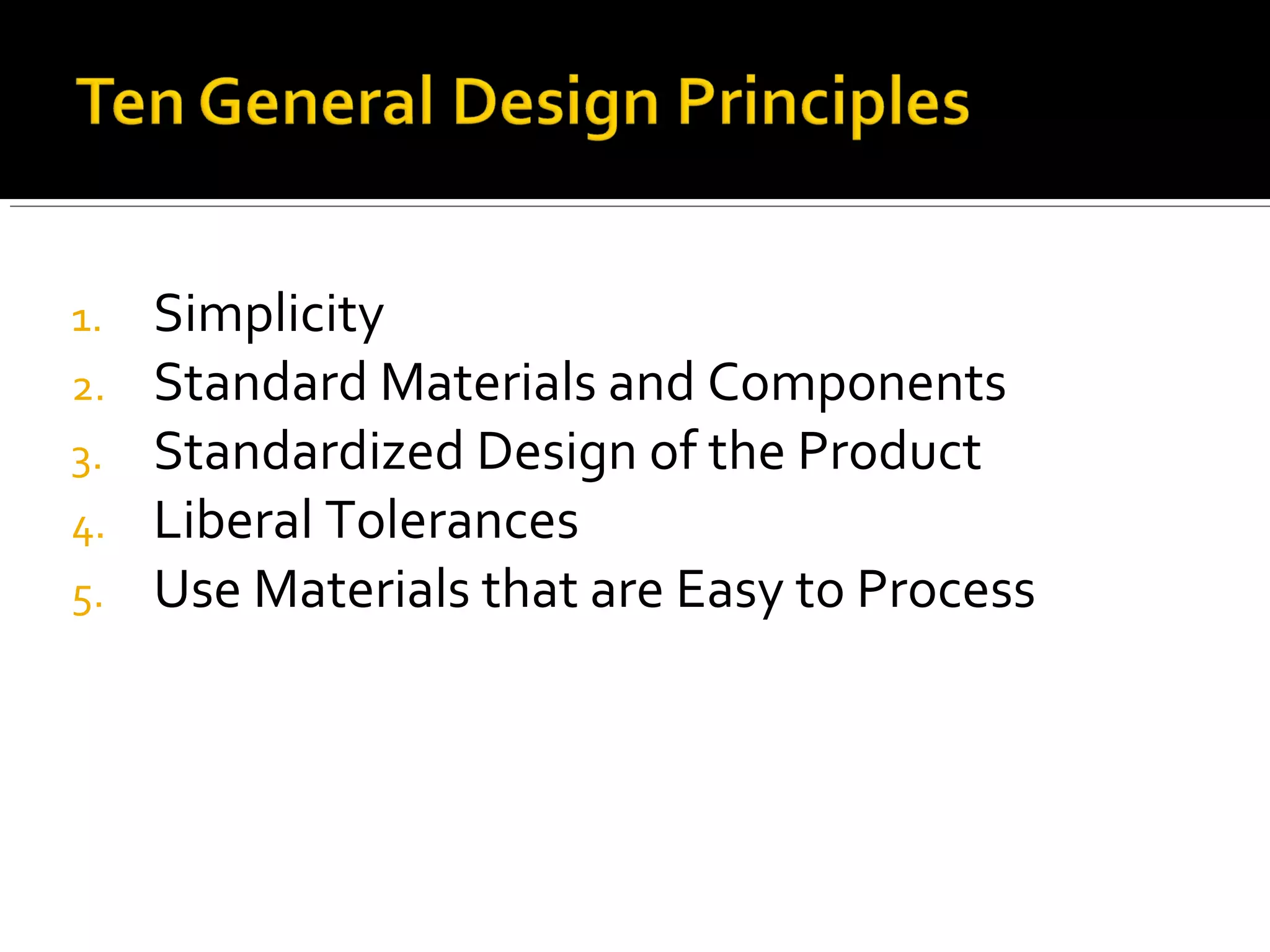

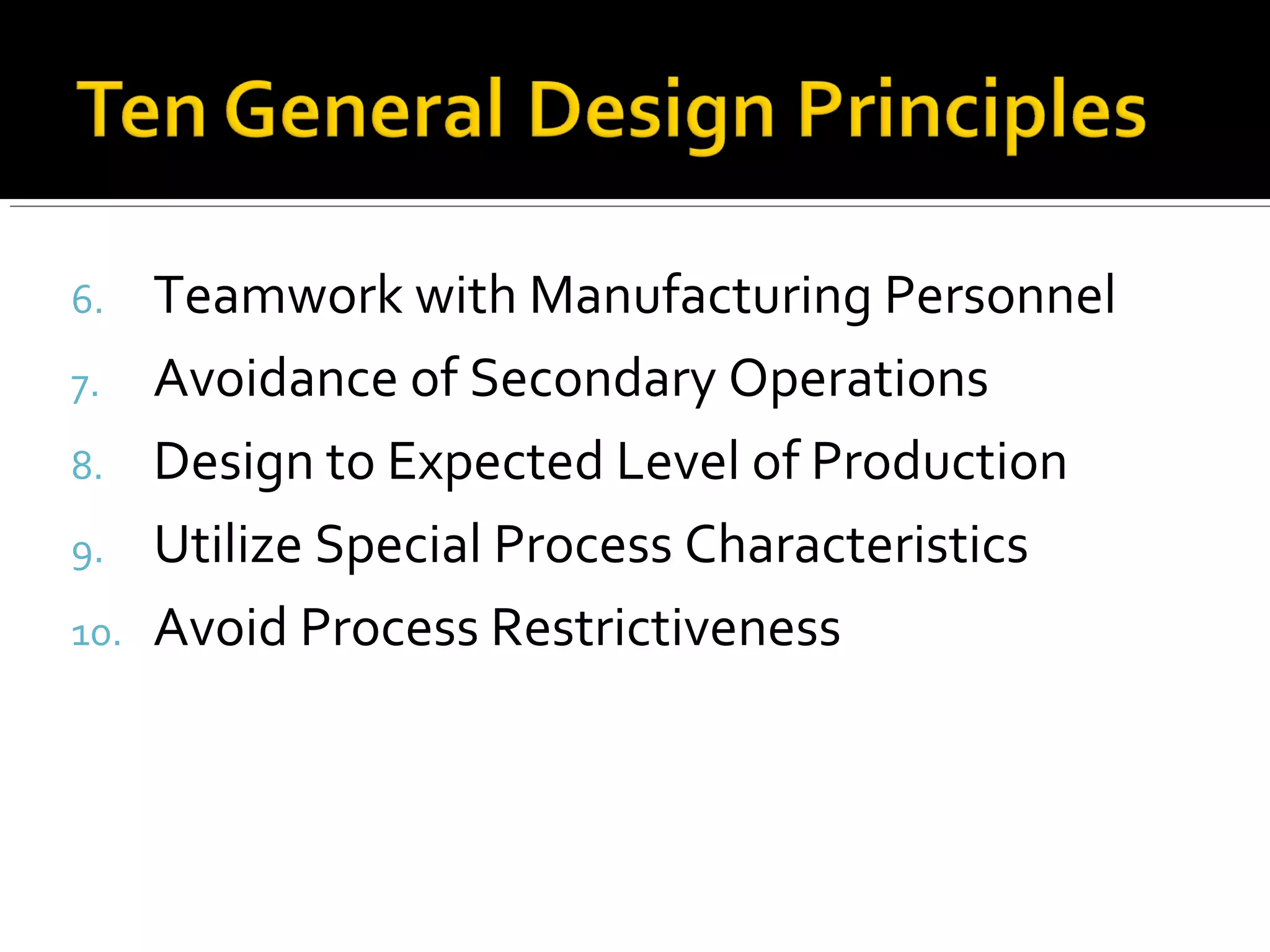

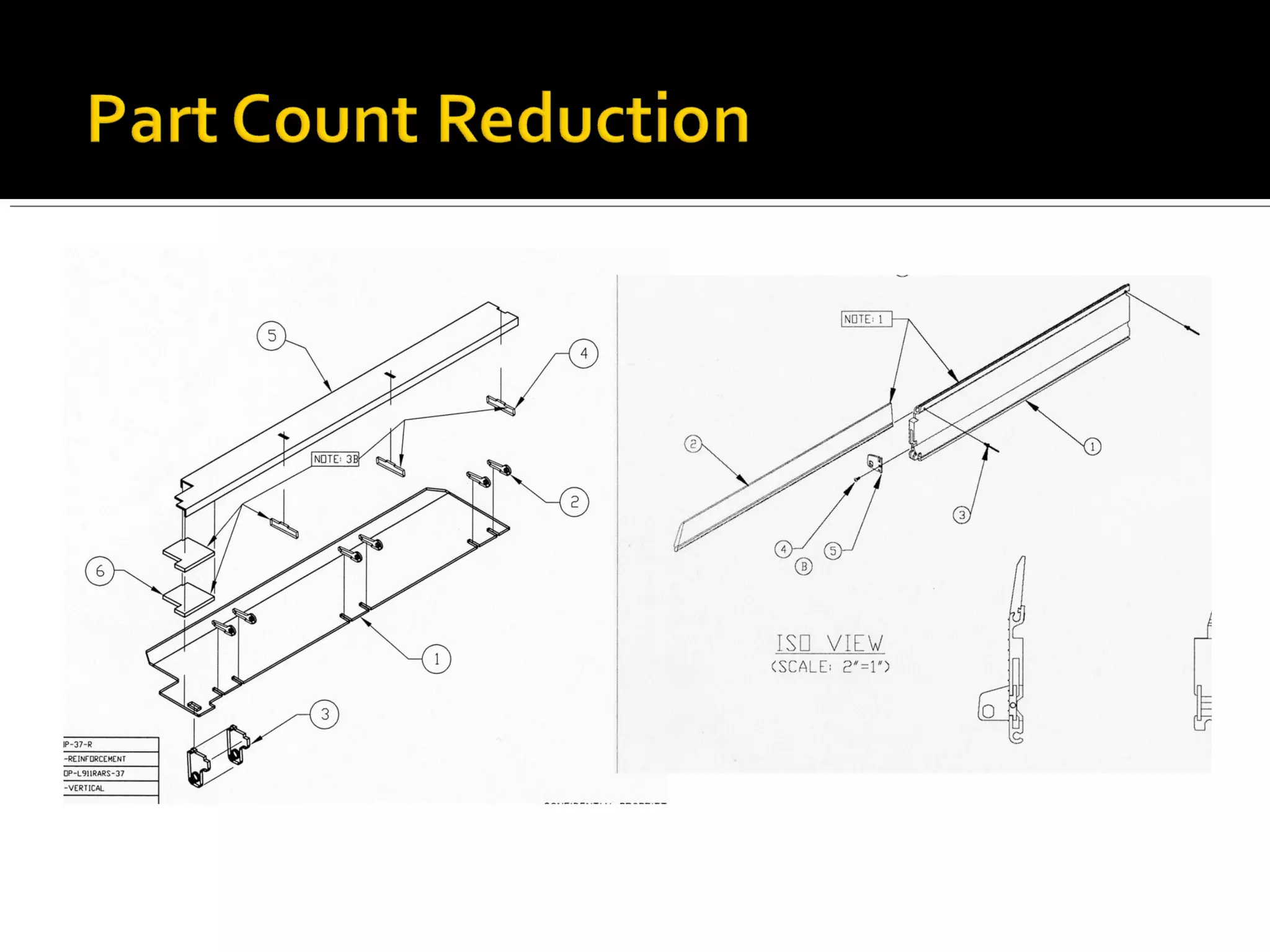

