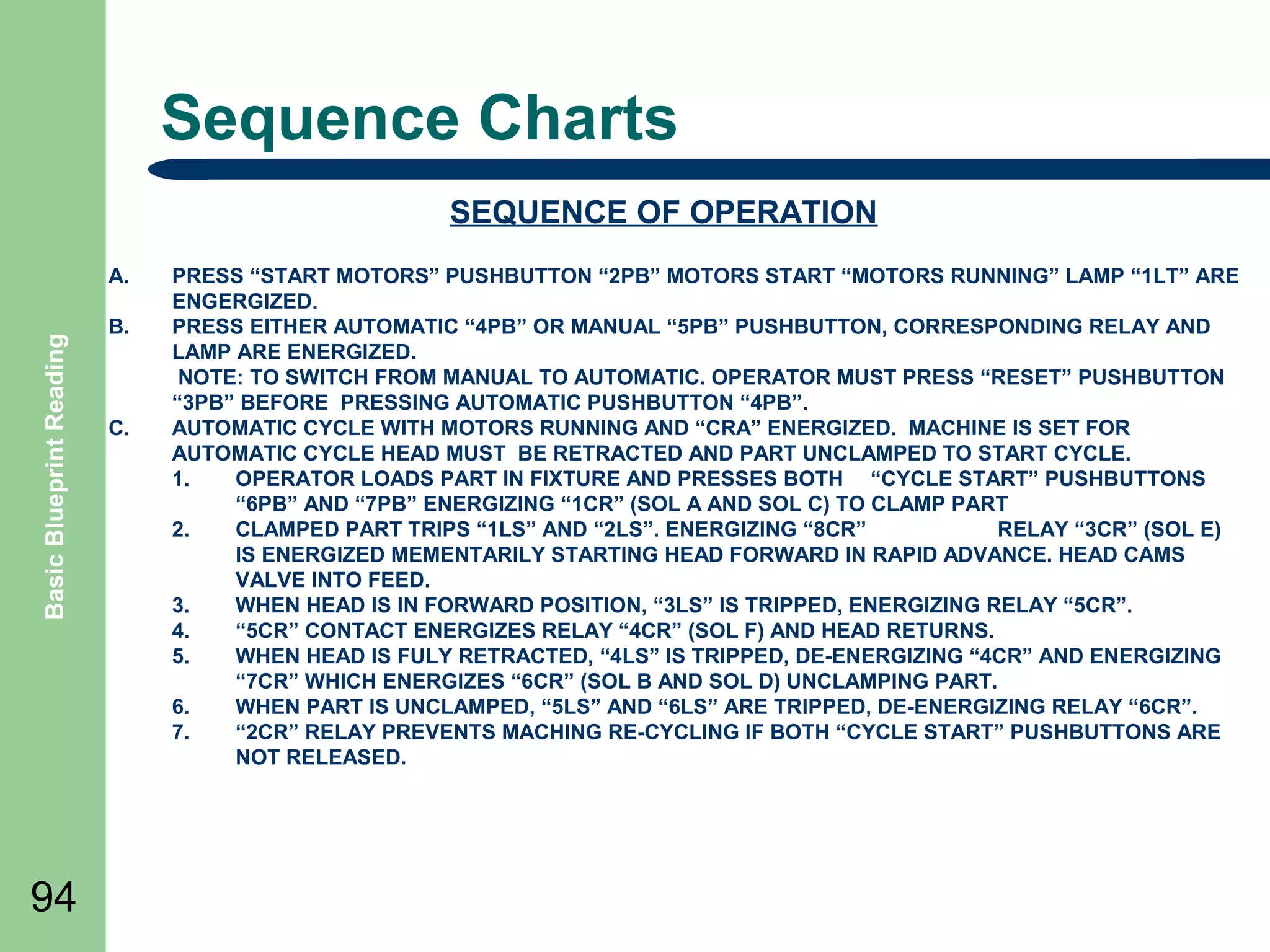

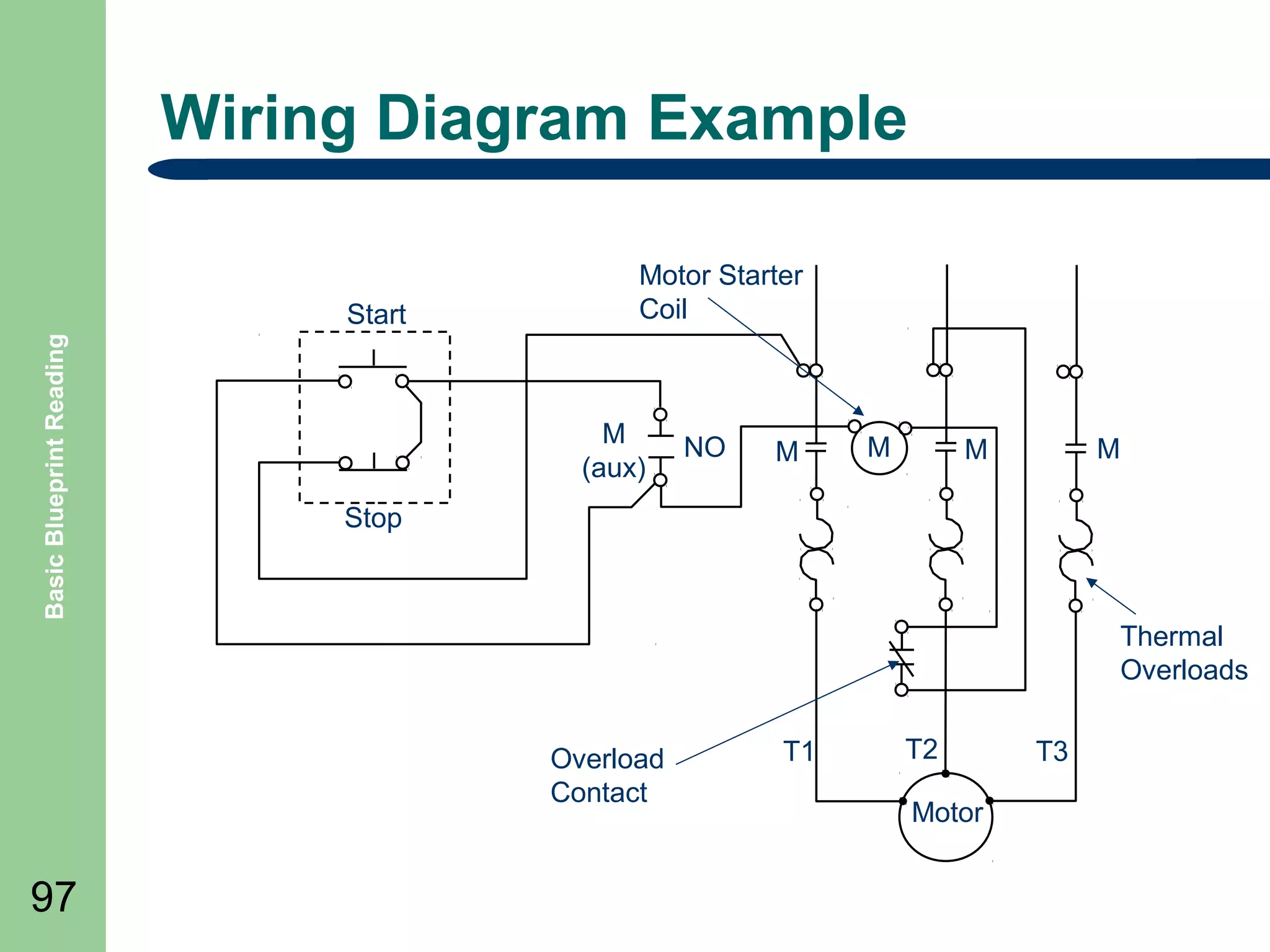

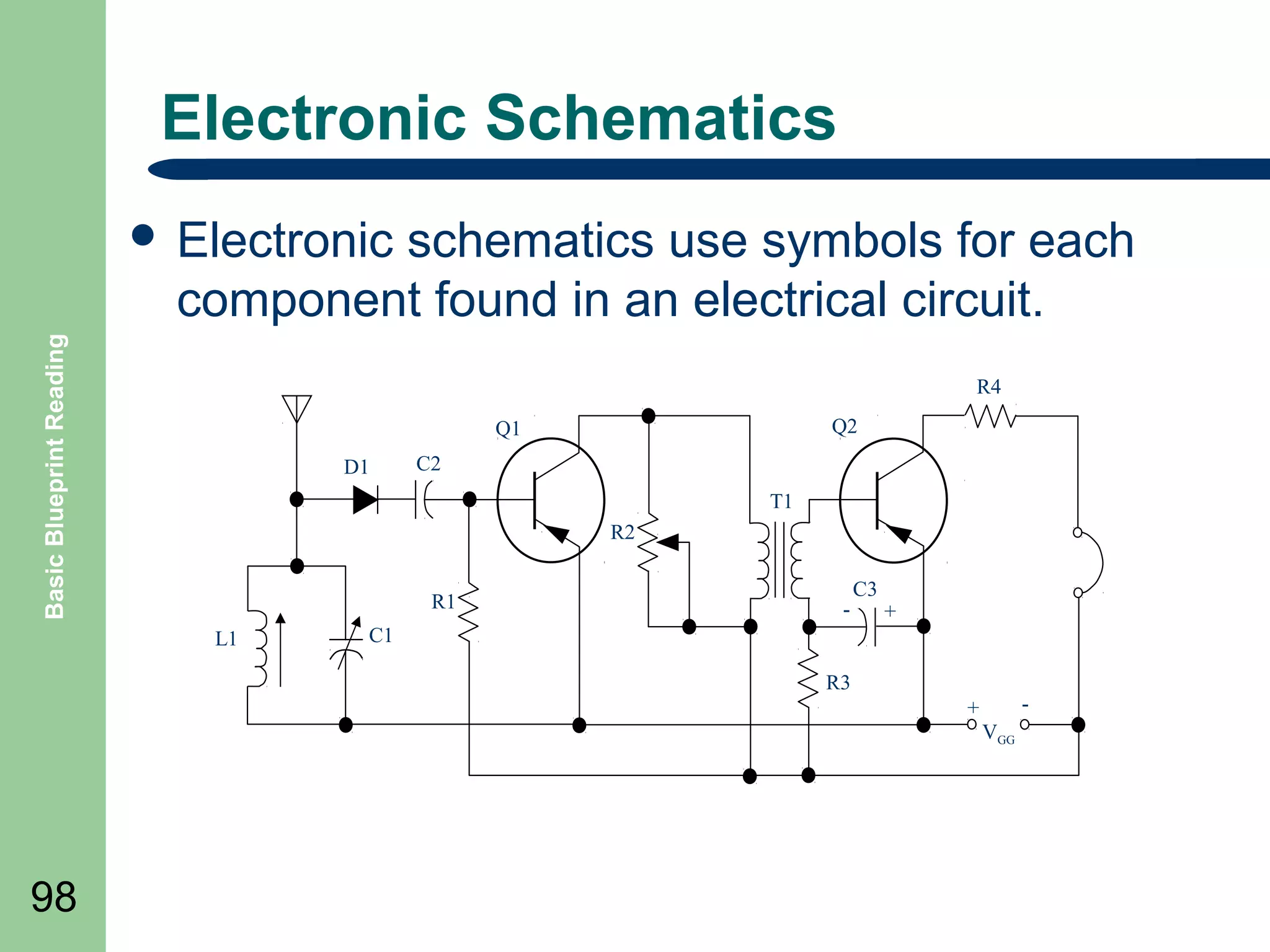

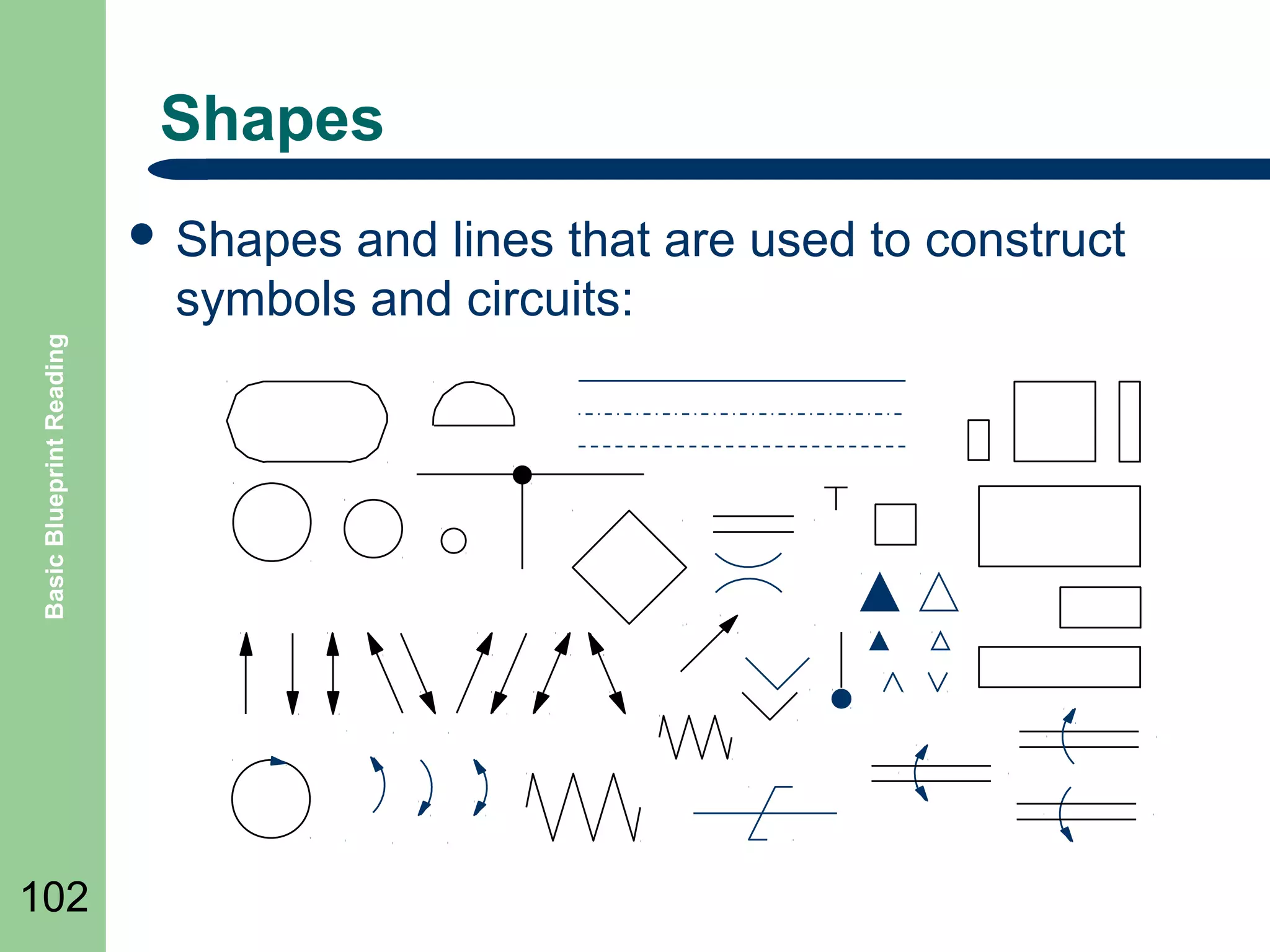

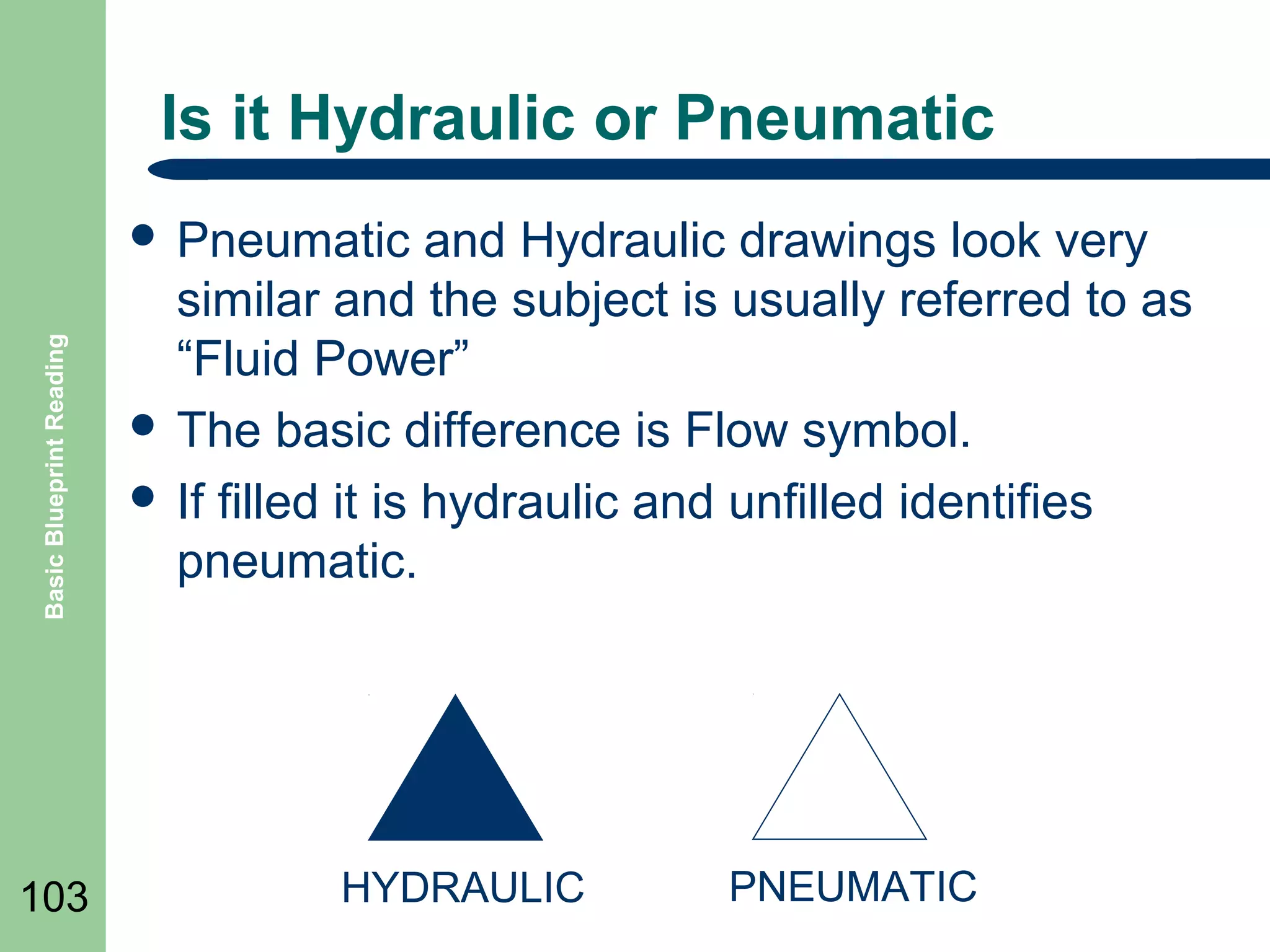

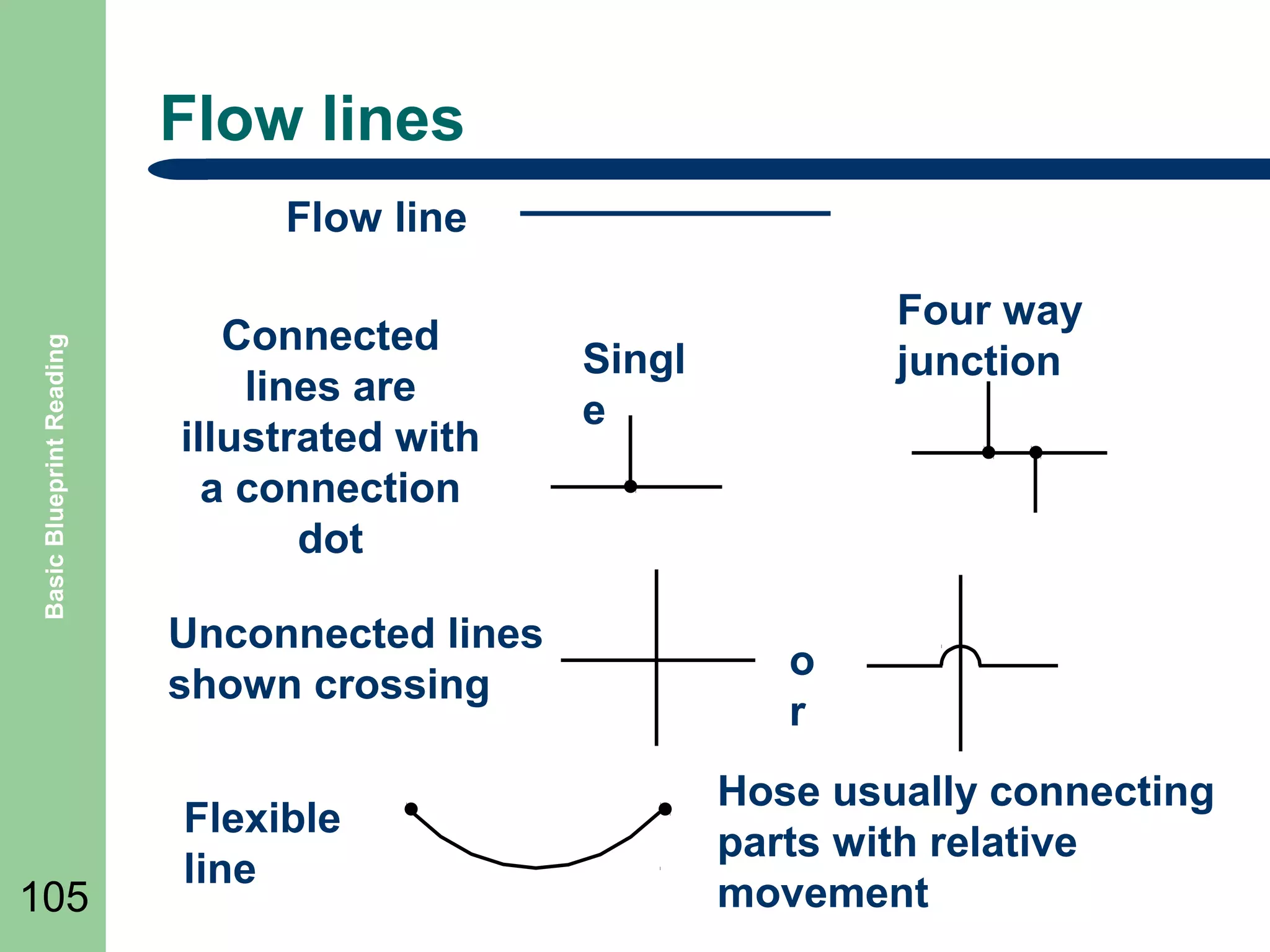

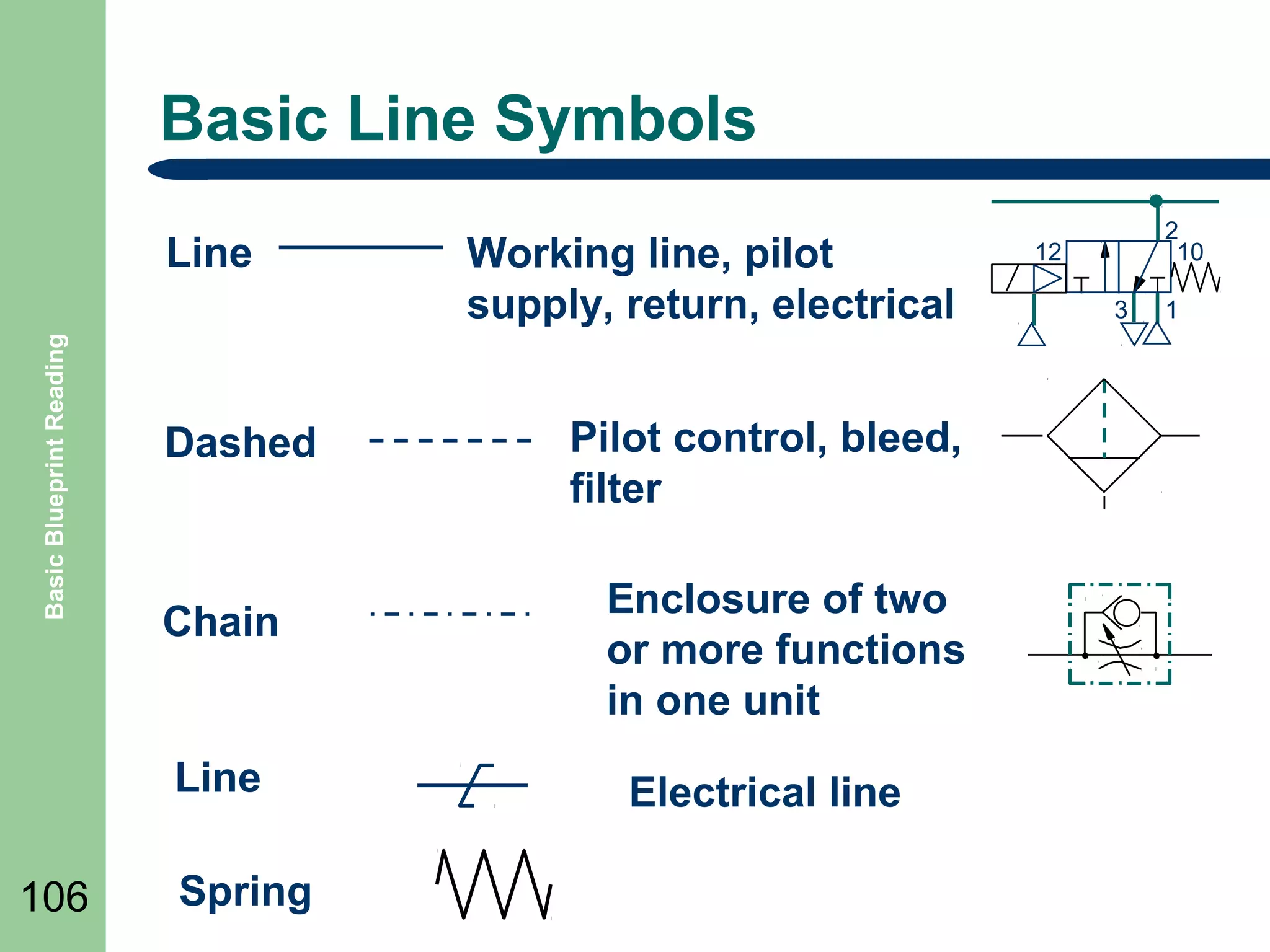

