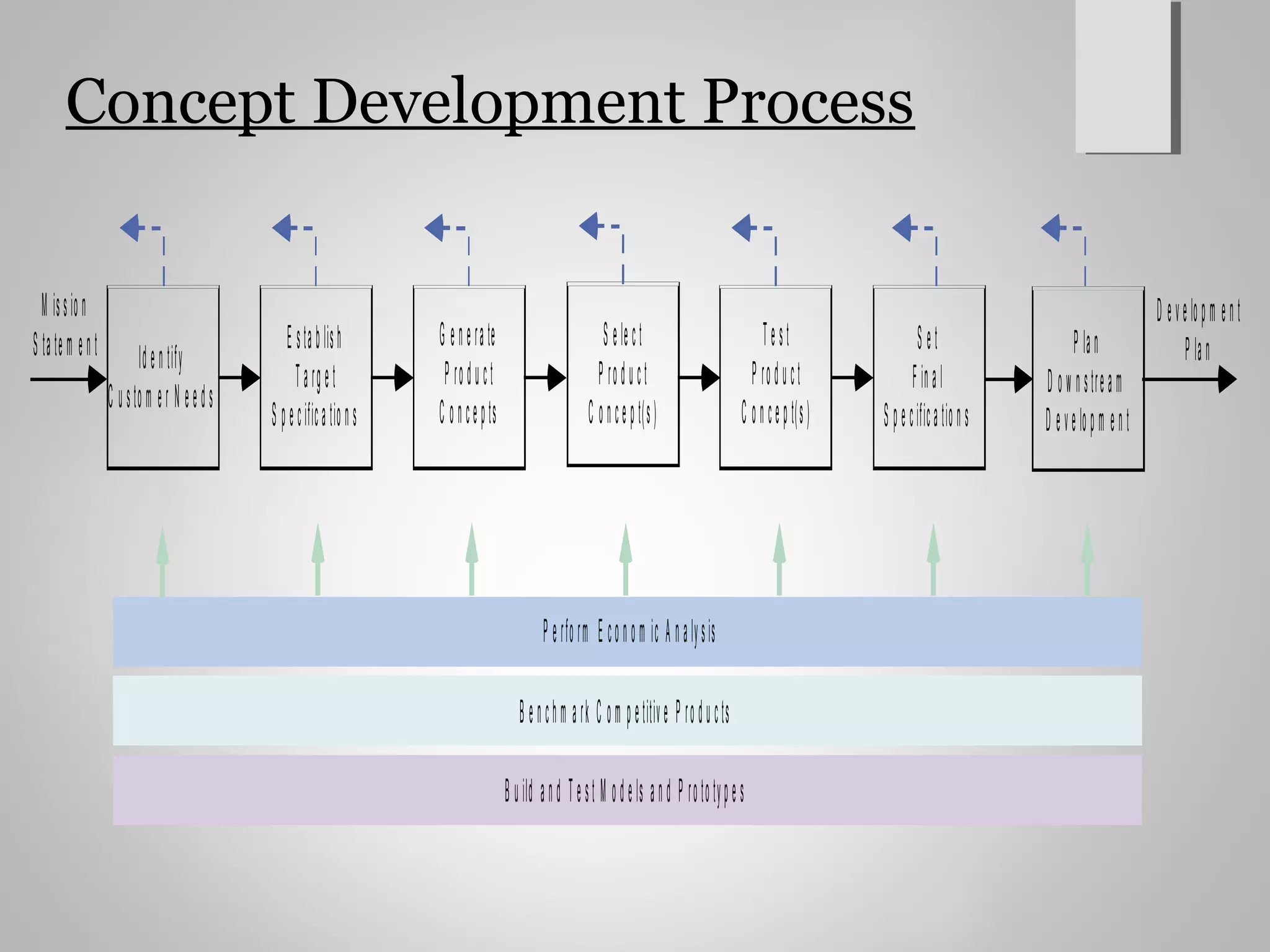

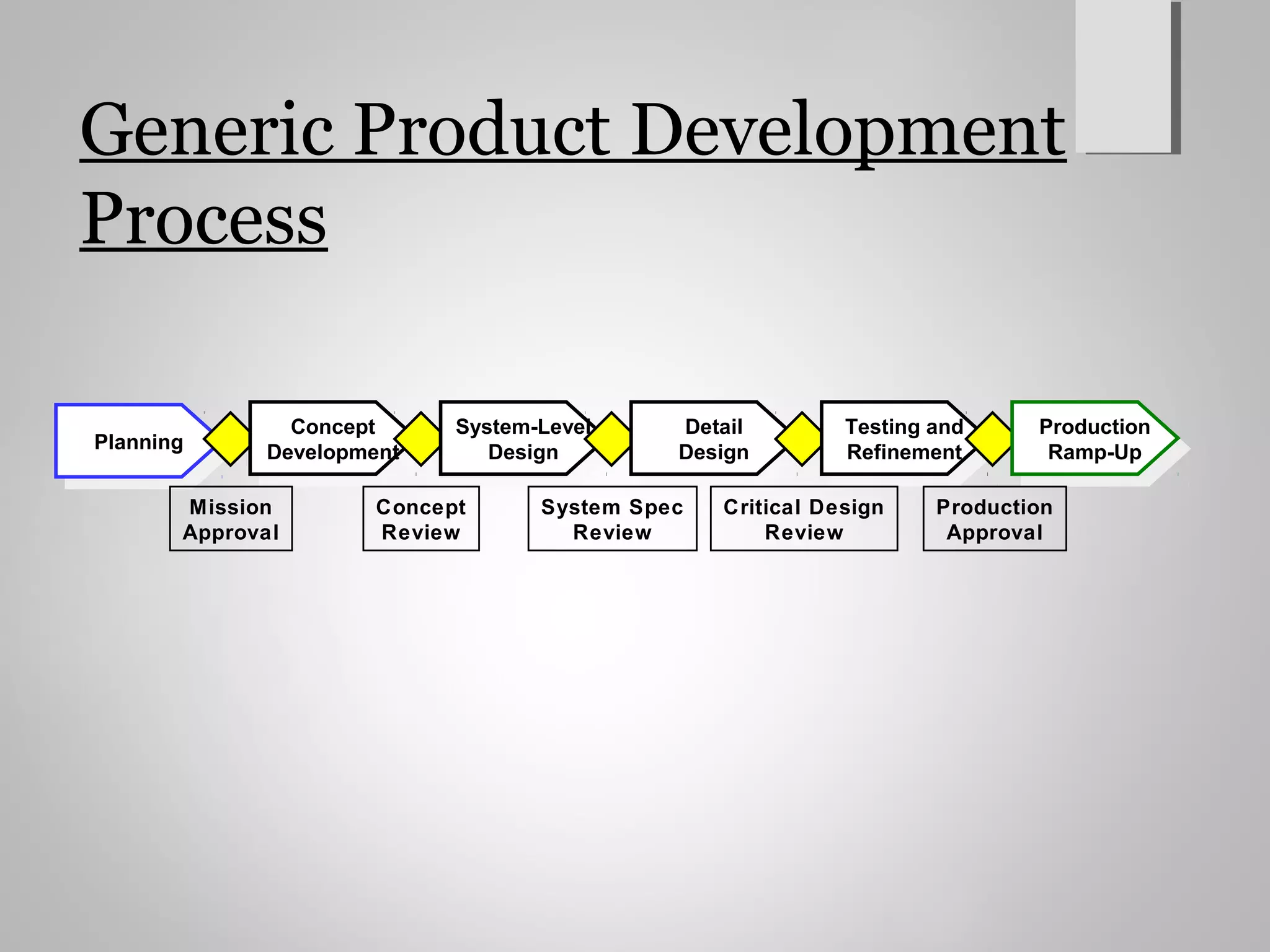