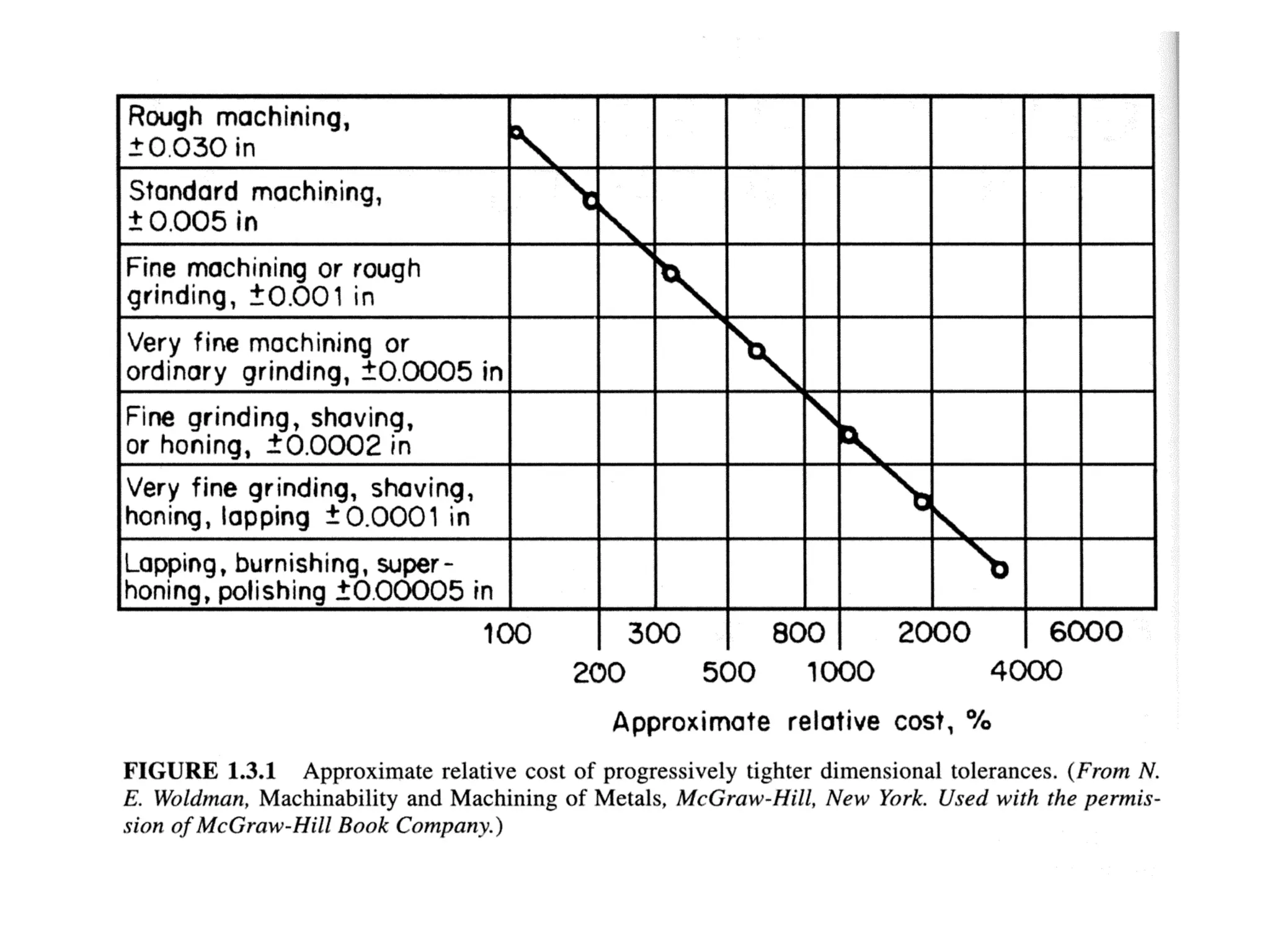

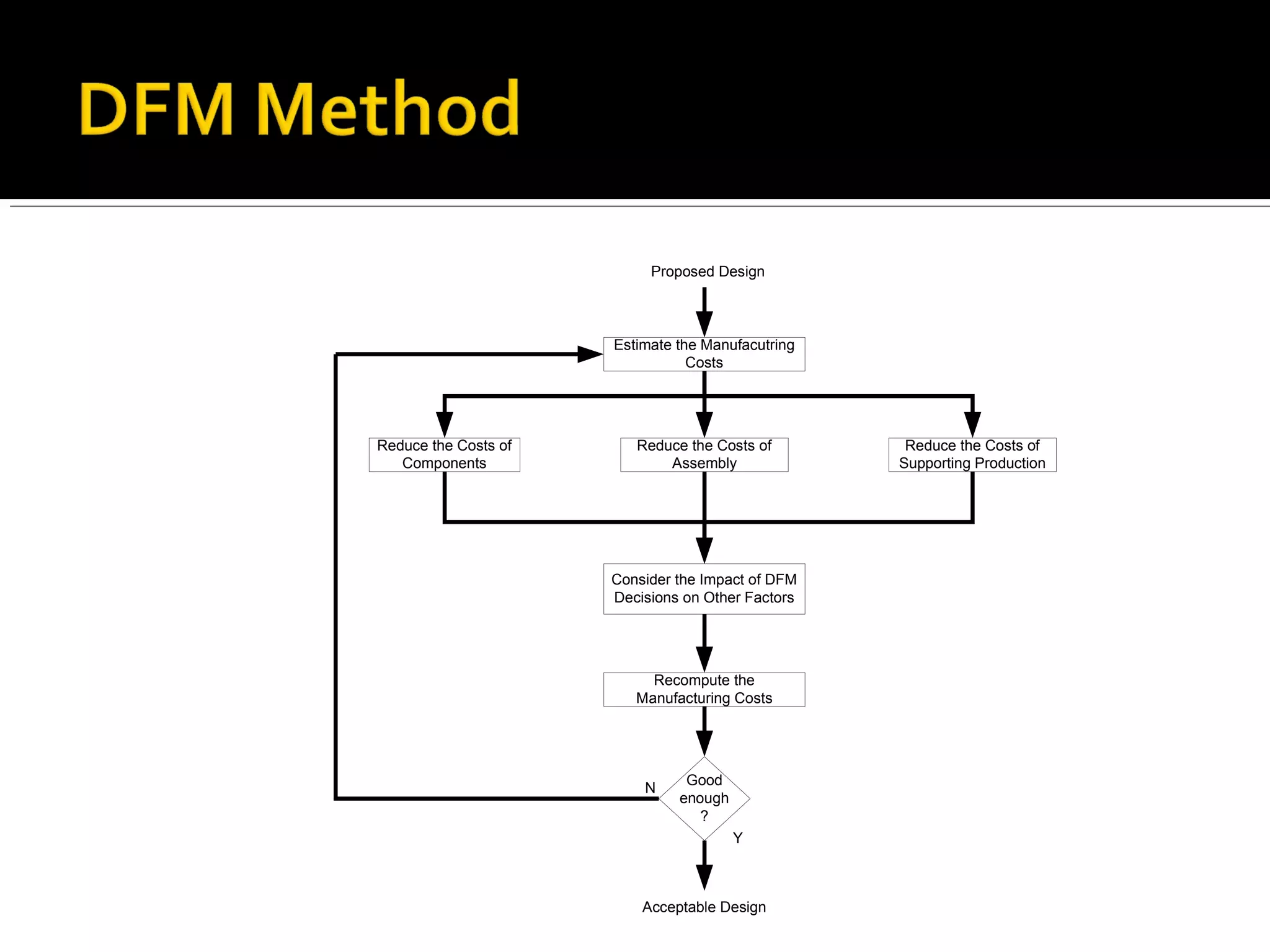