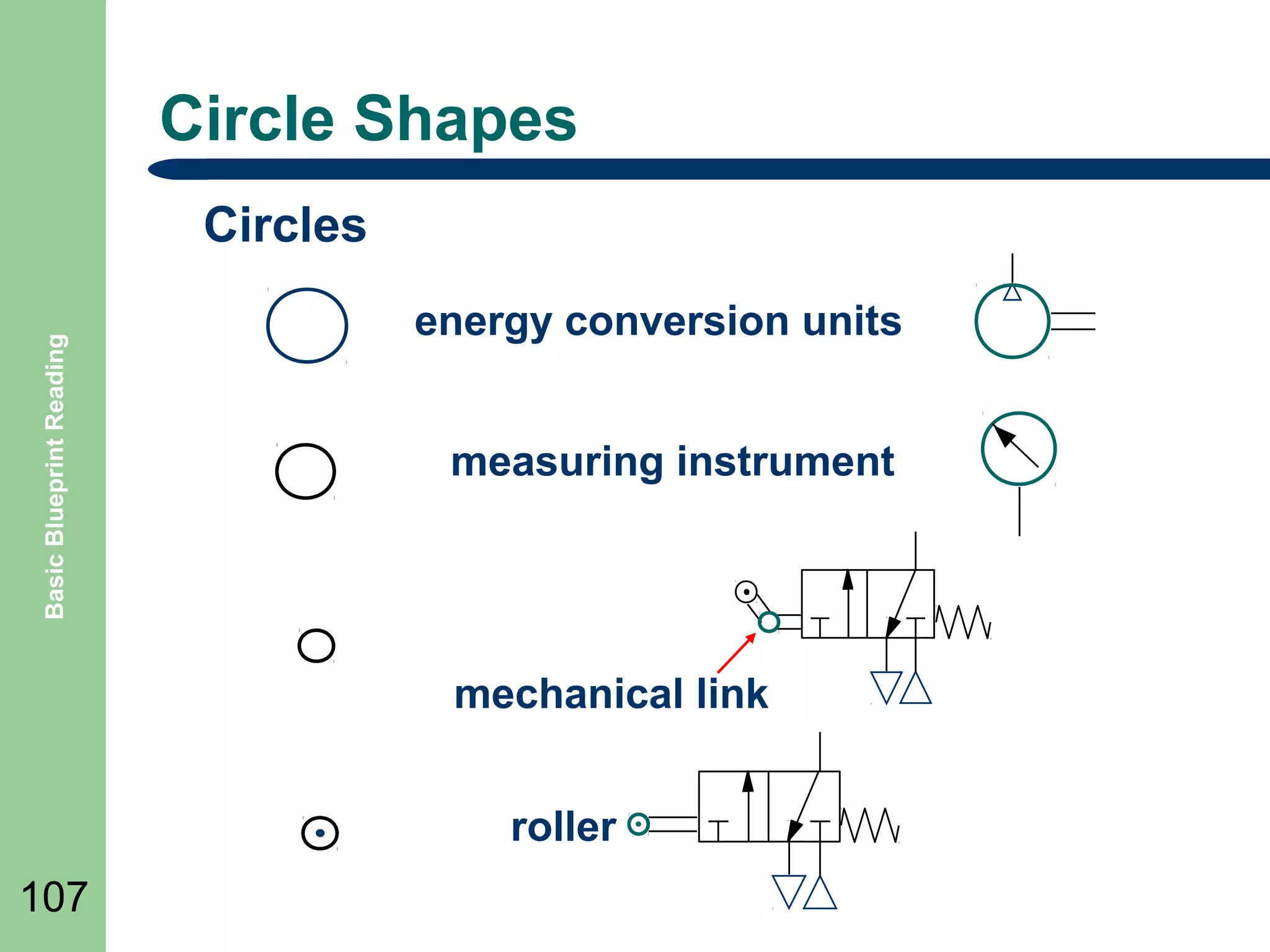

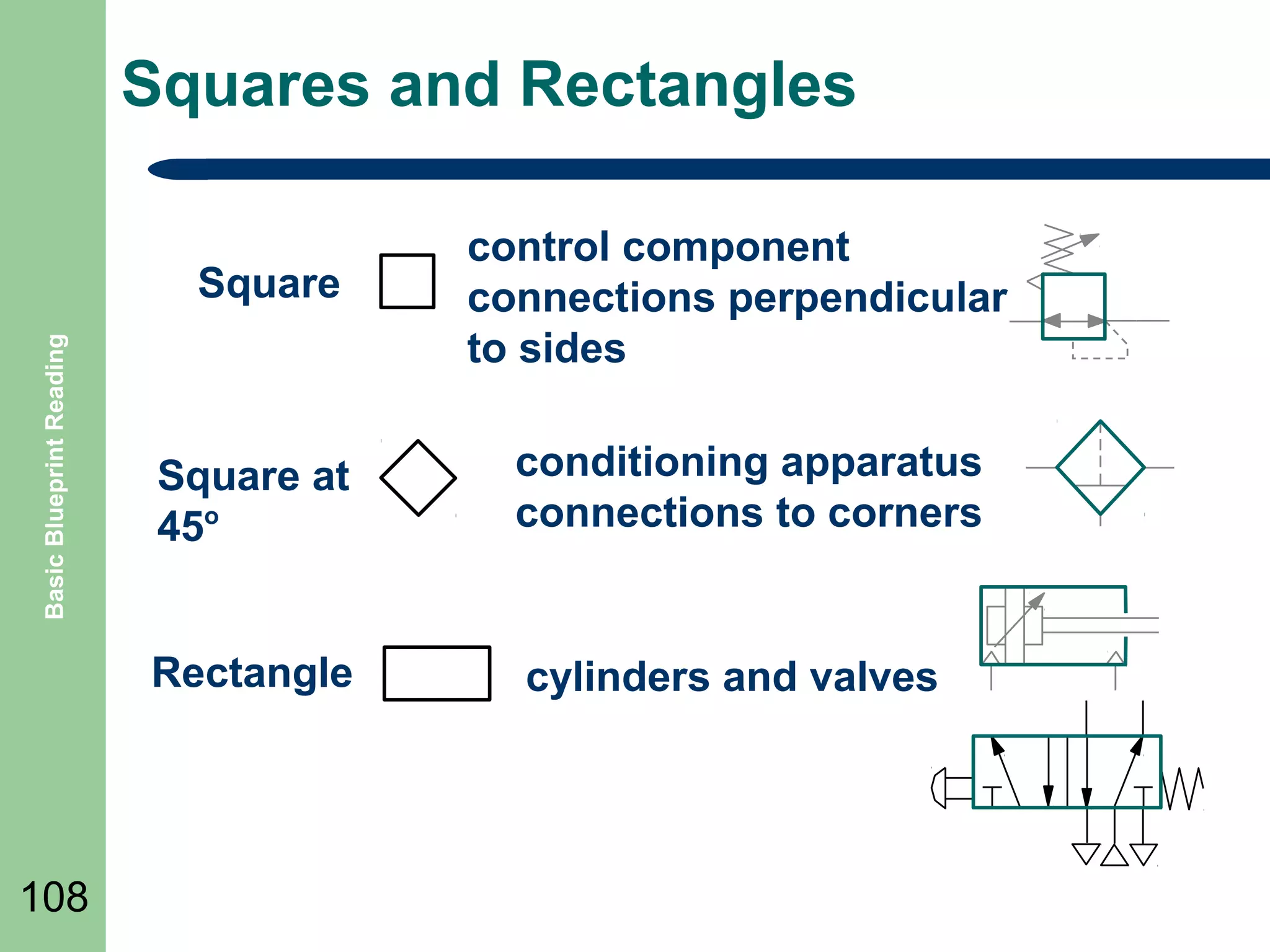

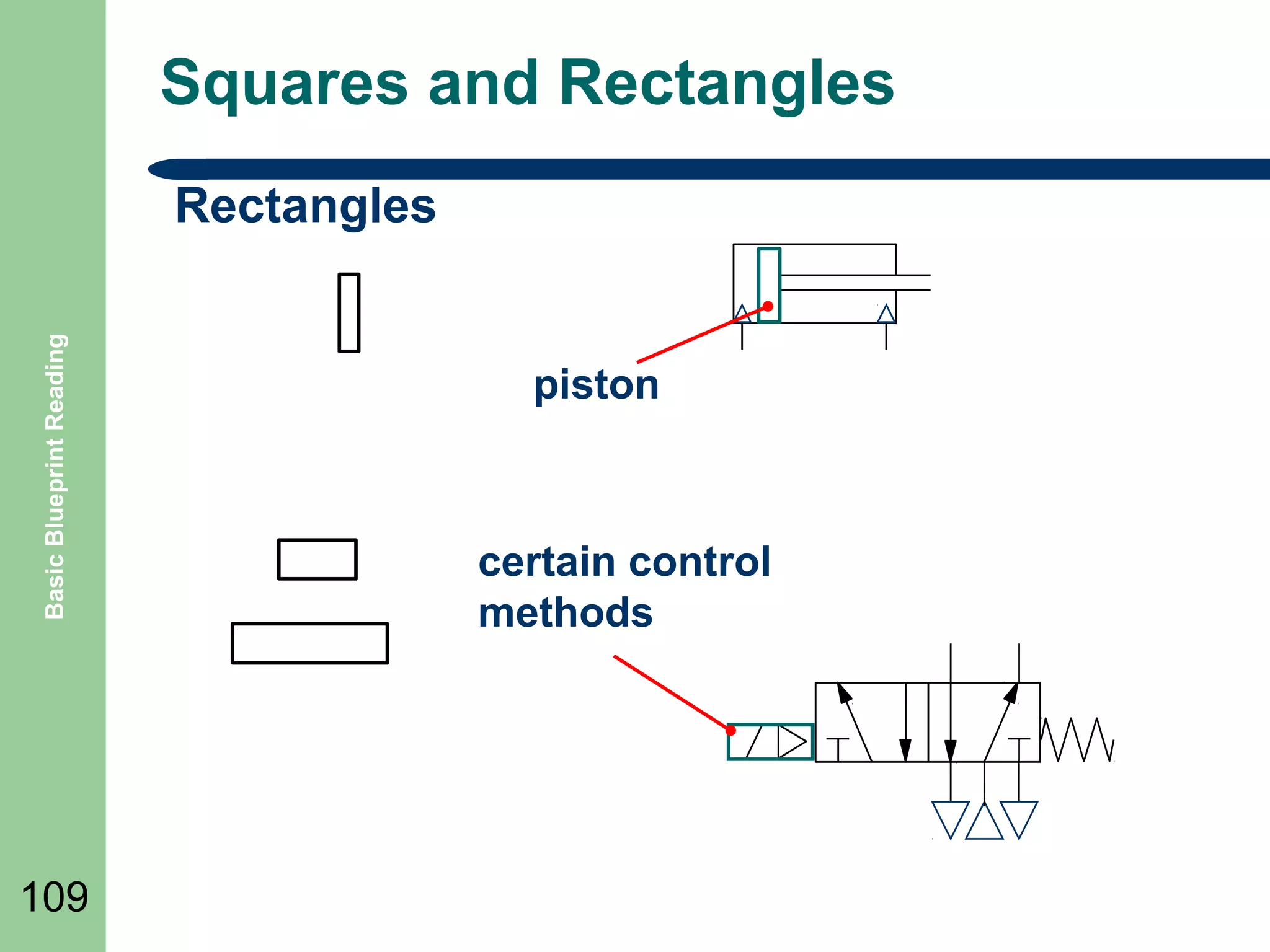

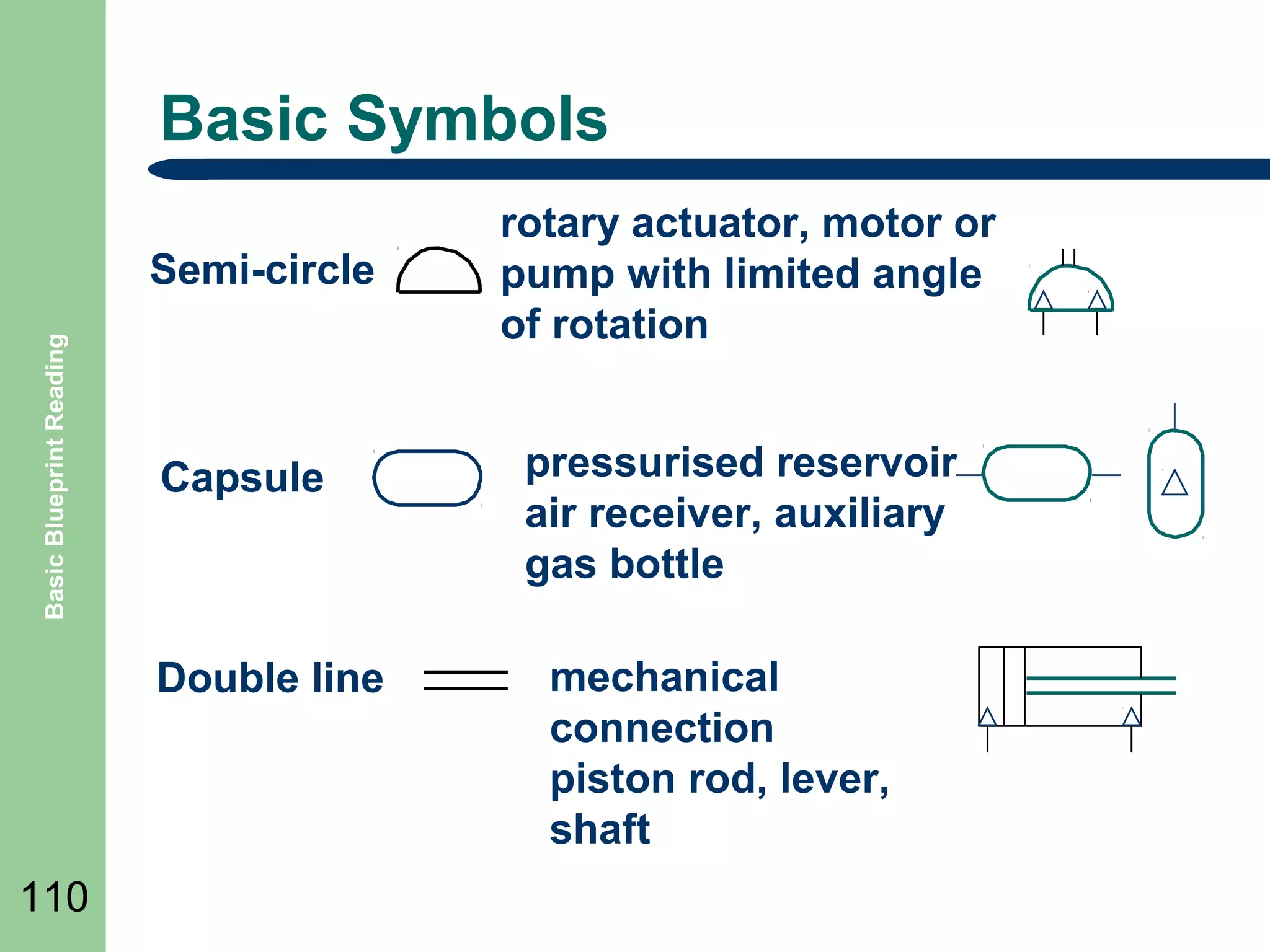

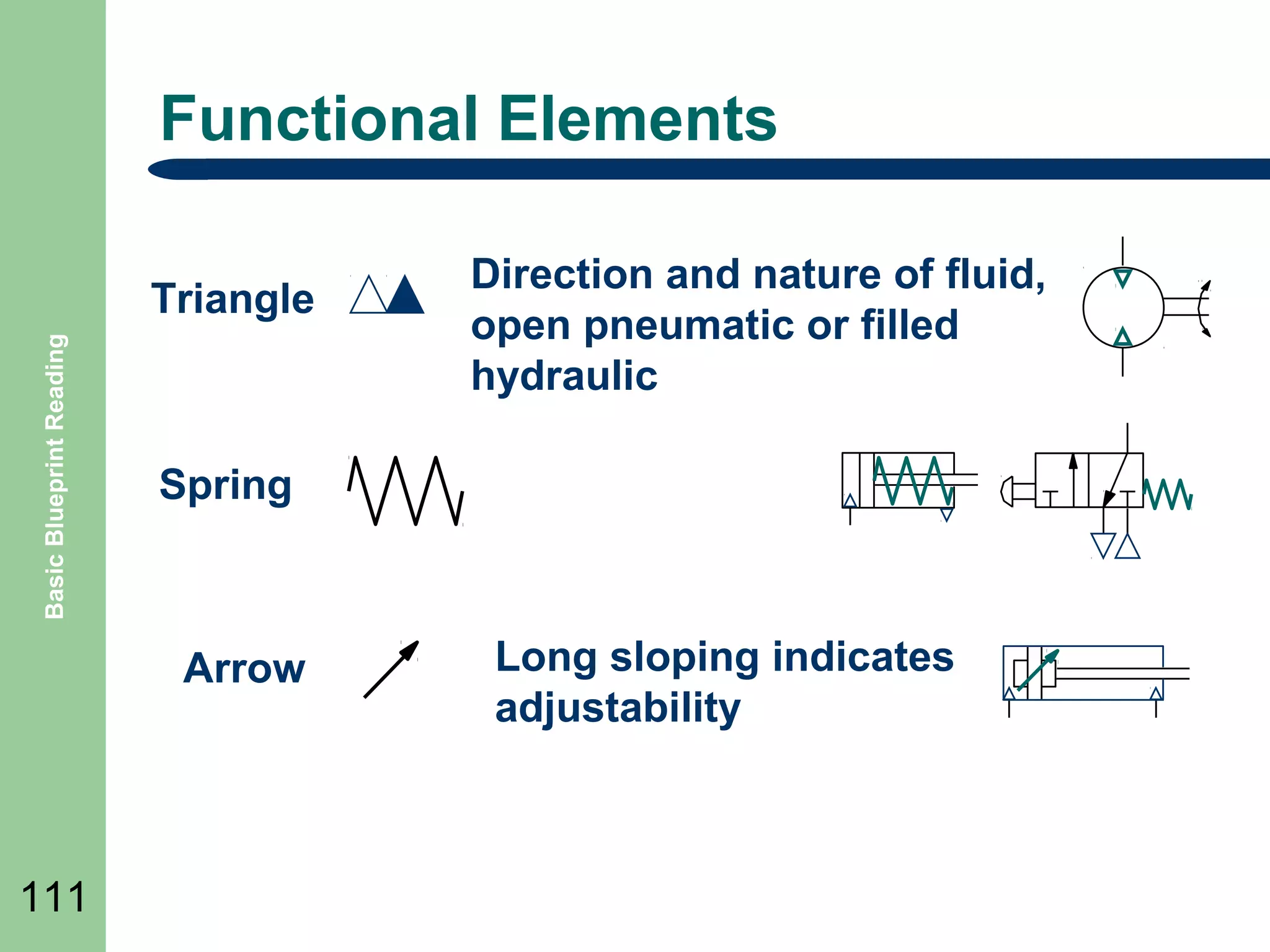

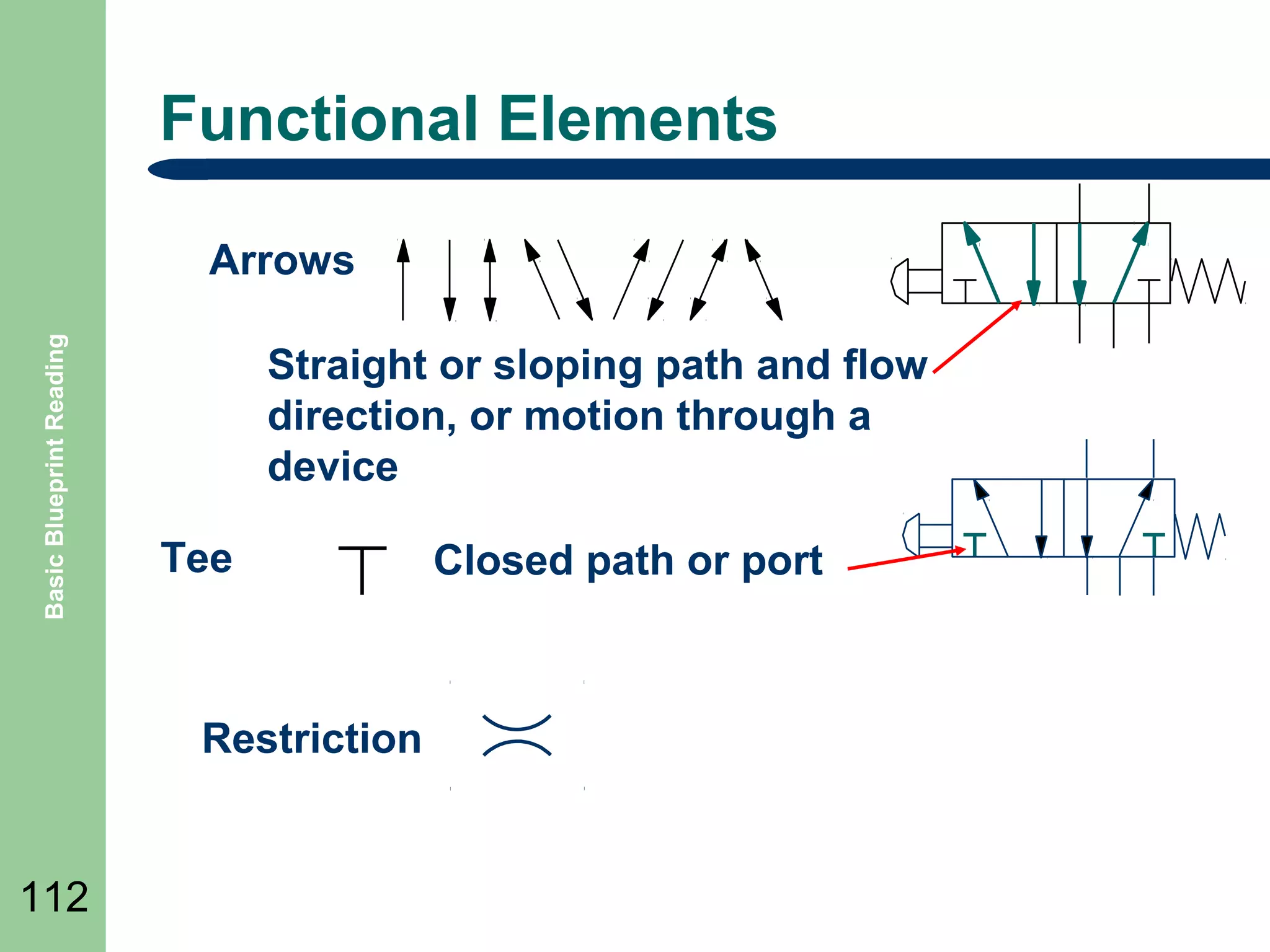

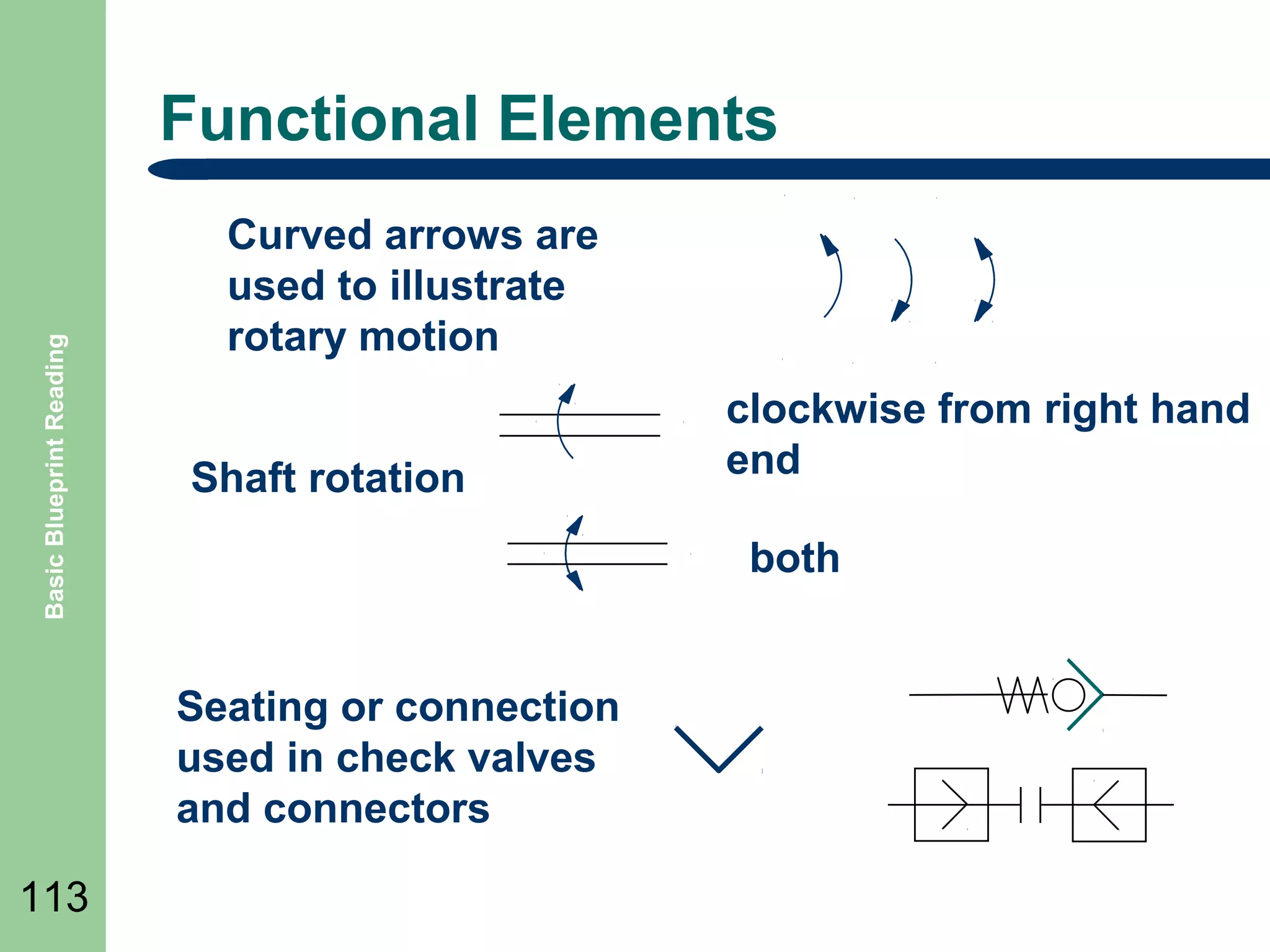