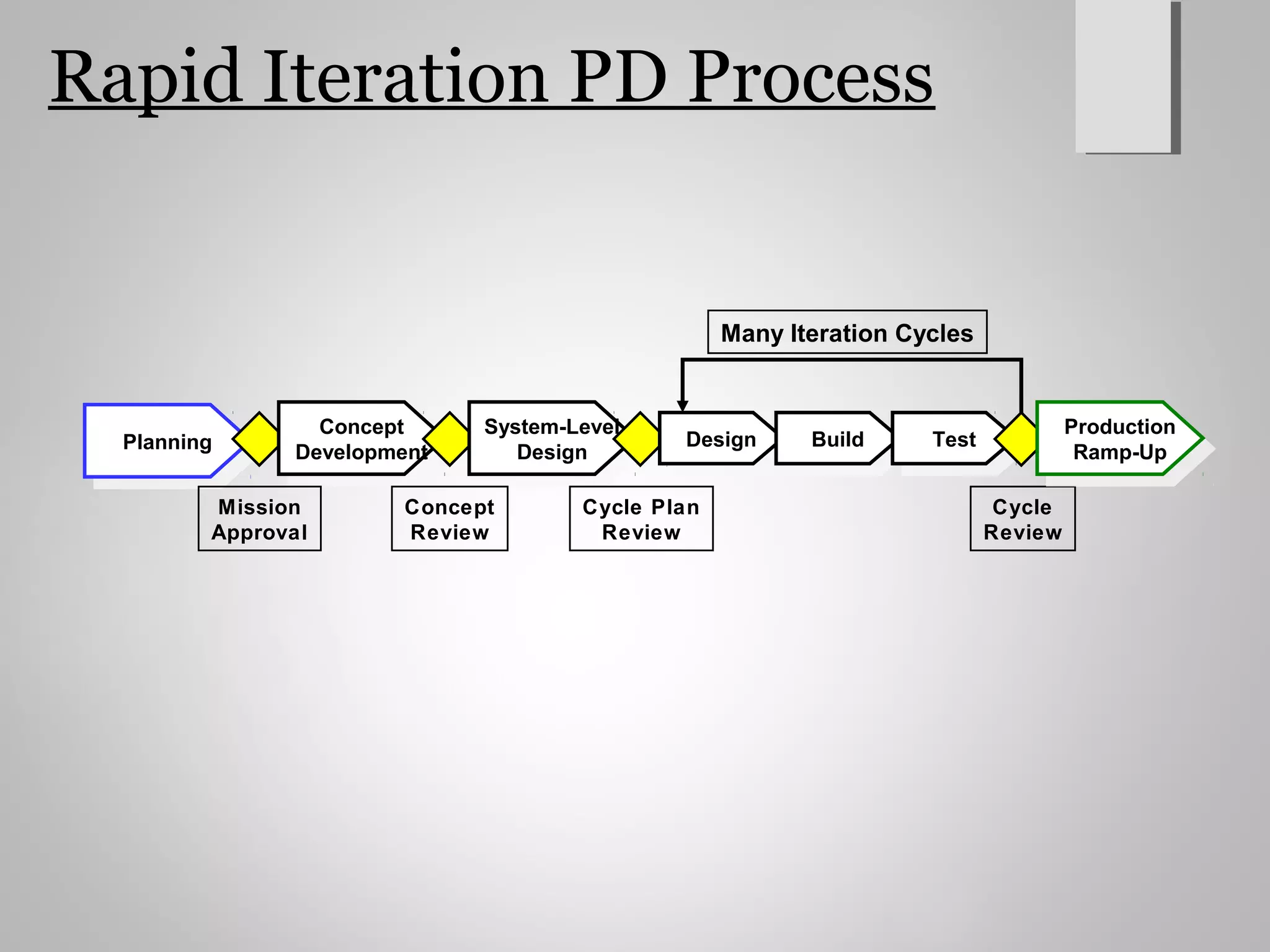

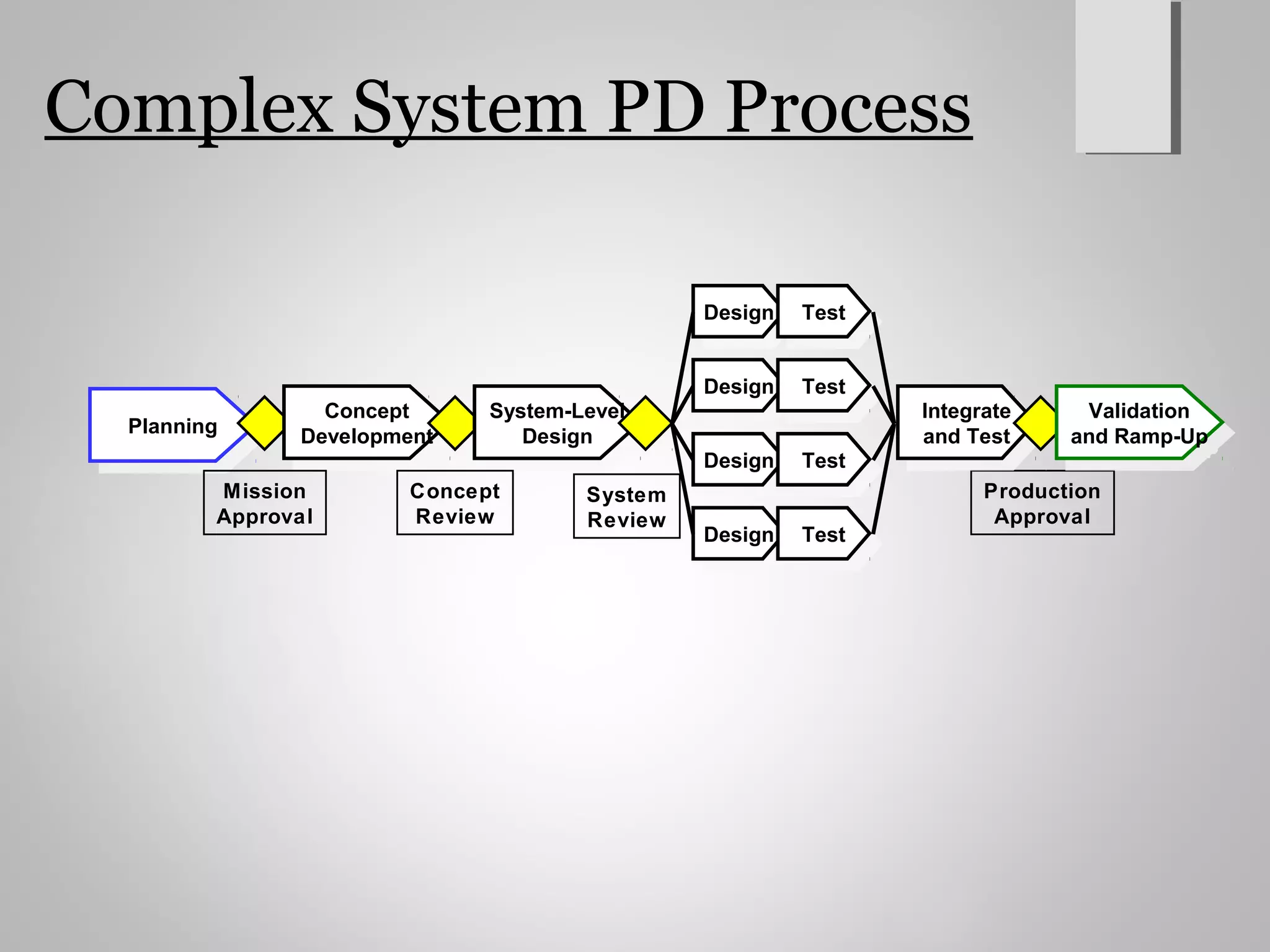

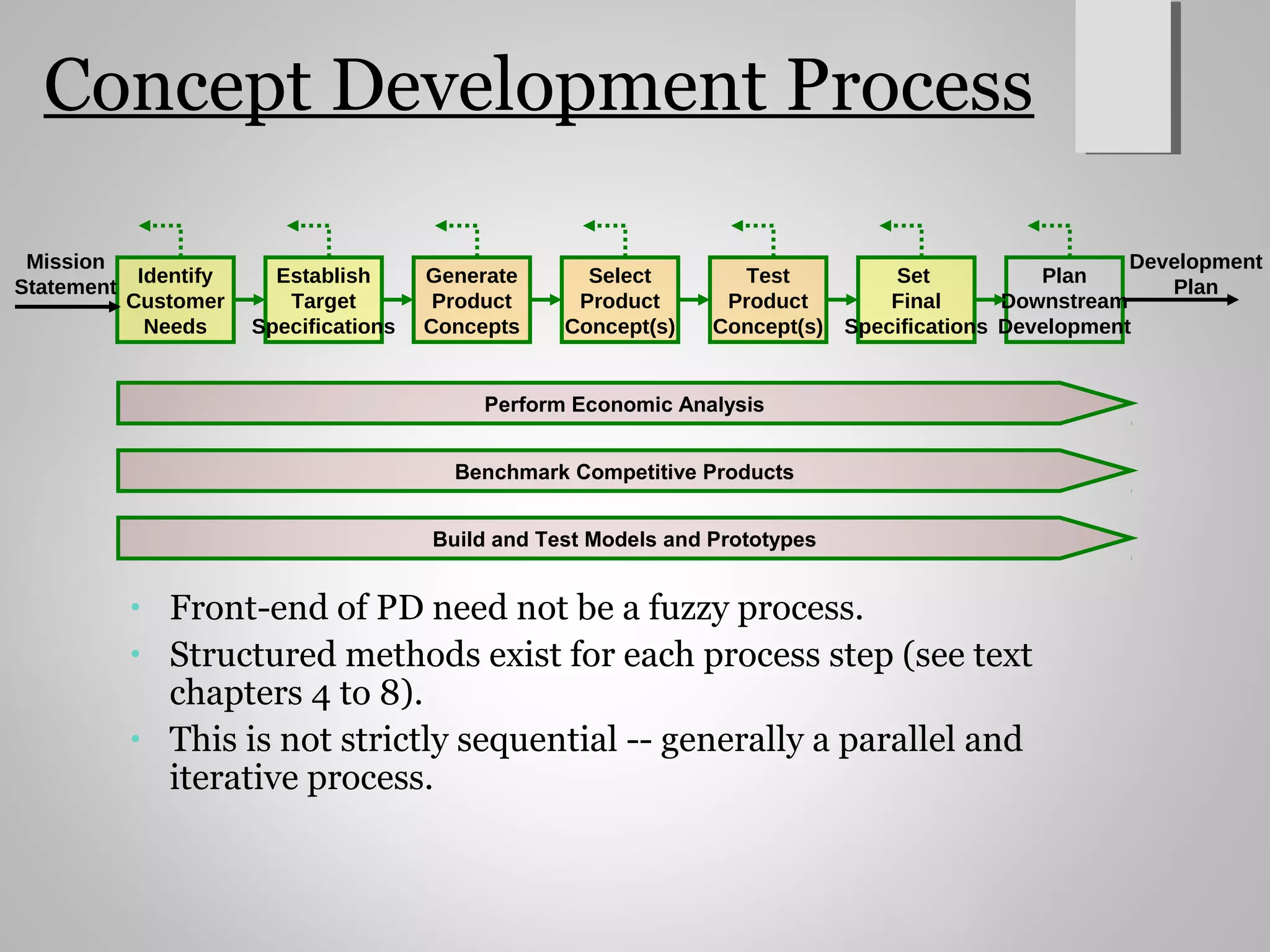