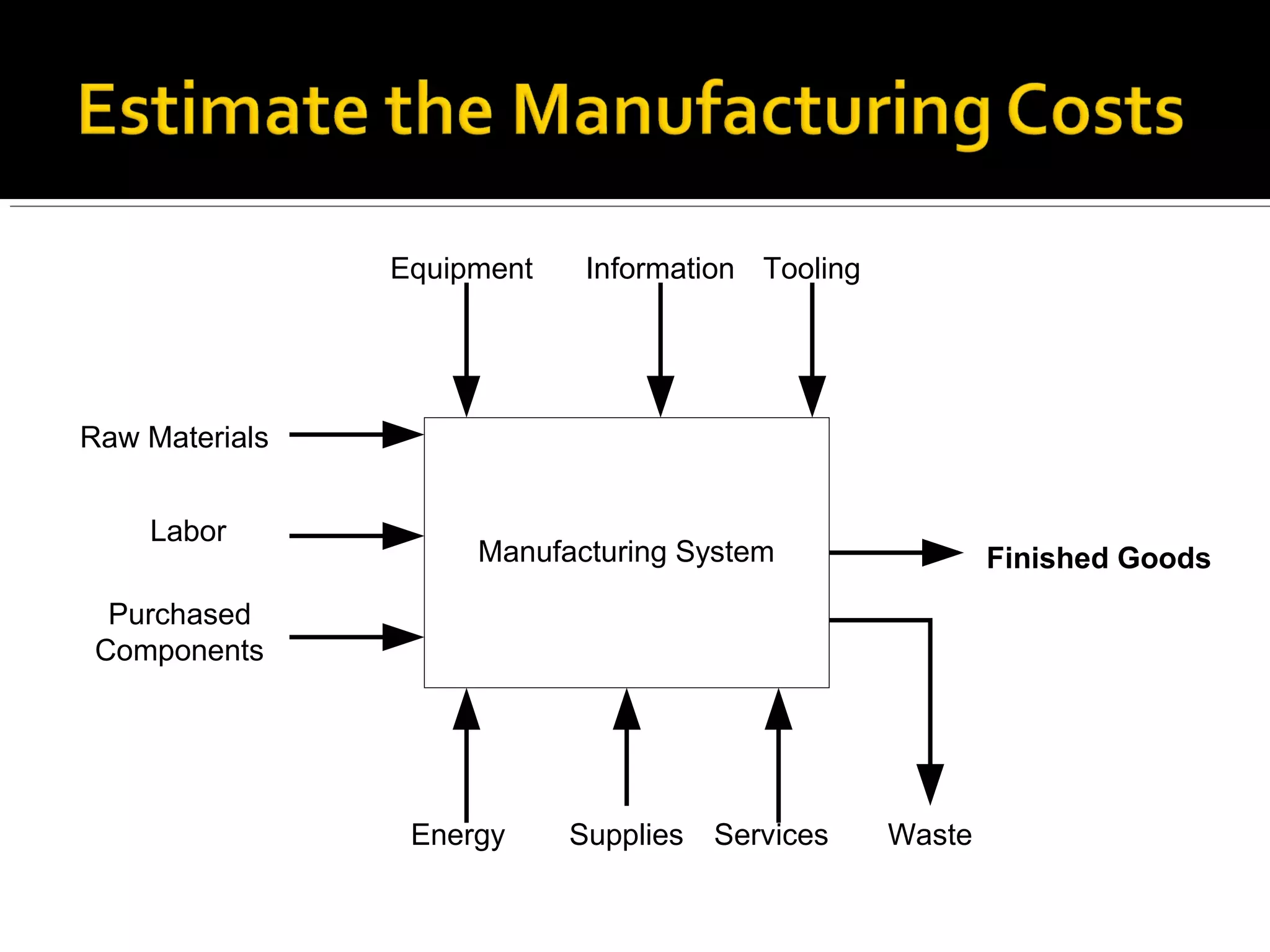

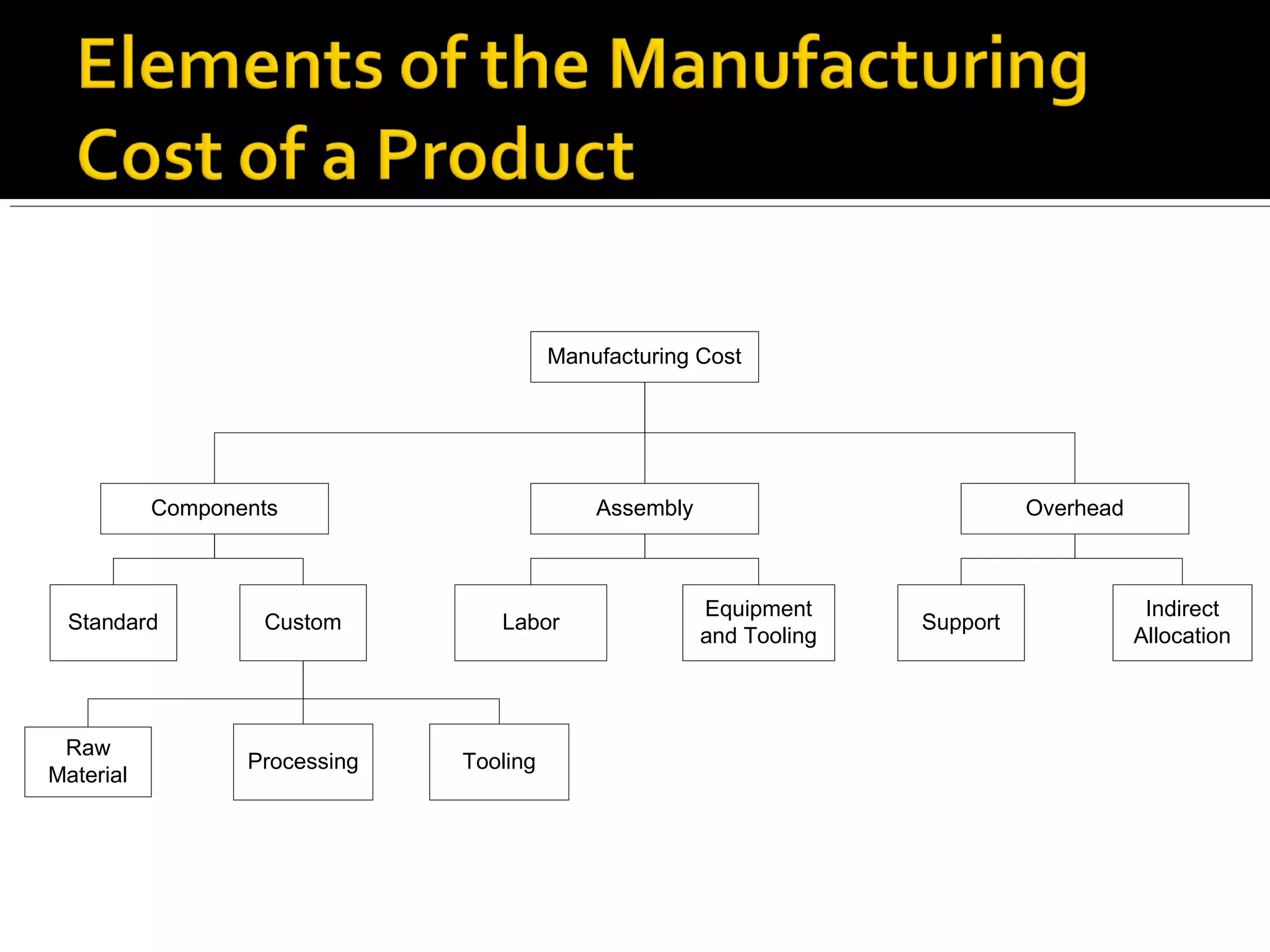

The document discusses key principles of design for manufacturing (DFM) including minimizing part count, using standard components and materials, designing for tolerances, collaborating with manufacturing, and understanding production processes and costs. It emphasizes reducing costs at each stage of production from components to assembly to overhead. Designs should be optimized through an iterative process of cost analysis and redesign while considering production volumes and other factors.