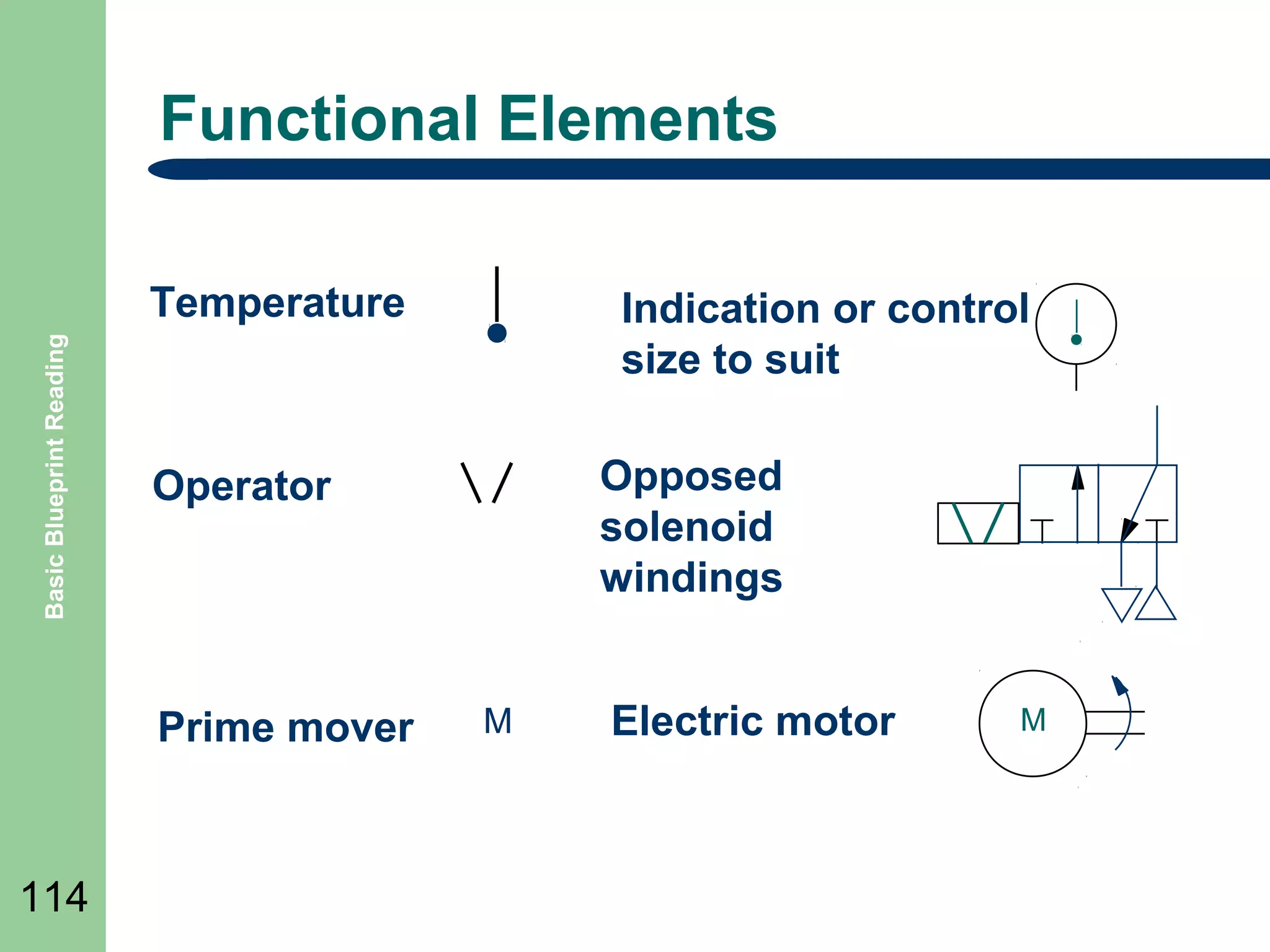

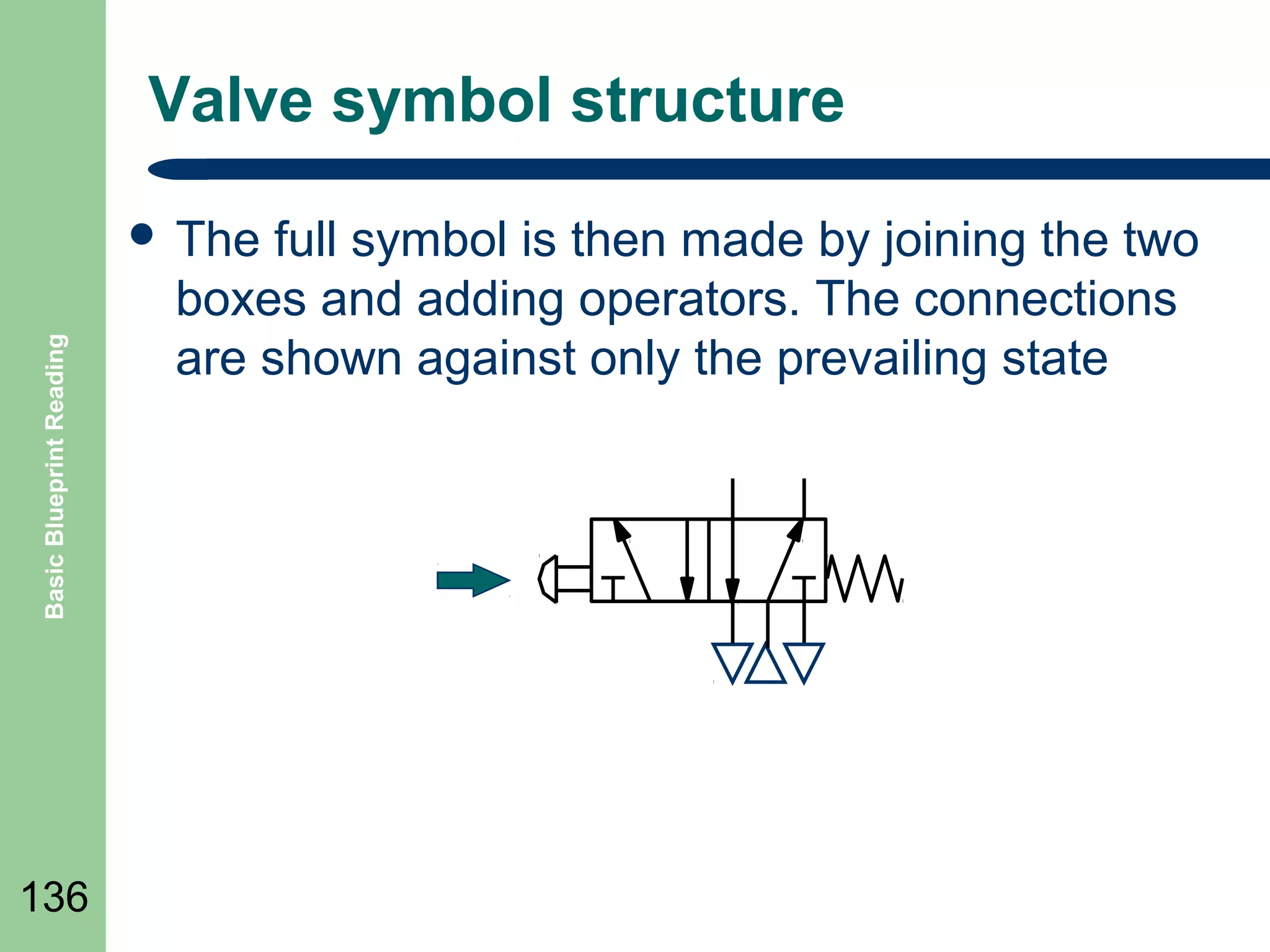

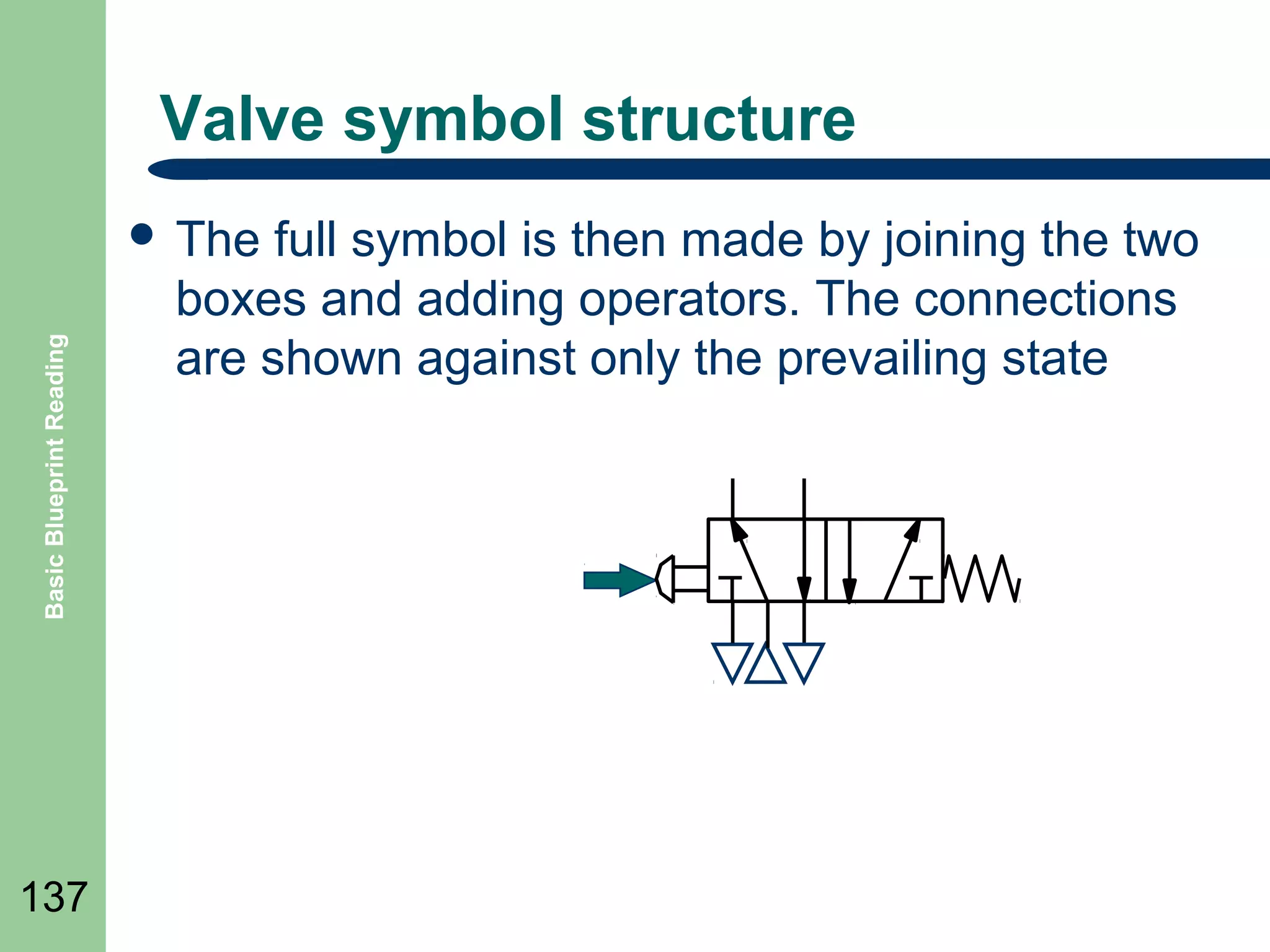

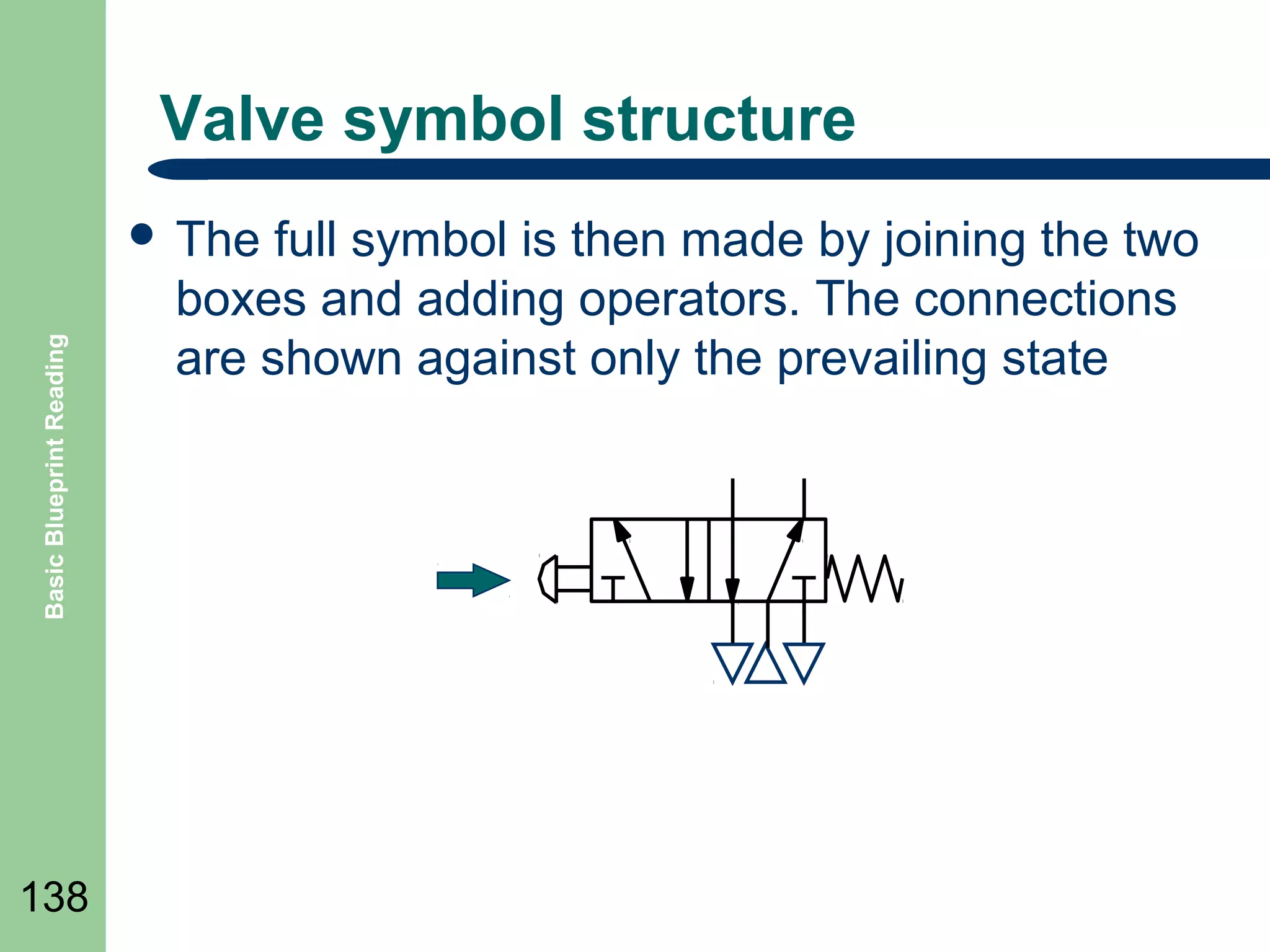

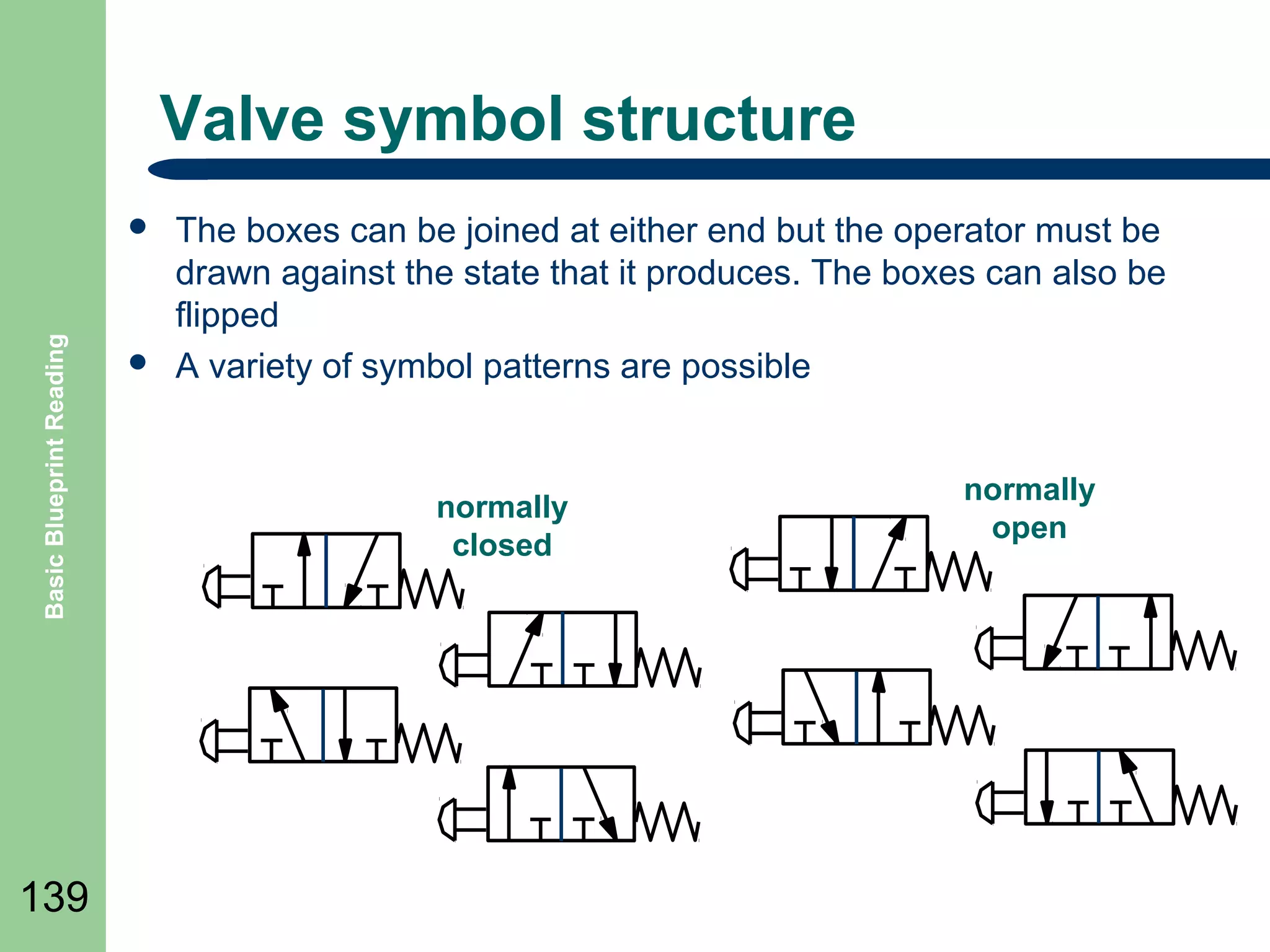

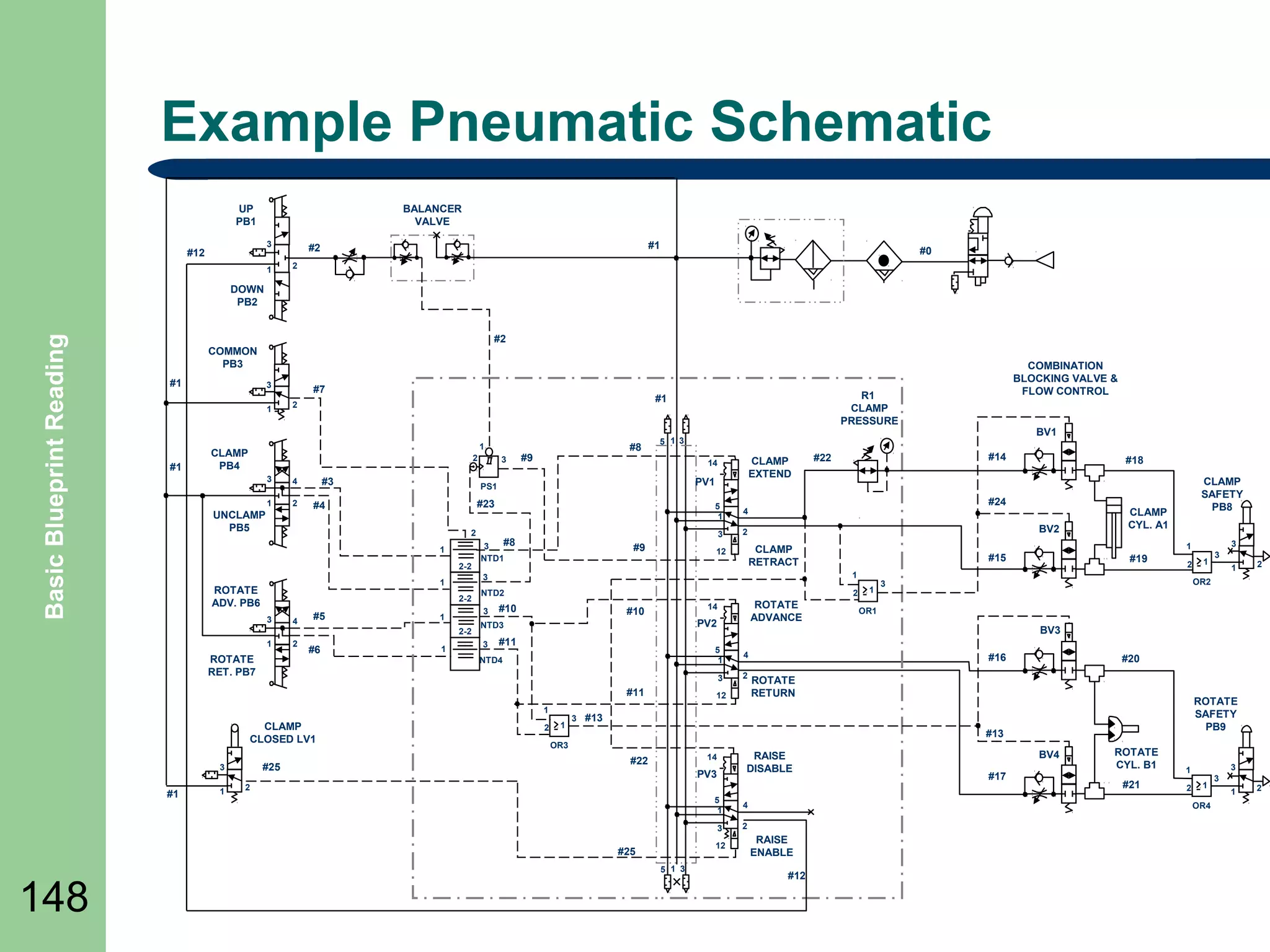

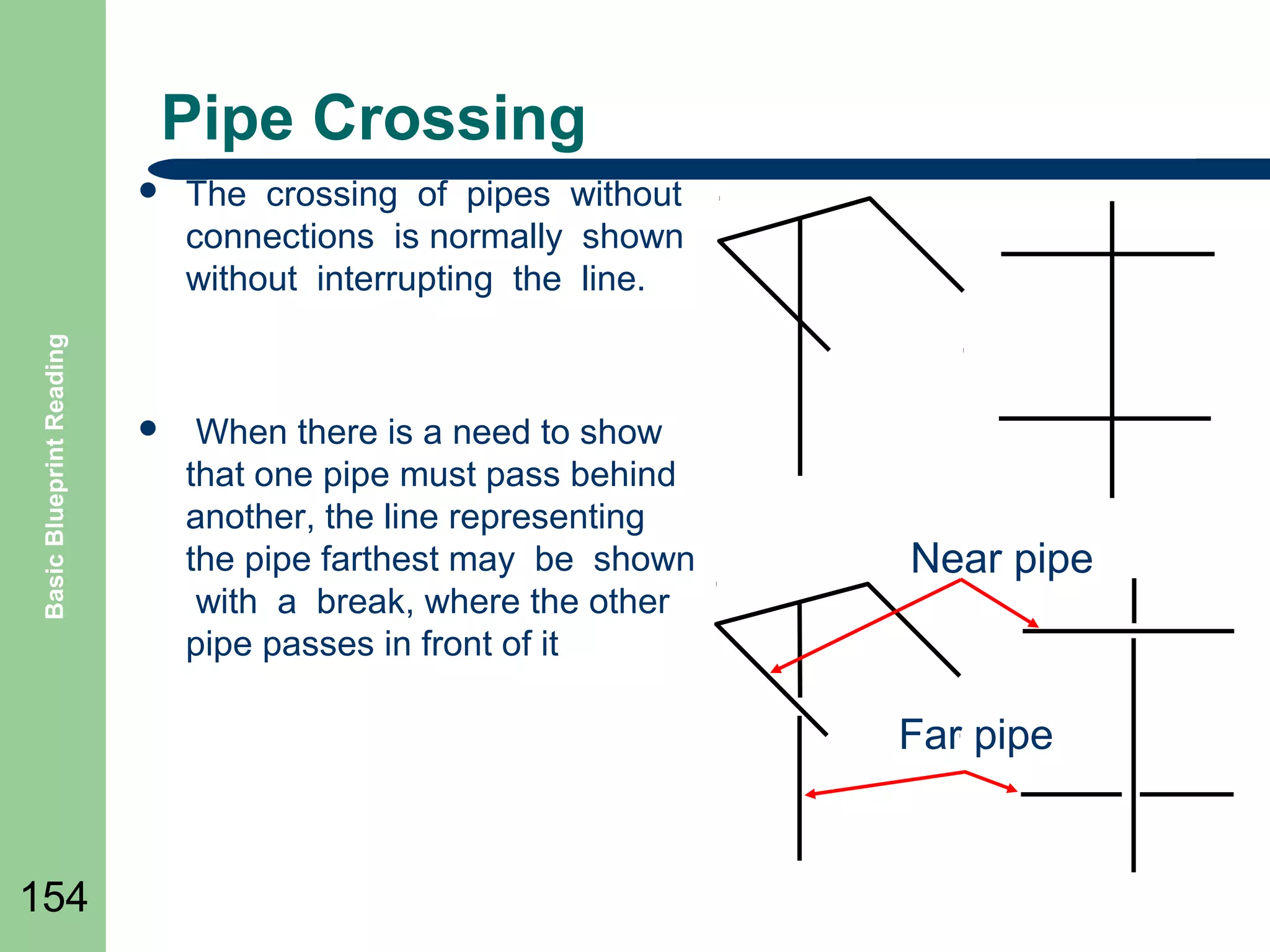