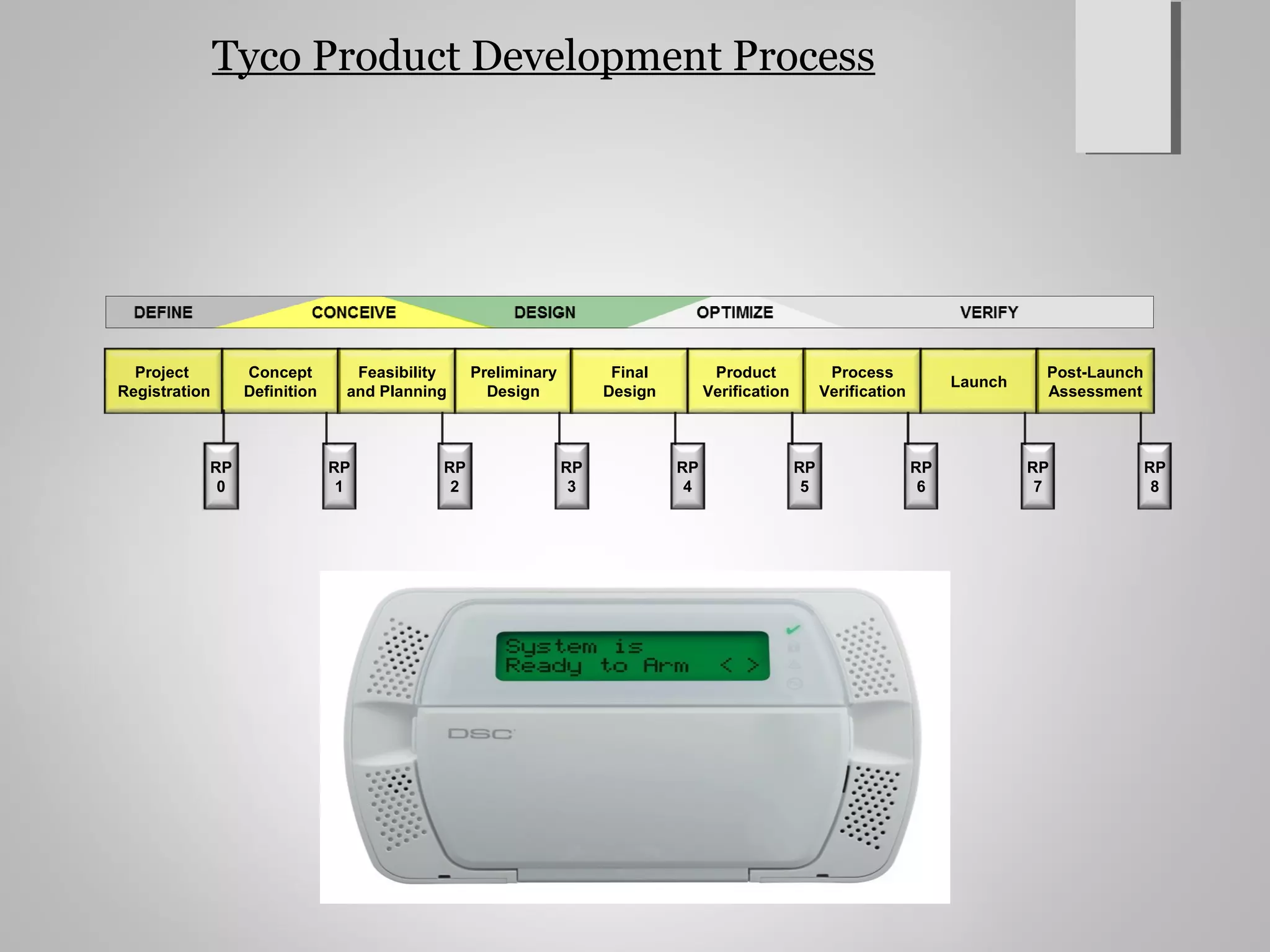

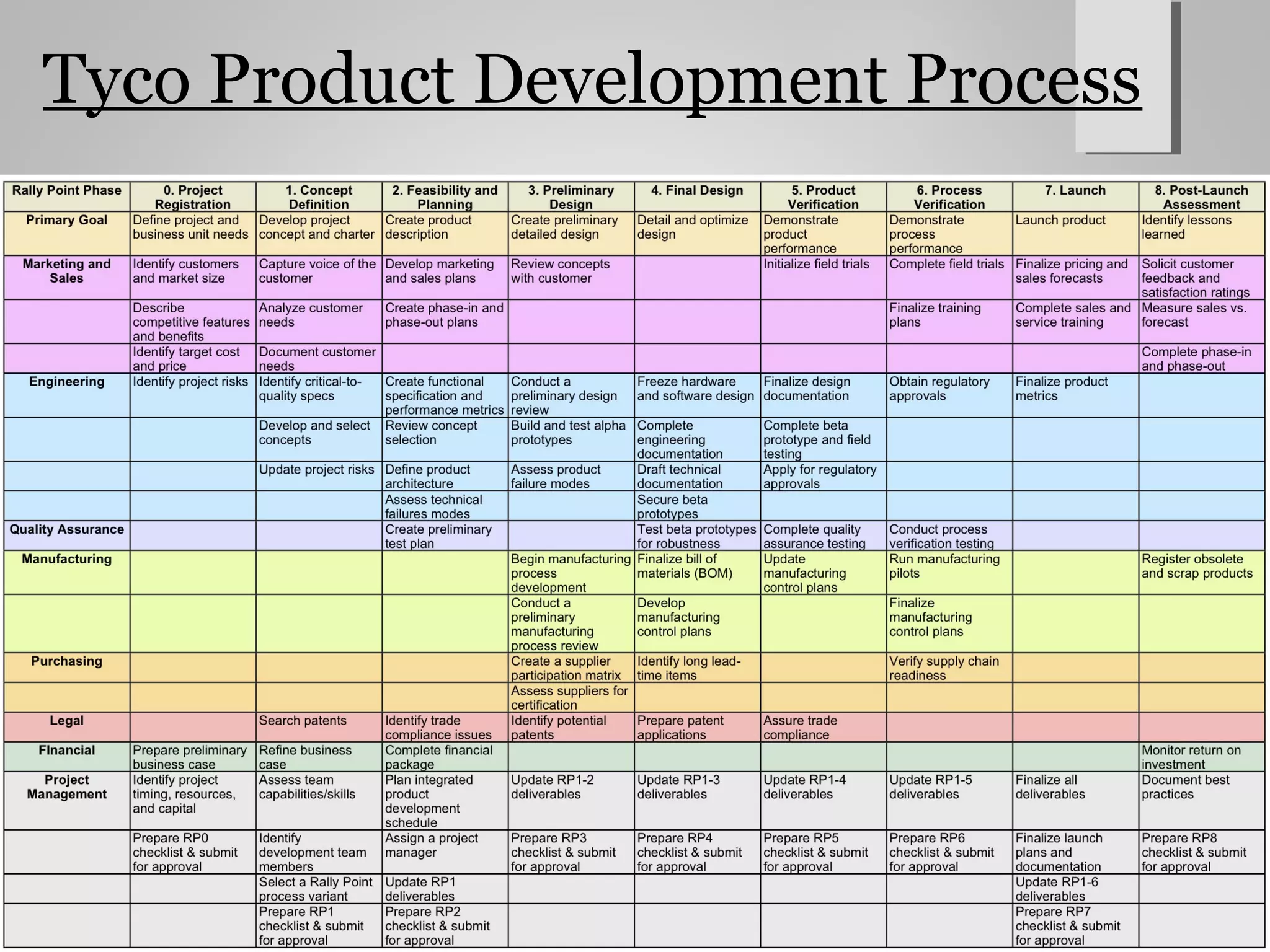