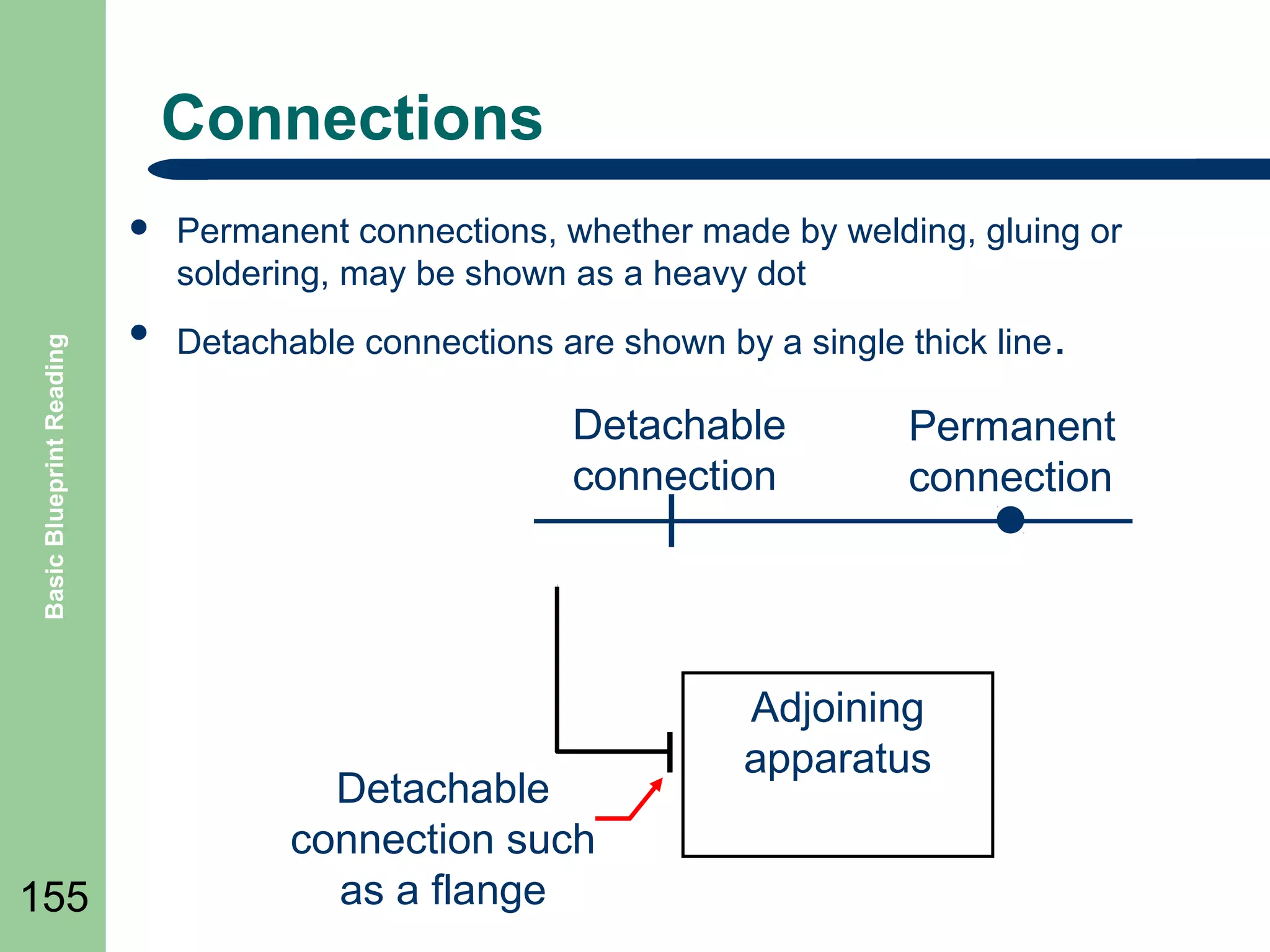

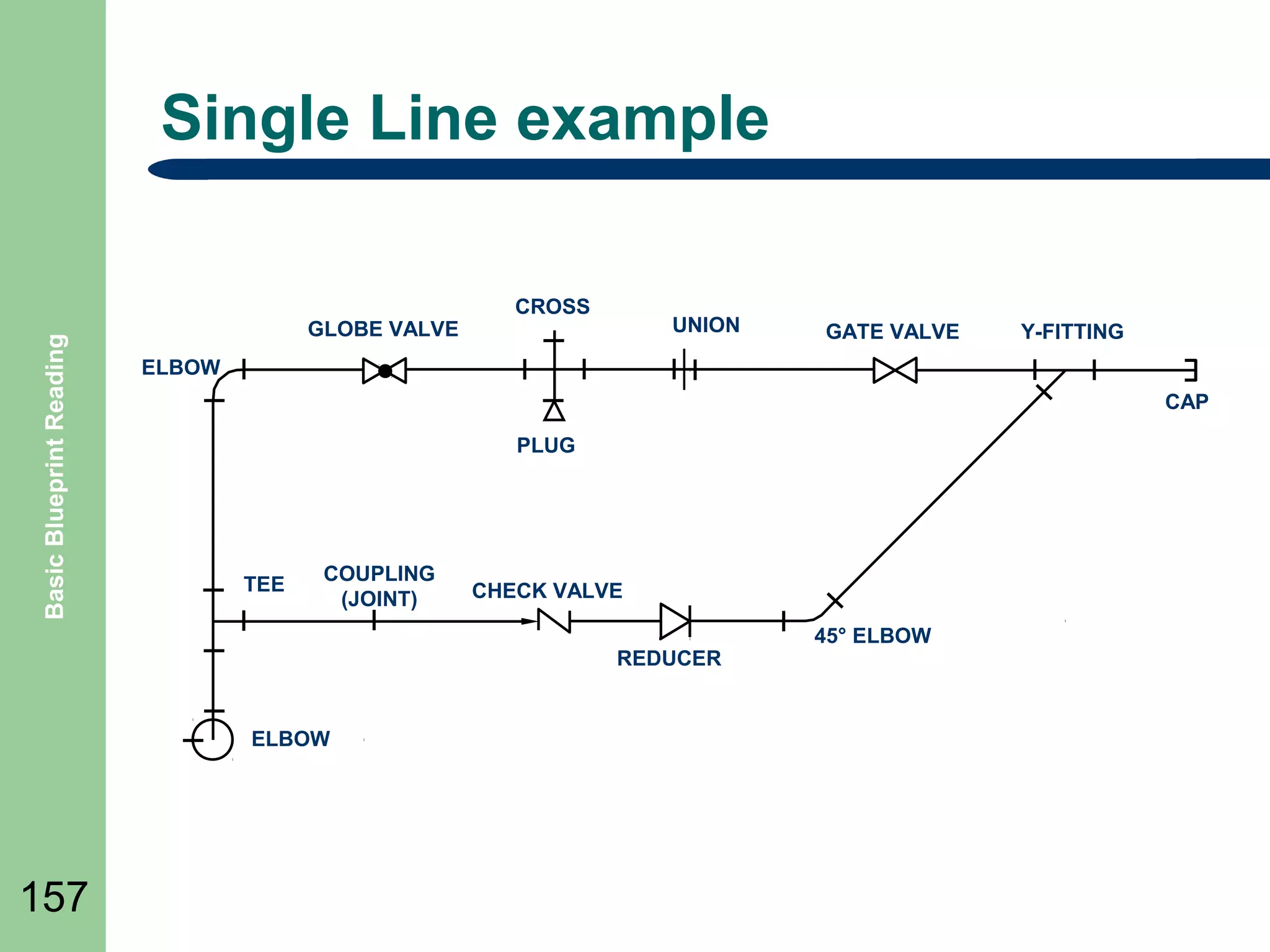

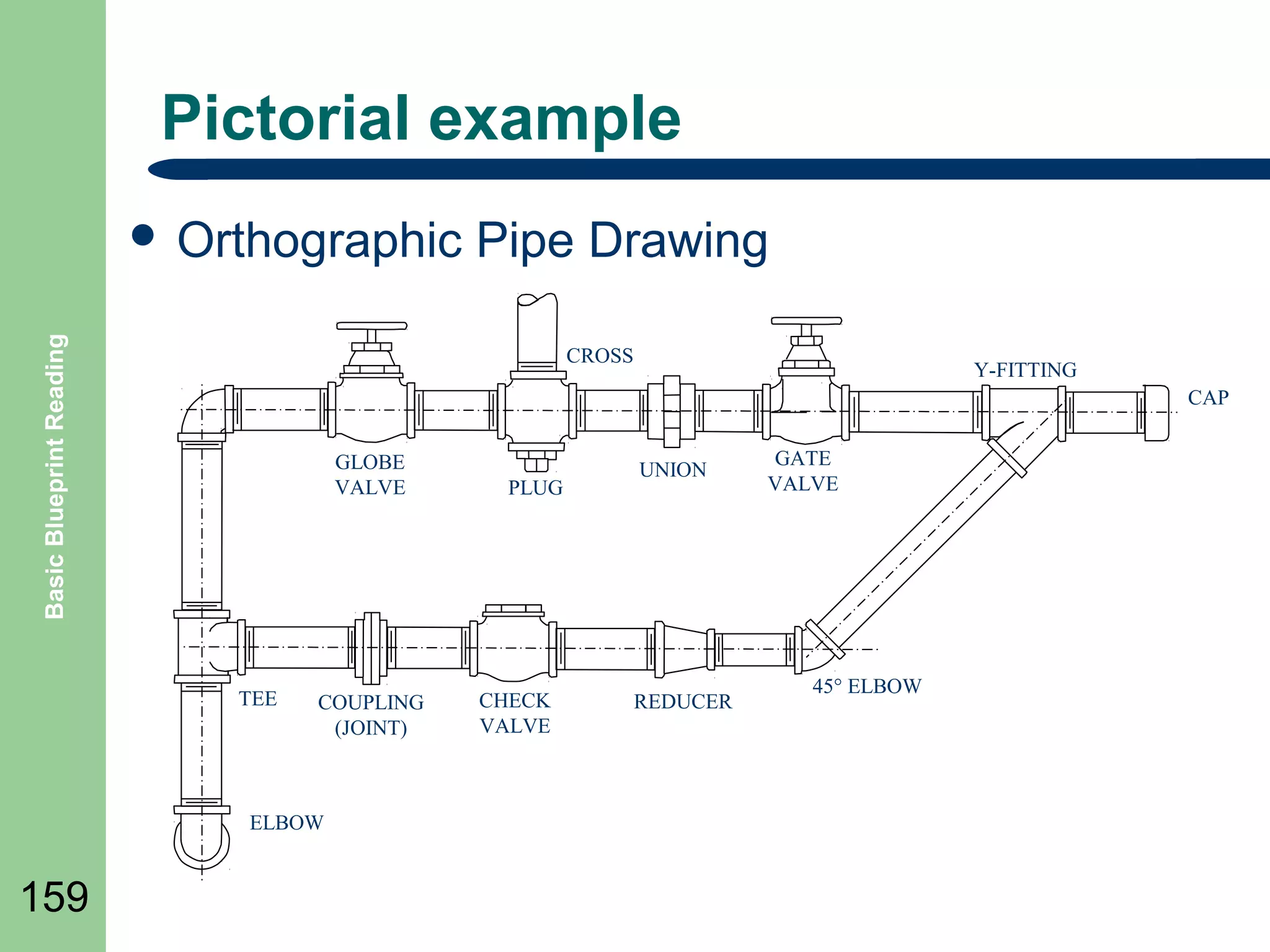

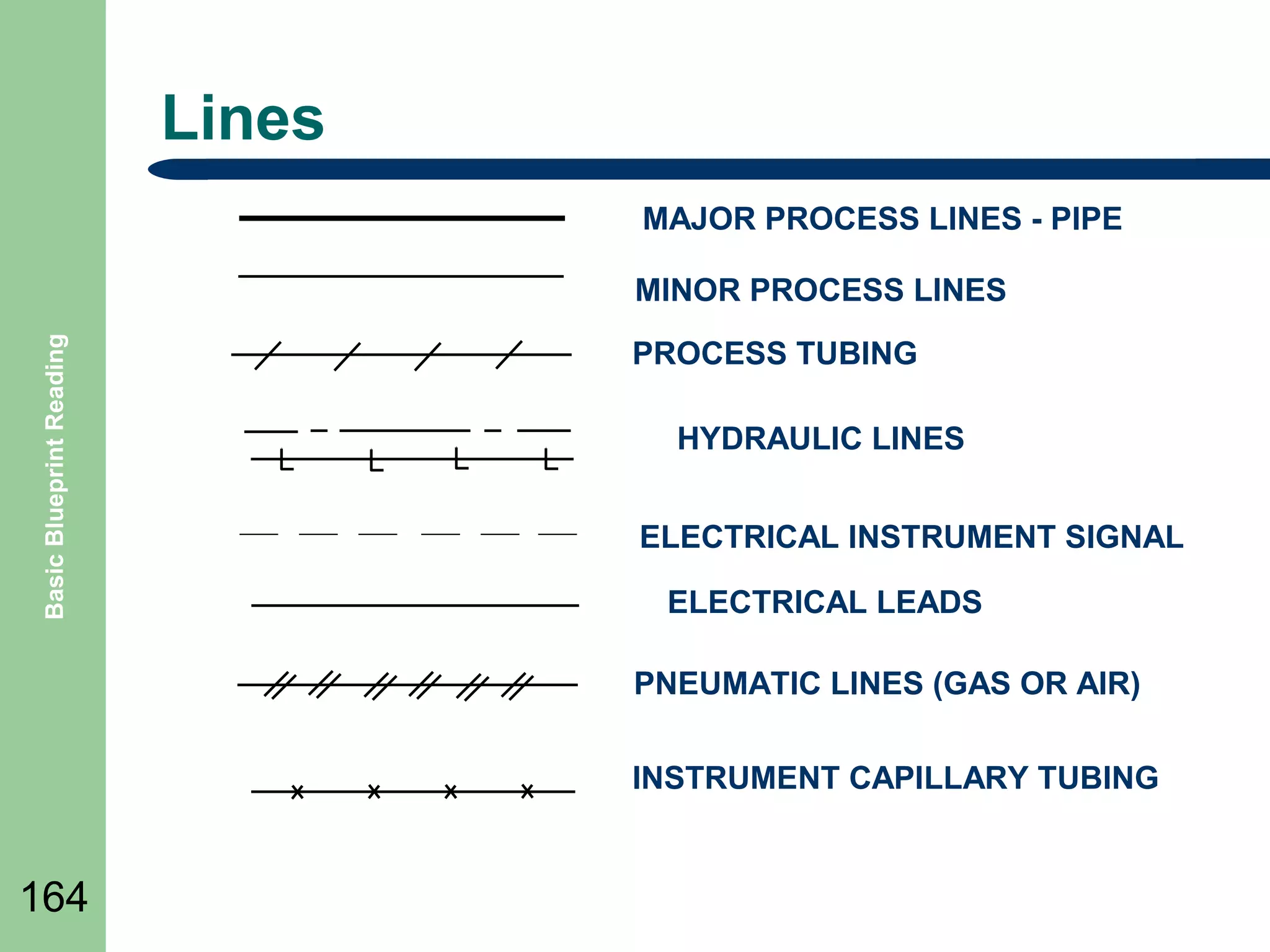

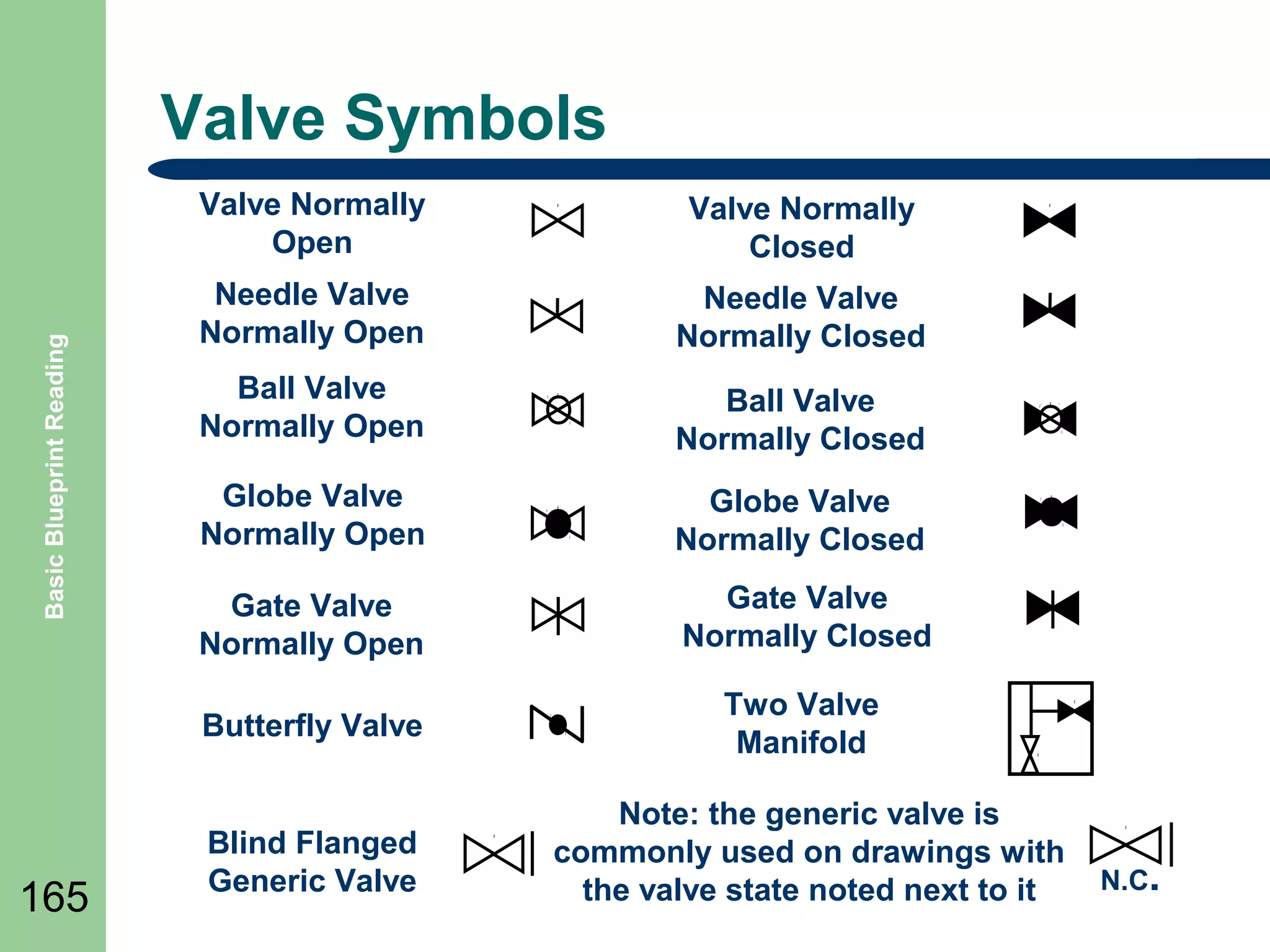

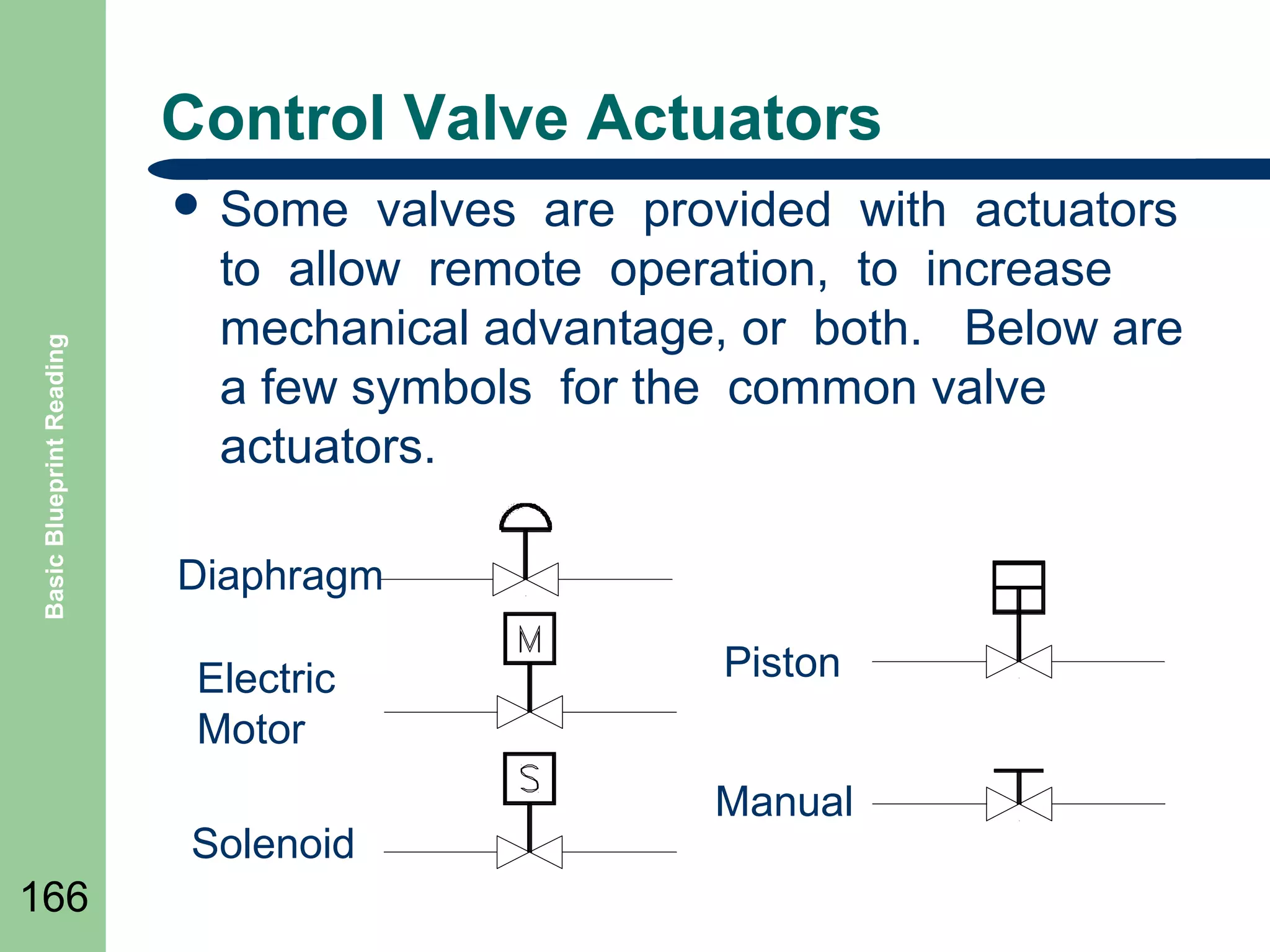

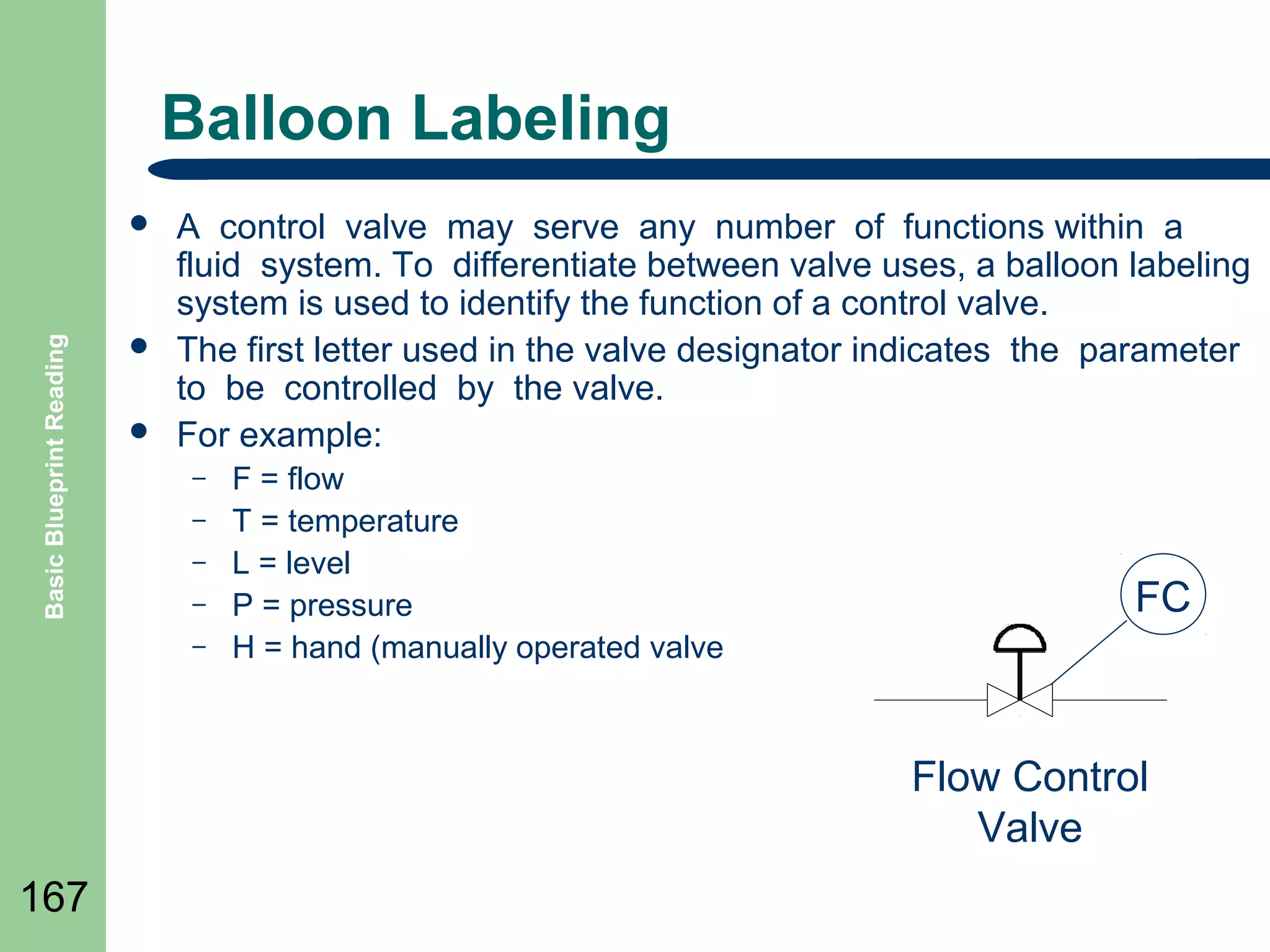

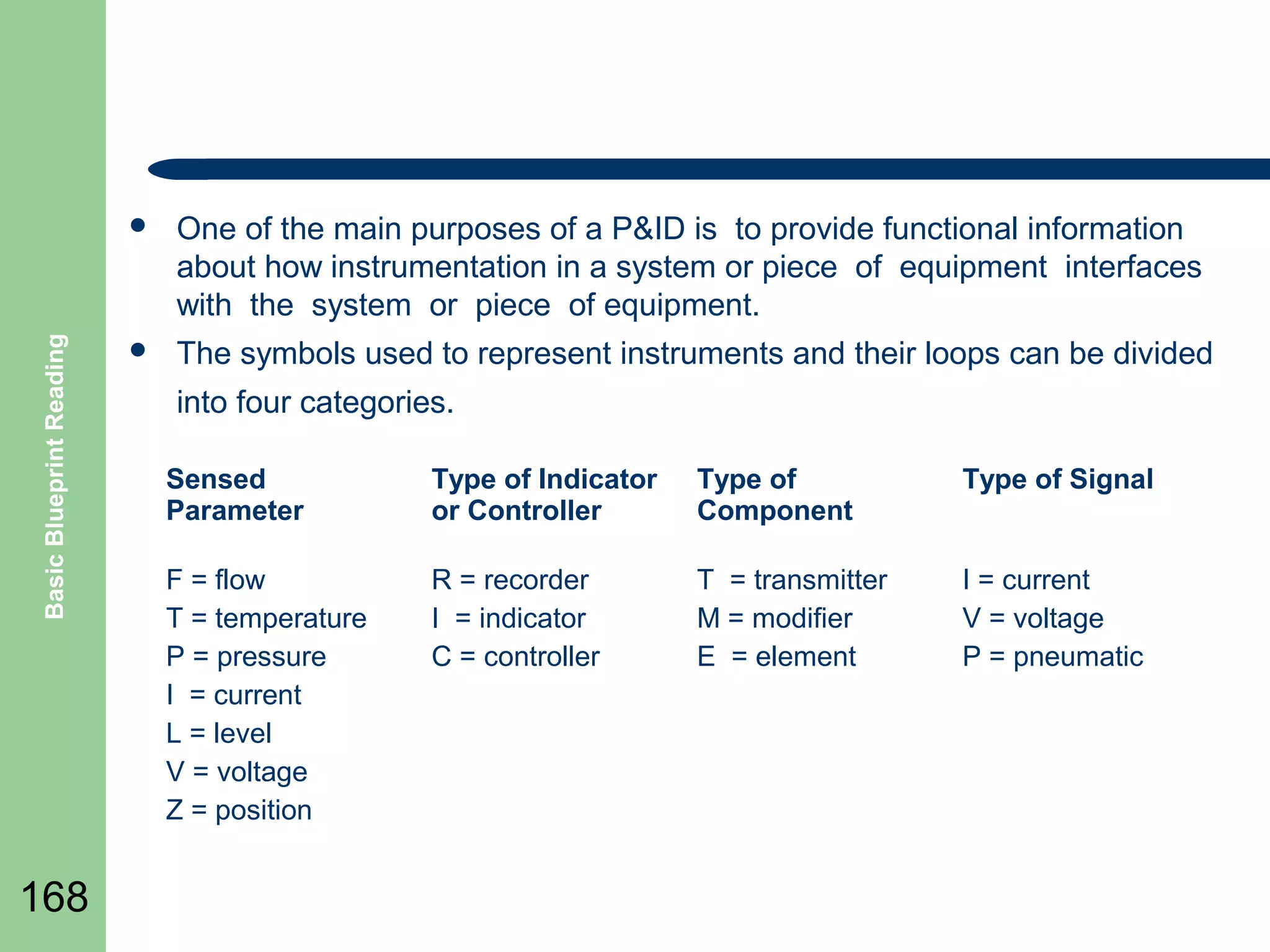

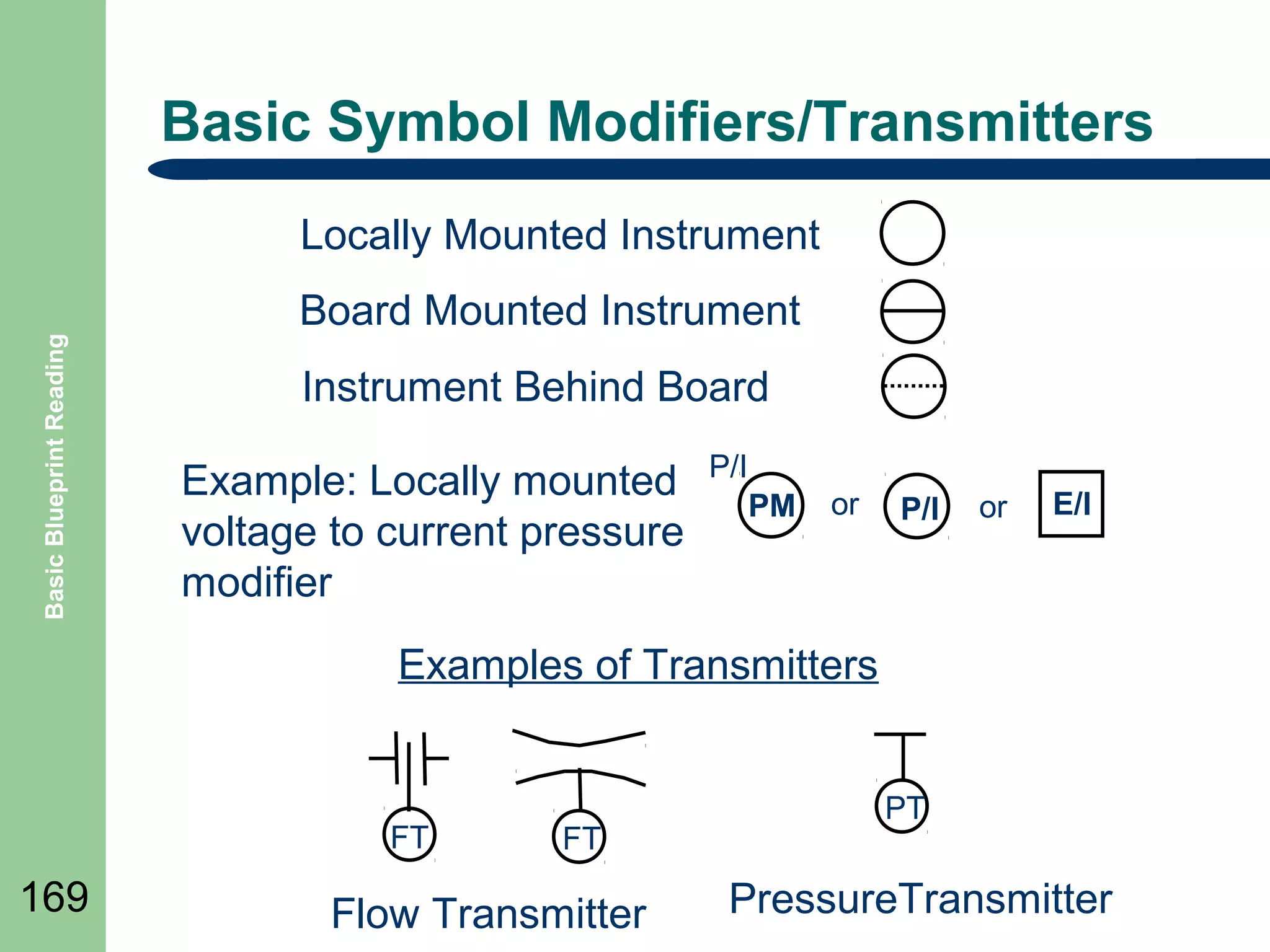

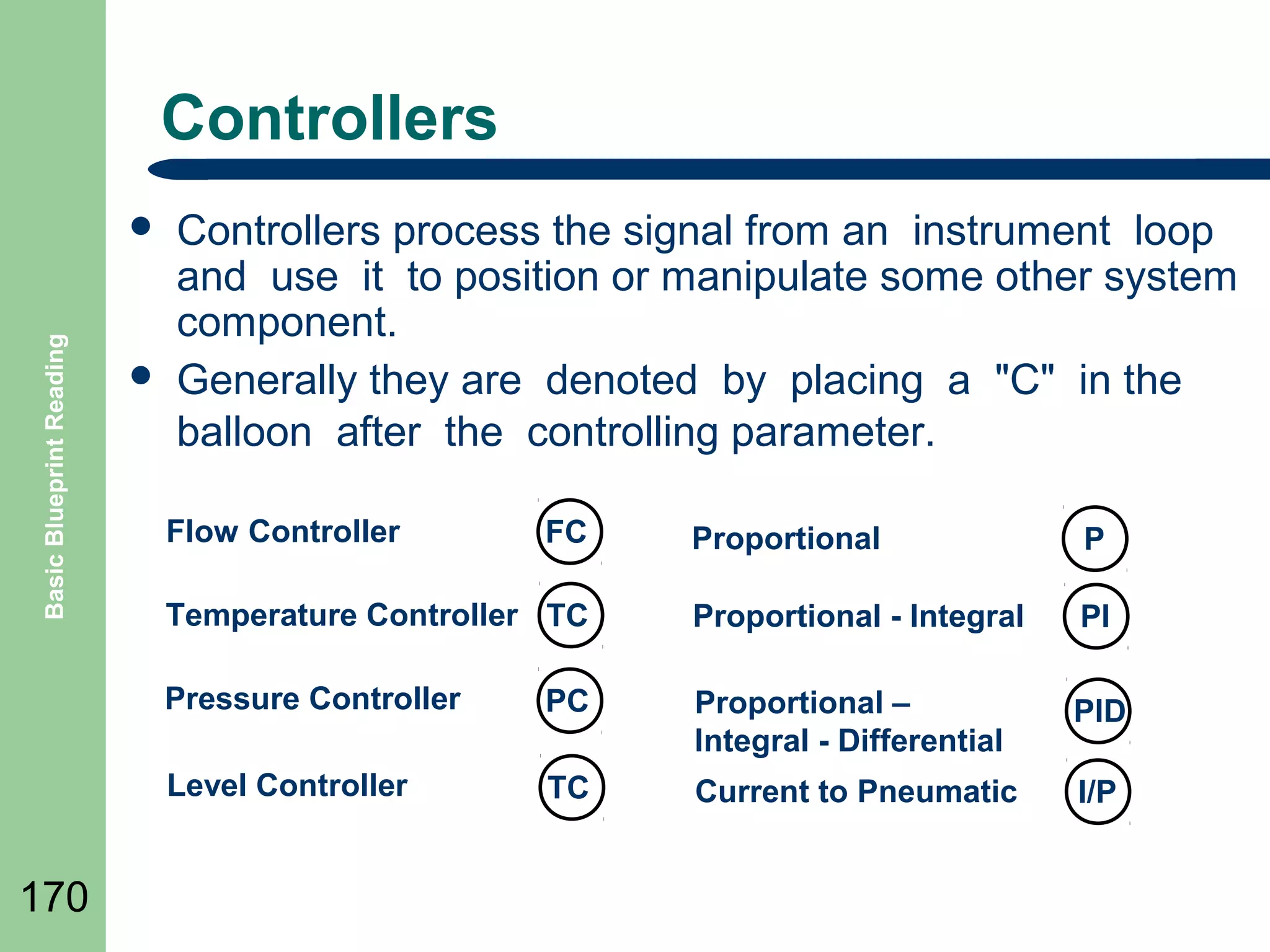

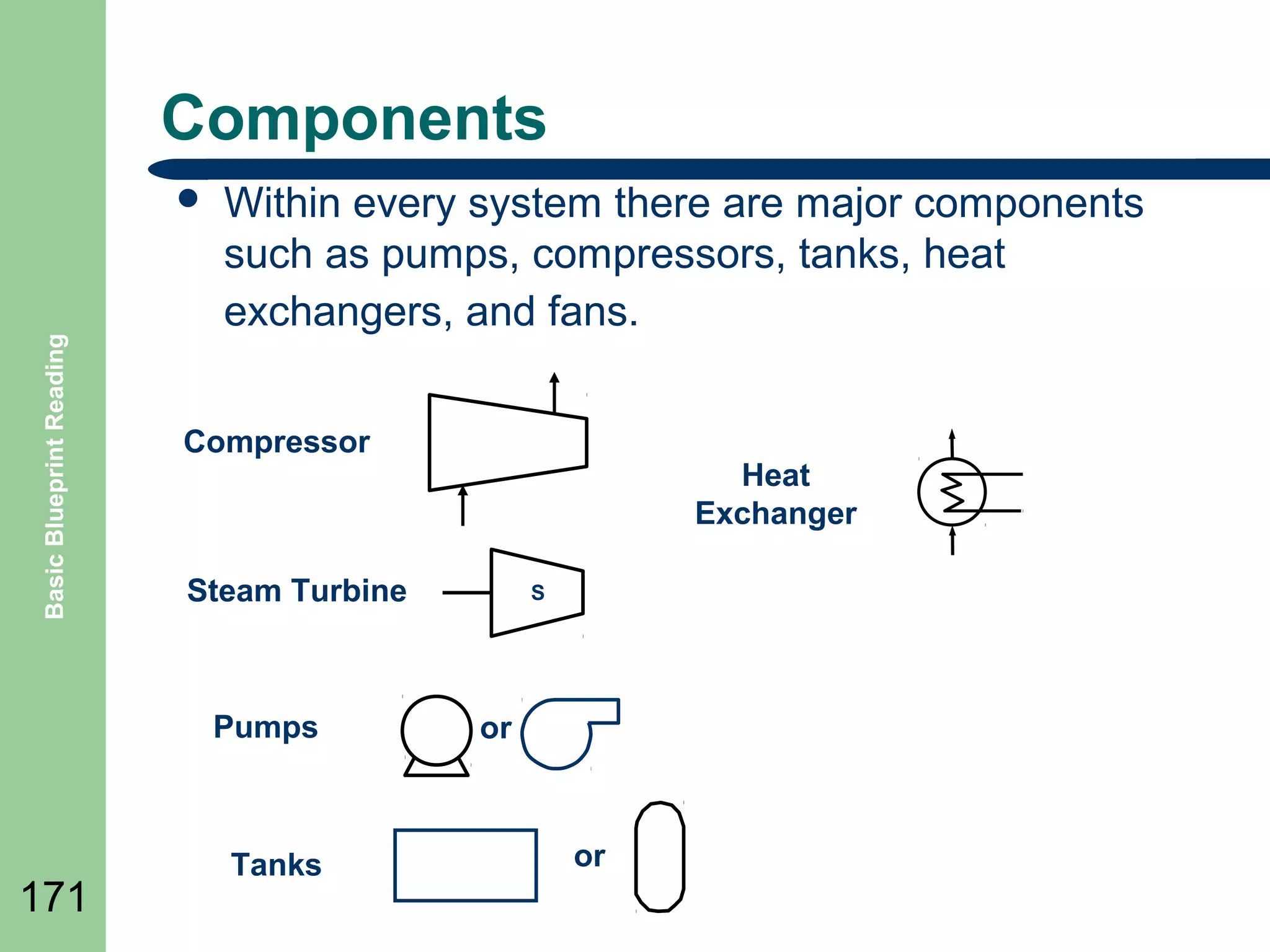

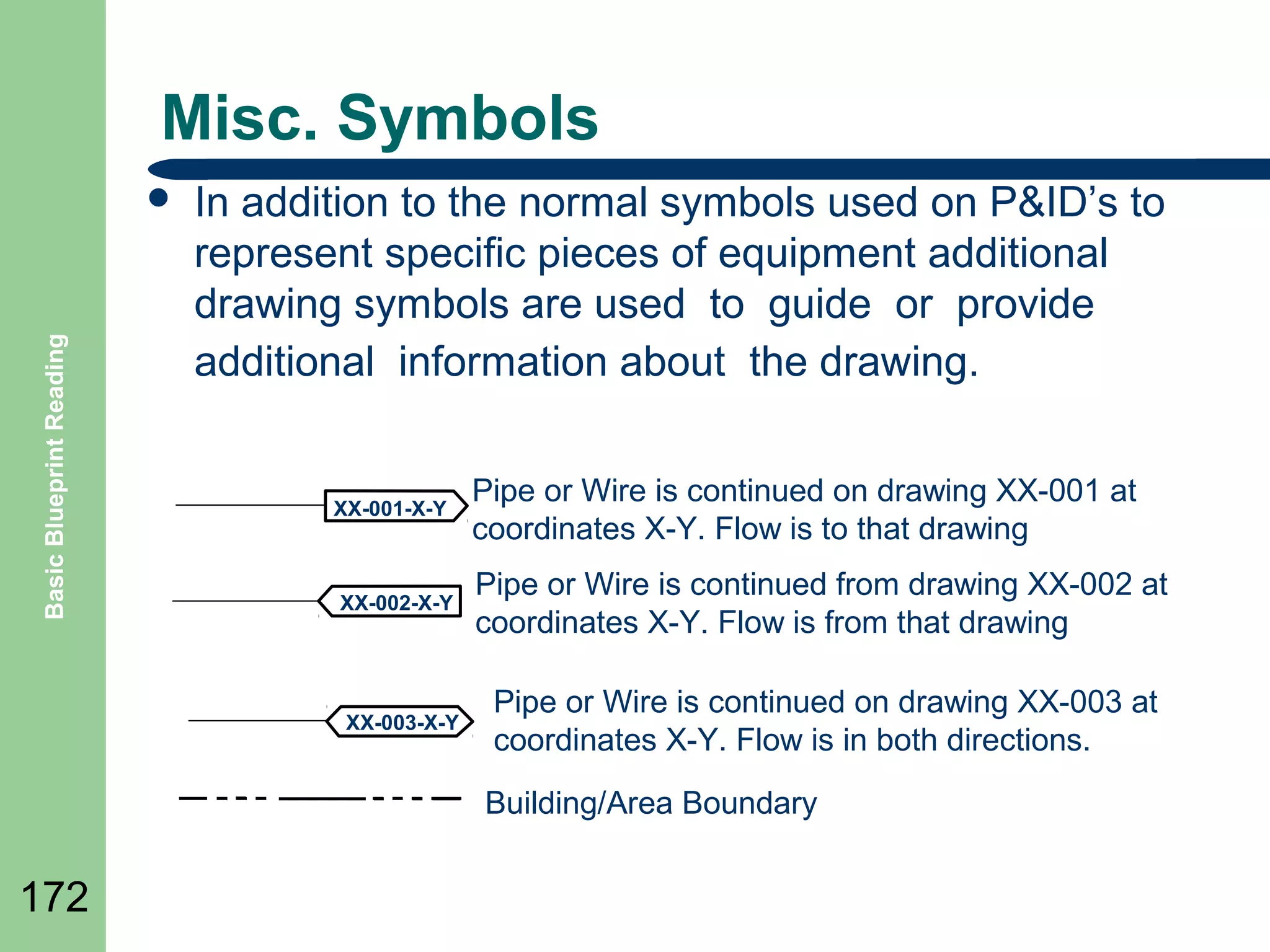

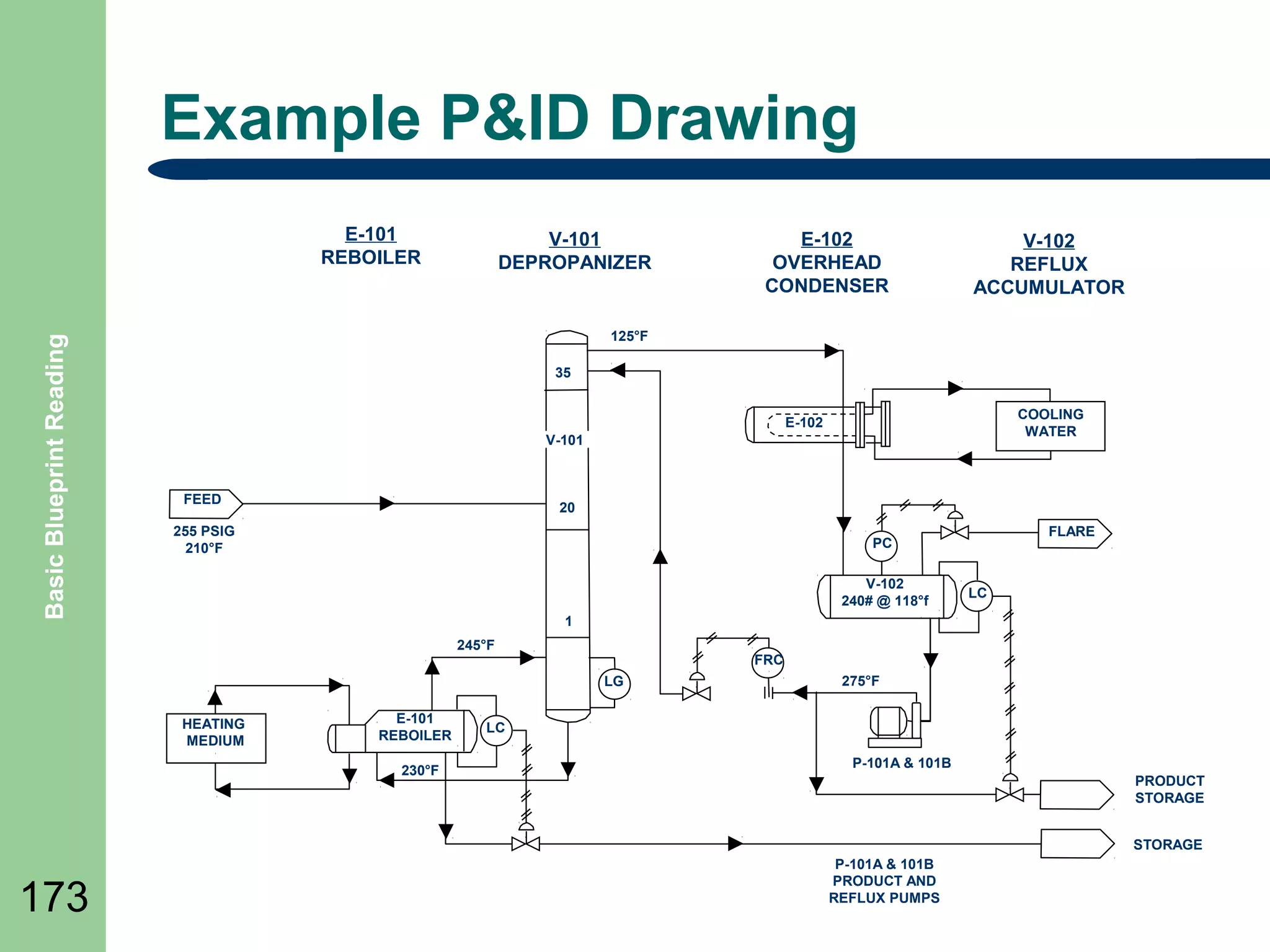