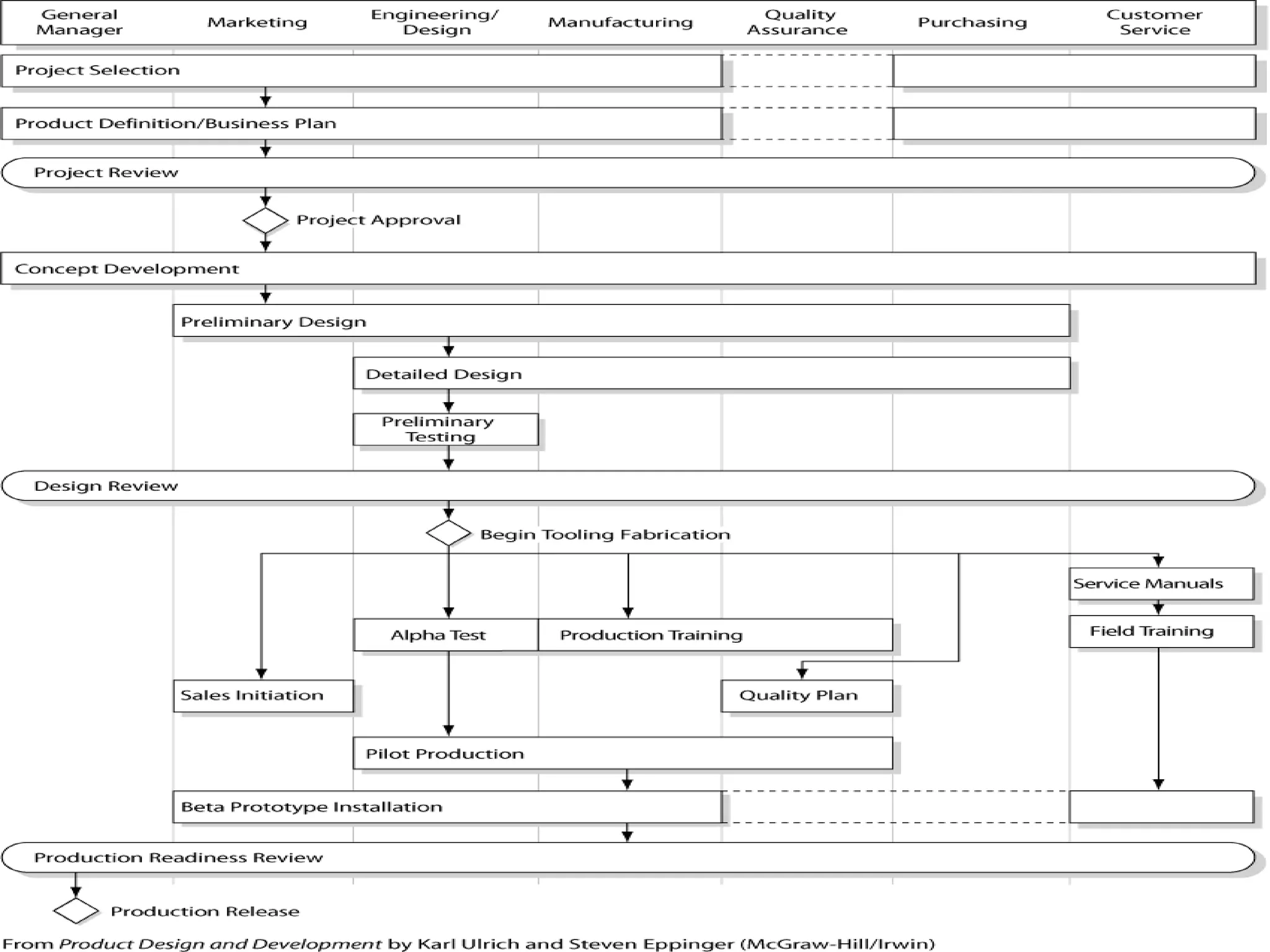

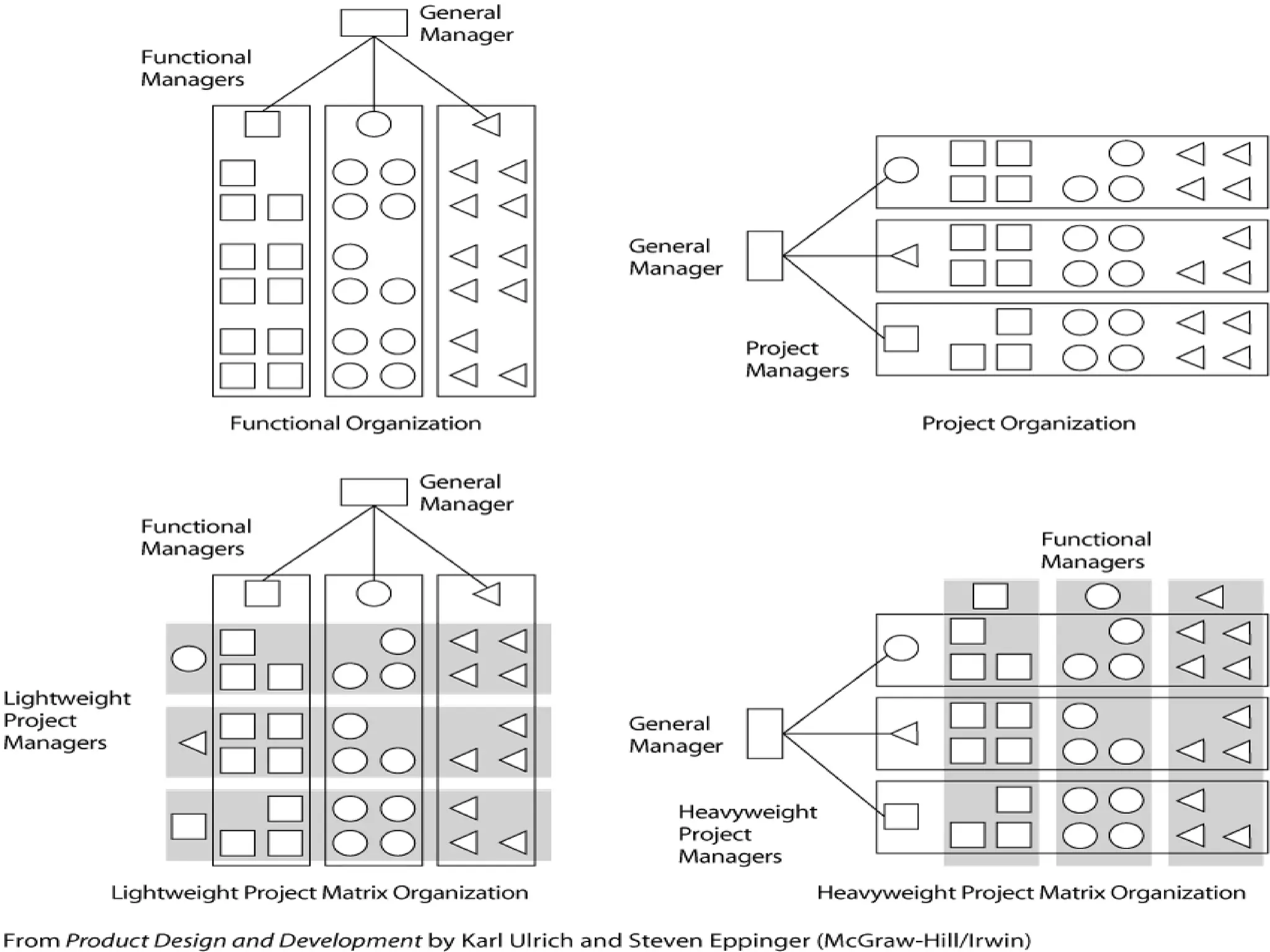

This document discusses development processes and organizations. It describes core development stages like concept development, architectural design, and detailed design. It also discusses generic concept development processes, product development processes like Tyco's, and organizational types like functional, project, and matrix structures. Finally, it covers traditional design methods and variants of development processes for different product types.