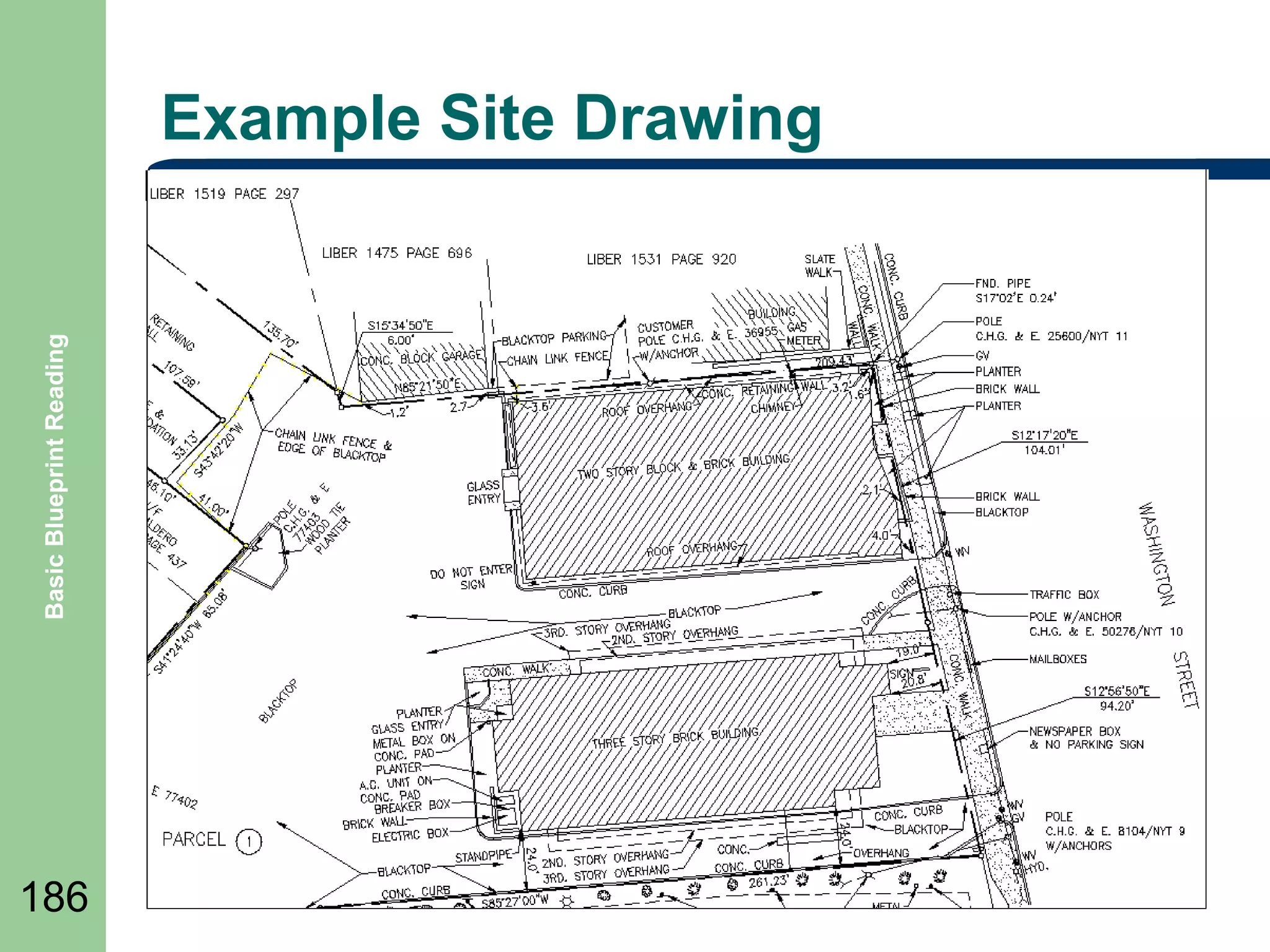

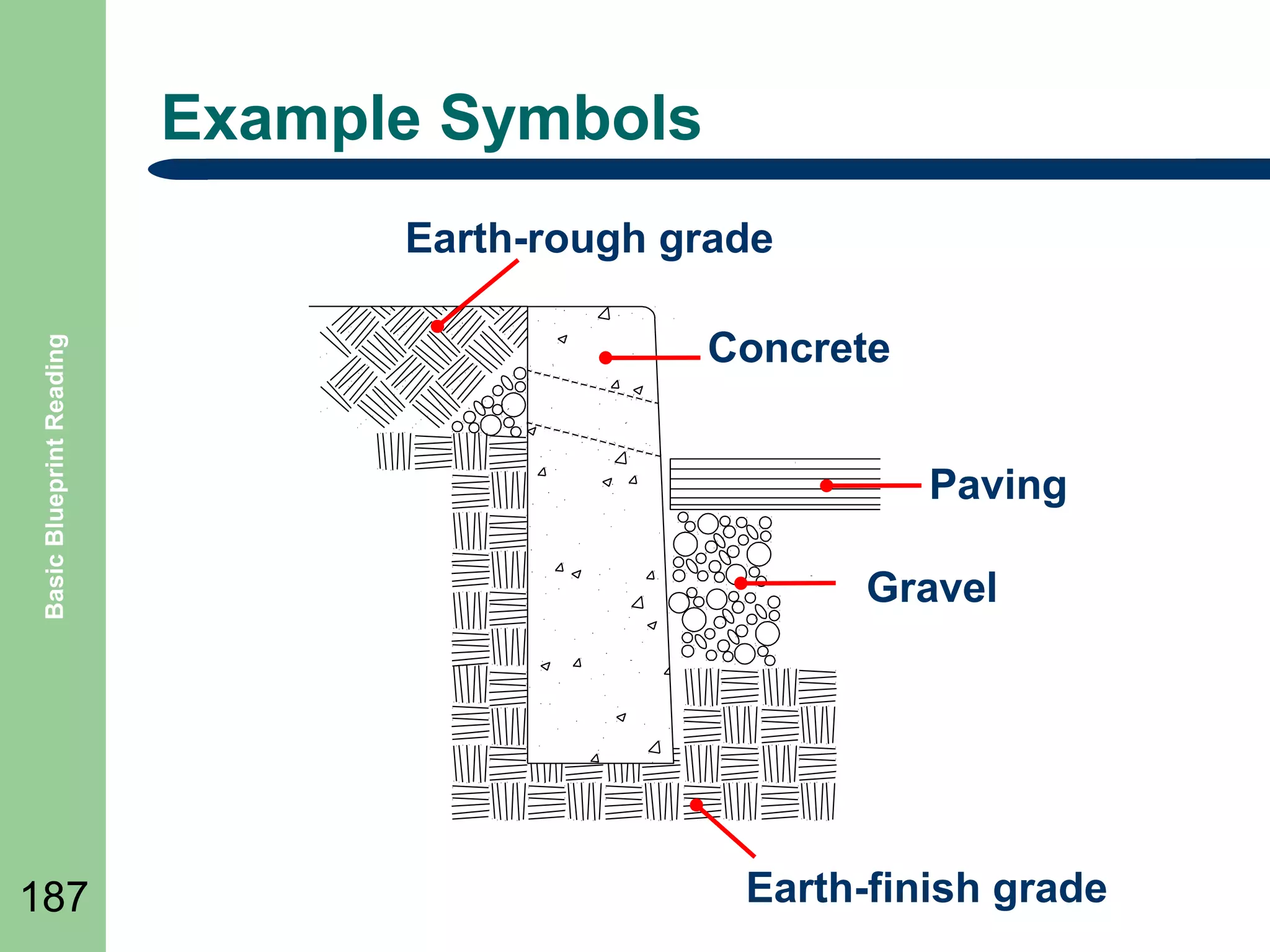

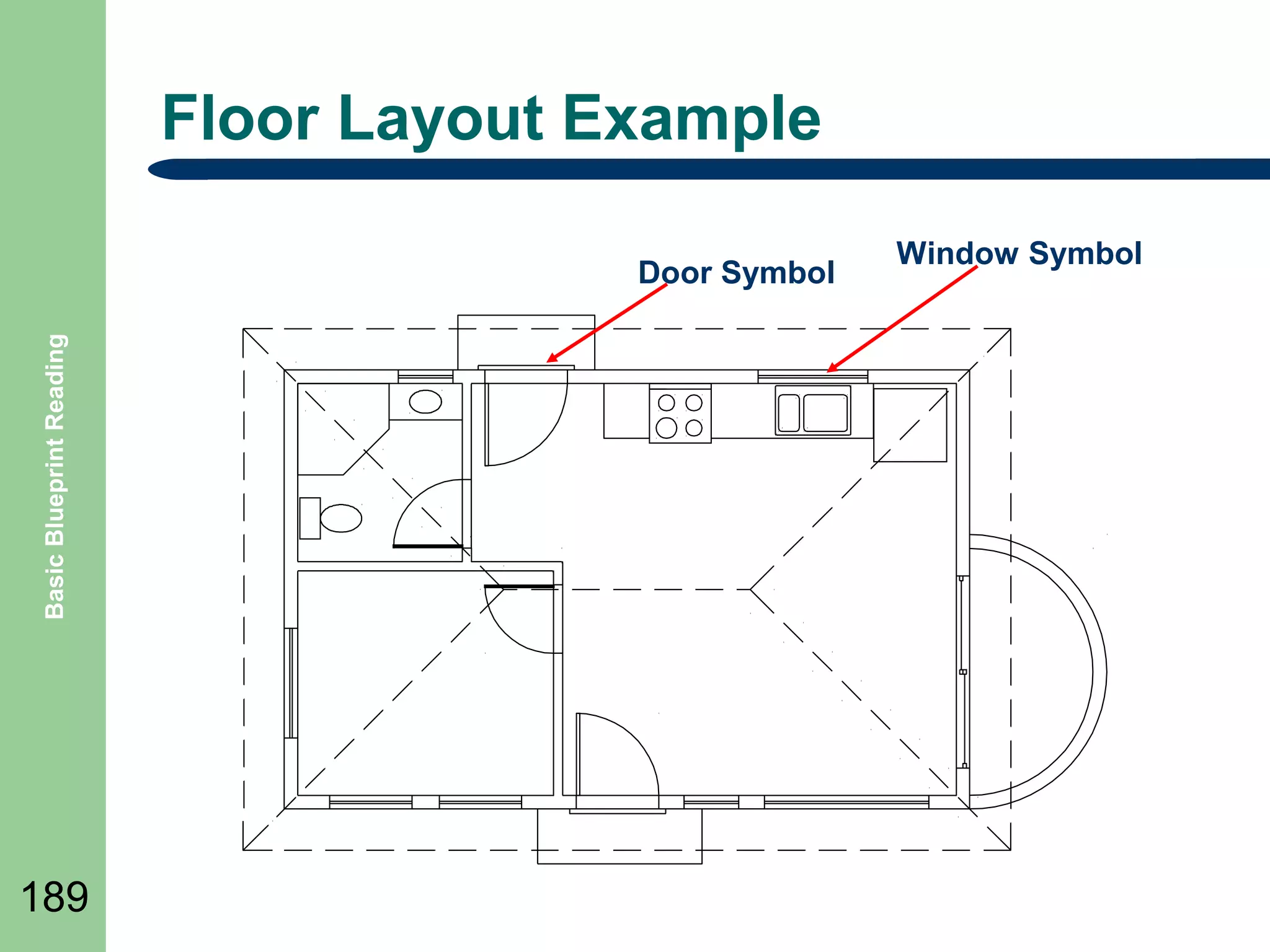

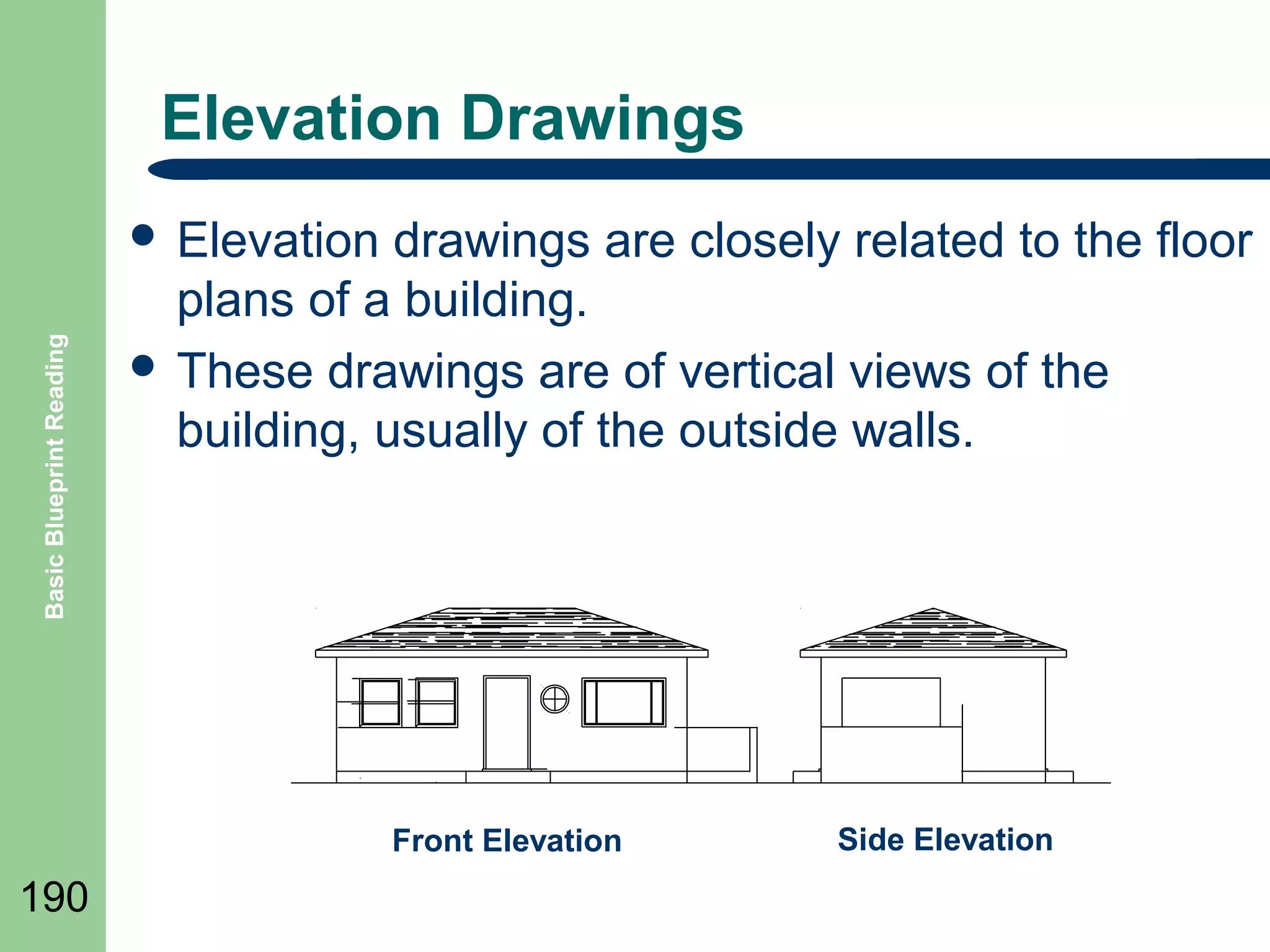

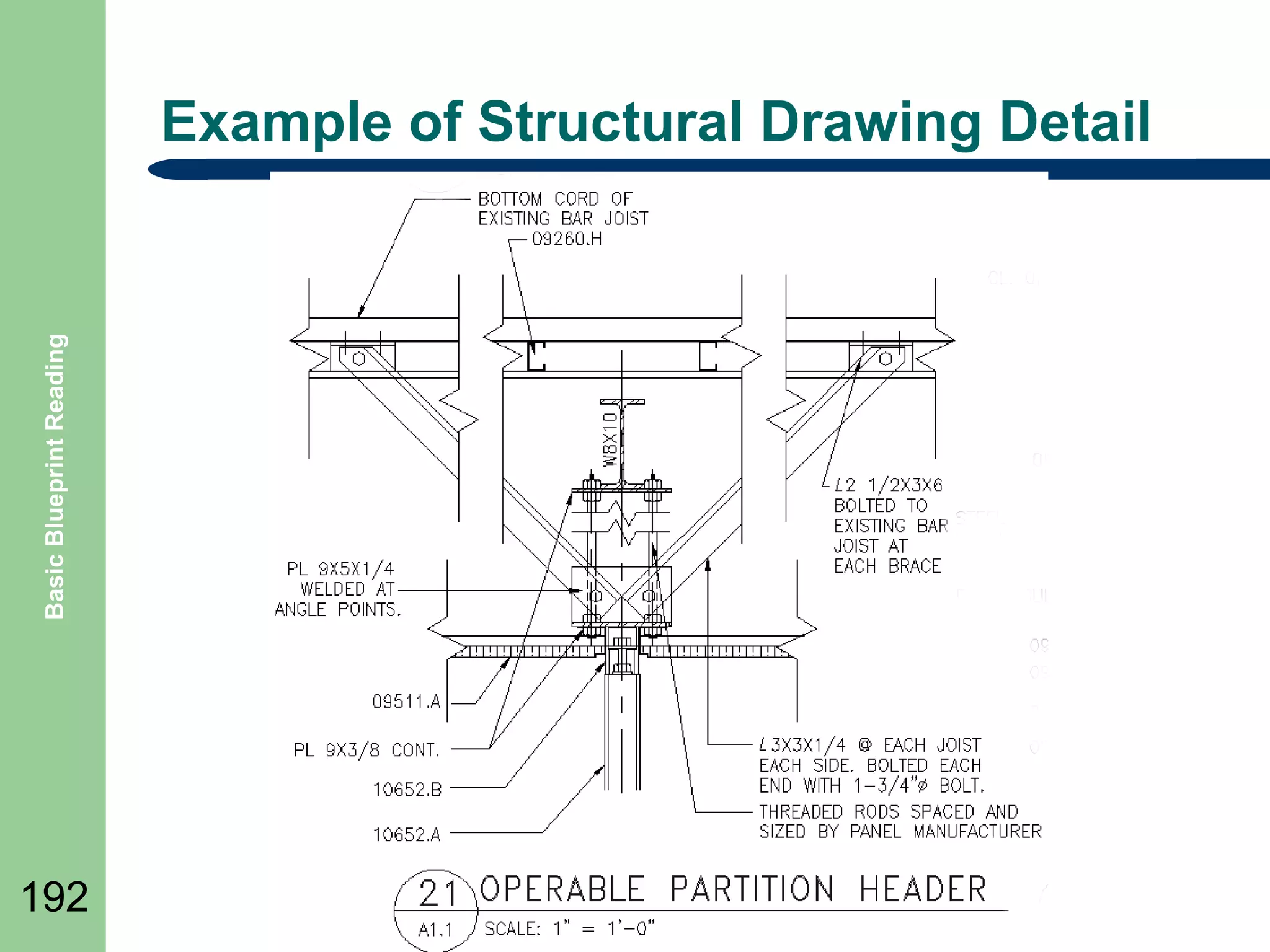

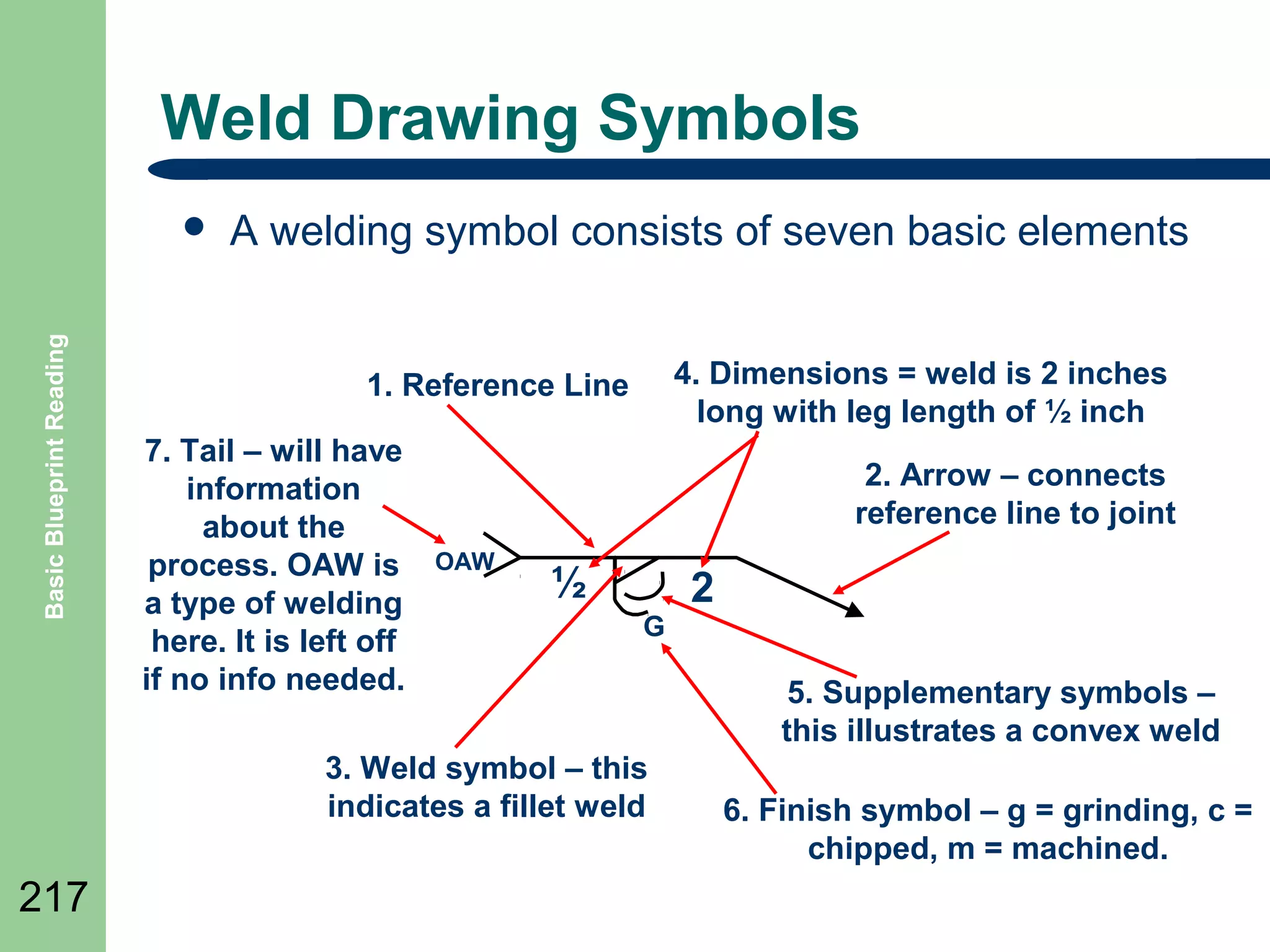

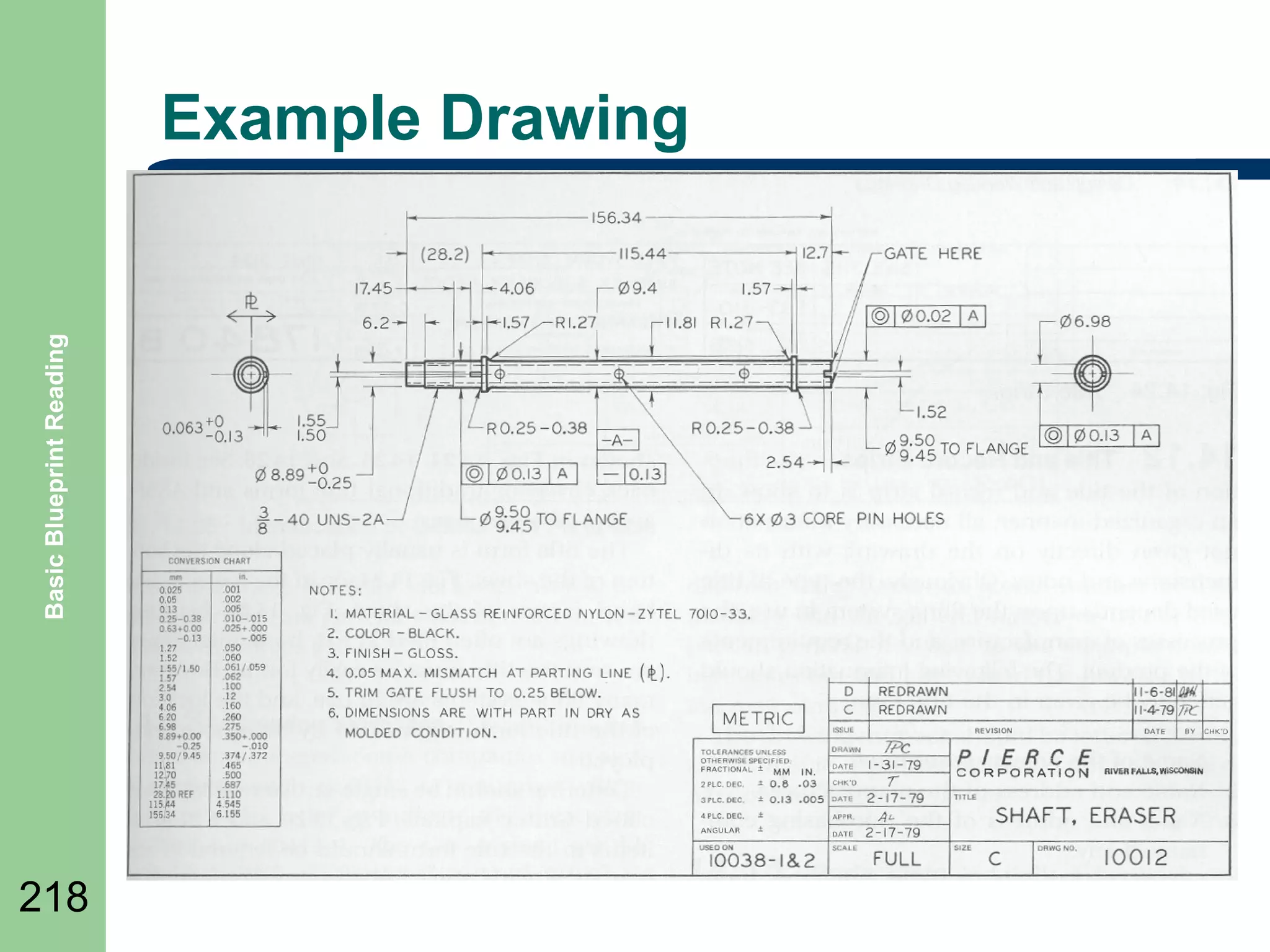

The document provides an overview of basic blueprint reading. It discusses the different types of drawings including mechanical, electrical, pneumatic, civil and architectural. It describes the common elements found on drawings such as title blocks, revision blocks, scales, line types, dimensions and abbreviations. Electrical drawings are commonly multi-sheet diagrams that use a ladder format to show wiring between devices. Understanding industrial drawings requires knowledge of the standardized symbols and visual communication methods used to convey design information.